- Home

- Forums

- Technical Articles/muscle cars

- C1-C6 Corvettes

- Engine: Repairs and Modifications & generally corv

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

K&N oem air filter repacements

- Thread starter toolhawg

- Start date

Ive used them in the past with good results, and will continue to do so in most cases, while they are a bit more expensive than the throw away oem paper filters they work as designed, and should save you money in the long run if you keep your car for years but the applications differ a good deal and in a few cases Ive seen no advantage to using them, (other than they are reusable, after cleaning,) over the oem filters if your looking for a power gains,as many guys seem to think they, will get if they reduce the air restriction into the engine, that any filter that actually filters the air is bound to do to some extent but over all, I think most are a good deal in that they seem to be a decent product, thats been reasonably well designed. (which is more than I can say of some products)

http://store.knfilters.com/filtercharger.htm

http://www.knfilters.com/facts.htm

http://store.knfilters.com/kits.htm

http://www.knfilters.com/testmethod.htm

K&N posted this info

http://store.knfilters.com/search/produ ... od=33-2014

http://www.knfilters.com/search/product ... od=33-2035

How Your Engine Works, Air Flow and Horsepower

If you are curious about how to go about getting more performance out of your car, or just have been taking your first steps in modifying your car for more power, then this section is for you. In it, I will present a primer for safely and effectively increasing both the performance and efficiency of your car’s engine. If you are a more advanced enthusiast with a firm understanding of the fundamentals of car modifications and tuning, you’ll find the K&N White Papers at (KNFilters.com) to be a more technical look at the how’s and why’s behind the performance basics covered here.

While automotive enthusiasts often have visions of some day becoming a mad scientist in the garage, or perhaps part of a finely honed pit crew in an F1 race, the better analogy to start with is a chef baking a cake. So don your imaginary chef’s hat for a moment, and I’ll explain how working with the internal combustion engine is a lot like baking a cake.

Baking a cake requires four basic ingredients -- sugar, flour, eggs and butter – mixed in the proper amounts relative to how big a cake you will be making. So, too, the engine in your car relies on four basic ingredients -- air, fuel, spark and timing – mixed in the proper amounts relative to how much power you will be making.

Let’s say I was to begin baking a cake that serves two people. I would use a ratio of the four cake ingredients above as appropriate to the serving size. Now let’s say that as I’m in the process of baking my cake, I get a phone call and learn that two more friends will be stopping by, and I will need to double the amount of cake that I have. It is not enough for me to add twice as much flour, for example, without also doubling the amount of eggs, sugar and butter in equal proportions, or my cake will be ruined. It seems a simple point to make, but in reality, behind all the glitz and glamour of manufacturers selling expensive and shiny parts to bolt-on under your hood, this point is almost universally the first one that is overlooked. Note that adding power under the hood is never a matter of simple math (for example, that if advertising materials or magazine articles tell you that a certain exhaust adds “up to†10 horsepower, an intake 5 horsepower, and a chip tune another 15 horsepower). While it is true that each component will add performance and compliment the others, the net result wills rarely, if ever, total 30 hp as the numbers might otherwise lead you to believe.

So, if your goal is to have your cake, and eat it too, be mindful of how parts you add under the hood change the ratio of ingredients to each other. So what is the correct ratio? Well, this is going be different for each car, depending on whether your car is outfitted with forced induction (for example, a turbocharger or supercharger), the compression ratio of your motor, and the tolerances that vary between manufacturers and according to the mileage and condition of your motor. However, most every engine has room to safely and reliably make more power, whether it’s double or triple the amount that they came with from the factory, or just a mild improvement, before experiencing added strain and a considerable impact on reliability and longevity. As a rule of thumb, a 5-10% increase from the amount of power your car makes, as delivered to you, is within the realm of safety. Nearly all engine components, regardless of the manufacturer, are designed with tolerances sufficient to withstand, on average, at least a 5-10% improvement in peak power.

I’m Ready for More… Where to Begin?

The internal combustion engine, as the name implies, relies on an explosion, or more specifically, a series of carefully timed explosions, to generate the power that moves your car down the road. These explosions consist of a mixture of air and fuel, ignited by spark, at precisely the right time. By altering the amount of air, fuel, spark, or timing, you are in effect creating a bigger explosion, and that bigger explosion generates more power. A car with a mild to moderate increase in power doesn’t have to be any less fuel efficient or any less reliable than the one that makes less power – but it does take a careful chef, one that uses only the finest ingredients, and ensures that the car is well maintained and in sound mechanical condition. If your car is exhibiting any signs of fatigue, adding more power is going to make matters worse, not better. Make sure your car is in top condition before moving on to bake the bigger cake. After all, there is no point in pouring ingredients into a pan that has a hole in the bottom.

Assuming you are ready to begin adding power, the first ingredient to go into the mix is air. In essence, your engine is a giant air pump, and the quantity of air that your engine is able to take in from the intake, and expel out of the exhaust, is directly proportional to the amount of power you will be able to generate. One analogy that I have heard used in performance circles for some time now is a marathon runner. Imagine your car’s air intake is the marathon runner’s lungs. A restrictive intake is the equivalent of a marathon runner trying to breathe through a tiny straw. A less restrictive intake allows him to breathe freely, and run much faster.

Since most factory intakes are designed around cheap, disposable air filters that choke off the engine, a simple filter change to a high-flow air filter is often the very first modification involved in making more power. K&N offers two ways of allowing your engine to breathe more freely and efficiently. A K&N factory replacement drop-in filter allows you to simply exchange the disposable filter element inside your factory air box with a high-flow cotton gauze lifetime filter that provides excellent filtration, yet presents less of a restriction to incoming air than disposable paper filters. Although a K&N lifetime filter costs a little more initially, you’ll be saving money in the long run since you never have to change it.

Beyond a drop-in filter, K&N also offers a series of Intake Systems as a next step in performance. These replace not just the filter element, but the entire maze of restrictive factory intake piping, with an open element air filter connected to a short, straight section of piping designed to bring the maximum amount of air into your engine. Intake Kits are popular upgrades both because of the significant improvements these make to the amount of air available to the engine, as well as the fact that they free up space under the hood, allowing for a more aesthetically pleasing engine compartment, and easier access to other engine components during routine service and for other mechanical upgrades.

Good air in - bad air out

Because your car is breathing more efficiently with the K&N filter installed, it is also a good idea to remove the restriction in the exhaust path to allow the additional air to exit smoothly and efficiently after combustion. Since the exhaust system consists of several components, including the exhaust manifold, down pipe (on turbo cars), b-pipe (or intermediate pipe), and ultimately the portion behind the rear axle terminating with the muffler canister and exhaust tip (known as the axle back), these components can be upgraded either individually, or all at once. However, because catalytic converters are present in the exhaust path to help clean up hydrocarbons and reduce emissions, if the vehicle code in your jurisdiction requires the use of emissions control devices, there are likely regulations in place concerning the legality of exhaust modifications to the catalytic converters themselves as well as the exhaust system upstream from the catalytic converters (the exact location will vary from car to car). At K&N, we encourage respect for the environment, and strongly discourage tampering with emissions control devices. Further, emissions technology has advanced to the point where in most cases; only nominal gains can be achieved by removing or tampering with catalytic converters.

Adding fuel to the fire

With the first ingredient in our recipe for a bigger serving of power, the ratio of air to fuel has changed. Fortunately, most late model engines are run by a factory ECU (Engine Control Unit) capable of adjusting fuel delivery to maintain a consistent ratio of air and fuel, even with a more free-flowing intake and exhaust.

However, if you have added even more air than just the filter itself – for example, in the form or a turbocharger or supercharger, the additional air volume will be well outside of the factory ECU’s ability to compensate (known as its enrichment parameters). Depending on how much additional air is being brought into the engine, the necessary fuel upgrades may consist of higher capacity fuel injectors, a bigger fuel pump, and/or a rising rate fuel regulator. In addition, the ECU will need to be optimized for this hardware. I will discuss the ECU’s role later, but for the time being, it is sufficient to say that any time dramatic changes are made to the amount of available air or fuel, the ECU will need to recalibrate the air, fuel, timing (and where applicable, boost) maps accordingly. Failure to install the appropriate fuel support modifications and recalibrate the ECU will most likely result in an overly lean air fuel mixture (too much air, relative to fuel). A lean mixture will burn too hot and in turn, lead to detonation (a condition in which the air/fuel mixture is too easily lit off at the wrong time) and major engine damage will likely result.

We have ignition!

With the appropriate amount of air and fuel in the mix, the next step in our recipe for power involves controlling the spark that ignites the mixture. Earlier, I commented on the importance of ensuring that the car is in top shape before attempting to go for more power. Perhaps that best example of the importance of a properly maintained engine is the ignition system. If you have not changed your sparkplugs and plug wires recently, along with your ignition cap and rotor (for car’s with distributor equipped ignitions), chances are good that your air/fuel explosion is being compromised and that you are getting a less-than-optimal burn of your air/fuel mixture. Without making any other changes to your car, you should find a noticeable improvement in both power and mileage simply by switching worn ignition components to fresh ones. Of course, if you are adding significant go-fast hardware under the hood for dramatically increased air and fuel capacity, a simple set of factory specification components may not be enough to ensure a clean burn for the mixture. In this case, you will want a stronger spark, coupled with a cooler spark plug, to best avoid fouling your spark plugs with air and fuel that has not been burned, transferring too much heat into the cylinder head, and/or not getting a complete burn of the available air and fuel.

In most cases, this can be remedied by switching to a spark plug that it is one to two heat ranges colder than those that came with your car from the factory. The heat range of spark plugs denotes the thickness of the porcelain insulators, and thus, their ability to transfer heat away from the cylinder head. You will also want to consider running a larger plug gap to expose more of the air and fuel to spark during combustion. However, in order to do so without immediately fouling the plugs (drenching them in fuel and rendering the electrode ineffective) you’ll want to consider adding an after market ignition amplifier consisting of a control box that uses either the factory ignition coil (or coil packs), or upgraded coil packs, to provide more electrical capacity to your spark. Different systems operate on very different principles, including firing the spark in rapid succession bursts, or simply storing and sending more spark energy to the plug through the coil (or coil packs), or some combination of the two, but the general idea is the same – more spark, for a bigger and more carefully controlled explosion.

Not every car will need extensive ignition upgrades. Many cars have very robust factory ignition components capable of sustaining horsepower levels that are often as much as double or triple the factory power figures. However, for other cars, this area is very much an Achilles heel. When in doubt about whether your car will benefit from expensive ignition upgrades, consult with a qualified tuning professional (local shops that offer “dyno†tuning services should be able to point you in the right direction and there are some terrific resources online in the form of car message boards for nearly any make and model of car).

Timing…. Is Everything

Your car’s ECU (Engine Control Unit), is the central command post that dictates when, how and for how long these other ingredients (fuel, air and spark) are combined in the recipe for more power. Again, like baking a cake, it is not enough to say mix the batter and bake it, the recipe itself should tell you in what order the ingredients are added, and for how long to bake it at what temperature. Of course, this is a gross oversimplification of what the ECU is actually doing. The ECU is continually making calculations and adjustments within fractions of a second based on feedback it receives from the car’s sensors, including the oxygen sensor, airflow meter or mass air pressure sensor, knock sensor, coolant and air temperature sensors, and a host of other input variables. Imagine if baking the cake involved measuring the temperature in the room, altitude at which you will be baking, relative humidity that day, whether there is any background noise while you will be cooking and the relative quality of the butter and flour that you intend to use, and performing a series of algorithms before telling you what temperature to bake your cake and how long to keep it in the oven.

So how does the ECU make these determinations? Quite simply, it continually refers to a fixed set of base tables to which it references back in establishing the burn characteristics for the air/fuel/spark mix. These base tables need to be modified as the under hood components themselves are changed, and a qualified tuning professional can help advise you on the best method for making these changes, as well as point you to a dynometer (or rolling road) to simulate the variables your car will encounter under load as you drive. Depending on a number of factors, including your budget, expectations, and the extent of your modifications, your preferred method of ECU control may be a piggyback controller that intercepts the 0-5 volt signal from your factory sensors and tweaks them before sending them on, a chip replacement or reflash that permanently installs a new set of maps in your ECU, or a standalone ECU that replaces your factory ECU entirely and allows the end user (or your tuner) to continually retune the car by laptop or hand-held controller.

Power is Served!

And there you have it… the fundamentals to making more power – a tasty treat if there ever was one. Of course, just as the bigger cake isn’t always the healthiest meal if you overindulge and don’t exercise, more power for your car is not always the healthiest thing for it if you aren’t prepared to make some additional adjustments. At the top of your list, any time you add power, consider upgrading the brakes, at a minimum with quality pads, lines and fluid. After all, the faster you go, the more stopping power you’ll need. Next, if you drive a manual transmission car, consider a clutch upgrade (or a beefier torque converter if you have an automatic) to cope with the extra strain that the motor is exerting, along with some high performance engine mounts and suspension bushings to help keep unwanted gyrations at a minimum. Of course, for maximum enjoyment, you’ll definitely want to invest in a nice suspension to help your car tackle any curves that the road throws at you, and maybe even a nice set of wheels with sticky tires to help get the added power to the ground.

As you can see, the sky is the limit when it comes to performance modifications, but rather than feel pressured to do everything at once, if you opt instead to tackle these upgrades in manageable and workable chunks, you’ll find that you appreciate the merits of each set of upgrades more, and can satisfy your performance cravings for a lifetime.

K&N Filters, performance that sells itself.

http://store.knfilters.com/filtercharger.htm

http://www.knfilters.com/facts.htm

http://store.knfilters.com/kits.htm

http://www.knfilters.com/testmethod.htm

K&N posted this info

http://store.knfilters.com/search/produ ... od=33-2014

http://www.knfilters.com/search/product ... od=33-2035

How Your Engine Works, Air Flow and Horsepower

If you are curious about how to go about getting more performance out of your car, or just have been taking your first steps in modifying your car for more power, then this section is for you. In it, I will present a primer for safely and effectively increasing both the performance and efficiency of your car’s engine. If you are a more advanced enthusiast with a firm understanding of the fundamentals of car modifications and tuning, you’ll find the K&N White Papers at (KNFilters.com) to be a more technical look at the how’s and why’s behind the performance basics covered here.

While automotive enthusiasts often have visions of some day becoming a mad scientist in the garage, or perhaps part of a finely honed pit crew in an F1 race, the better analogy to start with is a chef baking a cake. So don your imaginary chef’s hat for a moment, and I’ll explain how working with the internal combustion engine is a lot like baking a cake.

Baking a cake requires four basic ingredients -- sugar, flour, eggs and butter – mixed in the proper amounts relative to how big a cake you will be making. So, too, the engine in your car relies on four basic ingredients -- air, fuel, spark and timing – mixed in the proper amounts relative to how much power you will be making.

Let’s say I was to begin baking a cake that serves two people. I would use a ratio of the four cake ingredients above as appropriate to the serving size. Now let’s say that as I’m in the process of baking my cake, I get a phone call and learn that two more friends will be stopping by, and I will need to double the amount of cake that I have. It is not enough for me to add twice as much flour, for example, without also doubling the amount of eggs, sugar and butter in equal proportions, or my cake will be ruined. It seems a simple point to make, but in reality, behind all the glitz and glamour of manufacturers selling expensive and shiny parts to bolt-on under your hood, this point is almost universally the first one that is overlooked. Note that adding power under the hood is never a matter of simple math (for example, that if advertising materials or magazine articles tell you that a certain exhaust adds “up to†10 horsepower, an intake 5 horsepower, and a chip tune another 15 horsepower). While it is true that each component will add performance and compliment the others, the net result wills rarely, if ever, total 30 hp as the numbers might otherwise lead you to believe.

So, if your goal is to have your cake, and eat it too, be mindful of how parts you add under the hood change the ratio of ingredients to each other. So what is the correct ratio? Well, this is going be different for each car, depending on whether your car is outfitted with forced induction (for example, a turbocharger or supercharger), the compression ratio of your motor, and the tolerances that vary between manufacturers and according to the mileage and condition of your motor. However, most every engine has room to safely and reliably make more power, whether it’s double or triple the amount that they came with from the factory, or just a mild improvement, before experiencing added strain and a considerable impact on reliability and longevity. As a rule of thumb, a 5-10% increase from the amount of power your car makes, as delivered to you, is within the realm of safety. Nearly all engine components, regardless of the manufacturer, are designed with tolerances sufficient to withstand, on average, at least a 5-10% improvement in peak power.

I’m Ready for More… Where to Begin?

The internal combustion engine, as the name implies, relies on an explosion, or more specifically, a series of carefully timed explosions, to generate the power that moves your car down the road. These explosions consist of a mixture of air and fuel, ignited by spark, at precisely the right time. By altering the amount of air, fuel, spark, or timing, you are in effect creating a bigger explosion, and that bigger explosion generates more power. A car with a mild to moderate increase in power doesn’t have to be any less fuel efficient or any less reliable than the one that makes less power – but it does take a careful chef, one that uses only the finest ingredients, and ensures that the car is well maintained and in sound mechanical condition. If your car is exhibiting any signs of fatigue, adding more power is going to make matters worse, not better. Make sure your car is in top condition before moving on to bake the bigger cake. After all, there is no point in pouring ingredients into a pan that has a hole in the bottom.

Assuming you are ready to begin adding power, the first ingredient to go into the mix is air. In essence, your engine is a giant air pump, and the quantity of air that your engine is able to take in from the intake, and expel out of the exhaust, is directly proportional to the amount of power you will be able to generate. One analogy that I have heard used in performance circles for some time now is a marathon runner. Imagine your car’s air intake is the marathon runner’s lungs. A restrictive intake is the equivalent of a marathon runner trying to breathe through a tiny straw. A less restrictive intake allows him to breathe freely, and run much faster.

Since most factory intakes are designed around cheap, disposable air filters that choke off the engine, a simple filter change to a high-flow air filter is often the very first modification involved in making more power. K&N offers two ways of allowing your engine to breathe more freely and efficiently. A K&N factory replacement drop-in filter allows you to simply exchange the disposable filter element inside your factory air box with a high-flow cotton gauze lifetime filter that provides excellent filtration, yet presents less of a restriction to incoming air than disposable paper filters. Although a K&N lifetime filter costs a little more initially, you’ll be saving money in the long run since you never have to change it.

Beyond a drop-in filter, K&N also offers a series of Intake Systems as a next step in performance. These replace not just the filter element, but the entire maze of restrictive factory intake piping, with an open element air filter connected to a short, straight section of piping designed to bring the maximum amount of air into your engine. Intake Kits are popular upgrades both because of the significant improvements these make to the amount of air available to the engine, as well as the fact that they free up space under the hood, allowing for a more aesthetically pleasing engine compartment, and easier access to other engine components during routine service and for other mechanical upgrades.

Good air in - bad air out

Because your car is breathing more efficiently with the K&N filter installed, it is also a good idea to remove the restriction in the exhaust path to allow the additional air to exit smoothly and efficiently after combustion. Since the exhaust system consists of several components, including the exhaust manifold, down pipe (on turbo cars), b-pipe (or intermediate pipe), and ultimately the portion behind the rear axle terminating with the muffler canister and exhaust tip (known as the axle back), these components can be upgraded either individually, or all at once. However, because catalytic converters are present in the exhaust path to help clean up hydrocarbons and reduce emissions, if the vehicle code in your jurisdiction requires the use of emissions control devices, there are likely regulations in place concerning the legality of exhaust modifications to the catalytic converters themselves as well as the exhaust system upstream from the catalytic converters (the exact location will vary from car to car). At K&N, we encourage respect for the environment, and strongly discourage tampering with emissions control devices. Further, emissions technology has advanced to the point where in most cases; only nominal gains can be achieved by removing or tampering with catalytic converters.

Adding fuel to the fire

With the first ingredient in our recipe for a bigger serving of power, the ratio of air to fuel has changed. Fortunately, most late model engines are run by a factory ECU (Engine Control Unit) capable of adjusting fuel delivery to maintain a consistent ratio of air and fuel, even with a more free-flowing intake and exhaust.

However, if you have added even more air than just the filter itself – for example, in the form or a turbocharger or supercharger, the additional air volume will be well outside of the factory ECU’s ability to compensate (known as its enrichment parameters). Depending on how much additional air is being brought into the engine, the necessary fuel upgrades may consist of higher capacity fuel injectors, a bigger fuel pump, and/or a rising rate fuel regulator. In addition, the ECU will need to be optimized for this hardware. I will discuss the ECU’s role later, but for the time being, it is sufficient to say that any time dramatic changes are made to the amount of available air or fuel, the ECU will need to recalibrate the air, fuel, timing (and where applicable, boost) maps accordingly. Failure to install the appropriate fuel support modifications and recalibrate the ECU will most likely result in an overly lean air fuel mixture (too much air, relative to fuel). A lean mixture will burn too hot and in turn, lead to detonation (a condition in which the air/fuel mixture is too easily lit off at the wrong time) and major engine damage will likely result.

We have ignition!

With the appropriate amount of air and fuel in the mix, the next step in our recipe for power involves controlling the spark that ignites the mixture. Earlier, I commented on the importance of ensuring that the car is in top shape before attempting to go for more power. Perhaps that best example of the importance of a properly maintained engine is the ignition system. If you have not changed your sparkplugs and plug wires recently, along with your ignition cap and rotor (for car’s with distributor equipped ignitions), chances are good that your air/fuel explosion is being compromised and that you are getting a less-than-optimal burn of your air/fuel mixture. Without making any other changes to your car, you should find a noticeable improvement in both power and mileage simply by switching worn ignition components to fresh ones. Of course, if you are adding significant go-fast hardware under the hood for dramatically increased air and fuel capacity, a simple set of factory specification components may not be enough to ensure a clean burn for the mixture. In this case, you will want a stronger spark, coupled with a cooler spark plug, to best avoid fouling your spark plugs with air and fuel that has not been burned, transferring too much heat into the cylinder head, and/or not getting a complete burn of the available air and fuel.

In most cases, this can be remedied by switching to a spark plug that it is one to two heat ranges colder than those that came with your car from the factory. The heat range of spark plugs denotes the thickness of the porcelain insulators, and thus, their ability to transfer heat away from the cylinder head. You will also want to consider running a larger plug gap to expose more of the air and fuel to spark during combustion. However, in order to do so without immediately fouling the plugs (drenching them in fuel and rendering the electrode ineffective) you’ll want to consider adding an after market ignition amplifier consisting of a control box that uses either the factory ignition coil (or coil packs), or upgraded coil packs, to provide more electrical capacity to your spark. Different systems operate on very different principles, including firing the spark in rapid succession bursts, or simply storing and sending more spark energy to the plug through the coil (or coil packs), or some combination of the two, but the general idea is the same – more spark, for a bigger and more carefully controlled explosion.

Not every car will need extensive ignition upgrades. Many cars have very robust factory ignition components capable of sustaining horsepower levels that are often as much as double or triple the factory power figures. However, for other cars, this area is very much an Achilles heel. When in doubt about whether your car will benefit from expensive ignition upgrades, consult with a qualified tuning professional (local shops that offer “dyno†tuning services should be able to point you in the right direction and there are some terrific resources online in the form of car message boards for nearly any make and model of car).

Timing…. Is Everything

Your car’s ECU (Engine Control Unit), is the central command post that dictates when, how and for how long these other ingredients (fuel, air and spark) are combined in the recipe for more power. Again, like baking a cake, it is not enough to say mix the batter and bake it, the recipe itself should tell you in what order the ingredients are added, and for how long to bake it at what temperature. Of course, this is a gross oversimplification of what the ECU is actually doing. The ECU is continually making calculations and adjustments within fractions of a second based on feedback it receives from the car’s sensors, including the oxygen sensor, airflow meter or mass air pressure sensor, knock sensor, coolant and air temperature sensors, and a host of other input variables. Imagine if baking the cake involved measuring the temperature in the room, altitude at which you will be baking, relative humidity that day, whether there is any background noise while you will be cooking and the relative quality of the butter and flour that you intend to use, and performing a series of algorithms before telling you what temperature to bake your cake and how long to keep it in the oven.

So how does the ECU make these determinations? Quite simply, it continually refers to a fixed set of base tables to which it references back in establishing the burn characteristics for the air/fuel/spark mix. These base tables need to be modified as the under hood components themselves are changed, and a qualified tuning professional can help advise you on the best method for making these changes, as well as point you to a dynometer (or rolling road) to simulate the variables your car will encounter under load as you drive. Depending on a number of factors, including your budget, expectations, and the extent of your modifications, your preferred method of ECU control may be a piggyback controller that intercepts the 0-5 volt signal from your factory sensors and tweaks them before sending them on, a chip replacement or reflash that permanently installs a new set of maps in your ECU, or a standalone ECU that replaces your factory ECU entirely and allows the end user (or your tuner) to continually retune the car by laptop or hand-held controller.

Power is Served!

And there you have it… the fundamentals to making more power – a tasty treat if there ever was one. Of course, just as the bigger cake isn’t always the healthiest meal if you overindulge and don’t exercise, more power for your car is not always the healthiest thing for it if you aren’t prepared to make some additional adjustments. At the top of your list, any time you add power, consider upgrading the brakes, at a minimum with quality pads, lines and fluid. After all, the faster you go, the more stopping power you’ll need. Next, if you drive a manual transmission car, consider a clutch upgrade (or a beefier torque converter if you have an automatic) to cope with the extra strain that the motor is exerting, along with some high performance engine mounts and suspension bushings to help keep unwanted gyrations at a minimum. Of course, for maximum enjoyment, you’ll definitely want to invest in a nice suspension to help your car tackle any curves that the road throws at you, and maybe even a nice set of wheels with sticky tires to help get the added power to the ground.

As you can see, the sky is the limit when it comes to performance modifications, but rather than feel pressured to do everything at once, if you opt instead to tackle these upgrades in manageable and workable chunks, you’ll find that you appreciate the merits of each set of upgrades more, and can satisfy your performance cravings for a lifetime.

K&N Filters, performance that sells itself.

I,m not 100% sure but they can "cheat" by increasing the surface area , read carefully they have several layers of oiled cotton cloth, vs one layer of paper, each layer of cloth can be more porous yet flow more air with the same or less restriction and the total filter area being multi layered filter better.

you might want to think of it like this, lets represent air borne dirt as a hand full of pennies, that your going to throw thru a chain link fence, and the dirt(pennies that strike any wire get trapped on that wire), now if paper was represented by a single chain link fence with 1.5" holes in the network of stranded wire and clothe was represented by 4 layers of chain link fence , spaced randomly behind each proceeding fence but only inches apart,with 2" holes in the network of stranded wire in each individual fence, clothe would pass more air flow thru any given layer,or all layers, combined but the chances of a penny striking a wire in the multi layered clothe is greater

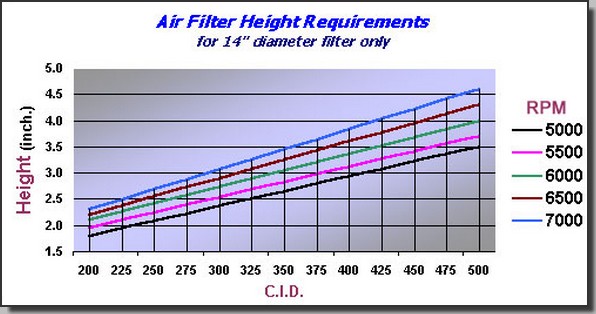

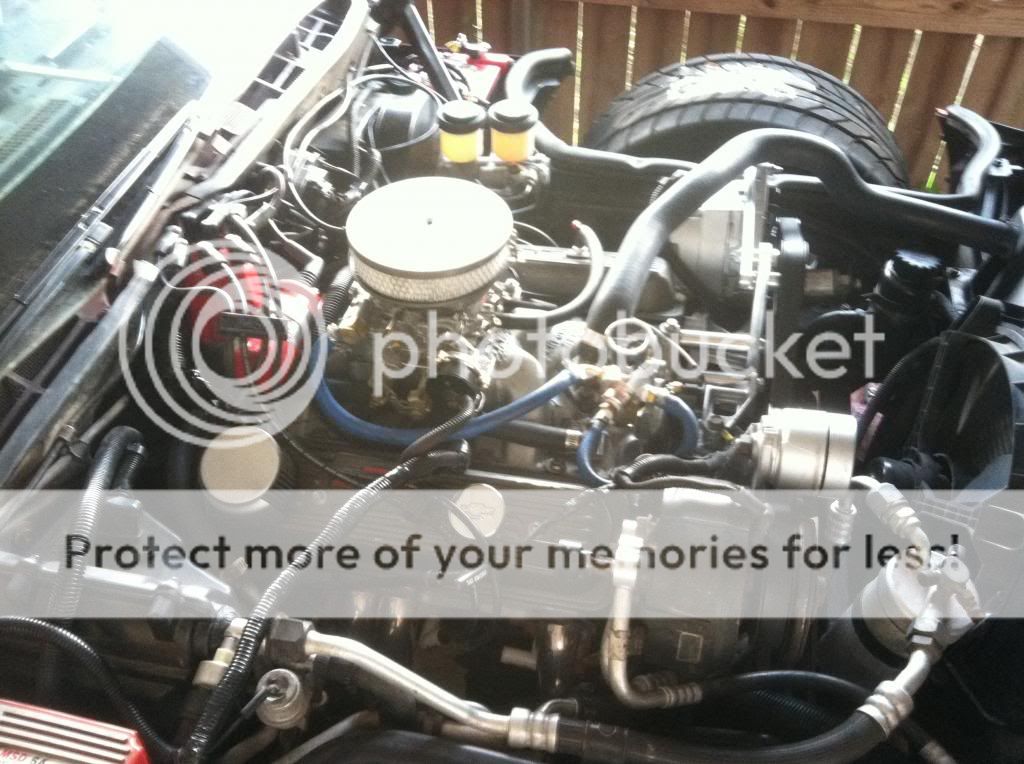

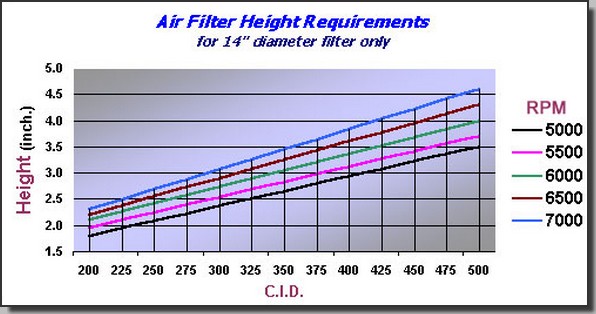

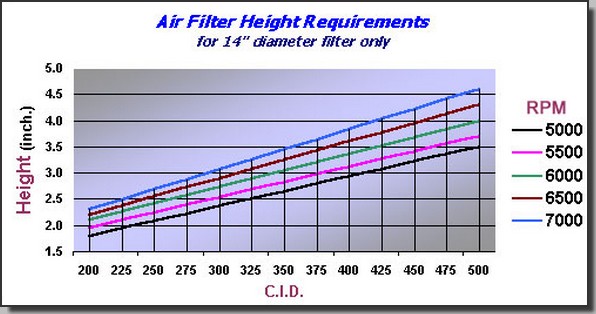

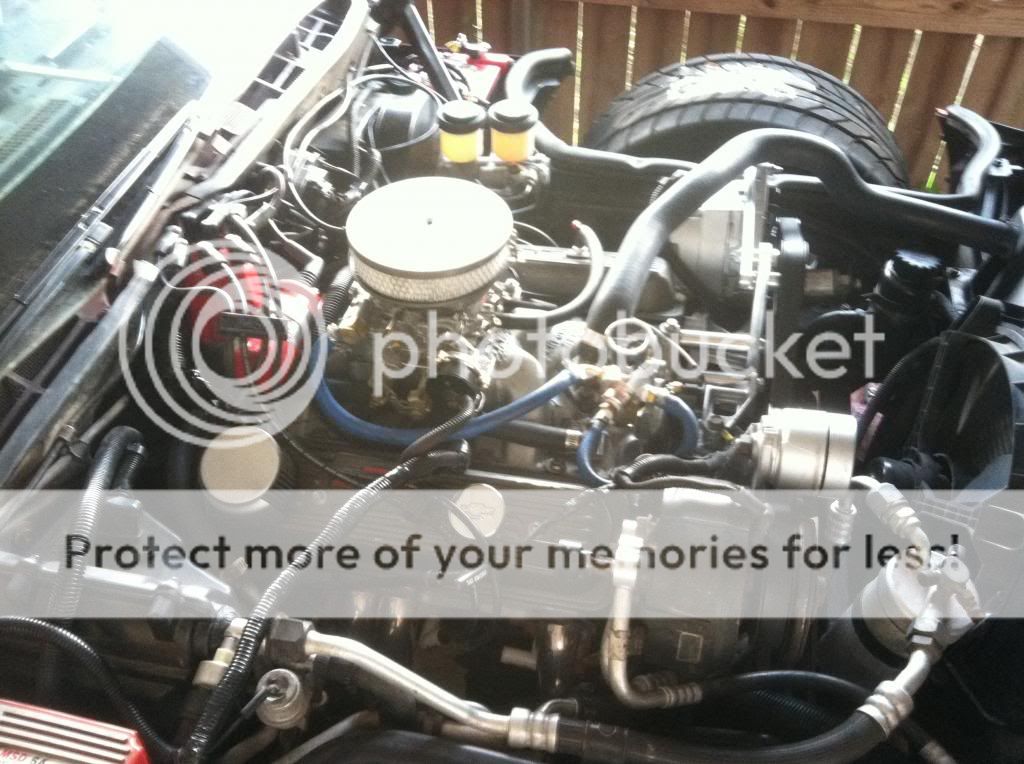

guys often resort to small in effective air filter designs when hood clearance becomes an issue,like on this C3 corvette,

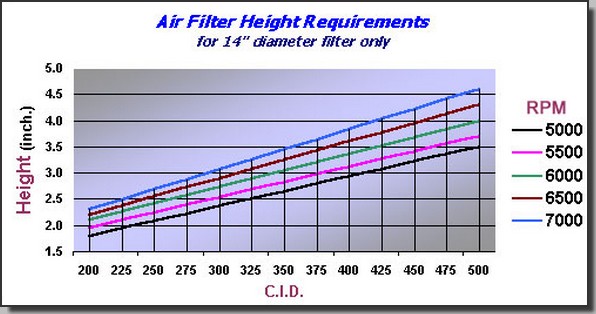

btw Ive done a few tests over the years and if your car currently has a smaller surface area air filter like the two pictured above, you might want to consider swapping to a larger drop base air cleaner ,something in the 14" diameter and 2"-3" tall range as I think youll find the reduced air flow restriction helps upper rpm power, I found that most of the smaller air cleaner elements became rather restrictive after about 4500rpm(vacuum gauge testing inside the filter helps) or the filter medium is so course its basically not very effective are preventing wear from air born grit and its certainly not expensive to get those few extra hp now that you did all the harder work

the car looks nice but Id point out that your restricting the engine with that air cleaner design, in both the degree of filtration which will eventually promote wear, and air flow rates which effects high rpm power,now Im fully aware hood clearance is a major issue with those year corvettes (having owned a 1968 and a 1976) but you can use a drop base air cleaner if you shop carefully of fabricate a custom air cleaner

[/url]

[/url]

http://www.ramairbox.com

these guys MIGHT help

http://www.ramairbox.com/product.html

http://www.ramairbox.com/bases.html

http://www.ramairbox.com/price_list.html

IF youve got the hood clearance a 3"-4" tall filter height helps reduce the restriction to air flow

you might want to think of it like this, lets represent air borne dirt as a hand full of pennies, that your going to throw thru a chain link fence, and the dirt(pennies that strike any wire get trapped on that wire), now if paper was represented by a single chain link fence with 1.5" holes in the network of stranded wire and clothe was represented by 4 layers of chain link fence , spaced randomly behind each proceeding fence but only inches apart,with 2" holes in the network of stranded wire in each individual fence, clothe would pass more air flow thru any given layer,or all layers, combined but the chances of a penny striking a wire in the multi layered clothe is greater

guys often resort to small in effective air filter designs when hood clearance becomes an issue,like on this C3 corvette,

btw Ive done a few tests over the years and if your car currently has a smaller surface area air filter like the two pictured above, you might want to consider swapping to a larger drop base air cleaner ,something in the 14" diameter and 2"-3" tall range as I think youll find the reduced air flow restriction helps upper rpm power, I found that most of the smaller air cleaner elements became rather restrictive after about 4500rpm(vacuum gauge testing inside the filter helps) or the filter medium is so course its basically not very effective are preventing wear from air born grit and its certainly not expensive to get those few extra hp now that you did all the harder work

the car looks nice but Id point out that your restricting the engine with that air cleaner design, in both the degree of filtration which will eventually promote wear, and air flow rates which effects high rpm power,now Im fully aware hood clearance is a major issue with those year corvettes (having owned a 1968 and a 1976) but you can use a drop base air cleaner if you shop carefully of fabricate a custom air cleaner

http://www.ramairbox.com

these guys MIGHT help

http://www.ramairbox.com/product.html

http://www.ramairbox.com/bases.html

http://www.ramairbox.com/price_list.html

IF youve got the hood clearance a 3"-4" tall filter height helps reduce the restriction to air flow

mass air flow sensors and air filters

http://www.youtube.com/watch?v=CXuO5OmKPyY

http://www.youtube.com/watch?v=sSuL58YE ... ure=relmfu

http://www.knfilters.com/MAF/massair.htm

http://www.knfilters.com/MAF/2MAFSensorVideo.htm

http://www.knfilters.com/MAF/3MAFSensorVideo.htm

http://www.knfilters.com/MAF/4MAFSensorVideo.htm

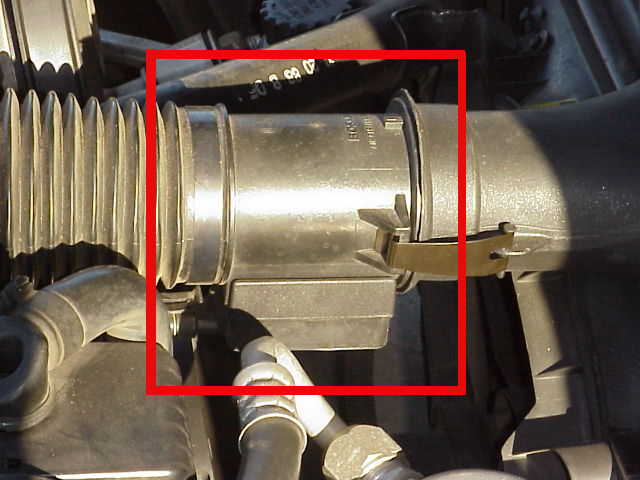

http://www.corvettephotographs.com/c4vettes/maf.htm

"Most of the C4 Corvettes used a MAF (Mass Air Flow) sensor to determine how much air is being pulled into the intake manifold. The exceptions are the 1984 Corvette that used a speed density system--a sort of predictive method of measurement---and the 1990 through 1993 C4 models which were also speed density based. In 1994, Corvette went back to the MAF based system but used the speed density approach as a back up. (1989 Bosch MAF installation shown at right).

A Mass Air Flow sensor has an extremely fine wire inside its bore. The 1985 through 1989 C4 engines used a Bosch MAF sensor that heated the wire to 100 C. The 1994 and later C4 models used a AC/Delco MAF that heated the wire to 200 C. The amount of current required to reach the temperature is measured in each case. (Note: the LT-5 engine used in the ZR-1 used a speed density system and continued to use that system in 1994 and 1995 since the engines had already been made prior to the last two years of production. The ZR-1 therefore has no MAF even after Corvette went back to the MAF based system).

Theory of Operation

As the air travels past the heated wire enroute to the intake manifold, it will cool the wire and additional current is added to again heat the wire to the design temperature. Since the amount of air moving past the sensor is directly related to the amount of cooling experienced by the heated wire, a feedback condition is established whereby the exact amount of moving air is directly related to the amount of current passing through the wire and the intake air is therefore precisely measured.

Once the amount of air is known, the computer controlling the engine can add or subtract fuel as required to maintain the magic 14.7:1 air-fuel mixture resulting in the cleanest burn possible from an emissions (pollution) standpoint.

It does this by varying the "on time" of the fuel injectors. The injectors are pulsed on and off and the width of the pulse is lengthened or shortened as required. When you first start a typical engine, the pulse width is around 4 milliseconds but as soon as the engine "catches" the pulse width is shortened to about 2.2 milliseconds for idle. During operation, the measured air flow through the MAF will cause the computer to increase or decrease the pulse width as explained above.

MAF Operating Conditions

The Bosch MAF is more complex than the AC/Delco version. Both measure the air flow but the Bosch MAF has a circuit called the 'burn-off circuit' that cycles on for about 2 seconds when you shut the engine down. This circuit heats the wire to a high enough temperature to burn off any residue that may have collected on the wire during operation. If you are in a quiet area, you can hear the relays click on and then off on a 1985-1989 C4 as the burn-off cycle occurs.

There are two relays involved with the Bosch MAF: A power relay that passes current to the MAF wire during normal operation and the burn-off relay that provides the current for the cleaning cycle. Both are located on the firewall in the engine compartment, just behind the battery on the drivers side. Bad MAF power and burn-off relays can cause hard starting problems and should be changed periodically as preventative measure and any time you experience hard starting conditions.

The AC/Delco MAF has a power relay but no burn-off relay. For this reason, you should pay even closer attention to the condition of your air filter on a later model C4 than normal since a contaminated wire in a AC/Delco MAF is going to stay contaminated for the most part and cause false signals to be passed to the computer.

Also, the Bosch MAF outputs its information as a analog signal to the computer but the AC/Delco sends its signal as a digital component of varying frequency. For this reason, you cannot measure it's operation directly.

A scan tool is generally the best way to troubleshoot engine problems and with the 1994 and later Corvette, it is virtually mandatory. (An oscilloscope will also work on the AC/Delco MAF but a regular test meter will not).

MAF Problems

Faulty MAF sensors will normally light the check engine light on the drivers information center if the problem is constant and store a trouble code. If intermittent, a trouble code will still be stored as long as the battery is not disconnected.

Normally, the problem is a poor connection at the sensor and wiggling the wires, unplugging and reinserting the connector will often cure the problem.

A faulty MAF will normally cause a no start or difficult start condition and although you can eventually get the car into the "limp-home" mode in most cases, you need to attend to the problem ASAP.

AC/Delco sensors can become intermittent or give false readings if the wires become contaminated as explained above.

The MAF is a critical part of the emission control system and as such will cause the computer to react to problems very quickly, setting trouble codes and reducing performance in ways that cannot be ignored for long.

MAF Mods

The Bosch MAF is often modified by removing the two screens that are present in the front and rear of the cylinder. Removing these screens significantly increases the air flow through them and this results in more horsepower. Removing the screens is an old trick from the Corvette Challenge days in 1988 and 1989. It does work but is illegal in many states so be advised not to do anything that will get you arrested for a pollution violation.

The AC/Delco MAF is not readily modified. It is what it is but since it is a larger diameter than the Bosch, it responds well to changing the air filter to a free flowing type such as the K&N filter."

http://www.mamotorworks.com/corvette-c4 ... 6-893.html

http://content.mamotorworks.com/pdf/601096.pdf

http://www.youtube.com/watch?v=CXuO5OmKPyY

http://www.youtube.com/watch?v=sSuL58YE ... ure=relmfu

http://www.knfilters.com/MAF/massair.htm

http://www.knfilters.com/MAF/2MAFSensorVideo.htm

http://www.knfilters.com/MAF/3MAFSensorVideo.htm

http://www.knfilters.com/MAF/4MAFSensorVideo.htm

http://www.corvettephotographs.com/c4vettes/maf.htm

"Most of the C4 Corvettes used a MAF (Mass Air Flow) sensor to determine how much air is being pulled into the intake manifold. The exceptions are the 1984 Corvette that used a speed density system--a sort of predictive method of measurement---and the 1990 through 1993 C4 models which were also speed density based. In 1994, Corvette went back to the MAF based system but used the speed density approach as a back up. (1989 Bosch MAF installation shown at right).

A Mass Air Flow sensor has an extremely fine wire inside its bore. The 1985 through 1989 C4 engines used a Bosch MAF sensor that heated the wire to 100 C. The 1994 and later C4 models used a AC/Delco MAF that heated the wire to 200 C. The amount of current required to reach the temperature is measured in each case. (Note: the LT-5 engine used in the ZR-1 used a speed density system and continued to use that system in 1994 and 1995 since the engines had already been made prior to the last two years of production. The ZR-1 therefore has no MAF even after Corvette went back to the MAF based system).

Theory of Operation

As the air travels past the heated wire enroute to the intake manifold, it will cool the wire and additional current is added to again heat the wire to the design temperature. Since the amount of air moving past the sensor is directly related to the amount of cooling experienced by the heated wire, a feedback condition is established whereby the exact amount of moving air is directly related to the amount of current passing through the wire and the intake air is therefore precisely measured.

Once the amount of air is known, the computer controlling the engine can add or subtract fuel as required to maintain the magic 14.7:1 air-fuel mixture resulting in the cleanest burn possible from an emissions (pollution) standpoint.

It does this by varying the "on time" of the fuel injectors. The injectors are pulsed on and off and the width of the pulse is lengthened or shortened as required. When you first start a typical engine, the pulse width is around 4 milliseconds but as soon as the engine "catches" the pulse width is shortened to about 2.2 milliseconds for idle. During operation, the measured air flow through the MAF will cause the computer to increase or decrease the pulse width as explained above.

MAF Operating Conditions

The Bosch MAF is more complex than the AC/Delco version. Both measure the air flow but the Bosch MAF has a circuit called the 'burn-off circuit' that cycles on for about 2 seconds when you shut the engine down. This circuit heats the wire to a high enough temperature to burn off any residue that may have collected on the wire during operation. If you are in a quiet area, you can hear the relays click on and then off on a 1985-1989 C4 as the burn-off cycle occurs.

There are two relays involved with the Bosch MAF: A power relay that passes current to the MAF wire during normal operation and the burn-off relay that provides the current for the cleaning cycle. Both are located on the firewall in the engine compartment, just behind the battery on the drivers side. Bad MAF power and burn-off relays can cause hard starting problems and should be changed periodically as preventative measure and any time you experience hard starting conditions.

The AC/Delco MAF has a power relay but no burn-off relay. For this reason, you should pay even closer attention to the condition of your air filter on a later model C4 than normal since a contaminated wire in a AC/Delco MAF is going to stay contaminated for the most part and cause false signals to be passed to the computer.

Also, the Bosch MAF outputs its information as a analog signal to the computer but the AC/Delco sends its signal as a digital component of varying frequency. For this reason, you cannot measure it's operation directly.

A scan tool is generally the best way to troubleshoot engine problems and with the 1994 and later Corvette, it is virtually mandatory. (An oscilloscope will also work on the AC/Delco MAF but a regular test meter will not).

MAF Problems

Faulty MAF sensors will normally light the check engine light on the drivers information center if the problem is constant and store a trouble code. If intermittent, a trouble code will still be stored as long as the battery is not disconnected.

Normally, the problem is a poor connection at the sensor and wiggling the wires, unplugging and reinserting the connector will often cure the problem.

A faulty MAF will normally cause a no start or difficult start condition and although you can eventually get the car into the "limp-home" mode in most cases, you need to attend to the problem ASAP.

AC/Delco sensors can become intermittent or give false readings if the wires become contaminated as explained above.

The MAF is a critical part of the emission control system and as such will cause the computer to react to problems very quickly, setting trouble codes and reducing performance in ways that cannot be ignored for long.

MAF Mods

The Bosch MAF is often modified by removing the two screens that are present in the front and rear of the cylinder. Removing these screens significantly increases the air flow through them and this results in more horsepower. Removing the screens is an old trick from the Corvette Challenge days in 1988 and 1989. It does work but is illegal in many states so be advised not to do anything that will get you arrested for a pollution violation.

The AC/Delco MAF is not readily modified. It is what it is but since it is a larger diameter than the Bosch, it responds well to changing the air filter to a free flowing type such as the K&N filter."

http://www.mamotorworks.com/corvette-c4 ... 6-893.html

http://content.mamotorworks.com/pdf/601096.pdf

obviously you can get creative and develop a better custom air filter design in some applications

http://garage.grumpysperformance.co...otal-panic-over-an-easy-fix.12177/#post-58940

but taking the fast and easy route(like the small restrictive dual air filters on this AC COBRA BELOW) is bound to cost, or restrict you from reaching some horse power that the correct air filter would allow you to use

Last edited by a moderator:

Randy_W

reliable source of info

My experience with K&N has been good for the most part. I also never saw any real power gains from the filter it's self but the fact that I don't have to go to the parts store for a new one, just clean, oil, reinstall. Over oiling can foul a mass air flow sensor so be careful with that.

Where I did get big gains was on my boat, I ran twin 540's in my Donzi and going from Mercruiser flame arrestors to twin K&N 9" velocity stacks gained 4 mph! That's on a boat that was running mid 80's at the time, that equates to about 80 h.p. It leaned my mixture to where I had to go from .086 jets to .090's which gained another 2 mph. In total going from stock metal arrestors to K&N's was worth roughly 100 h.p.! (50 h.p. per engine)Not bad for a $150 investment.

It was a combination of the factory stuff being restrictive and the velocity stacks themselves being very effective.

Where I did get big gains was on my boat, I ran twin 540's in my Donzi and going from Mercruiser flame arrestors to twin K&N 9" velocity stacks gained 4 mph! That's on a boat that was running mid 80's at the time, that equates to about 80 h.p. It leaned my mixture to where I had to go from .086 jets to .090's which gained another 2 mph. In total going from stock metal arrestors to K&N's was worth roughly 100 h.p.! (50 h.p. per engine)Not bad for a $150 investment.

It was a combination of the factory stuff being restrictive and the velocity stacks themselves being very effective.