https://www.hotrod.com/articles/new...4A7FD6D264A06747D0828DA5F78669AEEAFEC500A26C8

CAR CRAFT ENGINE

New Cam Adds 71 HP To Stock 6.0L LS With No Low-End Loss!

Written by

Richard Holdener on May 3, 2018

For all but a few of us, if given the choice between a smaller motor and a larger one, we’d choose the larger one. Of course, this assumes cost is not a factor, but the things we want most usually end up costing more, right? Such is the case when talk turns to choosing between a 5.3L and a 6.0L LS. If we were looking to build a cheap turbo motor, we’d opt for the smaller 5.3L, as they are considerably less expensive than the 6.0L and you can make a boatload of power under boost. By adding a cam and boost to a 5.3L, you could easily reach four-digit power levels, but if you are going the all-motor route, the tables are tipped in favor of the bigger 6.0L. Why you ask? The reason is obvious. Bigger motors simply make more power. The extra power and torque offered by the 6.0L come in handy when you are trying to motivate a heavy vehicle like a truck, or possibly tow a trailer. When it comes to torque, displacement is king, and no amount of cam timing or head porting will ever allow a 5.3L to thump out torque like a larger 6.0L. The question then becomes, if a 6.0L is already good, how do we make it even better?

Here is a tip for LS enthusiasts out there. If the question ever arises about how to make an LS better, your go-to response should always be swap the cam! Sure, cylinder heads and intake manifolds are most welcome (especially on cathedral-port applications), but their gains are all but dependant on the presence of wilder-than-stock cam timing. Since the LS was factory fortified with ample displacement, compression, and head flow (especially anything with rec-port heads like our LY6), they are basically begging for more cam timing. While a cam upgrade can make significant power gains, there is usually a trade-off inherent in the additional peak power. Cam swaps, especially serious performance grinds, are almost always a case of no free lunch.

The potential for massive top-end power gains exist, but the typical 100-plus hp cam swap often comes with a torque-loss penalty. This is less of a problem on a dedicated race motor, but it definitely must be considered on any kind of daily driver, or even dual-purpose, street/strip application for that matter.

For many, the ideal situation is a cam swap that combines plenty of peak power without sacrificing low-speed torque. In fact, the mark of a successful cam swap is a grind that offers what we call the “trifecta.” What exactly is the trifecta? Well, for our needs, the trifecta means the cam upgrade does three things: it increases the peak power, it fattens up the peak torque, and it does both with no loss anywhere in the power curve. Achieving one of the elements is easy, combining two gets more difficult, but the trifecta requires selection of just the right cam for the combination. To see if we could manage the trifecta, we set up a test with our 6.0L LY6. For those unfamiliar with the LY6, the 2008 LS motor featured a 4.0-inch bore, 3.622-inch stroke, and was blessed with things like rec-port LS3 heads and even Variable Valve Timing (VVT). For our test, we were only interested in the 6.0L displacement and use of the LS3-style cylinder heads, so we replaced the VVT with a factory LQ9 cam, then added an LS3 intake manifold. What we wound up with was a near-stock 6.0L truck motor that produced peak numbers of 443 hp at 5,400 rpm and 467 lb-ft of torque at 4,500 rpm.

With our baseline taken care of, it was time for cam selection. Achieving more peak power and more peak torque was not terribly difficult, but doing so without hurting power anywhere else (meaning down at lower engine speeds) was the real trick. In an effort to achieve all three, we selected a

TrackMax grind from Trick Flow Specialties (part No. 30602003). This TrackMax cam offers a .585-/.585-inch lift split, a 228-/230-degree duration split, and 112-degree LSA. A healthy cam to be sure, we just hoped it worked well with the free-flowing, rec-port heads and 6.0L displacement. The dyno soon put our fears to rest, as the cam swap on the LY6 netted impressive gains. The peak power output was 514 hp at 5,900 rpm, while peak torque was up to 493 lb-ft of torque at 4,600 rpm. (For those keeping score, that’s more HP and torque than a stock LS7, yet a full liter smaller.) So far, we had achieved two elements, but only if they came with no loss would we achieve the trifecta. A peek at the power curves revealed that the TrackMax cam had indeed improved the power output through the entire rev range, with gains coming as low as 3,000 rpm. Everyone likes big power and big torque, but you know you have selected the right came when you hit the trifecta!

On The Dyno:

Stock 6.0L Cam vs TFS TrackMax

The 6.0L LY6 was modified slightly from stock to better represent a typical 6.0L. The VVT cam was replaced by a fixed LQ9 and the LY6 intake was ditched in favor of an LS3 unit (though there is almost no difference between the two intakes). Run with Hooker headers and a 92mm cable-driven throttle body, the LS3-headed 6.0L produced peak numbers of 443 hp at 5,400 rpm and 467 lb-ft of torque at 4,500 rpm. Torque production exceeded 450 lb-ft for a 1,000-rpm spread; no wonder they used this motor on HD truck applications! After installation of the TFS TrackMax cam, the power output increased to 514 hp at 5,900 rpm and 493 lb-ft of torque at 4,600 rpm. Note that both peak power and torque increased, and that the cam swap improved power through the entire rev range.

If you improve both the peak power and peak torque without hurting low-speed power, that’s what we call the trifecta!

Though the cam swap can be applied to any stock 6.0L (or any other displacement), our test motor started out life as a 2008 LY6.

In addition to the iron block and aluminum, rec-port LS3 heads, the LY6 also featured VVT cam operation. The VVT cam and mechanism was removed prior to our test.

In place of the VVT cam, we installed a factory 6.0L LQ9 cam. The specs matched the VVT cam, with the exception of the adjustability.

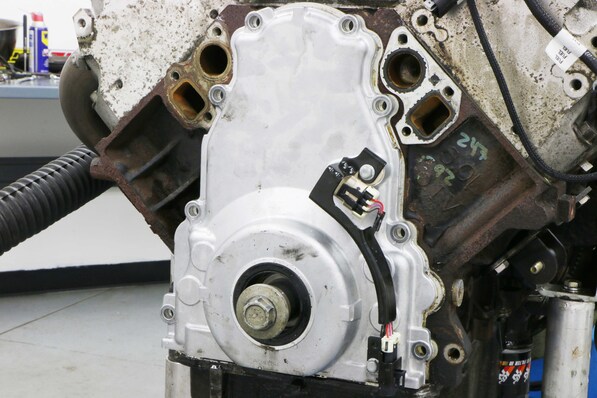

Removal of the VVT cam also required installation of a new front cover. Ours came courtesy of Gandrud Chevrolet.

The 2008 LY6 6.0L featured high-flow, rec-port LS3 heads (823 castings). With peak flow numbers of 315 cfm, the heads could easily support any power level offered by the cam swap.

The factory LS3 (823) heads used on the LY6 truck motor featured LS3-style valve springs. These were more than adequate for the .550-lift TFS cam.

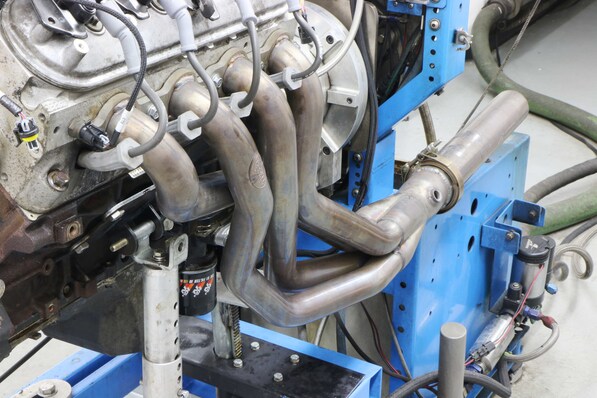

All testing was run with a set of 1 7/8-inch Hooker long-tube (LS Swap) headers feeding 18-inch collector extensions.

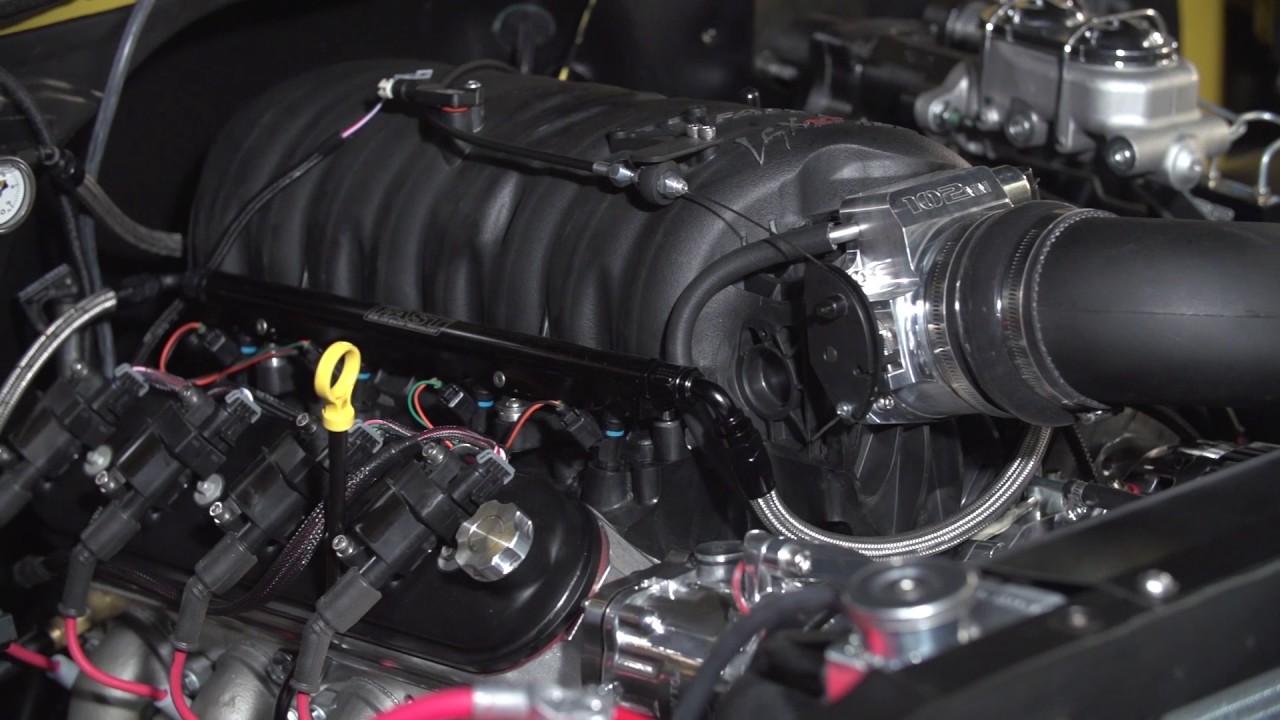

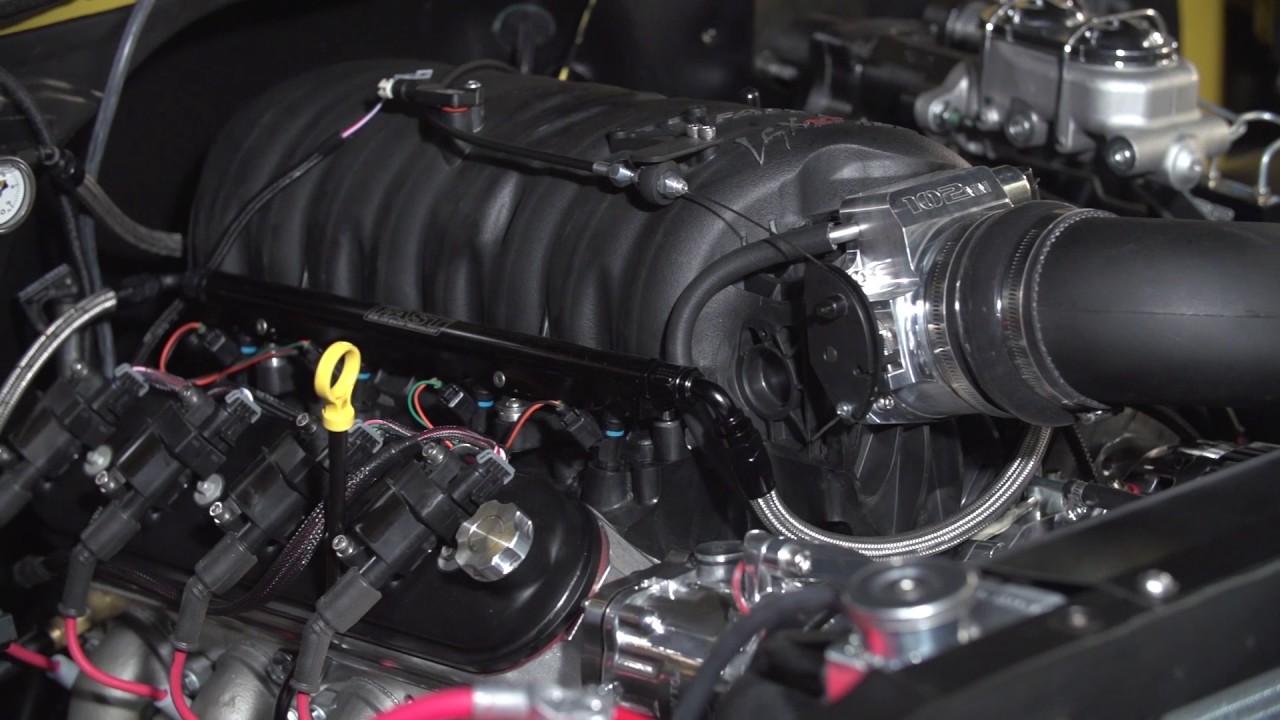

Though it offered no performance advantage, the factory LY6 truck intake was replaced a low-profile LS3 intake.

The stock LY6 injectors will easily feed the stock motor,

but we upgraded to a set of 75-pound injectors to ensure adequate fueling for future mods.

Tuning for each cam combo was left to a Holley HP ECU.

Run with the production LQ9 cam, the 6.0L produced peak numbers of 443 hp at 5,400 rpm and 467 lb-ft of torque at 4,500 rpm.

After our baseline run with the stock LQ9 cam, we removed the damper and front cover to allow access to the chain tensioner and cam gear

After removal the cam gear, we turned our attention to the cam retaining plate.

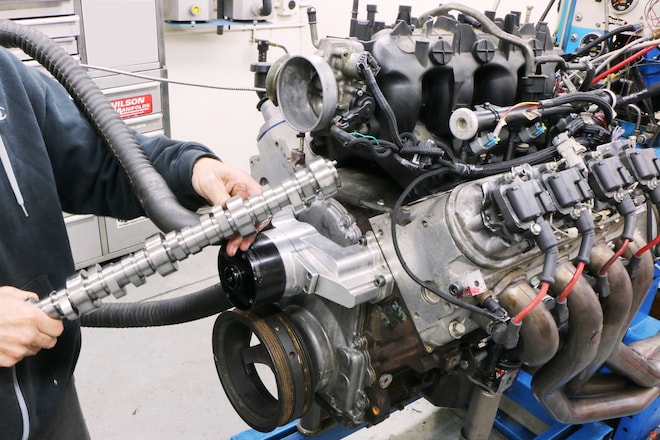

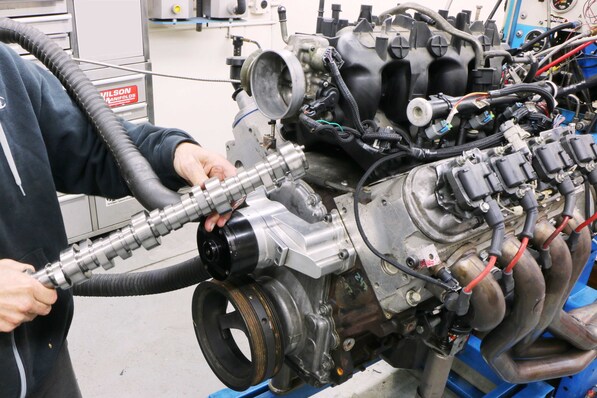

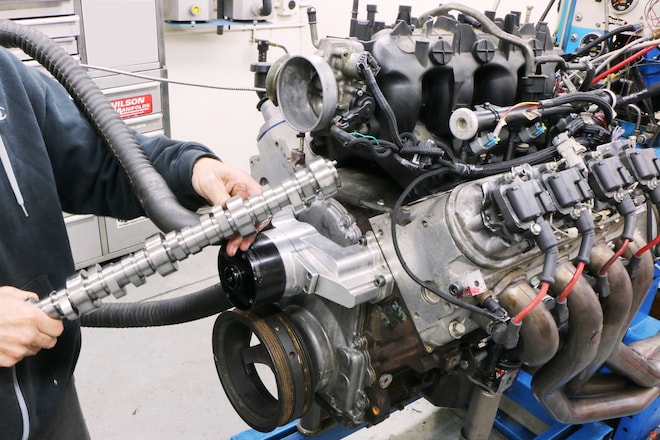

Next, we removed the factory LQ9 cam, taking care not to damage the high-mileage cam bearings. Note the use of special tools (no longer available) used to keep the lifters in place during the swap.

Removal of the stock cam allowed installation of the more aggressive

TFS TrackMax cam. The TFS cam (part No. 30602003)

offered .585-inch lift (intake and exhaust),

a 228-/230-degree duration split, and 112-degree LSA.

After installation of the TrackMax cam, the power output of the 6.0L LY6 jumped from 443 hp and 467 lb-ft of torque to 514 hp at 5,900 rpm and 493 lb-ft of torque at 4,600 rpm.

Daniel Westerbaan said

Here are some LS head porting links I have found:

https://ls1tech.com/forums/generati...759-diy-ls1-head-porting-home-can-help-4.html

https://ls1tech.com/forums/generation-iii-internal-engine/1522294-pics-my-diy-ported-heads.html

https://ls1tech.com/forums/generati...project-5-3-heads-lots-o-pics-56k-beware.html

There are also quite a few other good videos on this guys channel

If anyone reading has other LS head porting experience or suggestions (especially for 862/706 heads) let me know!