8

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

J&S Electronics Safeguard Individual Cylinder Knock Control System

8

87vette81big

Guest

8

87vette81big

Guest

Individual Cylinder Knock Control for Distributor Ignition

Features include:

• Two Rev Limits (Staging and Top End)

• Cranking Retard: Knob allows up to 20° retard. Re-advances one dgree per spark event.

• Nitrous Retard: Knob allows up to 20° retard when activated by 12v.

• Boost Retard/Vacuum Advance with Start and Rate control

• Individual Cylinder Knock Retard

• High Energy Inductive ignition with variable dwell

• Knock sensor sensitivity adjust

• Triggers from points, OEM electronic, magnetic pickup, Hall effect.

• Can trigger MSD or other CDI box

• How it works:

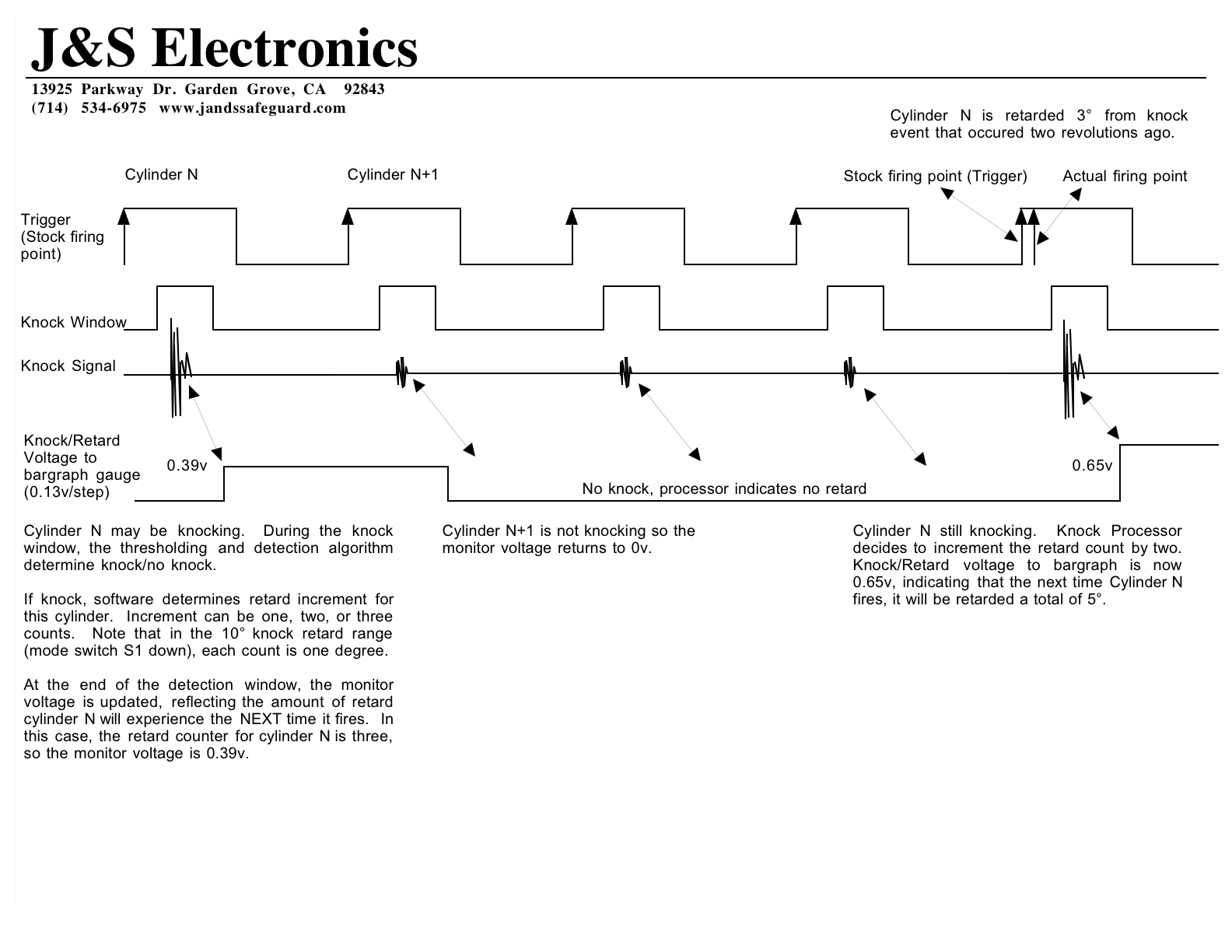

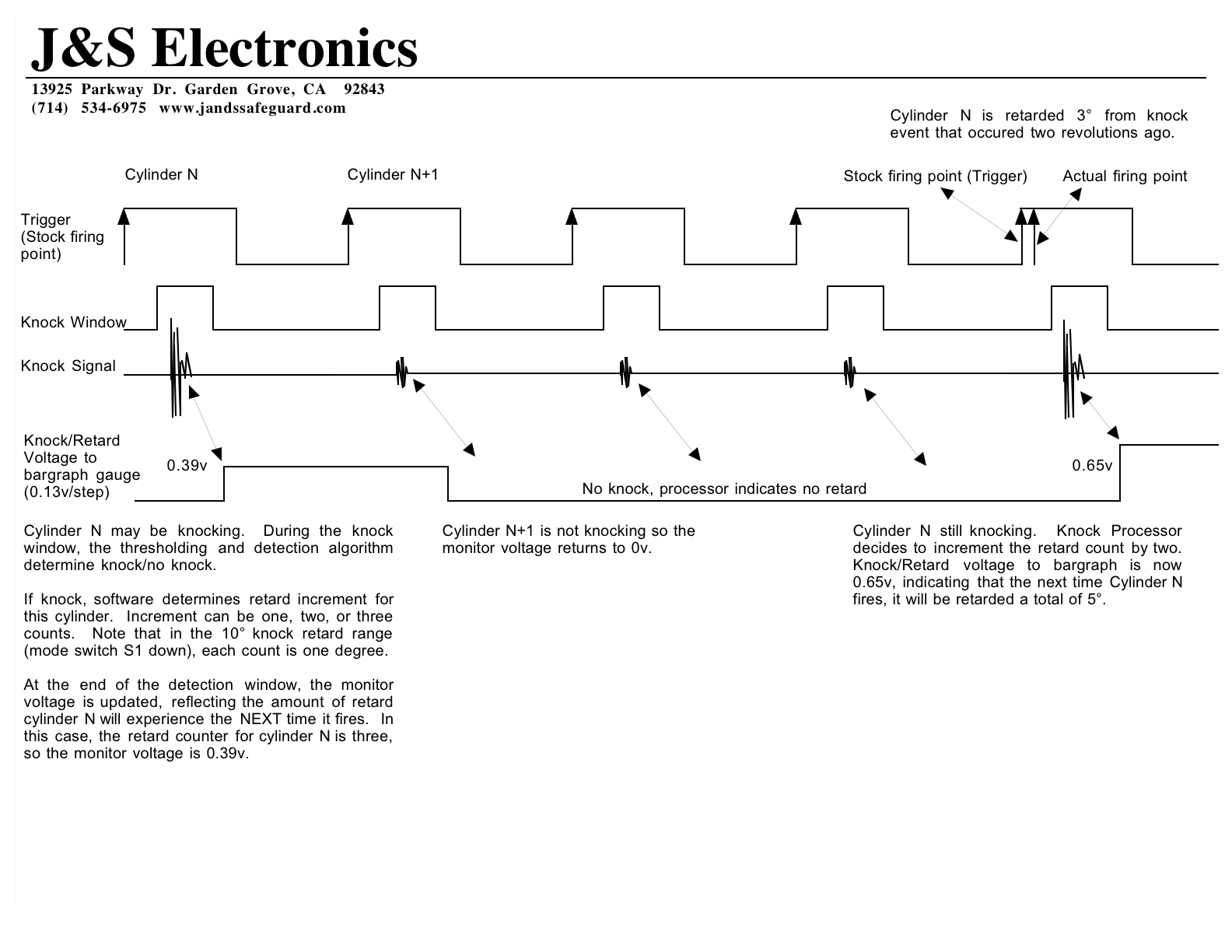

The system makes a spark, then decides if there was knock. If knock is detected, software "knows" it had to come from the cylinder that just fired, and that cylinder won't fire again for two revolutons.

When that cylinder comes up to fire the next time, software dials in the calculated amount of knock retard. It does this as each cylinder goes by, building up a different timing curve for each cylinder if knock is detected.

The unit retards in steps, a total of ten steps are possible. Each step is one or two degrees, depending on a user mode switch. When knock is detected, software retards in proportion to knock intensity.

The unit responds to inaudible knock, and retards quickly enough to prevent knock from becoming audible. The re-advance rate is one step every twenty revolutions. Note that the unit will not advance beyond stock timing. Of course, you may choose to bump the timing a bit after installing the unit.

Features include:

• Two Rev Limits (Staging and Top End)

• Cranking Retard: Knob allows up to 20° retard. Re-advances one dgree per spark event.

• Nitrous Retard: Knob allows up to 20° retard when activated by 12v.

• Boost Retard/Vacuum Advance with Start and Rate control

• Individual Cylinder Knock Retard

• High Energy Inductive ignition with variable dwell

• Knock sensor sensitivity adjust

• Triggers from points, OEM electronic, magnetic pickup, Hall effect.

• Can trigger MSD or other CDI box

• How it works:

The system makes a spark, then decides if there was knock. If knock is detected, software "knows" it had to come from the cylinder that just fired, and that cylinder won't fire again for two revolutons.

When that cylinder comes up to fire the next time, software dials in the calculated amount of knock retard. It does this as each cylinder goes by, building up a different timing curve for each cylinder if knock is detected.

The unit retards in steps, a total of ten steps are possible. Each step is one or two degrees, depending on a user mode switch. When knock is detected, software retards in proportion to knock intensity.

The unit responds to inaudible knock, and retards quickly enough to prevent knock from becoming audible. The re-advance rate is one step every twenty revolutions. Note that the unit will not advance beyond stock timing. Of course, you may choose to bump the timing a bit after installing the unit.

8

87vette81big

Guest

(See also links at bottom of page)

Knock aricle we wrote for the April 1991 Turbo magazine Newsletter:

Engine Knock-that annoying rattling sound that sometimes comes from under the hood of your pride and joy, is a killer. We have all heard the stories of blown head gaskets and broken pistons. Maybe it has already happened to you, too. But just what is knock, sometimes also referred to as detonation?

The knocking sounds you hear are the cylinder walls set into oscillation by intense pressure waves, caused by abnormal combustion. Normal combustion is a controlled burn that starts from the spark plug and spreads outward, causing a pressure rise in the combustion chamber. This pressure is then converted into torque on the crankshaft. Ideally, the peak pressures will occur about ten to fifteen degrees after top dead center (TDC), as the piston is on its way down.

Detonation is a form of abnormal combustion that starts off right, but at the last millisecond, something goes wrong. The remaining air-fuel mixture, called the "end gas", explodes all at once, instead of burning in a controlled way. Resultant engine damage is caused by an instantaneous pressure rise that can excede 1500 psi. This is more than double the normal peak combustion pressure, and will blow head gaskets, break piston ring lands and hammer the rod bearings. Another form of damage seen is that the tops of the pistons will be eroded and can even melt.

High octane fuels are resistant to detonation because they contain compounds that slow down the chemical chain reaction we call combustion. If left unchecked, these chain reactions would quickly escalate, resulting in increasing damage to the piston and other engine components. All fuels, regardless of octane, have a knock limit. This is reached when the temperature of the "end gas" reaches an autoignition point. Combustion chamber designers use high swirl inlets and large "quench areas" to fight this "autoignition" problem. There are other factors beyond these mechanical design features which influence "end gas" temperatures. Some of these are: (1) Intake charge temperature, (2) Coolant temperature, (3) Compression Ratio, (4) Boost pressure, (5) Spark timing, (6) Air-fuel ratio, and (6) Humidity.

An increase in compression ratio, boost pressure, or spark timing will increase peak cylinder pressure, which in turn raises the "end gas" temperature. Higher inlet and coolant temperatures also increase the "end gas" temperature. Richer mixtures can be used to cool the charge. At some point beyond about 10:1, however, will again increase the tendency to detonate. A decrease in humidity will also tend to increase detonation.

Solutions:

Some things you can change, and some you are stuck with. Obvious things to do are get cold, fresh air to your air cleaner, use the best form of charge cooling (intercoolers) you can afford, and work on your cooling system to bring the temperatures down. Get an Air-fuel meter (O2 meter), and if necessary, install a fuel enrichment device. For turbo/supercharged engines water-alcohol injection can be very effective, but the volumes required mean constant refilling and maintenance, so in the long term it is a specialized solution that has a lot of drawbacks.

Spark retard, within limits is the most powerful means of controlling detonation. Traditionally, this has been a manual affair by simply cranking the distributor back "x" degrees, Some electronic devices can retard timing in relation to manifold or boost pressure and other devices offer simple manual knobs you can alter the timing with if an audible "ping" is heard. Many newer cars are quipped with knock sensors that retard the timing when detonation occurs. This form of closed loop spark control where the vehicle's ecu automatically retards all cylinders when detonation occurs, a situation we call "retard all". On a select few modern engine controllers (Porsche, Corvette) the microprocessor is programmed to retard individual cylinders as knock or detonation occurs. The problem with either of these approaches is twofold: First, the OEM carefully maps a complex set of spark curves and only allows a small degree of retard to take place, typically 4 degrees; Secondly, these ecus are highly specific and are not readily adaptable or programmable for other applications.

SafeGuard versus Knock

J&S Electronics has developed the SafeGuard which uses a knock sensor to provide feedback to it's microprocessor which, in turn, controls the timing for each cylinder on an individual, optimized basis. DINAN Enginneering, Kenne Bell, and CarTech have successfully used SafeGuards in their installations. DINAN used SafeGuards in their BMW turbo kits which set very high standards for performance and sophistication. Kenne Bell has used SafeGuards in Syclone and Typhoon V-6 turbos to complete a very successful upgrade program for these General Motors vehicles. By adding a J&S SafeGuard and returning timing to factory specs the missing low end performance and extra horsepower were rediscovered.

J&S Electronics has twenty five years of experience in knock-sensing and detonation control. It is not a simple matter of attaching a microphone on the engine and listening for the tell-tale "knock". If you have discussions with OEM powertrain engineers they can tell you of the difficulties they face in the areas of signal discrimination or "noise" as well as the issues related to how the actual control over the timing should be done. The SafeGuard has sophisticated mathematical controls or algorithms than discriminate between noise and actual "knock", and has user adjustable controls that allow for sensitivity as well as amount and speed of retard. Whereas OE retard schemes are limited to say 4 degrees, the SafeGuard can be set for up to 20 degrees of ignition retard. This prevents catastrophic failure that can occur should you loose engine coolant or some other unforseen event. The SafeGuard will control the timing of each cylinder in proportion to the degree of detonation occuring, thus maximizing performance and preventing engine damage.

Detonation is the precursor to preignition and only J&S Electronics can provide you a real-time solution to your ignition timing that both maximizes performance and protects your investment.

Principle of Operation

Using a single knock sensor, the system detects the onset of detonation and retards the timing on a per cylinder basis, up to a total of ten increments. A mode switch lets you select a maximum of either ten degrees or twenty degrees of knock retard. In the ten degree range, each increment is one degree, double that for the twenty degree range.

When knock is detected, software determines knock intensity and decides how many increments to retard this cylinder the next time it fires. The control software retards in proportion to the knock event, up to a maximum of seven steps with one knock event.

The system is always trying to re-advance to stock timing. In the ten degree mode, it re-advances at the rate of one degree every twenty revolutions, double that in the twenty degree mode.

The system does not need a cam or crankshaft reference to determine which cylinder to retard. The unit is programmed to "know" that the knocking cylinder is the one that just fired, and that it won't fire again for two more revolutions. When the knocking cylinder comes around to fire again, software dials in the retard amount for that cylinder. It does this as each cylinder goes by, building up a different retard amount for each cylinder.

The detection algorithm employs a "knock window" to listen for knock at the appropriate time in the combustion cycle. Refer to the diagram below:

Allen Cline's article

John Deakin's article

Knock aricle we wrote for the April 1991 Turbo magazine Newsletter:

Engine Knock-that annoying rattling sound that sometimes comes from under the hood of your pride and joy, is a killer. We have all heard the stories of blown head gaskets and broken pistons. Maybe it has already happened to you, too. But just what is knock, sometimes also referred to as detonation?

The knocking sounds you hear are the cylinder walls set into oscillation by intense pressure waves, caused by abnormal combustion. Normal combustion is a controlled burn that starts from the spark plug and spreads outward, causing a pressure rise in the combustion chamber. This pressure is then converted into torque on the crankshaft. Ideally, the peak pressures will occur about ten to fifteen degrees after top dead center (TDC), as the piston is on its way down.

Detonation is a form of abnormal combustion that starts off right, but at the last millisecond, something goes wrong. The remaining air-fuel mixture, called the "end gas", explodes all at once, instead of burning in a controlled way. Resultant engine damage is caused by an instantaneous pressure rise that can excede 1500 psi. This is more than double the normal peak combustion pressure, and will blow head gaskets, break piston ring lands and hammer the rod bearings. Another form of damage seen is that the tops of the pistons will be eroded and can even melt.

High octane fuels are resistant to detonation because they contain compounds that slow down the chemical chain reaction we call combustion. If left unchecked, these chain reactions would quickly escalate, resulting in increasing damage to the piston and other engine components. All fuels, regardless of octane, have a knock limit. This is reached when the temperature of the "end gas" reaches an autoignition point. Combustion chamber designers use high swirl inlets and large "quench areas" to fight this "autoignition" problem. There are other factors beyond these mechanical design features which influence "end gas" temperatures. Some of these are: (1) Intake charge temperature, (2) Coolant temperature, (3) Compression Ratio, (4) Boost pressure, (5) Spark timing, (6) Air-fuel ratio, and (6) Humidity.

An increase in compression ratio, boost pressure, or spark timing will increase peak cylinder pressure, which in turn raises the "end gas" temperature. Higher inlet and coolant temperatures also increase the "end gas" temperature. Richer mixtures can be used to cool the charge. At some point beyond about 10:1, however, will again increase the tendency to detonate. A decrease in humidity will also tend to increase detonation.

Solutions:

Some things you can change, and some you are stuck with. Obvious things to do are get cold, fresh air to your air cleaner, use the best form of charge cooling (intercoolers) you can afford, and work on your cooling system to bring the temperatures down. Get an Air-fuel meter (O2 meter), and if necessary, install a fuel enrichment device. For turbo/supercharged engines water-alcohol injection can be very effective, but the volumes required mean constant refilling and maintenance, so in the long term it is a specialized solution that has a lot of drawbacks.

Spark retard, within limits is the most powerful means of controlling detonation. Traditionally, this has been a manual affair by simply cranking the distributor back "x" degrees, Some electronic devices can retard timing in relation to manifold or boost pressure and other devices offer simple manual knobs you can alter the timing with if an audible "ping" is heard. Many newer cars are quipped with knock sensors that retard the timing when detonation occurs. This form of closed loop spark control where the vehicle's ecu automatically retards all cylinders when detonation occurs, a situation we call "retard all". On a select few modern engine controllers (Porsche, Corvette) the microprocessor is programmed to retard individual cylinders as knock or detonation occurs. The problem with either of these approaches is twofold: First, the OEM carefully maps a complex set of spark curves and only allows a small degree of retard to take place, typically 4 degrees; Secondly, these ecus are highly specific and are not readily adaptable or programmable for other applications.

SafeGuard versus Knock

J&S Electronics has developed the SafeGuard which uses a knock sensor to provide feedback to it's microprocessor which, in turn, controls the timing for each cylinder on an individual, optimized basis. DINAN Enginneering, Kenne Bell, and CarTech have successfully used SafeGuards in their installations. DINAN used SafeGuards in their BMW turbo kits which set very high standards for performance and sophistication. Kenne Bell has used SafeGuards in Syclone and Typhoon V-6 turbos to complete a very successful upgrade program for these General Motors vehicles. By adding a J&S SafeGuard and returning timing to factory specs the missing low end performance and extra horsepower were rediscovered.

J&S Electronics has twenty five years of experience in knock-sensing and detonation control. It is not a simple matter of attaching a microphone on the engine and listening for the tell-tale "knock". If you have discussions with OEM powertrain engineers they can tell you of the difficulties they face in the areas of signal discrimination or "noise" as well as the issues related to how the actual control over the timing should be done. The SafeGuard has sophisticated mathematical controls or algorithms than discriminate between noise and actual "knock", and has user adjustable controls that allow for sensitivity as well as amount and speed of retard. Whereas OE retard schemes are limited to say 4 degrees, the SafeGuard can be set for up to 20 degrees of ignition retard. This prevents catastrophic failure that can occur should you loose engine coolant or some other unforseen event. The SafeGuard will control the timing of each cylinder in proportion to the degree of detonation occuring, thus maximizing performance and preventing engine damage.

Detonation is the precursor to preignition and only J&S Electronics can provide you a real-time solution to your ignition timing that both maximizes performance and protects your investment.

Principle of Operation

Using a single knock sensor, the system detects the onset of detonation and retards the timing on a per cylinder basis, up to a total of ten increments. A mode switch lets you select a maximum of either ten degrees or twenty degrees of knock retard. In the ten degree range, each increment is one degree, double that for the twenty degree range.

When knock is detected, software determines knock intensity and decides how many increments to retard this cylinder the next time it fires. The control software retards in proportion to the knock event, up to a maximum of seven steps with one knock event.

The system is always trying to re-advance to stock timing. In the ten degree mode, it re-advances at the rate of one degree every twenty revolutions, double that in the twenty degree mode.

The system does not need a cam or crankshaft reference to determine which cylinder to retard. The unit is programmed to "know" that the knocking cylinder is the one that just fired, and that it won't fire again for two more revolutions. When the knocking cylinder comes around to fire again, software dials in the retard amount for that cylinder. It does this as each cylinder goes by, building up a different retard amount for each cylinder.

The detection algorithm employs a "knock window" to listen for knock at the appropriate time in the combustion cycle. Refer to the diagram below:

Allen Cline's article

John Deakin's article

8

87vette81big

Guest

All prices USD

Part

Number Description Price

2002 Dual Monitor (Knock Retard/Air-Fuel)- 52mm billet

A/F section calibrated for standard narrowband oxygen sensor

$179.00

2001 Single Monitor (Knock Retard) - 52mm billet $89.00

2003 Combination Knock/Retard and Knock-Finder gauge for Vampire, shows the knocking cylinders and amount of retard. $179.00

1004-Interceptor Controls up to eight ignition channels. Use with "smart coils" which have internal igniter, or multi-channel ignition modules.

6ch $585

8ch $595

1004-Vampire Connects to coil negative of each coil. Controls waste spark or COP coils.

6ch $575

8ch $595

1004-Uni.V3

Sensors "Donut" style Knock Sensor (Bosch, Siemens, or NTK)

Includes 10' shielded cable and sealed Delphi connector

BSK-8MM $50

BSK-10MM $55

Orders and Payment

NOW ACCEPTING P

Part

Number Description Price

2002 Dual Monitor (Knock Retard/Air-Fuel)- 52mm billet

A/F section calibrated for standard narrowband oxygen sensor

$179.00

2001 Single Monitor (Knock Retard) - 52mm billet $89.00

2003 Combination Knock/Retard and Knock-Finder gauge for Vampire, shows the knocking cylinders and amount of retard. $179.00

1004-Interceptor Controls up to eight ignition channels. Use with "smart coils" which have internal igniter, or multi-channel ignition modules.

- Knock-meter indicates knocking cylinder

- Individual cylinder knock retard

- Boost retard with Rate and Start knob

- Proportional nitrous retard capability

- Headphone amplifier to listen for knock

6ch $585

8ch $595

1004-Vampire Connects to coil negative of each coil. Controls waste spark or COP coils.

- Individual cylinder knock retard

- Boost retard with Rate and Start knobs

- Proportional nitrous retard capability

6ch $575

8ch $595

1004-Uni.V3

- Universal unit for distributor ignition featuring:

- Two revlimits (staging and top end)

- Cranking retard

- Nirous retard

- Boost retard with Rate and Start knob

- Individual cylinder knock retard

- High energy inductive discharge ignition with variable dwell

Sensors "Donut" style Knock Sensor (Bosch, Siemens, or NTK)

Includes 10' shielded cable and sealed Delphi connector

BSK-8MM $50

BSK-10MM $55

Orders and Payment

NOW ACCEPTING P

8

87vette81big

Guest

Telephone:

(714) 534 6975

E-Mail:

jpizzuto@jandssafeguard.com

Address:

J&S Electronics

13925 Parkway Dr.

Garden Grove, CA 92843

(Please

8

87vette81big

Guest

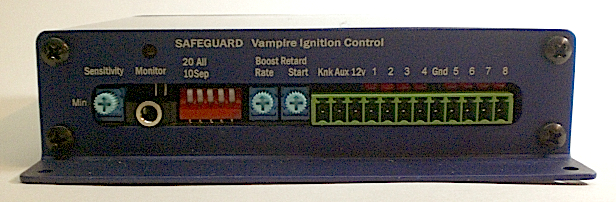

Applications Front Panel

Universal version for distributor with single coil. Triggers from points, magnetic, Hall, or digital from ECU. Features high energy dwell control ignition, can also trigger MSD, etc. Optional dual coil driver for Porsche with twin plug distributor.

More information

Example diagrams:

General Installation Instructions

Porsche with Bosch CDI Instructions

Look inside

Interceptor version controls up to eight ignition channels. Drives ignition modules or smart coils (coils with internal igniter). Features "knock-finder" display and headphone output. Please specify number of channels when ordering.

More information

Example diagrams:

One channel MR2 Instructions

RX7 Interceptor (same as one channel MR2) Controls leading coil igniter

Two channel Miata Instructions

Three channel Mitsubishi 3000GT Instructions

Four channel MR2 Spyder Instructions

Six channel Instructions

Eight channel Instructions

Look inside

Vampire version connects directly to coil negative signals without interrupting existing stock ignition. Controls up to eight ignition channels. Please specify number of channels when ordering.

More information

Example diagrams:

Single coil Instructions

RX7 Vampire (see single coil) Controls leading coil igniter

Dual coil Ford Focus Instructions

Electromotive XDI-2 three channel waste spark Instructions

Four channel '96-'98 Ford Instructions

Six channel 300ZX Instructions

Eight channel '99 and later Ford COP Instructions

Eight channel '99 and later Ford COP Progressive Nitrous Retard Instructions

Look inside

8

87vette81big

Guest

Fits 2 1/16" (52mm) gauge pod Instructions

A built-in light sensor dims the display automatically at night, and increases brightness in direct sunlight.

A ten segment bargraph display shows amount of retard, and thus gives an indication of the engine's tendency to knock at any particular time. The monitor is conected to the J&S SafeGuard with a 3.5 mm stereo cable supplied in the kit. The new SafeGuard units have an onboard LED that glows in proportion to the amount of knock retard. This will assist you in setup of the SafeGuard, but the bargraph gives much more information.

The display shows how much tiiming is being taken out by the SafeGuard. When the SafeGuard is set for 20° control range, each LED is worth 2°. If the SafeGuard is set for "retard all", and it is taking out say 12° of timing, then you would see the 6th LED on. If the SafeGuard is set for "retard separate", then the display becomes more complex. Since the SafeGuard can retard each cylinder by a separate amount, you will see one LED on for each cylinder that is being retarded, and the position of that LED indicates how far. For example, let's say that one cylinder is retarded 4°, another 6°, and another 8°, then you would see the 2nd, 3rd, and 4th LEDs on.

The ten segment LED (GGGYYYYRRR) Air Fuel Display now has a dual resolution feature with a switch that allows accurate tuning for both cruise and full power modes.

When the switch is in the "Power" mode, the gauge reads between 0.81v and 0.90v, so it may be used with any standard narrow band O2 sensor.

Knock/Retard Monitor

8

87vette81big

Guest

Good products for all us but me Grumpy.

Not Losing my Vertex Magnetos on my 1963 Grand Prix or my 1970-1/2 Trans Am.

Just need some $ to buy the products shown.

Not Losing my Vertex Magnetos on my 1963 Grand Prix or my 1970-1/2 Trans Am.

Just need some $ to buy the products shown.

8

87vette81big

Guest

Its also great for the few Corvette guys running LS -X power in their Vettes converted to a carburetor.

Best of Old School simplicity & high tech spark knock ignition control.

Its a 1st here on Grumpys site.

Never on Corvette Forum.

Or DC.

Ford 5.0 Guys their Race sight I found....

Best of Old School simplicity & high tech spark knock ignition control.

Its a 1st here on Grumpys site.

Never on Corvette Forum.

Or DC.

Ford 5.0 Guys their Race sight I found....

8

87vette81big

Guest

I found more Grumpy.thank you Brian, for taking the time to post some valid and useful info that may prove useful, for several members

Dirt cheap affordable for us right now.

Think will come in Handy for Rick & me.

Post soon on a new thread.

GLHS60

Well-Known Member

Chrysler 4 cylinder Turbo Engines had the ability to reduce timing for individual cylinder's beginning with the 1985 model year.

Cool feature that can be monitored with most scanners.

Helps isolate which cylinders are more detonation prone, normally # 3 in the 2.2/2.5 SOHC Turbo Engines.

Thanks

Randy

Cool feature that can be monitored with most scanners.

Helps isolate which cylinders are more detonation prone, normally # 3 in the 2.2/2.5 SOHC Turbo Engines.

Thanks

Randy

8

87vette81big

Guest

I never knew Randy.Chrysler 4 cylinder Turbo Engines had the ability to reduce timing for individual cylinder's beginning with the 1985 model year.

Cool feature that can be monitored with most scanners.

Helps isolate which cylinders are more detonation prone, normally # 3 in the 2.2/2.5 SOHC Turbo Engines.

Thanks

Randy

I will keep your tips in mind.