Greetings, my name is Ken I own a 1987 Corvette 4+3 Coupe. The car has spent most of it's life in storage. I'm replacing rocker arms,valve springs,valve seals,valve hardware. Z28 springs with .060 shim on ex side. Seat pressure on both banks 100lbs-105lbs. Should say Comp Cams roller tip rockers. Could not find std replacement lifters. Purchased GM#12499225 LS7 lifters and have heard many stories and tales about preload. I used the Proform blue checker and adjustable pushrod (Com Cams) for valve stem center contact. I would like to order 1 set of pushrods and be finished ! I'm thinking .050 lifter preload after looking at lifter plunger travel,anyone used these before? Has anyone had to deal with the AC bracket torx bolt I think T45 just below the pulley? Plan on changing water pump & timing set. Look's like somebody had a try on the bolt in question. I really like driving the car and will more than likely own another one maybe a C5 and keep this one too. A mixture of decades of motorcycle drag racing, 4 cylinder engine building, high RPM 2 cam engines but never spent much time on a SBC. I'm looking for a reliable set up for my driver Vette. Thanks, Ken

- Home

- Forums

- Technical Articles/muscle cars

- C1-C6 Corvettes

- Engine: Repairs and Modifications & generally corv

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lifters

- Thread starter BNB-LLC

- Start date

welcome to the site!

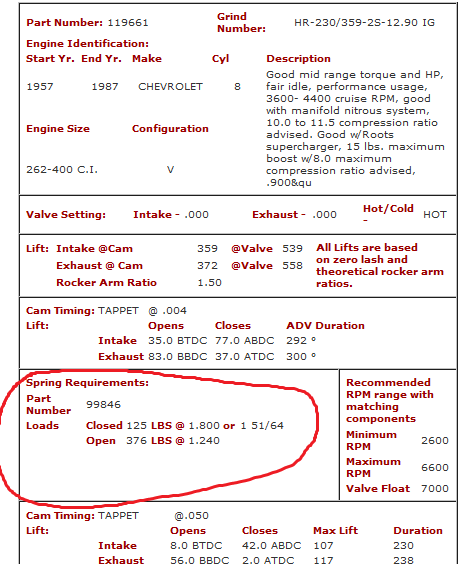

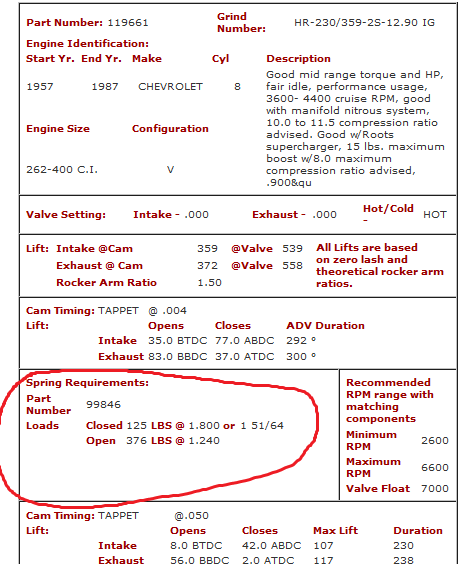

To answer your questions, hydraulic roller lifters, ( partly because they are fairly heavy compared to flat tappet lifters) generally require valve spring load rates in the 120-135lb seat -to-330-370lb open range ,to insure the lifter stays in contact with the cam lobe acceleration ramps as the rpms and inertial loads increase,heres the hydraulic roller cam I'm using

even the chevy hot cam valve springs

809-12551483

which most guys upgrade from have

Seat Pressure: 110 lbs @ 1.160"

Spring Rate: 356 lbs/in

btw the best deal I found lately on basic hydraulic flat tappet lifters

http://www.summitracing.com/parts/sum-ht817/overview/

the load rates you quote of" Seat pressure on both banks 100lbs-105lbs' are very likely to result in loss of lifter to lobe contact at rpm levels lower than you might anticipate, if you intend to push the engines limits, which can result in valve train durability issues, Id suggest consulting the cam manufacturer for his advise on suggested valve spring load rates, or at least the local machine shop that does valve jobs and id strongly suggest a minimum of .060 valve spring to coil bind clearance at full lift and Id point out that lifter pre-load is not a consideration in selecting push rod length, lifter pre-loads in the .020-.040 range are generally used.

I think youll find these links and the sub links they contain,worth reading thru

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=399

viewtopic.php?f=52&t=1376

viewtopic.php?f=52&t=528

To answer your questions, hydraulic roller lifters, ( partly because they are fairly heavy compared to flat tappet lifters) generally require valve spring load rates in the 120-135lb seat -to-330-370lb open range ,to insure the lifter stays in contact with the cam lobe acceleration ramps as the rpms and inertial loads increase,heres the hydraulic roller cam I'm using

even the chevy hot cam valve springs

809-12551483

which most guys upgrade from have

Seat Pressure: 110 lbs @ 1.160"

Spring Rate: 356 lbs/in

btw the best deal I found lately on basic hydraulic flat tappet lifters

http://www.summitracing.com/parts/sum-ht817/overview/

the load rates you quote of" Seat pressure on both banks 100lbs-105lbs' are very likely to result in loss of lifter to lobe contact at rpm levels lower than you might anticipate, if you intend to push the engines limits, which can result in valve train durability issues, Id suggest consulting the cam manufacturer for his advise on suggested valve spring load rates, or at least the local machine shop that does valve jobs and id strongly suggest a minimum of .060 valve spring to coil bind clearance at full lift and Id point out that lifter pre-load is not a consideration in selecting push rod length, lifter pre-loads in the .020-.040 range are generally used.

I think youll find these links and the sub links they contain,worth reading thru

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=399

viewtopic.php?f=52&t=1376

viewtopic.php?f=52&t=528

Last edited by a moderator:

Thanks for all the info and links!! I should of stated the L98 is all stock including camshaft. If it makes a difference on spring pressures? Would the Cloyes # 9-1145 timing set fit under a stock timing cover? Have heard in the 80's GM retarded cam timing for emission standards? Figured while changing water pump do front seal and timing set. Have you tried 0 index on these Cloyes set with a stock engine granted no clearance issues are present? Just thinking of gaining more torque?

http://www.summitracing.com/parts/clo-9-1145

yes these fit just fine

TORQUE is the result of the effective cylinder pressure curve , cylinder displacement and crank stroke to bore ratio, the larger the bore the more effective surface area the cylinder pressure generated has to work against.

longer strokes allow the pressure to work against a more effective leverage ratio, and higher compression ratios generally result in higher average cylinder pressures during peak burn times which potentially allow more efficient use of the fuels caloric content.

think about this, a 350 has a 4' bore diam and a 3.48" stroke , that 12.588 square inches of piston surface area

think about this, a 454 has a 4.25' bore diam and a 4" stroke , that 14.210 square inches of piston surface area

that gives the 454 a 13% mechanical leverage advantage, a 12% INCREASED SURFACE AREA, OVER EACH PISTON, FOR CYLINDER PRESSURE TO WORK WITH, and approximately 30% more displacement, not even counting the larger more efficient splayed valves , thats in theory a significant advantage and why the larger engine easily produces more torque, its also why you seldom see 327 and 302 chevy engines being build vs 383-406-427 sbc engines, the larger displacement and longer strokes effectively produce more useable torque.

look even if you make 1.25 hp and ft lb of torque fron a 350 thats 437 hp and 437 ft lbs which is above average for a street 350, but simply building the larger 383 with the longer crank stroke and making the exact same 1.25 hp/ft lbs =478 hp/ 478 ft lbs

how crank stroke effects piston movement and acceleration, notice how the blue piston simulating the longer stroke provides both more volume included in the stroke and more compression at top dead center on compression

related info

http://victorylibrary.com/mopar/cam-tech-c.htm

http://victorylibrary.com/mopar/rod-tech-c.htm

http://victorylibrary.com/mopar/m-table-c.htm

Thanks again for all the input and info. The C4 is finished and runs GREAT! 20-30 mins with the 1/2" Milwaukee wrist breaker to get oil at rockers while turning crank. The only noise while running is the fuel injectors. Com Cam magnum roller tip rockers, new springs,new valve seals,port matching,removed boogers from intake runners,K&N air filter with high flow air box lid,adjustable fuel pressure reg. Just these minor changes and a complete tune up with tps adjustment made a night and day difference.Will be dialing in fuel pressure just to tweak some more.Presently @ 42psi running with vacuum hose on.Again thanks very much for the complete info,was excellent reading!

BNB-LLC said:20-30 mins with the 1/2" Milwaukee wrist breaker to get oil at rockers while turning crank.

The only noise while running is the fuel injectors. Com Cam magnum roller tip rockers, new springs,new valve seals,port matching,removed boogers from intake runners,K&N air filter with high flow air box lid,adjustable fuel pressure reg. Just these minor changes and a complete tune up with tps adjustment made a night and day difference.

Now that takes determination ..... you turned it over by hand with a breaker

bar to get oil pressure???

Even little things add up to make a noticeable difference, job well done!!!

Indycars said:...

Even little things add up to make a noticeable difference, job well done!!!

[/size][/color]

yes a fact all too often ignored by the vast majority of people assembling engines, ...many of whom ,who seem memorized by the constantly skillfully repeated marketing concept of always needing to buy the next one last "MAGIC" part that will FINAL make their engine run correctly, when the TRUTH is that a PROPERLY MATCHED AND CAREFULLY ASSEMBLED and CAREFULLY RESEARCHED LIST OF COMPONENTS will consistently produce better results, than a extensive list of expensive components that are randomly assembled, which is what best describes the vast majority of engines I see

Strictly Attitude

solid fixture here in the forum

I hear that grumpy!!!! I put hours of research it every thing I build and it pays off 7 fold.