This project had to sit for awhile, some of my other rigs developed problems and needed attention, ya gotta keep 'em on the road and runnin', ya know?

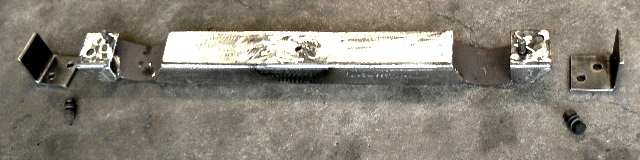

Anyway, dug out all the Heidt's suspension parts that I had sitting on the shelf:

Upper and lower tubular A-arms,

Coil-overs,

2" dropped spindles,

the earlier GM disk brakes for this setup, look like Chevelle to me....

Also picked up a 500 power steering box, and a painted (well, I'm gonna paint it....) Ididit tilt steering column to go with it.

Have the "new style" Earl Williams side mounts, they are very nice!

The last time I had it on the road, I had narrowed a 9" and moved the leaf springs under the frame rails in preparation for the "minitubs". I had put "slappers" on the springs to prevent windup, but not have a set of CalTrax to put on. It will take a little bit of modification with the spring setup I have, but they should work well.

Eventually the body is going to come off, but wanted to have the steering etc. parts all on there when I fitted the LT1 and T56 in, with the Hooker Super Comp headers, and welded in the new motor mounts. Plus I think that tranny is going to hit the floor tunnel, and that might need some modification.

Got the frame well scrubbed in front, and painted it with the Rusteoleum black Hammertone paint, it came out nice. Still needs more paint where the motor mounts will go, but it's a start....

With all that sheet metal gone, no motor, that front end is pretty light. When I jacked the bottom A-arm to compress the coil-overs for installation, had to tie the frame to a 4x4 under the jack! What fun....

I'll post more pix as I get more done here, with the cleaning and painting, where wasn't much to show.

The plan is to install the exhaust system, get all the hangers, etc. that will be needed welded onto the frame, then the body is coming off and the frame will get cherried out.

Aloha,

Willy

Steering and Suspension Page