Loves302Chevy

"One test is worth a thousand expert opinions."

refer to these previous posts for the complete story:

http://garage.grumpysperformance.com/index.php?threads/update-334-sbc-lives-again.11882/

http://garage.grumpysperformance.co...help-i-might-have-no-oil-to-the-rockers.3397/

http://garage.grumpysperformance.co...e-parts-dont-come-in-plain-white-boxes.11940/

After I finally got all the problems I had with the 334 SBC worked out, I started to clean up and re-organize

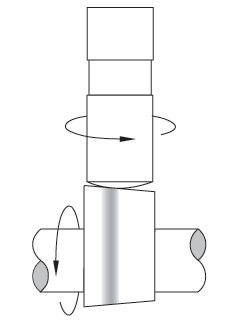

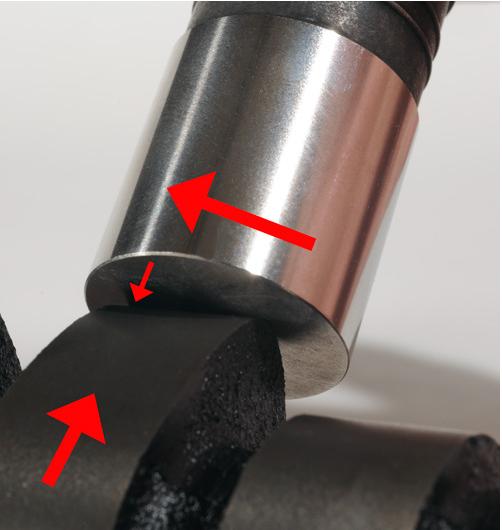

my engine parts. I came across a set of used GM Delphi type hydraulic lifters with the hardened bases.

I can't remember what SBC engine they came out of, or why I saved them, but I think it was because the bases

on every lifter in this entire set were mirror polished with not even the slightest bit of wear and I kept them as

a reminder to myself that I wanted to use this type of lifter with my next flat-tappet hydraulic camshaft.

For those reading this for the first time, for the 334 I bought these lifters - http://www.skipwhiteperformance.com/detail.aspx?Item=J-817

The ad says: "You will receive genuine Delphi / GM lifters. Use nothing but Genuine Delphi lifters. 100% made in the USA

We have contacted the three cam companies we deal with, Crane, Lunati, and Howards, and all highly approve of this lifter. In the past we marketed these lifters under the former name, "Eaton" They are the exact same lifter.

We purchase our Delphi lifters in bulk trays of 122 each, as all engine builders do. We use them in all of our engines running a hyd. flat tappet cam. You will receive a complete set of 16 in an unmarked well protected package. The cost difference is well worth the difference, but rest assured these are genuine Delphi lifters. We can provide proof for those that are concerned. They are genuine Delphi tappets, made in the USA"

from Robert's post on another site, "The major 'offshore' producer of lifters is currently Eaton with plants in Mexico, India, Turkey and a new plant in China."

So I guess that sellers can get away with advertising MADE IN THE USA even if the parts really aren't made here!

So now I had my opportunity to do a side-by-side comparison between this lifter and the "JUNK" set that

did not pump oil to the rocker arms below about 1700 rpm and started to eat a lobe on my new camshaft.

Hopefully, I would discover the difference that caused these lifters not to work, AND I DID!

The spring of the used GM is slightly shorter than the one in the 2.5 hours used JUNK Delphi, but

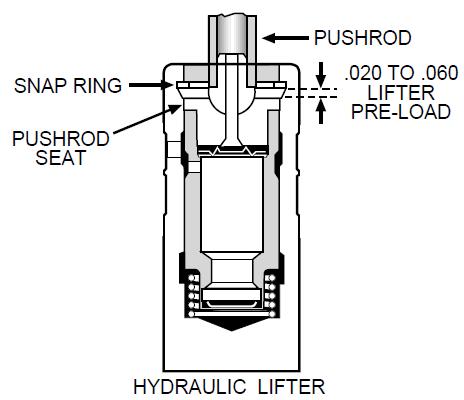

who knows how many miles are on the GOOD GMs. The big difference is in the pushrod seats.

The JUNK Delphi measures .299" and GM measures .241" for a difference of .058". When both

are put back together without the retaining rings, the seat on the JUNK Delphi sticks out the

thickness of 2 pennies, or .119".

During normal operation the metering disc is supposed to momentarily unseat from the bottom of

the pushrod seat, and the oil inside the lifter can then flow out to the pushrod and rocker arm.

It is my belief that the reduced clearance from the thicker seat and resultant increased plunger

spring pressure does not allow the metering disc to function properly, causing the oil to remain

trapped inside the lifter. This might also keep the valves in the heads from seating.

Part of me wants to swap the pushrod seats from the GM lifter into the Junk Delphis and test them

in an engine to prove whether I solved this mystery, or not. But I will resist.

http://garage.grumpysperformance.com/index.php?threads/update-334-sbc-lives-again.11882/

http://garage.grumpysperformance.co...help-i-might-have-no-oil-to-the-rockers.3397/

http://garage.grumpysperformance.co...e-parts-dont-come-in-plain-white-boxes.11940/

After I finally got all the problems I had with the 334 SBC worked out, I started to clean up and re-organize

my engine parts. I came across a set of used GM Delphi type hydraulic lifters with the hardened bases.

I can't remember what SBC engine they came out of, or why I saved them, but I think it was because the bases

on every lifter in this entire set were mirror polished with not even the slightest bit of wear and I kept them as

a reminder to myself that I wanted to use this type of lifter with my next flat-tappet hydraulic camshaft.

For those reading this for the first time, for the 334 I bought these lifters - http://www.skipwhiteperformance.com/detail.aspx?Item=J-817

The ad says: "You will receive genuine Delphi / GM lifters. Use nothing but Genuine Delphi lifters. 100% made in the USA

We have contacted the three cam companies we deal with, Crane, Lunati, and Howards, and all highly approve of this lifter. In the past we marketed these lifters under the former name, "Eaton" They are the exact same lifter.

We purchase our Delphi lifters in bulk trays of 122 each, as all engine builders do. We use them in all of our engines running a hyd. flat tappet cam. You will receive a complete set of 16 in an unmarked well protected package. The cost difference is well worth the difference, but rest assured these are genuine Delphi lifters. We can provide proof for those that are concerned. They are genuine Delphi tappets, made in the USA"

from Robert's post on another site, "The major 'offshore' producer of lifters is currently Eaton with plants in Mexico, India, Turkey and a new plant in China."

So I guess that sellers can get away with advertising MADE IN THE USA even if the parts really aren't made here!

So now I had my opportunity to do a side-by-side comparison between this lifter and the "JUNK" set that

did not pump oil to the rocker arms below about 1700 rpm and started to eat a lobe on my new camshaft.

Hopefully, I would discover the difference that caused these lifters not to work, AND I DID!

The spring of the used GM is slightly shorter than the one in the 2.5 hours used JUNK Delphi, but

who knows how many miles are on the GOOD GMs. The big difference is in the pushrod seats.

The JUNK Delphi measures .299" and GM measures .241" for a difference of .058". When both

are put back together without the retaining rings, the seat on the JUNK Delphi sticks out the

thickness of 2 pennies, or .119".

During normal operation the metering disc is supposed to momentarily unseat from the bottom of

the pushrod seat, and the oil inside the lifter can then flow out to the pushrod and rocker arm.

It is my belief that the reduced clearance from the thicker seat and resultant increased plunger

spring pressure does not allow the metering disc to function properly, causing the oil to remain

trapped inside the lifter. This might also keep the valves in the heads from seating.

Part of me wants to swap the pushrod seats from the GM lifter into the Junk Delphis and test them

in an engine to prove whether I solved this mystery, or not. But I will resist.

Last edited by a moderator: