2Loose

reliable source of info

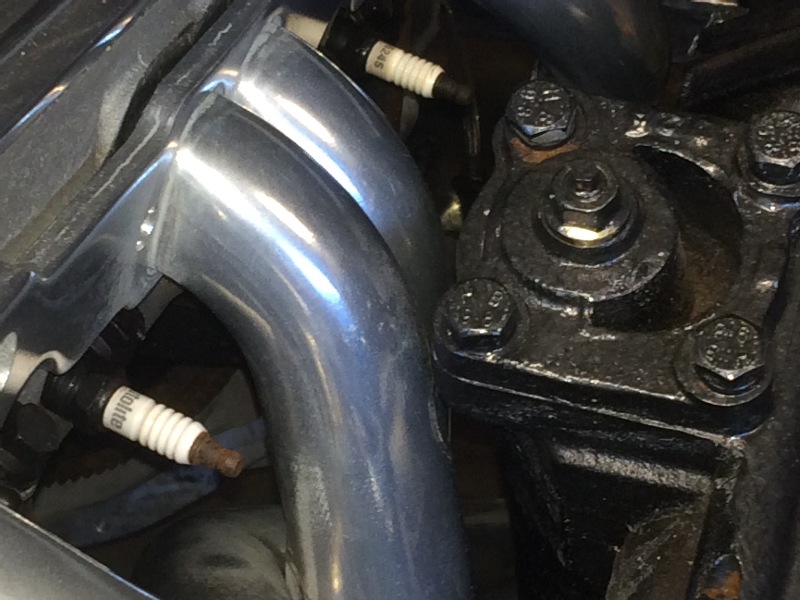

I spent a lot of time online looking for a new throwout bearing, and finally found one at ebay. It came in 3 days, on Friday, and my buddies and I bolted everything together and put it in the frame on "Fender Friday" (our weekly get together with beer and BBQ). But now the drive shaft I ordered from Strange Engineering is too long. I still have a copy of the order sheet, it clearly states 53-1/2", the one they sent me is 56" long. I'll call them on Monday.

I had sent them a damaged drive shaft from my '55 Chevy gasser, it has a shorter gearbox and that drive shaft was 56". The rear u-joint yoke was damaged on that one, (I blew it up drag racing) and I had asked them to shorten it to 53-1/2" and put a new yoke on it. They called after receiving the damaged drive shaft and said it was also slightly bent, and was not repairable, so I had told them to just make me a new one. But obviously they ignored the order sheet and made a replacement for the damaged driveshaft. It's their mistake, let's see how they handle it.

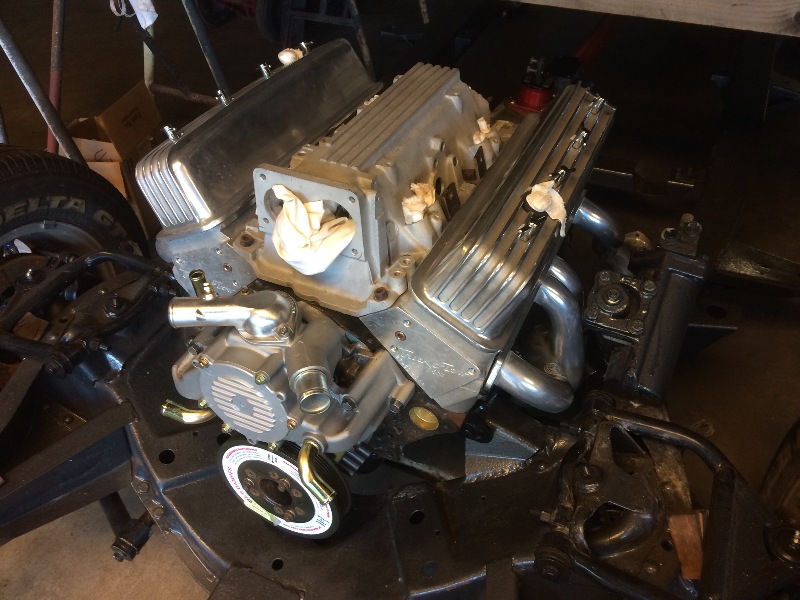

Here's how it sits now...

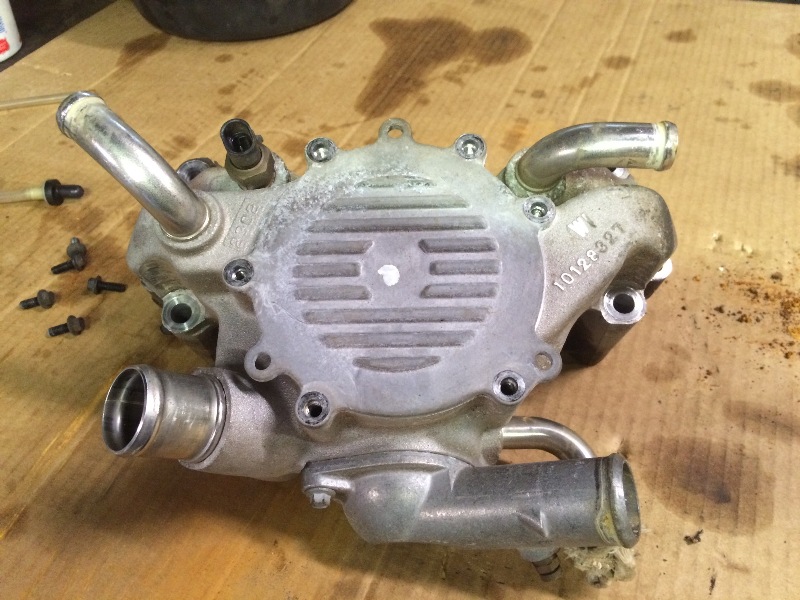

Now to finish the motor (starter, water pump, ignition, efi, alternator, PS pump, pulleys and belts) and add the exhaust system and fuel system, and as much else as I can think of before putting the body back on.

Am I having fun? You bet! I've never had the time before to do this much detail on a car, and on my favorite, a '55 Sport Coupe, I'm a lucky guy...

Aloha,

Willy

I had sent them a damaged drive shaft from my '55 Chevy gasser, it has a shorter gearbox and that drive shaft was 56". The rear u-joint yoke was damaged on that one, (I blew it up drag racing) and I had asked them to shorten it to 53-1/2" and put a new yoke on it. They called after receiving the damaged drive shaft and said it was also slightly bent, and was not repairable, so I had told them to just make me a new one. But obviously they ignored the order sheet and made a replacement for the damaged driveshaft. It's their mistake, let's see how they handle it.

Here's how it sits now...

Now to finish the motor (starter, water pump, ignition, efi, alternator, PS pump, pulleys and belts) and add the exhaust system and fuel system, and as much else as I can think of before putting the body back on.

Am I having fun? You bet! I've never had the time before to do this much detail on a car, and on my favorite, a '55 Sport Coupe, I'm a lucky guy...

Aloha,

Willy