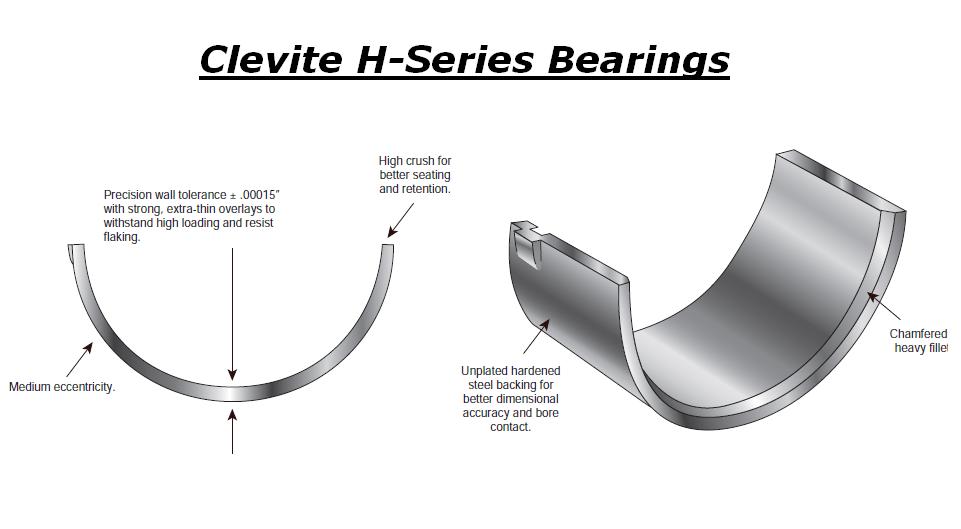

Ive almost exclusively used CLEVITE (H) series engine bearings for decades, and see no reason to change, most bearing failures can be traced to either improper installation, failure to carefully check clearances or lack of maintaining consistent and constant high oil flow rates over the bearing surfaces.

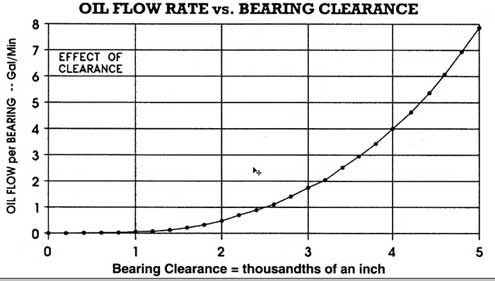

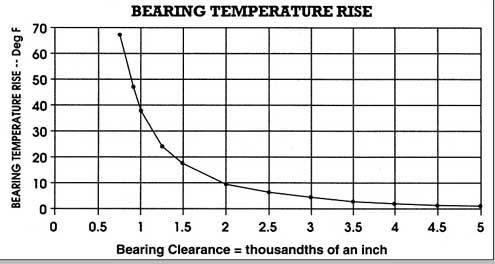

in a properly operating engine the crank journals are supported on a pressurized oil cushion between the bearings and rotating crank,

adding a 7-8 quart baffled oil pan with a windage tray and crank scraper is a good start, read these threads carefully.

obviously the quality of the oil used the temperature of the oil and the efficiency of the oil filter used has a huge effect on maintaining that oil flow protecting the bearing surface.

Ive built dozens of high performance big block engines over the years and have not had a single bearing failure ,of the guys I have seen have engine failures the most common sources of problems are related to guys using low octane fuel or over heating engines resulting in detonation, and no bearing or piston or rings can withstand frequent detonation or being abused with dirty oil being used, and guys who don,t have the valve train built to control the valves at high rpms. simple mods like use of a rocker stud girdle , the correct valve spring, bearing and piston clearances and spring load rates, correct rocker geometry, not exceeding about 4200fpm in piston speed, and use of a 7-8 quart oil pan, with a windage tray, can do wonders for durability

viewtopic.php?f=53&t=2726

viewtopic.php?f=53&t=852

viewtopic.php?f=53&t=9955

viewtopic.php?f=54&t=64

viewtopic.php?f=54&t=52

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=120

viewtopic.php?f=54&t=117

viewtopic.php?f=54&t=3536

http://www.jegs.com/p/Clevite/Clevite-7 ... PerPage=30

http://stealth316.com/misc/clevite-77-r ... arings.pdf

http://catalog.mahleclevite.com/bearing/

http://www.summitracing.com/search/Prod ... n-Bearings

http://underthehood.mahleclevite.com/?p=246

http://catalog.mahleclevite.com/bearing/

Bearing Markings

The backs of most bearings have numerous markings and there are a range of things that could be on the shell.

Below are just a few examples (See photos for a better understanding):

Production Date (Month/Year)- Example would be 8-10 or 8/10

Material Used – Example would be AS

Shift – Example would be B-11 or A-10

Part Number – Example would be CB663P

Position – Example would be Upper or Lower

Size – Example would be Std. or 0.25mm

Bearing Failures

Bearing failures do happen… and often, we look for someone or something to blame for the failure. MAHLE Clevite offers a web-based bearing failure guide with 22 different causes of bearing failures. The guide is complete with digital photos, causes, prevention, and remedial actions. I promise you won’t find anything like it, and the best part is there’s no charge to use it. Why, isn’t that nice of MAHLE Clevite?

To explain failures briefly – 40% of engine bearing failures are caused by dirt and the main sources of dirt are #1 – dirt left in during the overhaul #2 – airborne abrasives and #3 – contaminated lubricants. Myself and the engineers at Clevite can’t stress enough how important it is to clean your crank, rods and pistons before assembly. Scrub oil galleries with a bristle brush, wash parts with hot, soapy water and clean, clean, clean!

read thru these links

http://vandervell.co.uk/images/slidesho ... forman.pdf

http://www.stealth316.com/misc/clevite- ... ooving.pdf

TB 2051 2/10/2000

Influence of Grooving on Main Bearing Performance

Various forms of main bearing grooving have been used over the years. We are

frequently asked what difference grooving makes.

First, it’s essential to understand that bearings depend on a film of oil to keep them

separated from the shaft surface. This oil film is developed by shaft rotation. As the shaft

rotates it pulls oil into the loaded area of the bearing and rides up on this film much like a

tire hydroplaning on wet pavement. Grooving in a bearing acts like tread in a tire to break

up the oil film. While you want your tires to grip the road, you don’t want your bearings

to grip the shaft.

The primary reason for having any grooving in a main bearing is to provide oil to the

connecting rods. Without rod bearings to feed, a simple oil hole would be sufficient to

lubricate a main bearing. Many early engines used full grooved bearings and some even

used multiple grooves. As engine and bearing technology developed, bearing grooving

was removed from modern lower main bearings. The result is in a thicker film of oil for

the shaft to ride on. This provides a greater safety margin and improved bearing life.

Upper main shells, which see lower loads than the lowers, have retained a groove to

supply the connecting rods with oil.

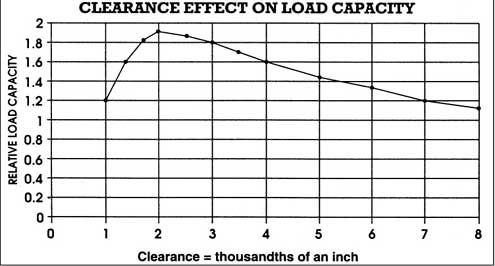

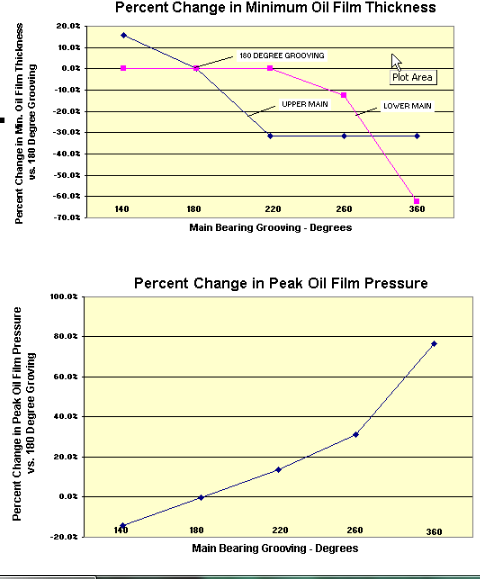

In an effort to develop the best possible main bearing designs for High Performance

engines, we’ve investigated the effects of main bearing grooving on bearing performance.

The graphs on the next page illustrate that a simple 180

°

groove in the upper main shell is

still the best overall design.

While a slightly shorter groove of 140

°

provides a marginal gain, most of the benefit is to

the upper shell, which doesn’t need improvement. On the other hand, extending the

groove into the lower half, even as little as 20

°

at each parting line (220

°

in total), takes

away from upper bearing performance without providing any benefit to the lower half.

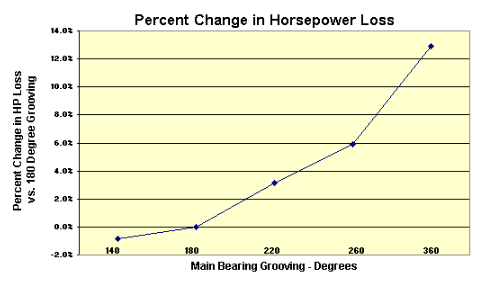

It’s also interesting to note that as groove length increases so do Horsepower Loss and

Peak Oil Film Pressure which is transmitted directly to the bearing