Grumpy,

Please point me to which I need. I have poured over post after post and I'm probably over thinking it. I have a 69 camaro. 3500lb car or so. 3.42 gear, 4-speed tranny with a higher 2.20:1 1st gear tranny. I have a dart shp block. Balanced scat rotating assembly. Flat top 5cc relief piston. I want to use a profiler head. I actually have the 210cc runner, 72cc chamber. I calculated around 10.5:1 compression. I'm torn on which head (I can send the 210 back and get 195cc, and I'm torn on the cam. I want useable street manners. Good useable power. Good torque. I want to go with a hydraulic roller. Unsure about intake. I have either a Holley single plane or an air gap. Can you help me with some sound advice for this 400? I can argue either head, I can talk myself into several different cams.... I'm looking for some advice from someone who has built tons of these. I trust yourinput. I just don't want to piece together the wrong components and it be a slug on the bottom end. I have followed and read a ton of threads and links you provided and it's a wealth of knowledge. I'm truly appreciative of all the info. Please help my confused mind

sounds like a good combo, yes Id go with the 210 cc heads,

Air Flow Detail #176 SBC All American Head - 210cc Runner

Pro Filer Small Block Chevy All American Heads with 210cc Intake Runner, 2.08" Intake Valve and 1.60" exhaust valve. Flow data based on Cylinder #1 intake and exhaust port. Flow measured at 28" of depression.

Air Flow Detail #176 - 210cc Runner

Lift Intake CFM Exh CFM % Exh/Int

0.200 145 110 76%

0.300 207 145 70%

0.400 258 180 70%

0.500 283 206 73%

0.600 285 213 75%

0.700 291 216 74%

0.800 297 218 73%

Air Flow Chart #176 - 210cc Runner

https://www.profilerperformance.com/176-sbc-23-degree-heads.html

you might be worried the larger ports potentially kill lower rpm torque..DON'T BE!

the rear gear and manual trans, and the high static compression will more than off set that,you will be fine!

I would specify the 72 cc combustion chambers on the 210cc heads

your potentially dealing with detonation issues more than a loss of off idle torque,

youll want a cam with a bit of duration to bleed down the lower rpm effective cylinder compression,

and because of the manual transmission and rear gear ratio,

and displacement, you can get away with more cam duration, than most people

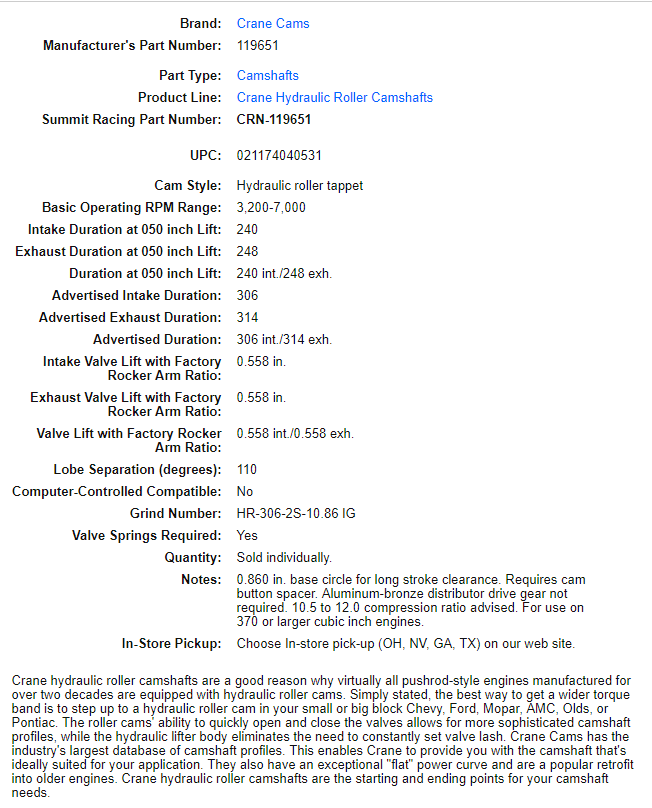

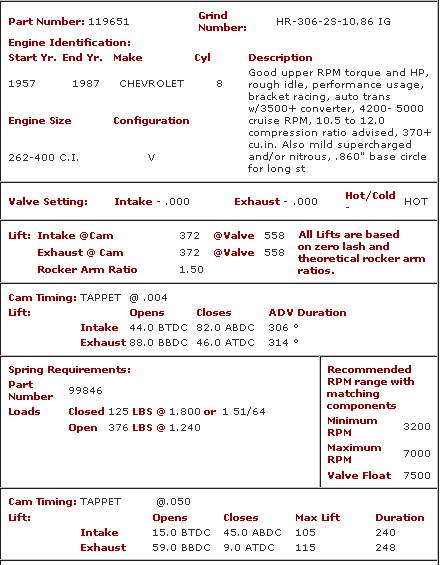

Id select the air gap dual plane intake and most likely a crane 119651 hydraulic roller cam

(personally ID install it split overlap or strait up)

and roller rockers, don,t forget youll want a 7-8 quart baffled oil pan

rock solid durability and a wide torque curve in the useful rpm range, is more important that peak power

, 1 3/4 full length headers

verify all clearances and yes youll need premium octane fuel.

MAYBE RICK CAN POST A SOFTWARE DYNO??

keep in mind this is a small base circle cam with asymmetrical cam lobes you must use the .050 lift and duration numbers in calcs

https://www.summitracing.com/parts/...MIisTdgsuL3QIVlrjACh0EnAAjEAAYASAAEgKCTvD_BwE

Last edited: