I recently needed to do some welding repairs on a rather large, but thin sheet steel box, I grabbed my TIG,welder, only to find the tank of shield gas empty,

and thats the same tank I use on the MIG, so rather than going to get the tank re-filled like I should have done,

I grabbed the ARC welder and some 1/8' sticks and did the repair, with the arc welder, which Ive used mostly for thicker welding on 1/4" and heavier welding, jobs like brackets on rear differentials or frame repairs,for about 12 years now, (which is mostly what I bought it for)

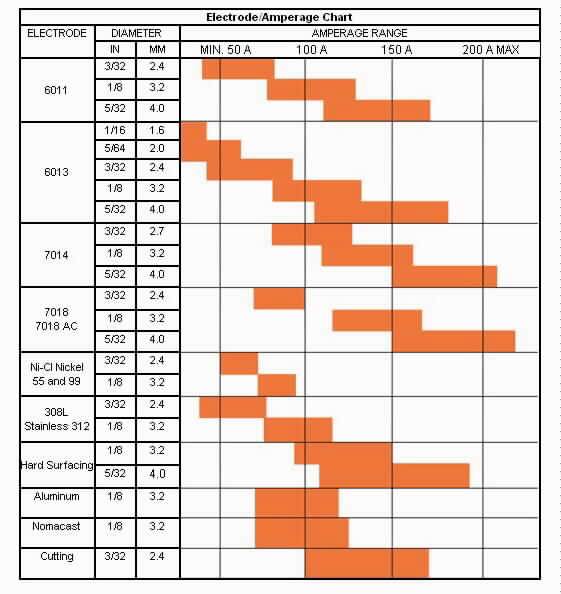

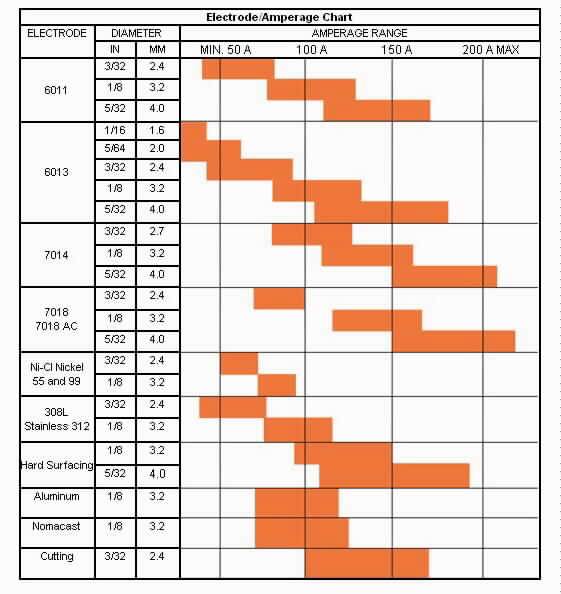

obviously much of the problem is I should have used 1/16" weld rods also, because the larger 1/8" were just a bit to large for the job really.

the weld quality and strength was fine, when I finished but it was tricky not burning thru the thin sheet steel, with weld rods that were marginally too large. and the end result was that ,the weld looked like crap compared to what it would have if tig welded, and because it looked like crap, it required, a good deal of work with a belt sander, hand file and hand sanding that would have been FAR less extensive with the MIG or TIG welders before I could paint the box and have it appear to be new and UN-molested.

my LINCOLN ARC welder is not the problem, I freely admit its the guy using it who spends most of his time with the TIG, ox-acetolene torch or MIG welder(in about that order) so if your ever about to make a similar ,less than brilliant move think it thru and go get the darn tank of shield gas refilled, even if you need to skip a few lunches to afford it, because its a P.I.T.A. cleaning up a weld you know you could have done with FAR better less messy results, with a TIG welder, and you will spend the time anyway reconditioning the welded area.

viewtopic.php?f=60&t=66&p=81#p81

and thats the same tank I use on the MIG, so rather than going to get the tank re-filled like I should have done,

I grabbed the ARC welder and some 1/8' sticks and did the repair, with the arc welder, which Ive used mostly for thicker welding on 1/4" and heavier welding, jobs like brackets on rear differentials or frame repairs,for about 12 years now, (which is mostly what I bought it for)

obviously much of the problem is I should have used 1/16" weld rods also, because the larger 1/8" were just a bit to large for the job really.

the weld quality and strength was fine, when I finished but it was tricky not burning thru the thin sheet steel, with weld rods that were marginally too large. and the end result was that ,the weld looked like crap compared to what it would have if tig welded, and because it looked like crap, it required, a good deal of work with a belt sander, hand file and hand sanding that would have been FAR less extensive with the MIG or TIG welders before I could paint the box and have it appear to be new and UN-molested.

my LINCOLN ARC welder is not the problem, I freely admit its the guy using it who spends most of his time with the TIG, ox-acetolene torch or MIG welder(in about that order) so if your ever about to make a similar ,less than brilliant move think it thru and go get the darn tank of shield gas refilled, even if you need to skip a few lunches to afford it, because its a P.I.T.A. cleaning up a weld you know you could have done with FAR better less messy results, with a TIG welder, and you will spend the time anyway reconditioning the welded area.

viewtopic.php?f=60&t=66&p=81#p81