It seems that the numbers provided by the manufactures are limited in the information that they provide and going by the application description (see note 1 for example) this leaves alot to be desired. Exactly how do they come up with the power range or cruise range see below (3600-4400 cruise RPM) or the converter stall speed needed??? Ask ten manufacture's and get ten different answers. Two cams could have exactly the same duration, lift and timing numbers, but be completely different cams.

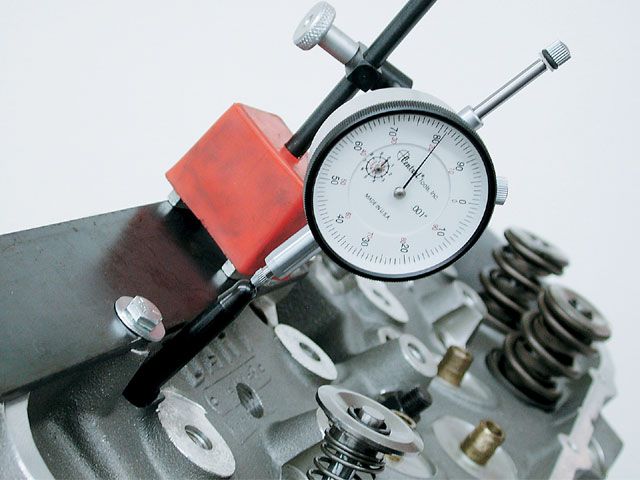

Wouldn't the lift curve provide another very good tool for evaluating the different cams. But I don't see the manufactures providing this info....right??? Is it available somewhere??? That would be like showing the world your research data. But that doesn't mean we can't do our own lift curves. I would guess that you already have some data if you would be willing to share.

I would like to see what I can do with Excel plotting these curves and putting some on them on the same graph for heads-up evaluation. If you have some data, say every 5 degress vs. lift that you can provide, then I would like to see what I can do. Everything I find out would be provided here on the forum for everyone to use.

Comments???

Note: Example - Crane 119661 - http://www.cranecams.com/pdf/_catalogs/ ... 54-107.pdf Page 68

1.) Good mid range torque and HP, fair idle, performance

usage, 3600-4400 cruise RPM, good with manifold

nitrous system, 10.0 to 11.5 compression ratio advised.

Good w/Roots supercharger, 15 lbs. maximum boost

w/8.0 maximum compression ratio advised, .900†base

circle for long stroke clearance.

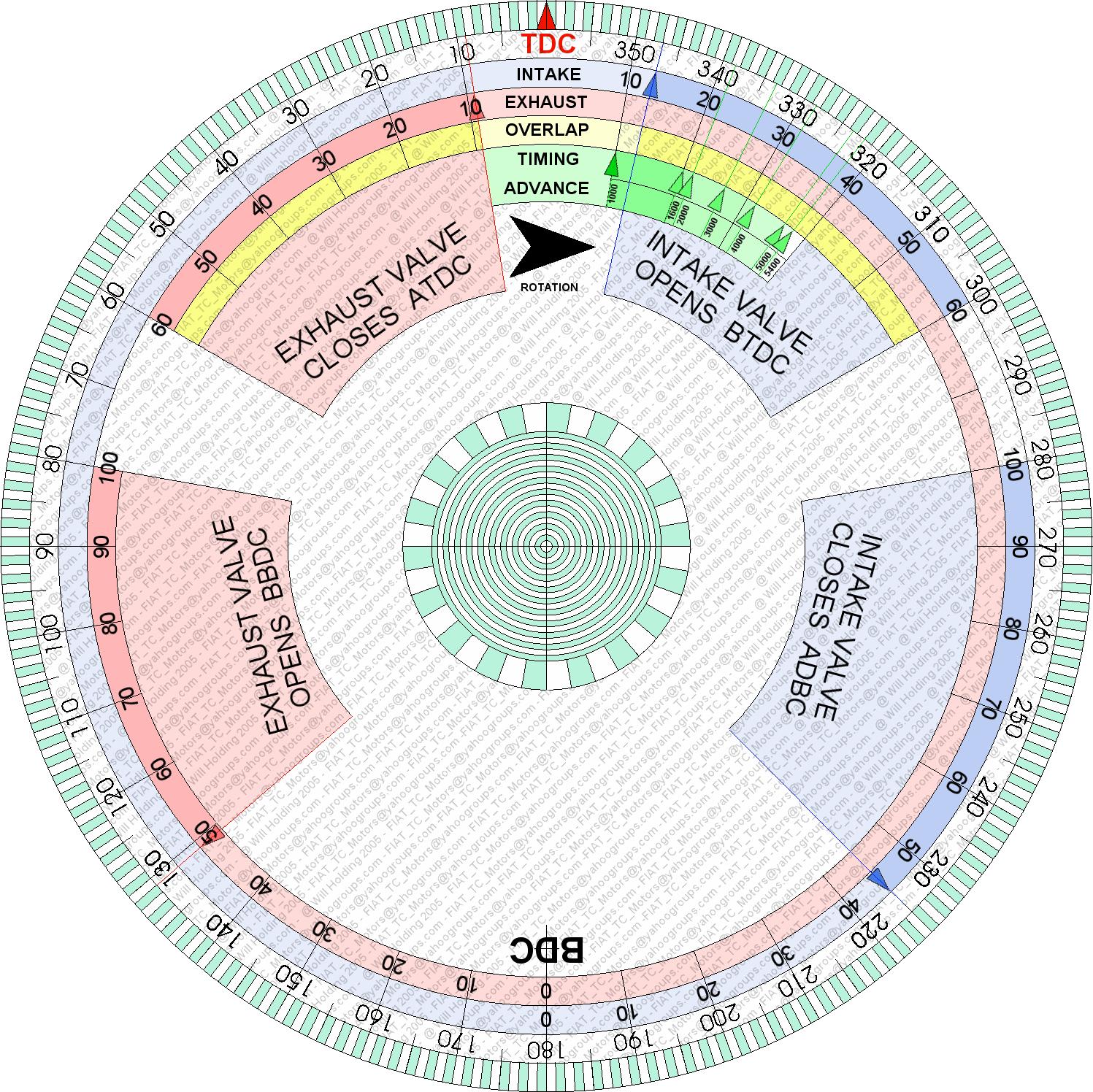

Lift Curve Example:

Wouldn't the lift curve provide another very good tool for evaluating the different cams. But I don't see the manufactures providing this info....right??? Is it available somewhere??? That would be like showing the world your research data. But that doesn't mean we can't do our own lift curves. I would guess that you already have some data if you would be willing to share.

I would like to see what I can do with Excel plotting these curves and putting some on them on the same graph for heads-up evaluation. If you have some data, say every 5 degress vs. lift that you can provide, then I would like to see what I can do. Everything I find out would be provided here on the forum for everyone to use.

Comments???

Note: Example - Crane 119661 - http://www.cranecams.com/pdf/_catalogs/ ... 54-107.pdf Page 68

1.) Good mid range torque and HP, fair idle, performance

usage, 3600-4400 cruise RPM, good with manifold

nitrous system, 10.0 to 11.5 compression ratio advised.

Good w/Roots supercharger, 15 lbs. maximum boost

w/8.0 maximum compression ratio advised, .900†base

circle for long stroke clearance.

Lift Curve Example: