Maniacmechanic1

solid fixture here in the forum

The Isky will have best torque curve for Accelerating on the Street.

Not that I am aware of. I haven't seen much in the way of added grinds lately. I guess lunati has added a few, and comp has those 4 pattern grinds.Looked at comp lobe catalog all are similar .050 and advertised gotta say Isky here. Pretty close all specs reality comes to who you want cam from I like the Isky but that's me Brian loves Isky also what we have ran and used in past. Just as grumpy Rick used crower and crane. Has Crane added any grinds lately I have not been on there site in long time.

Isky Cammed Engines Sounds like all Holy Hell Unleashed.So, what explains the dip in the torque curves in all the graphs? Just curious. Impressive graphs btw. And what will that isky of Brian's sound like?

What about at idle?Isky Cammed Engines Sounds like all Holy Hell Unleashed.

It will be good or very good.What about at idle?

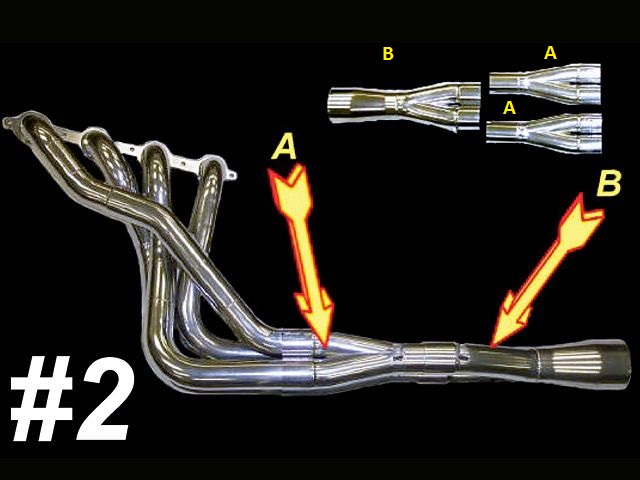

Quench will be .039". I'm gasket matching everything. The Doug's headers I have are pretty decent. 3" exhaust with an x-pipe is the plan. Id do larger, but no one bends larger close to me. Grumpy, how do you feel about that strange dip that's there in all the runs? What's your thoughts about what's mis-matched. Thanks for all you guy's input. And clearances will be carefully performed and springs will be placed at cam manufacturer recommendationno mater what roller cam you select, youll need to get ,

the valve train geometry, clearances and spring load rates correct,

youll ideally want to get the quench distance in the .040-.042 range ,

port match the intake selected to the heads, and do all the other related checks and clearancing.

keep in mind scavenging the cylinders correctly requires a properly designed set of headers,

and open or at least very low flow restriction exhaust

I didn't either, although the software is pretty foreign to me.Im looking over the parts list and software to try to locate the probable cause, currently I don,t see anything obvious,

it will be rather interesting to see if you build the engine similar to the listed info, if the predicted software dyno result and reality are close to similar!

Port Velocity Air Speed Dip I believe Grumpy.Im looking over the parts list and software to try to locate the probable cause, currently I don,t see anything obvious,

it will be rather interesting to see if you build the engine similar to the listed info, if the predicted software dyno result and reality are close to similar!

Not a single person here in my memory has ever built custom 1 off headers Grumpy.if thats the case its something that can be tuned out through indexing the cam timing ,

header design changes, like a different collector diam and length,

or intake manifold design changes,( theres dozens of different options)

like adding a open spacer (changing the plenum volume)

or swapping to a different intake, or if you went to stack injection,

its simply swapping to different stack lengths.

one of many reasons software dyno results are best at predicting trends,

but not always accurate representations of a well tuned combo,

Ive seem many engines where a bit of advance or retarding cam timing,

ignition advance curve, and changes in header collector length,

made a very noticeable change in the power curve.