Is the lifter boring tool a good idea for all kinds of lifters, including both type of roller lifters ??? Seems it's main advantage would be with the flat face lifter.

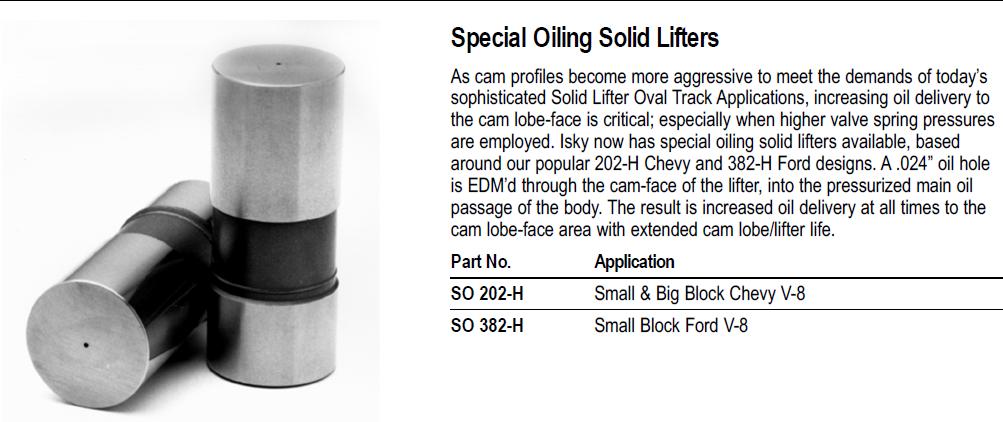

Since the Dart SHP block has "Main Priority Oiling", are the lifters and camshaft at more of disadvantage than in an OEM style oiling where the oil goes to the lifters first ???

It would be expensive for a one time use at $141.

http://www.summitracing.com/parts/CCA-5003/

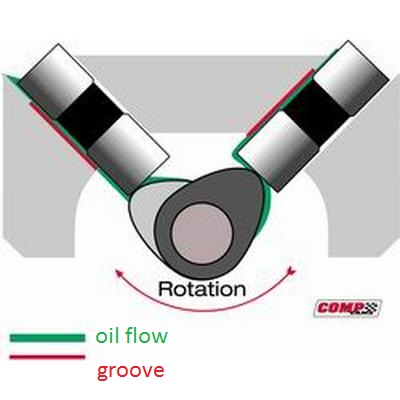

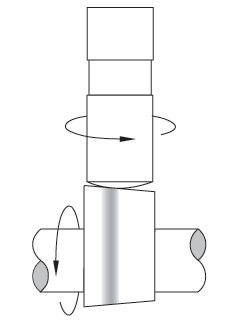

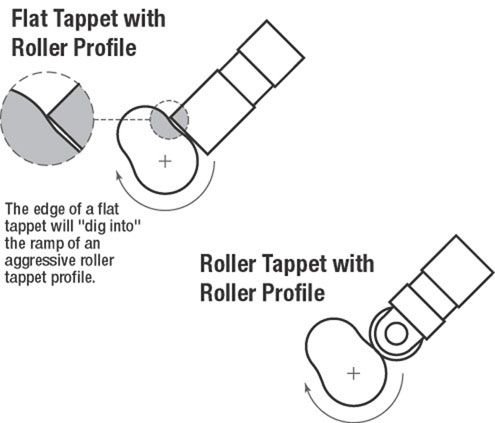

occasionally I get someone who points out that the roller lifter wheels are not exactly centered on the roller cam lobes , that a function of the original block design being for flat tappet lifters, with flat tappet lifter the lifter bores are purposely not supposed to be in the center. The lifter bores are off center from the lobes and always have been. This was to promote rotation of the lifters, the lobes are slightly tapered and the lifters ran off center. GM did not change the lifter bore spacing when they went to roller lifters

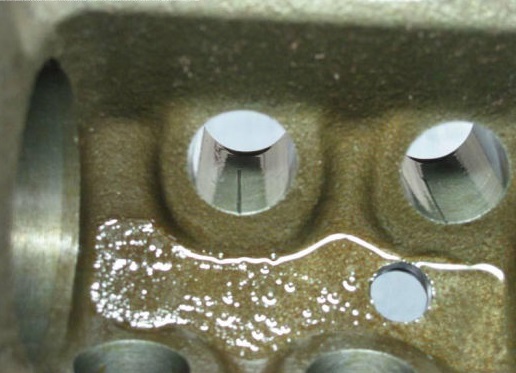

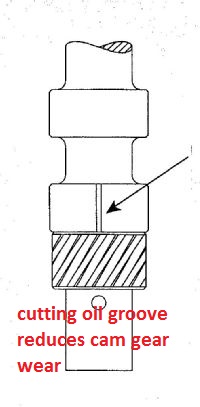

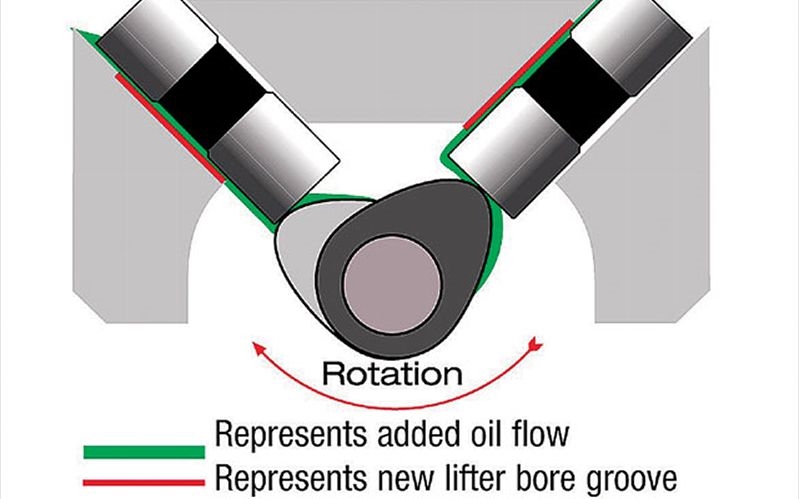

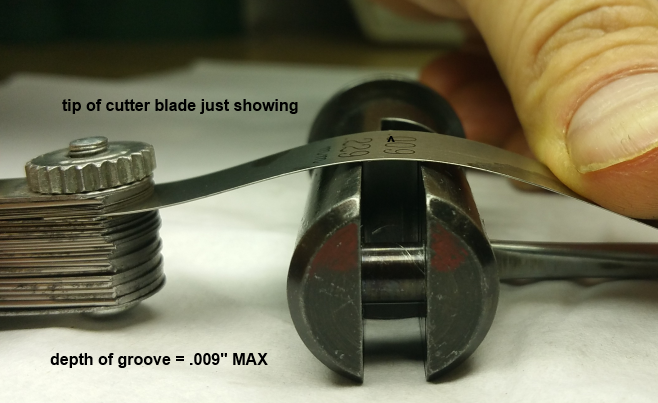

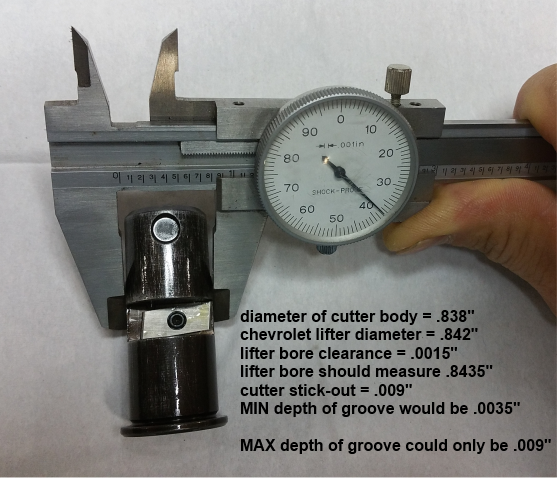

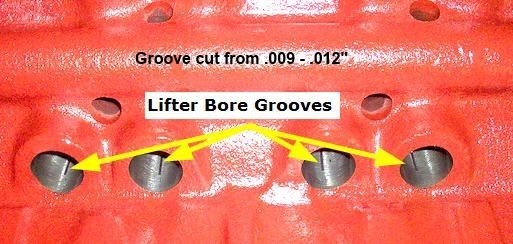

COMP SELLS A TOOL TO GROOVE LIFTER BORES

Attachments

Last edited by a moderator: