busterrm

solid fixture here in the forum

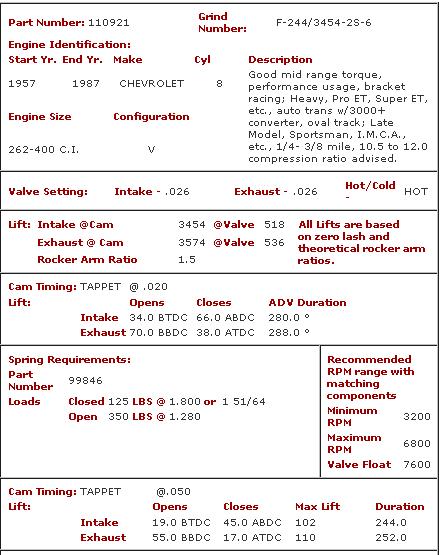

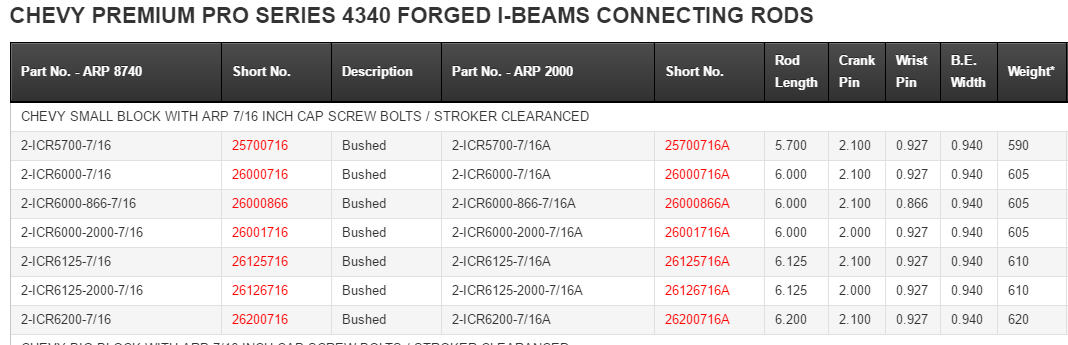

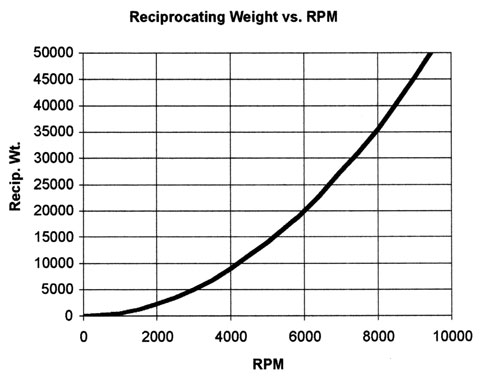

I watch another forum, and the question came up about building a SBC 302, using a longer rod than stock. Several are convinced that 6.25 in rod would be good, also 6 in and 5.94 were mentioned. I did some easy math and suggested 5.85 in rod with a 327 piston. There was no mention of it being a street engine or a racing engine. Through the years, I have known many engine builders and most of them have told me that anything longer than 5.85 rod(in a small CID engine) is a waste unless it's going to be a all out race engine. Each stated that the longer dwell time of the longer rods would necessitate the use of more radical cam with a overlap of 70 or more degrees. In addition to the more radical cam you would need larger port heads to supply the flow of the more radical cam. I got a ration of shit from everybody about my suggestion. I was thinking of a street engine and the ability to buy off the shelf parts for the build. The budget wasn't mentioned either, so I thought a set of hyper pistons and a set of rods from Ohio Crankshafts would be good with the price at about $590. I just don't understand I was just offering opinion and another option. GEES!!!! I realize the piston would be heavier, but Mahle makes a set of pistons without skirts that is lighter and are forged, cost would be a few hundred dollars more. Just scratching my head! Is my thinking wrong on this guys? With the other options either machining of the pistons, decking the block, or having special pistons made would be needed.

Last edited: