while the difference in rod length looks like a big deal at first its really NOT. heres why,the difference in effective angle between a 5.7" rod and a 6.125" rods is about a 1.25 degree difference, and although the longer rod shorter piston combo tends to be lighter in weight and have slightly less friction in the bore the effective difference is minimal

Table 1

ROD LENGTH RELATIONSHIPS*

(with Crank @ 90 deg ATDC)

Piston Position Crankpin/Rod Angle

Stroke Rod Length Rod Angle from TDC ATDC

3.5 5.70 17.88 2.025 72.12

3.5 5.85 17.40 2.018 72.59

3.5 6.00 16.96 2.011 73.04

3.5 6.20 16.39 2.002 73.60

as a general rule, shorter rods tend to get better results with a tighter cam LSA and larger ports, a longer rod tends to favor slightly smaller ports and a slightly wider cam LSA but again the differences are minimal

POSTED ON ISKY CAMS

Rod Lengths/Ratios: Much ado about almost nothing.

Why do people change connecting rod lengths or alter their rod length to stroke ratios? I know why, they think they are changing them. They expect to gain (usually based upon the hype of some magazine article or the sales pitch of someone in the parts business) Torque or Horsepower here or there in rather significant "chunks". Well, they will experience some gains and losses here or there in torque and or H.P., but unfortunately these "chunks" everyone talks about are more like "chips".

To hear the hype about running a longer Rod and making more Torque @ low to mid RPM or mid to high RPM (yes, it is, believe it or not actually pitched both ways) you'd think that there must be a tremendous potential for gain, otherwise, why would anyone even bother? Good question. Let's begin with the basics. The manufacture's (Chevy, Ford, Chrysler etc.) employ automotive engineers and designers to do their best (especially today) in creating engine packages that are both powerful and efficient. They of course, must also consider longevity, for what good would come form designing an engine with say 5% more power at a price of one half the life factor? Obviously none. You usually don't get something for nothing - everything usually has its price. For example: I can design a cam with tremendous high RPM/H.P. potential, but it would be silly of me (not to mention the height of arrogance) to criticize the engineer who designed the stock camshaft. For this engine when I know how poorly this cam would perform at the lower operating RPM range in which this engineer was concerned with as his design objective!

Yet, I read of and hear about people who do this all the time with Rod lengths. They actually speak of the automotive engine designer responsible for running "such a short Rod" as a "stupid SOB." Well, folks I am here to tell you that those who spew such garbage should be ashamed of themselves - and not just because the original designer had different design criteria and objectives. I may shock some of you, but in your wildest dreams you are never going to achieve the level of power increase by changing your connecting rod lengths that you would, say in increasing compression ratio, cam duration or cylinder head flow capacity. To illustrate my point, take a look at the chart below. I have illustrated the crank angles and relative piston positions of today's most popular racing engine, the 3.48" stroke small block 350 V8 Chevy in standard 5.7", 6.00", 6.125" and 6.250" long rod lengths in 5 degree increments. Notice the infinitesimal (look it up in the dictionary) change in piston position for a given crank angle with the 4 different length rods. Not much here folks, but "oh, there must be a big difference in piston velocity, right?" Wrong! Again it's a marginal difference (check the source yourself - its performance calculator).

To hear all this hype about rod lengths I'm sure you were prepared for a nice 30, 40, or 50 HP increase, weren't you? Well its more like a 5-7 HP increase at best, and guess what? It comes at a price. The longer the rod, the closer your wrist pin boss will be to your ring lands. In extreme situations, 6.125" & 6.250" lengths for example, both ring and piston life are affected. The rings get a double whammy affect. First, with the pin boss crowding the rings, the normally designed space between the lands must be reduced to accommodate the higher wrist pin boss. Second, the rings wobble more and lose the seal of their fine edge as the piston rocks. A longer Rod influences the piston to dwell a bit longer at TDC than a shorter rod would and conversely, to dwell somewhat less at BDC. This is another area where people often get the information backwards.

In fact, this may surprise you, but I know of a gentleman who runs a 5.5" Rod in a 350 Small Block Chevy who makes more horsepower (we're talking top end here) than he would with a longer rod. Why? Because with a longer dwell time at BDC the short rod will actually allow you a slightly later intake closing point (about 1 or 2 degrees) in terms of crank angle, with the same piston rise in the cylinder. So in terms of the engines sensitivity to "reversion" with the shorter rod lengths you can run about 2-4 degrees more duration (1-2 degrees on both the opening & closing sides) without suffering this adverse affect! So much for the belief that longer rod's always enhance top end power!

Now to the subject of rod to stroke ratios. People are always looking for the "magic number" here - as if like Pythagoras they could possibly discover a mathematical relationship which would secure them a place in history. Rod to stroke ratios are for the most part the naturally occurring result of other engine design criteria. In other-words, much like with ignition timing (spark advance) they are what they are. In regards to the later, the actual number is not as important as finding the right point for a given engine. Why worry for example that a Chrysler "hemi" needs less spark advance that a Chevrolet "wedge" combustion chamber? The number in and of itself is not important and it is much the same with rod to stroke ratios. Unless you want to completely redesign the engine (including your block deck height etc.) leave your rod lengths alone. Let's not forget after all, most of us are not racing at the Indy 500 but rather are hot rodding stock blocks.

Only professional engine builders who have exhausted every other possible avenue of performance should ever consider a rod length change and even they should exercise care so as not to get caught up in the hype.

info thats well worth the time to read thru

http://victorylibrary.com/mopar/rod-tech-c.htm

http://www.stahlheaders.com/Lit_Rod%20Length.htm

http://www.iskycams.com/ART/techinfo/ncrank1.pdf

viewtopic.php?f=53&t=110

viewtopic.php?f=53&t=1017

viewtopic.php?f=53&t=1168

viewtopic.php?f=53&t=510

I get asked all the time if 6" or 5.7" rods are the best selection for the 383 sbc builds, the truth is both have some advantages and disadvantages, as an example I selected two very similar forged KB pistons to compare with similar compression ratios that might be used in a kick butt racing combo, with 12.5:1 cpr for a weekend warrior style 383 sbc

so lets look at the differences as they will have similar traits to other pistons

heres a link to KB pistons, Ive used dozens of these sets with good results

http://www.kb-silvolite.com/

MORE SOURCES

viewtopic.php?f=53&t=2208

advantages & disadvantages of the 5.7" rods and pistons, in a 383 sbc

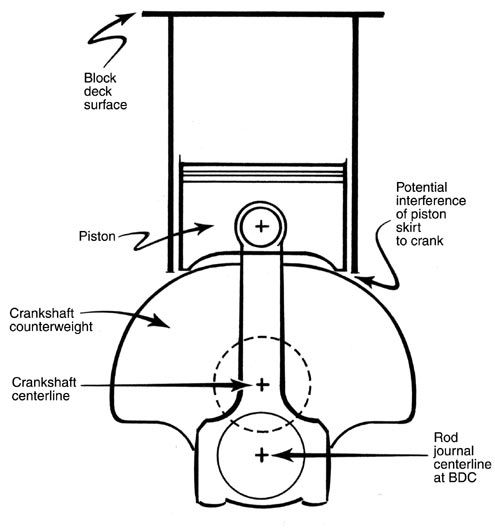

less clearance for the counter weights , to pass under the skirt, higher thrust loads on cylinder walls

higher reciprocating weight

481 grams piston / 132 grams pin

rings fully supported in oil ring groove, as the piston pin is lower

slightly longer and potentially more stable bore skirt contact area

advantages & disadvantages of the 6" rods and pistons, in a 383 sbc

lower reciprocating weight

http://www.kb-silvolite.com/test/icon/i ... s&P_id=391

more clearance for the counter weights , to pass under the skirt, lower thrust loads on cylinder walls

418 grams piston / 132 grams pin

THATS 63 grams lighter than the 5.7" piston

rings not fully supported in oil ring groove, as the pin by-sects the lower oil ring groove

slightly shorter and potentially less stable bore skirt contact area

related info

http://www.stahlheaders.com/Lit_Rod%20Length.htm

http://www.rustpuppy.org/rodstudy.htm

http://victorylibrary.com/mopar/rod-tech-c.htm

ISKY CAMS POSTED THIS INFO

Tech Tip - 2005

Rod Lengths/Ratios: Much ado about almost nothing.

Why do people change connecting rod lengths or alter their rod length to stroke ratios? I know why, they think they are changing them. They expect to gain (usually based upon the hype of some magazine article or the sales pitch of someone in the parts business) Torque or Horsepower here or there in rather significant "chunks". Well, they will experience some gains and losses here or there in torque and or H.P., but unfortunately these "chunks" everyone talks about are more like "chips".

To hear the hype about running a longer Rod and making more Torque @ low to mid RPM or mid to high RPM (yes, it is, believe it or not actually pitched both ways) you'd think that there must be a tremendous potential for gain, otherwise, why would anyone even bother? Good question. Let's begin with the basics. The manufacture's (Chevy, Ford, Chrysler etc.) employ automotive engineers and designers to do their best (especially today) in creating engine packages that are both powerful and efficient. They of course, must also consider longevity, for what good would come form designing an engine with say 5% more power at a price of one half the life factor? Obviously none. You usually don't get something for nothing - everything usually has its price. For example: I can design a cam with tremendous high RPM/H.P. potential, but it would be silly of me (not to mention the height of arrogance) to criticize the engineer who designed the stock camshaft. For this engine when I know how poorly this cam would perform at the lower operating RPM range in which this engineer was concerned with as his design objective!

Yet, I read of and hear about people who do this all the time with Rod lengths. They actually speak of the automotive engine designer responsible for running "such a short Rod" as a "stupid SOB." Well, folks I am here to tell you that those who spew such garbage should be ashamed of themselves - and not just because the original designer had different design criteria and objectives. I may shock some of you, but in your wildest dreams you are never going to achieve the level of power increase by changing your connecting rod lengths that you would, say in increasing compression ratio, cam duration or cylinder head flow capacity. To illustrate my point, take a look at the chart below. I have illustrated the crank angles and relative piston positions of today's most popular racing engine, the 3.48" stroke small block 350 V8 Chevy in standard 5.7", 6.00", 6.125" and 6.250" long rod lengths in 5 degree increments. Notice the infinitesimal (look it up in the dictionary) change in piston position for a given crank angle with the 4 different length rods. Not much here folks, but "oh, there must be a big difference in piston velocity, right?" Wrong! Again it's a marginal difference (check the source yourself - its performance calculator).

To hear all this hype about rod lengths I'm sure you were prepared for a nice 30, 40, or 50 HP increase, weren't you? Well its more like a 5-7 HP increase at best, and guess what? It comes at a price. The longer the rod, the closer your wrist pin boss will be to your ring lands. In extreme situations, 6.125" & 6.250" lengths for example, both ring and piston life are affected. The rings get a double whammy affect. First, with the pin boss crowding the rings, the normally designed space between the lands must be reduced to accommodate the higher wrist pin boss. Second, the rings wobble more and lose the seal of their fine edge as the piston rocks. A longer Rod influences the piston to dwell a bit longer at TDC than a shorter rod would and conversely, to dwell somewhat less at BDC. This is another area where people often get the information backwards.

In fact, this may surprise you, but I know of a gentleman who runs a 5.5" Rod in a 350 Small Block Chevy who makes more horsepower (we're talking top end here) than he would with a longer rod. Why? Because with a longer dwell time at BDC the short rod will actually allow you a slightly later intake closing point (about 1 or 2 degrees) in terms of crank angle, with the same piston rise in the cylinder. So in terms of the engines sensitivity to "reversion" with the shorter rod lengths you can run about 2-4 degrees more duration (1-2 degrees on both the opening & closing sides) without suffering this adverse affect! So much for the belief that longer rod's always enhance top end power!

Now to the subject of rod to stroke ratios. People are always looking for the "magic number" here - as if like Pythagoras they could possibly discover a mathematical relationship which would secure them a place in history. Rod to stroke ratios are for the most part the naturally occurring result of other engine design criteria. In other-words, much like with ignition timing (spark advance) they are what they are. In regards to the later, the actual number is not as important as finding the right point for a given engine. Why worry for example that a Chrysler "hemi" needs less spark advance that a Chevrolet "wedge" combustion chamber? The number in and of itself is not important and it is much the same with rod to stroke ratios. Unless you want to completely redesign the engine (including your block deck height etc.) leave your rod lengths alone. Let's not forget after all, most of us are not racing at the Indy 500 but rather are hot rodding stock blocks.

Only professional engine builders who have exhausted every other possible avenue of performance should ever consider a rod length change and even they should exercise care so as not to get caught up in the hype.

http://www.iskycams.com/ART/techinfo/ncrank1.pdf