Good day...well I've got my LM1 350 complete rebuilt. New cam installed and everything check, double checked and triple checked in terms of setting valve lash, etc. Heads are rebuilt with full valve job, new springs and so on.

Got the engine on the TDC #1 compression stroke, got the distributor in, fired it up and it sounded like hell, like a misfire. Because its a flat tappet cam I put it up to 2000 RPM for the break in right away anyway, for about 2 minutes but the engine wasn't smoothing out so I shut it down. (Yes, I know you want to avoid doing that on a cam break in). I checked everything over (again), all looked good. Tried to restart it and got a massive (and I mean like a shot gun) BANG out the carb. So that's it, not cranking it again until I've found the problem.

The distributor is not 180 degrees out, if it was it wouldn't have run at all. I checked all the pushrods by rolling them between my fingers, none seem bent. I checked all the plug wire connections, and double checked the firing order on the cap, all is well. The only thing I can see is maybe the distributor was advanced too far on that inital start up, I didn't have it running long enough to be able to get a timing reading as I as immediately trying to find the misfire. The short time is was running, advancing or retarding the distributor seemed unresponsive.

So - if the distributer was somehow far too advanced to begin with do you get into an area where it will run like its missing, backfire out the carb and be far enough out that small changes by hand while running do nothing?

(Honestly the bang was so loud, I'm a little freaked out that its something else more internal being 100% brand new everything).

I did not see you mention checking all the valve train geometry,

and valve train clearances and the piston to valve clearances

,like spring bind, retainer to valve seal,

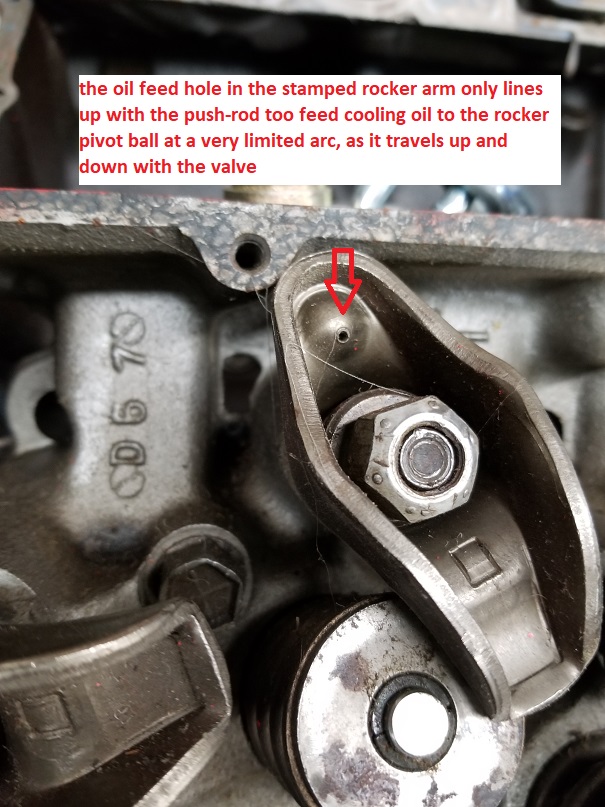

push rod to cylinder head slot,or guide plate,or rocker slot,too rocker stud,etc.

nor that you degreed in the cam,

nor did I see the valves properly adjusted in the list?

do you have good oil pressure?

you may want to pull the plugs and verify the ground electrodes are not bent?

I.d for sure back off the rockers and verify the valve adjustment was done correctly

yes I know you think it was... verify it carefully

I start checking clearances and if those check out,

Id do a compression check,

verify the firing order, and plug wire connections,

and check the ignition timing, advance curve,verify TDC

Id reset the valves adjustment very carefully

http://www.acdelco.com/auto-parts/v...engine-oil-supplement-assembly-lubricant.html

yes several hours reading in the links and sub links below, and don,t ignore the links,

but you may find that you know 90% of the info but that new 10% you ignore or forgot,

can get VERY expensive...

readings much faster and cheaper that parts replacing

http://garage.grumpysperformance.co...ectly-and-get-it-to-last-cam-install-info.90/

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/correctly-adjusting-valves.196/

http://garage.grumpysperformance.com/index.php?threads/valve-spring-installation-questions.12833/

http://garage.grumpysperformance.co...op-dead-center-1-for-timing-ignition-cam.966/

http://garage.grumpysperformance.com/index.php?threads/stock-gm-push-rod-length.3844/

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-12045

http://garage.grumpysperformance.co...ear-articles-you-need-to-read.282/#post-52473

http://garage.grumpysperformance.co...ing-down-a-valve-train-noise.6237/#post-32472

http://garage.grumpysperformance.co...swap-in-1-6-1-ratio-rockers.10671/#post-46039

http://garage.grumpysperformance.co...o-rockers-and-the-pushrods-rub.198/#post-3033

http://garage.grumpysperformance.com/index.php?threads/verifying-your-real-advance-curve.4683/

Last edited: