Ive always been rather amazed at the fact that youll rarely if ever see one of the performance aftermarket engine block suppliers list the iron alloy used its surface hardness or any info about what the metal alloy being used in the engine blocks they sell contain.

to most guys simply saying its a cast iron block or an aluminum block seems to answer the basic question, of "whats the block made of?"

but if your an old geezer like myself with an engineering back ground , I know that saying somethings cast from ast iron block or aluminum , leaves a whole lot of info un-answered ,

theres a potential huge difference in rigidity surface hardness tensil strength , machineability ,wear resistance, corrosion resistance, and weight between various alloys in either "cast iron" or aluminum"

yes Im rather sure the design engineers will tend to select a material that should perform well above the minimal predicted stress and heat and vibration levels predicted, to provide a significant extra safety margin, , under the intended stress levels and yeah!

most engineers I know want any project they were or are envolved in to produce something of exceptional durability and strength,and yes theres almost always a second group,

theres, bound too be a group of accountants that will inevitably resist the use of the best option, and insist on something marginal thats cheaper in many cases.

what I find rather iratating at times is even when you call up and ask to speak to the engineering departments youll rarely get specific facts or a link to test results.

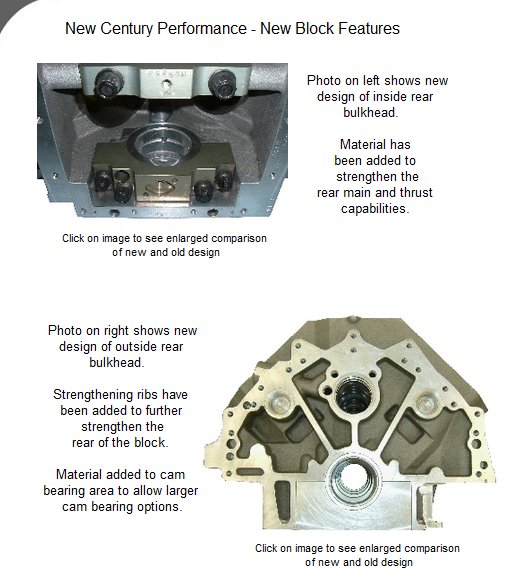

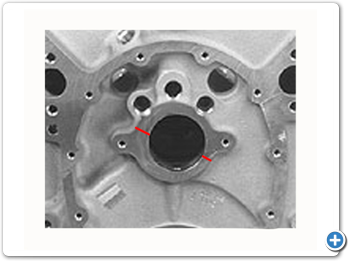

Core shift is a result of a block, cylinder head, or other engine casting shifting in its mold when the molten metal is poured in. When core shift occurs the cylinder bores, lifter bores, main bearing and cam tunnels shift from their blueprinted positions. If the shift is significant, mechanical problems can occur and some cylinder walls may be critically thin. This is especially of concern if the engine is to be used for racing applications.

The only way to guarantee cylinder wall thickness is to have the block sonic-tested, but this can be difficult when you go to purchase a used engine.

Core shift example

Core shift example

On engines with in-block cams, you can always take a look at the cam bearing bore. If it is noticeably offset in its machined boss, you should suspect core shift.

keep in mind theres ALWAYS some one willing to produce something with less precision, made from cheaper materials so they can extract a greater potential profit who really could not care less about long term durability as long as the component sells briskly at a significant profit!

not all import parts are inferior or made from less desirable materials, just as not ALL AMERICAN, produced parts will be top quality, but I have found that the better name brand parts like

DART, AFR,BRODIX,EDELBROCK,CRANE,TRICKFLOW,CALLIES and SCAT , have a reputation to maintain, so they generally won,t sell low end crap, but it always helps to ask questions ,do research,never trust a machine shops work without carefully meassuring and verifying any work was done correctly and owning accurate precision tools for measuring is mandatory if your serious about engine building!

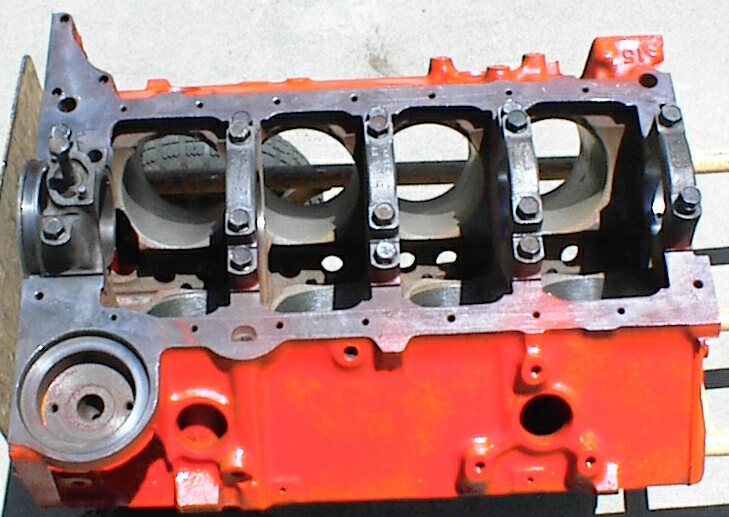

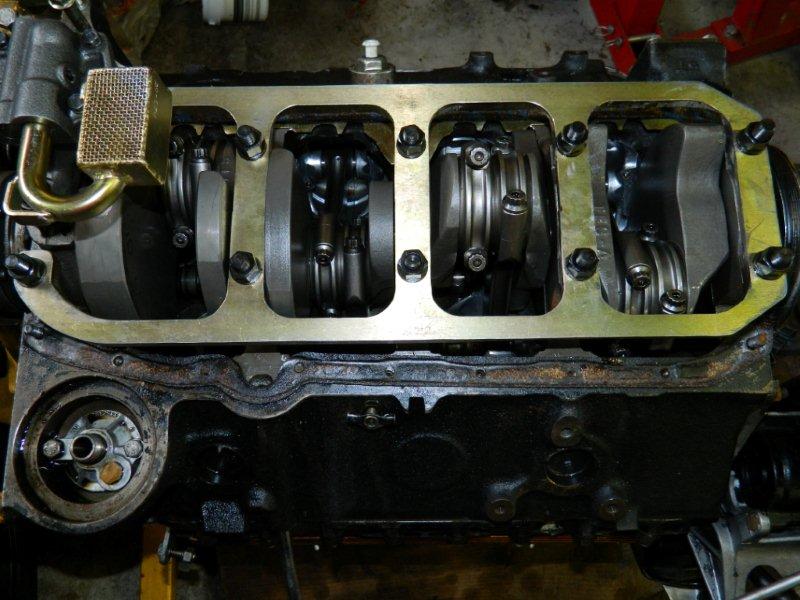

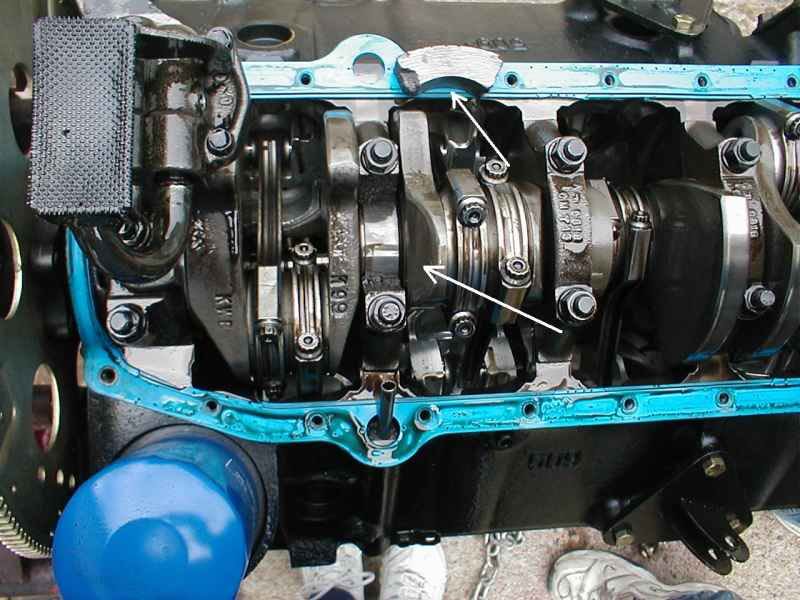

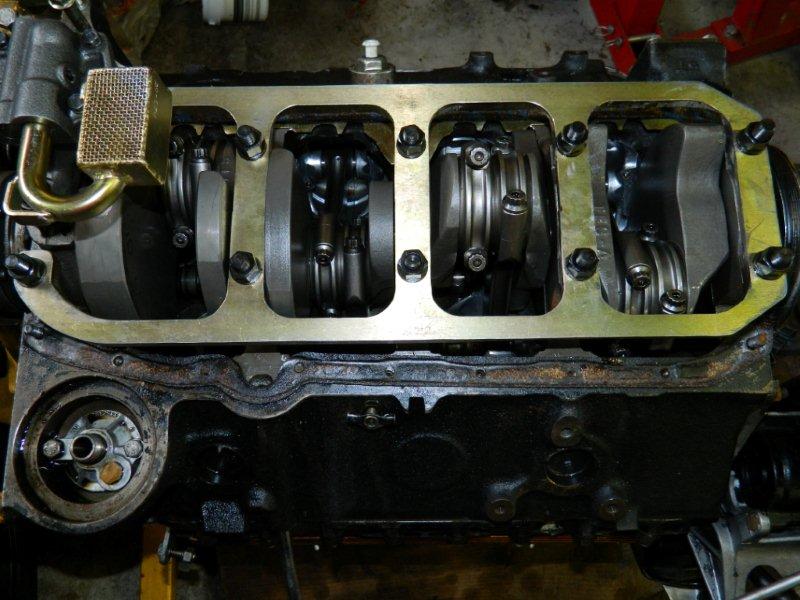

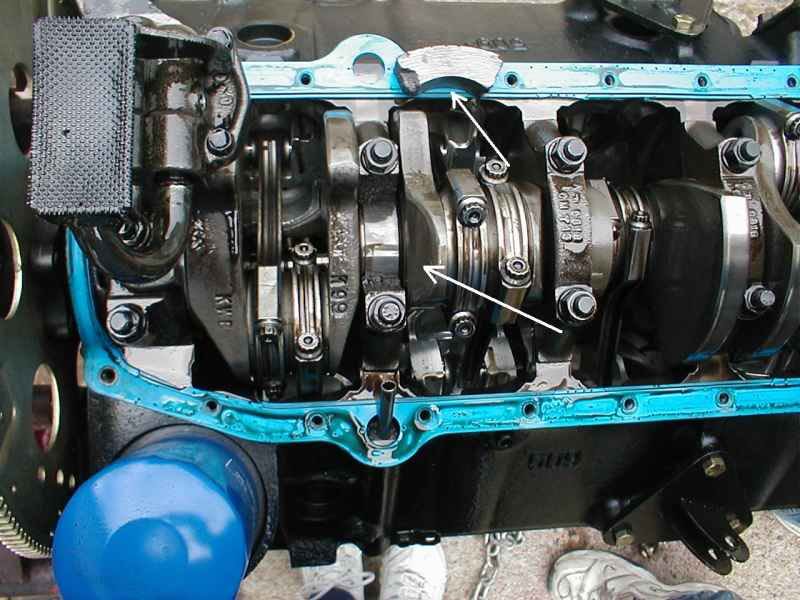

TWO BOLT MAIN CAP BLOCK

4 bolt SBC block

the block pictured above is NOT A CHEVY, but it gives you some idea of what the block internal coolant passages and cylinder walls look like

you tend to get what you pay for in most brand name performance products

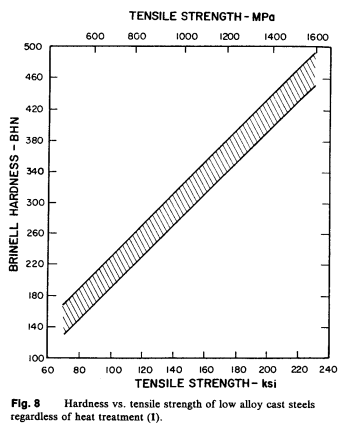

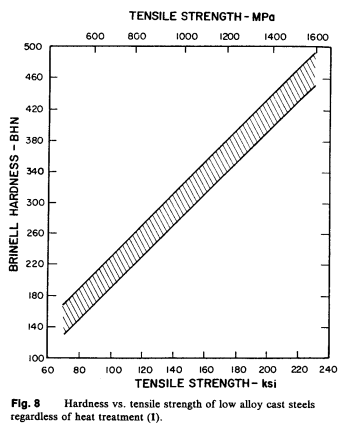

notice the much stronger alloy used in some block castings

Some of the Key ingredients in cast iron to make it strong are Nickel,Molybdenum, Copper

The Little-M nickel content is 0.149, Molybdenum 0.211, Copper 0.404

Dart SHP Nickel content is 0.071, Molybdenum .016, copper 0.283

Chinese block Nickel content is 0.005, Molybdenum 0.005, Copper 0.020

Leo did the Brinell test by using the Rockwell B Scale and converting it to Brinell scale and he will back this test.

Little-M tested 200

SHP 190

Chinese block 107

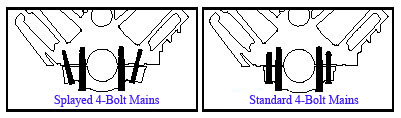

if you check you'll find that stud girdle use does little or nothing for the individual main cap strength but it does marginally increase main cap stability and block flex.

now the potential difference is probably not worth the expense, in that your generally spending cash that would be better used in the purchase of the stronger aftermarket block casting from a known source like DART.

look through the links and read the sub links

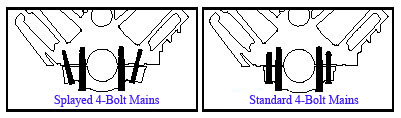

the billet splayed main caps on the aftermarket block is the stronger route, but Id bet 90% of the guys building their first engine think they will save money using the O.E.M. block they already own.....well, until... they add up all the machine work costs and price of parts like aftermarket splayed caps, ARP main studs ,the labor costs from the machine shop, etc. but by that time the machine shop owner is smiling all the way to the bank, and youve just figured out the true cost of that cheaper O.E.M BLOCK

related info

http://machinedesign.com/basics-design/cast-iron

https://www.sfsa.org/sfsa/pubs/hbk/s5.pdf

http://www.wisconsinprecision.com/plain-carbon-low-alloy-steel-investment-castings.php

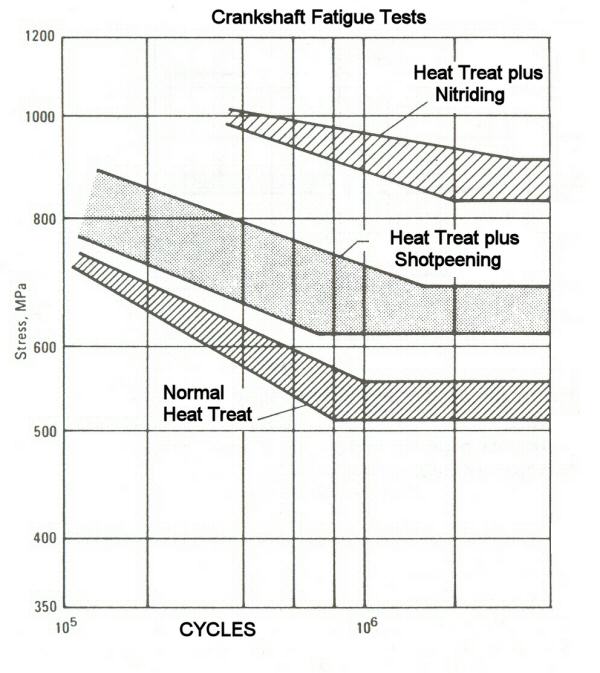

http://garage.grumpysperformance.com/index.php?threads/types-of-crankshaft-steel.204/

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-24723

http://garage.grumpysperformance.com/index.php?threads/block-choice.10472/

http://garage.grumpysperformance.com/index.php?threads/engine-block-cylinder-wall-thickness.976/

http://garage.grumpysperformance.com/index.php?threads/sbc-cylinder-wall-thickness.7646/

http://garage.grumpysperformance.co...a-scat-rotating-assembly-be.11495/#post-52962

http://garage.grumpysperformance.com/index.php?threads/which-dart-shp-4-0-or-4-125.3219/#post-44637

http://garage.grumpysperformance.co...bearing-studs-torque-stretch.9409/#post-34241

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-24723

http://garage.grumpysperformance.com/index.php?threads/main-cap-fit-in-block.5945/#post-51651

http://www.afsinc.org/files/images/iron alloys.pdf

http://www.sbintl.com/tech_library/...standing_the_metallurgy_in_todays_engines.pdf

http://what-when-how.com/automobile/cylinder-block-automobile/

http://www.enginebuildermag.com/2013/06/sleeves-liners/

to most guys simply saying its a cast iron block or an aluminum block seems to answer the basic question, of "whats the block made of?"

but if your an old geezer like myself with an engineering back ground , I know that saying somethings cast from ast iron block or aluminum , leaves a whole lot of info un-answered ,

theres a potential huge difference in rigidity surface hardness tensil strength , machineability ,wear resistance, corrosion resistance, and weight between various alloys in either "cast iron" or aluminum"

yes Im rather sure the design engineers will tend to select a material that should perform well above the minimal predicted stress and heat and vibration levels predicted, to provide a significant extra safety margin, , under the intended stress levels and yeah!

most engineers I know want any project they were or are envolved in to produce something of exceptional durability and strength,and yes theres almost always a second group,

theres, bound too be a group of accountants that will inevitably resist the use of the best option, and insist on something marginal thats cheaper in many cases.

what I find rather iratating at times is even when you call up and ask to speak to the engineering departments youll rarely get specific facts or a link to test results.

Core shift is a result of a block, cylinder head, or other engine casting shifting in its mold when the molten metal is poured in. When core shift occurs the cylinder bores, lifter bores, main bearing and cam tunnels shift from their blueprinted positions. If the shift is significant, mechanical problems can occur and some cylinder walls may be critically thin. This is especially of concern if the engine is to be used for racing applications.

The only way to guarantee cylinder wall thickness is to have the block sonic-tested, but this can be difficult when you go to purchase a used engine.

Core shift example

Core shift exampleOn engines with in-block cams, you can always take a look at the cam bearing bore. If it is noticeably offset in its machined boss, you should suspect core shift.

keep in mind theres ALWAYS some one willing to produce something with less precision, made from cheaper materials so they can extract a greater potential profit who really could not care less about long term durability as long as the component sells briskly at a significant profit!

not all import parts are inferior or made from less desirable materials, just as not ALL AMERICAN, produced parts will be top quality, but I have found that the better name brand parts like

DART, AFR,BRODIX,EDELBROCK,CRANE,TRICKFLOW,CALLIES and SCAT , have a reputation to maintain, so they generally won,t sell low end crap, but it always helps to ask questions ,do research,never trust a machine shops work without carefully meassuring and verifying any work was done correctly and owning accurate precision tools for measuring is mandatory if your serious about engine building!

TWO BOLT MAIN CAP BLOCK

4 bolt SBC block

the block pictured above is NOT A CHEVY, but it gives you some idea of what the block internal coolant passages and cylinder walls look like

you tend to get what you pay for in most brand name performance products

notice the much stronger alloy used in some block castings

Some of the Key ingredients in cast iron to make it strong are Nickel,Molybdenum, Copper

The Little-M nickel content is 0.149, Molybdenum 0.211, Copper 0.404

Dart SHP Nickel content is 0.071, Molybdenum .016, copper 0.283

Chinese block Nickel content is 0.005, Molybdenum 0.005, Copper 0.020

Leo did the Brinell test by using the Rockwell B Scale and converting it to Brinell scale and he will back this test.

Little-M tested 200

SHP 190

Chinese block 107

if you check you'll find that stud girdle use does little or nothing for the individual main cap strength but it does marginally increase main cap stability and block flex.

now the potential difference is probably not worth the expense, in that your generally spending cash that would be better used in the purchase of the stronger aftermarket block casting from a known source like DART.

look through the links and read the sub links

the billet splayed main caps on the aftermarket block is the stronger route, but Id bet 90% of the guys building their first engine think they will save money using the O.E.M. block they already own.....well, until... they add up all the machine work costs and price of parts like aftermarket splayed caps, ARP main studs ,the labor costs from the machine shop, etc. but by that time the machine shop owner is smiling all the way to the bank, and youve just figured out the true cost of that cheaper O.E.M BLOCK

related info

http://machinedesign.com/basics-design/cast-iron

https://www.sfsa.org/sfsa/pubs/hbk/s5.pdf

http://www.wisconsinprecision.com/plain-carbon-low-alloy-steel-investment-castings.php

http://garage.grumpysperformance.com/index.php?threads/types-of-crankshaft-steel.204/

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-24723

http://garage.grumpysperformance.com/index.php?threads/block-choice.10472/

http://garage.grumpysperformance.com/index.php?threads/engine-block-cylinder-wall-thickness.976/

http://garage.grumpysperformance.com/index.php?threads/sbc-cylinder-wall-thickness.7646/

http://garage.grumpysperformance.co...a-scat-rotating-assembly-be.11495/#post-52962

http://garage.grumpysperformance.com/index.php?threads/which-dart-shp-4-0-or-4-125.3219/#post-44637

http://garage.grumpysperformance.co...bearing-studs-torque-stretch.9409/#post-34241

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-24723

http://garage.grumpysperformance.com/index.php?threads/main-cap-fit-in-block.5945/#post-51651

http://www.afsinc.org/files/images/iron alloys.pdf

http://www.sbintl.com/tech_library/...standing_the_metallurgy_in_todays_engines.pdf

http://what-when-how.com/automobile/cylinder-block-automobile/

http://www.enginebuildermag.com/2013/06/sleeves-liners/

Last edited: