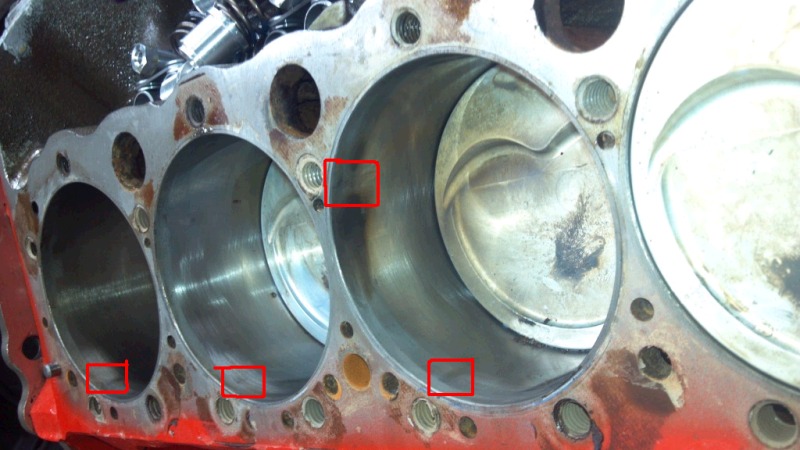

I recently had a guy bring me a 396 BBC bare block he wanted me to rebuild for him,

after using a pressure cleaner and solvent to remove the grease and loose paint ,

(the block was covered in grease and dirt, and I think it was partly done by the seller to cover the flaws)

..... looking over the block and taking several measurements

,after cleaning it with a pressure leaner, solvent and a stiff brush,

engine building is about 75% technology and science and 10% art, and 15% skill gained through experience,over time.

doing it successfully mandates the person involved, in the process, can accurately observe, think, and recognize problems,

and if required, stop and think up solutions.

yes it involves knowing how components are intended to function and accurate precision measurement and access to some specific tools and a skilled well equiped machine shop you can trust, is a mandatory factor and skill set.

so many guys seem to be under the absurd impression that any and all solutions,

to any and all problems,

invariably involve, throwing away some component,

and installing some new out of the box part,

instead of acting logically and actually measuring,

thinking and potentially custom clearancing or at least reading the instructions,

and as most experienced engine builders will tell you ,

almost nothing you can buy fits and functions correctly in out-of-the-box, condition

,too near its true potential.after its ,

carefully, inspected, and correctly clearanced, and fitted.

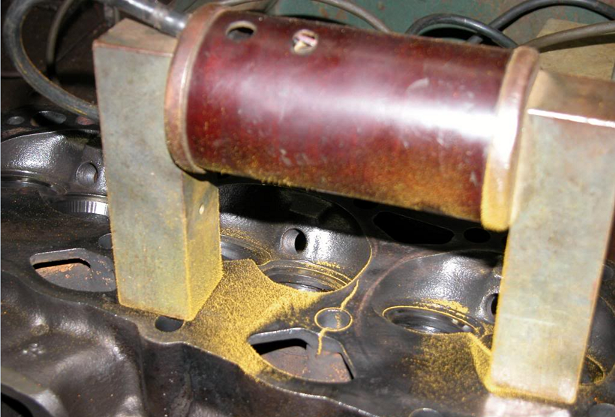

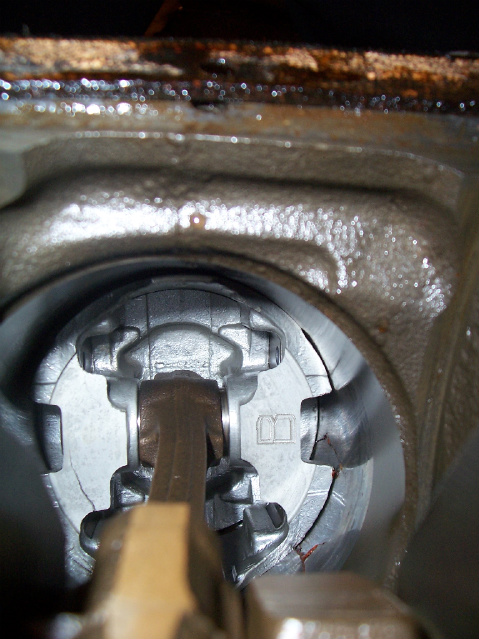

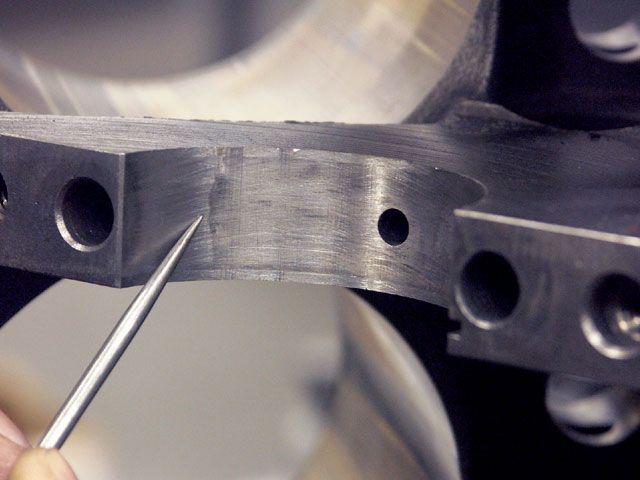

clean any block you buy and look for obvious cracks and if you have doubts get the machine shop to mag or dye test the block or heads

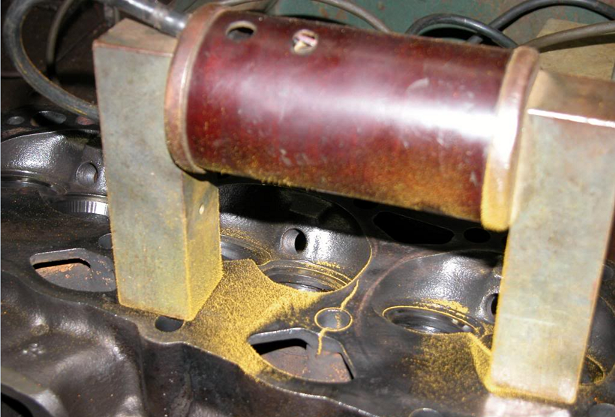

lifter bores

and lifter gallery

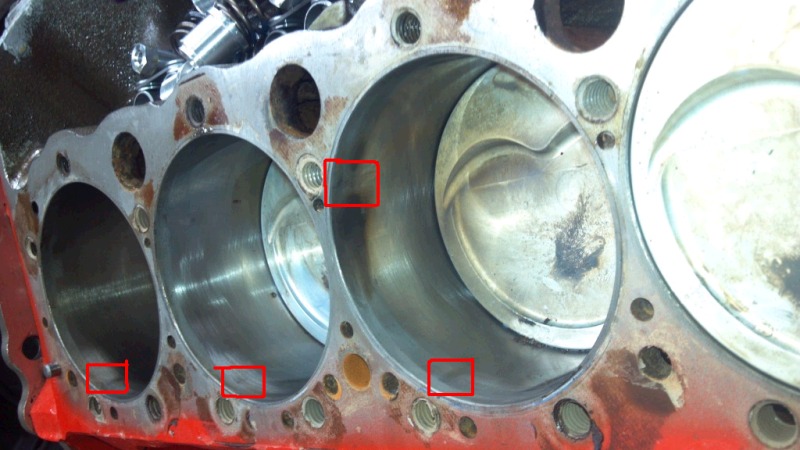

,piston bore walls,

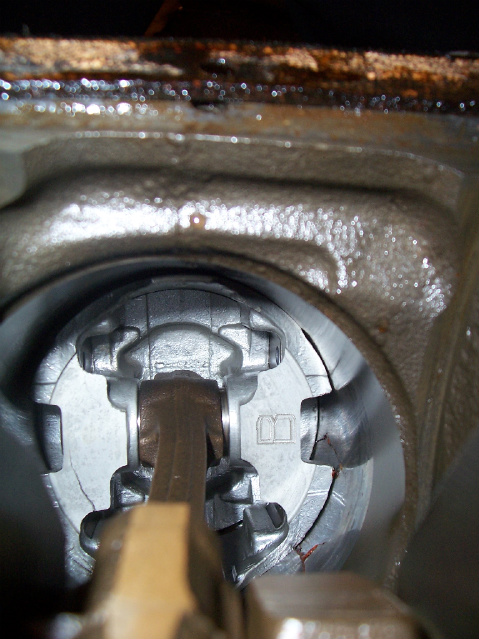

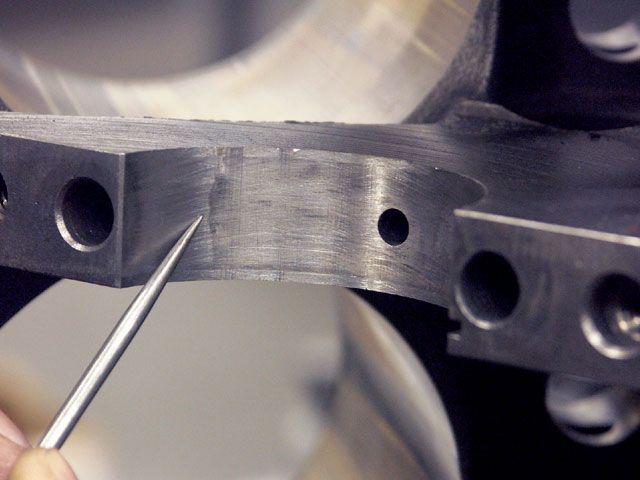

block main cap web support areas

heads between the valves in valve seat area

look for stripped head and manifold and oil pan mounting bolt threads,

in threaded holes and cracks in block radiating from the holes

http://www.tooltopia.com/fowler-72-646-300.aspx

http://www.globalindustrial.com/p/t...mpaignId=T9F&gclid=CL3al-3ZqNECFVU6gQodqAQF-g(ABOUT $250 a set)

http://www.mscdirect.com/product/details/06400865

(ABOUT $415 a set)

https://www.greatgages.com/products...MIyYigxdnA1QIVU2p-Ch1Z7wX8EAQYASABEgLrvvD_BwE

we found several non-repairable cracks in the main saddle bearing areas, making the block effectively trash....

and of course the guy selling the block was no where to be found.

now obviously if your buying a used block at a swap meet or out of some guys pick-up truck bed at a yard sale .

you'll want too either, very carefully inspect the block before hand over cash... or

ideally you will take it to a local machine shop for a good cleaning and careful inspection,

and you'll also generally be far less likely to get financially screwed,

if you purchase a block from a trusted local machine shop or major national vendor,

like DART, or JEGS, or SUMMIT

now luckily he had not spent a great deal of cash

($100) but yes he was effectively scammed and cheated

http://www.lowes.com/pd_600025-24212-65 ... Heavy-duty

that was hardly the first time nor is it likely to be the last time,

that guys that don,t really know how to look over a block for defects

(or even some of us that do, that might over look a flaw)

find we bought used blocks that are effectively trash,

so yes there are bargains in used parts too be found on occasion,

but on the whole, paying a bit more up front,

and buying from a trusted machine shop or national vendor limits,

your chances of getting screwed on an expensive block ,

or other major component purchase.

be sure to disassemble, carefully clean degrease and inspect any used components very carrefully

cleaning valves and steel OEM rockers is best done in my opinion,

with a good over night soak in carb cleaner and a rotary wire brush on a drill/drill press

brass being softer is a marginal improvement over steel wire rotary brushes

For bare heads and blocks a good spray with a quality de-greasing agent and a pressure cleaning would be my first step.

long ago I purchased a decent pressure cleaner as it makes getting the crud and grease off a block or transmission much less difficult

http://www.lowes.com/pd_600025-24212-65 ... Heavy-duty

a high pressure air nozzle ,with a extended tip,

that allows you to get into and remove solvent and dry the surfaces in the the small recessed areas is a great idea

its a darn good idea to use a heat gun

https://www.harborfreight.com/1500-watt-dual-temperature-heat-gun-56434.html?_br_psugg_q=heat+gun

to dry parts and immediately coat with WD40 to prevent flash rusting

its a very good idea to buy and use disposable plastic gloves when working with solvents

https://www.magidglove.com/Magid-Co...itrile-Disposable-Gloves-by-Magid-T9339L.aspx

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/

http://garage.grumpysperformance.com/index.php?threads/carb-cleaning.12303/#post-60502

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-68861

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://garage.grumpysperformance.co...-up-those-common-oil-spills.12350/#post-61082

after using a pressure cleaner and solvent to remove the grease and loose paint ,

(the block was covered in grease and dirt, and I think it was partly done by the seller to cover the flaws)

..... looking over the block and taking several measurements

,after cleaning it with a pressure leaner, solvent and a stiff brush,

engine building is about 75% technology and science and 10% art, and 15% skill gained through experience,over time.

doing it successfully mandates the person involved, in the process, can accurately observe, think, and recognize problems,

and if required, stop and think up solutions.

yes it involves knowing how components are intended to function and accurate precision measurement and access to some specific tools and a skilled well equiped machine shop you can trust, is a mandatory factor and skill set.

so many guys seem to be under the absurd impression that any and all solutions,

to any and all problems,

invariably involve, throwing away some component,

and installing some new out of the box part,

instead of acting logically and actually measuring,

thinking and potentially custom clearancing or at least reading the instructions,

and as most experienced engine builders will tell you ,

almost nothing you can buy fits and functions correctly in out-of-the-box, condition

,too near its true potential.after its ,

carefully, inspected, and correctly clearanced, and fitted.

clean any block you buy and look for obvious cracks and if you have doubts get the machine shop to mag or dye test the block or heads

lifter bores

and lifter gallery

,piston bore walls,

block main cap web support areas

heads between the valves in valve seat area

look for stripped head and manifold and oil pan mounting bolt threads,

in threaded holes and cracks in block radiating from the holes

http://www.tooltopia.com/fowler-72-646-300.aspx

http://www.globalindustrial.com/p/t...mpaignId=T9F&gclid=CL3al-3ZqNECFVU6gQodqAQF-g(ABOUT $250 a set)

http://www.mscdirect.com/product/details/06400865

(ABOUT $415 a set)

https://www.greatgages.com/products...MIyYigxdnA1QIVU2p-Ch1Z7wX8EAQYASABEgLrvvD_BwE

we found several non-repairable cracks in the main saddle bearing areas, making the block effectively trash....

and of course the guy selling the block was no where to be found.

now obviously if your buying a used block at a swap meet or out of some guys pick-up truck bed at a yard sale .

you'll want too either, very carefully inspect the block before hand over cash... or

ideally you will take it to a local machine shop for a good cleaning and careful inspection,

and you'll also generally be far less likely to get financially screwed,

if you purchase a block from a trusted local machine shop or major national vendor,

like DART, or JEGS, or SUMMIT

now luckily he had not spent a great deal of cash

($100) but yes he was effectively scammed and cheated

http://www.lowes.com/pd_600025-24212-65 ... Heavy-duty

that was hardly the first time nor is it likely to be the last time,

that guys that don,t really know how to look over a block for defects

(or even some of us that do, that might over look a flaw)

find we bought used blocks that are effectively trash,

so yes there are bargains in used parts too be found on occasion,

but on the whole, paying a bit more up front,

and buying from a trusted machine shop or national vendor limits,

your chances of getting screwed on an expensive block ,

or other major component purchase.

be sure to disassemble, carefully clean degrease and inspect any used components very carrefully

cleaning valves and steel OEM rockers is best done in my opinion,

with a good over night soak in carb cleaner and a rotary wire brush on a drill/drill press

brass being softer is a marginal improvement over steel wire rotary brushes

For bare heads and blocks a good spray with a quality de-greasing agent and a pressure cleaning would be my first step.

long ago I purchased a decent pressure cleaner as it makes getting the crud and grease off a block or transmission much less difficult

http://www.lowes.com/pd_600025-24212-65 ... Heavy-duty

a high pressure air nozzle ,with a extended tip,

that allows you to get into and remove solvent and dry the surfaces in the the small recessed areas is a great idea

its a darn good idea to use a heat gun

https://www.harborfreight.com/1500-watt-dual-temperature-heat-gun-56434.html?_br_psugg_q=heat+gun

to dry parts and immediately coat with WD40 to prevent flash rusting

its a very good idea to buy and use disposable plastic gloves when working with solvents

https://www.magidglove.com/Magid-Co...itrile-Disposable-Gloves-by-Magid-T9339L.aspx

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/

http://garage.grumpysperformance.com/index.php?threads/carb-cleaning.12303/#post-60502

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-68861

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://garage.grumpysperformance.co...-up-those-common-oil-spills.12350/#post-61082

Last edited: