it helps if you buy and actually carefully read ,

related printed reference info.

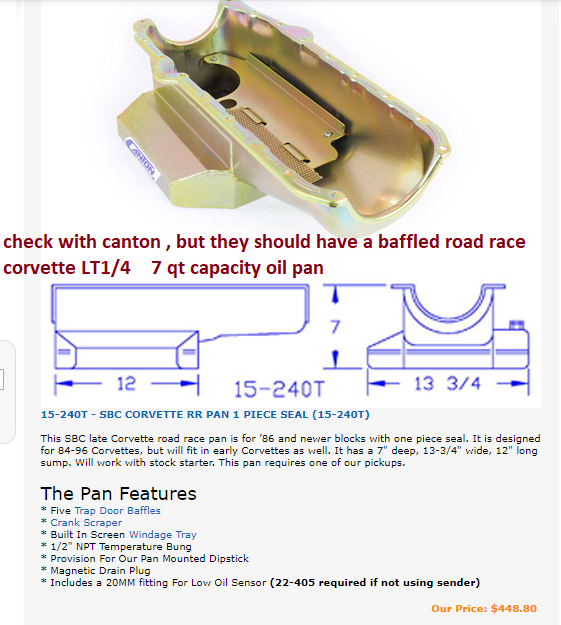

I was asked to propose a lt1-4 performance build

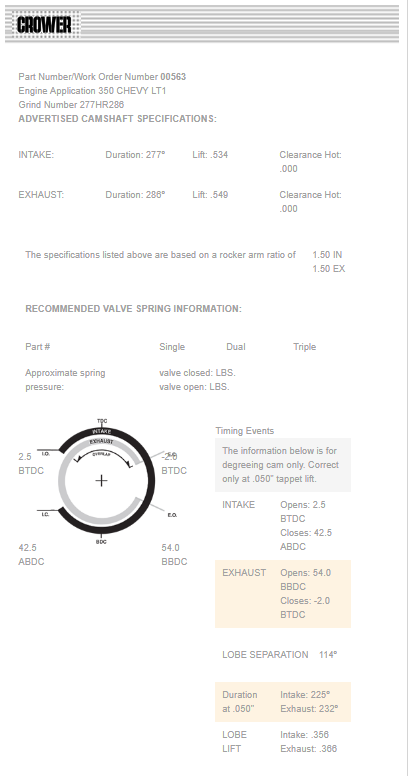

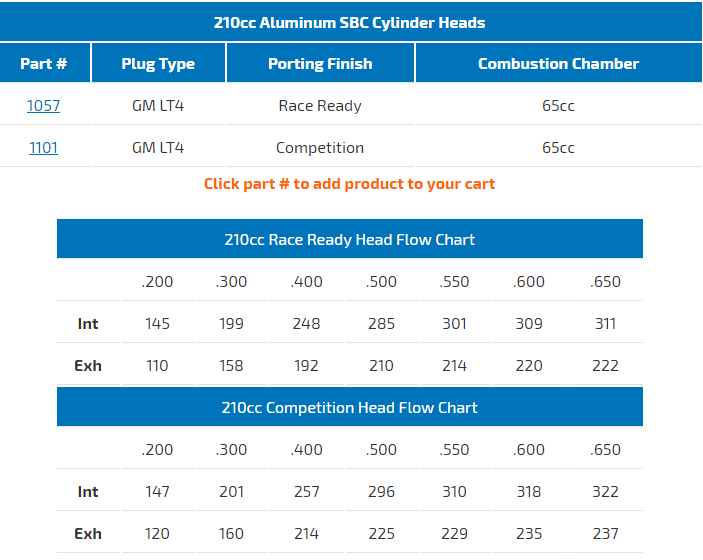

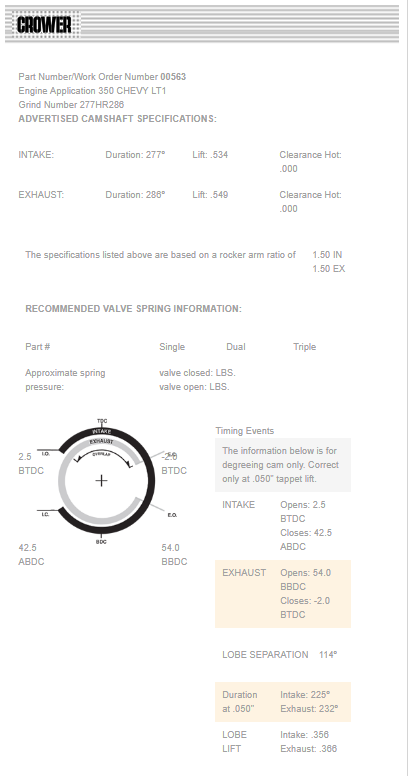

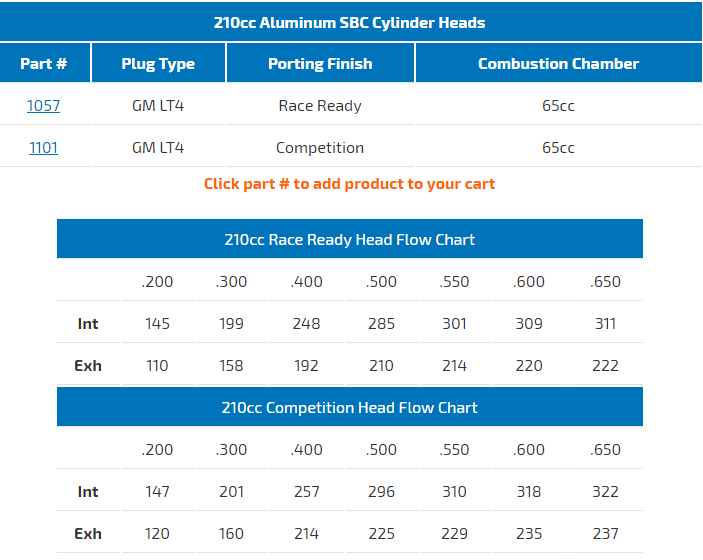

Id start with a 396 stroker kit, with a 4340 forged crank, and forged pistons and 210cc afr LT1 heads. Id use the melrose headers and exhaust, Id select 8:1 forged dished pistons because Id want to use a pro charger super charger and the crower roller cam linked below.

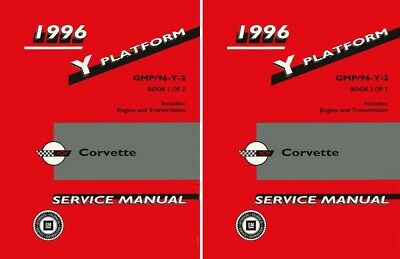

as with any corvette BUY THE CORRECT YEAR FACTORY SHOP MANUAL

related linked info,

read the links for related useful info

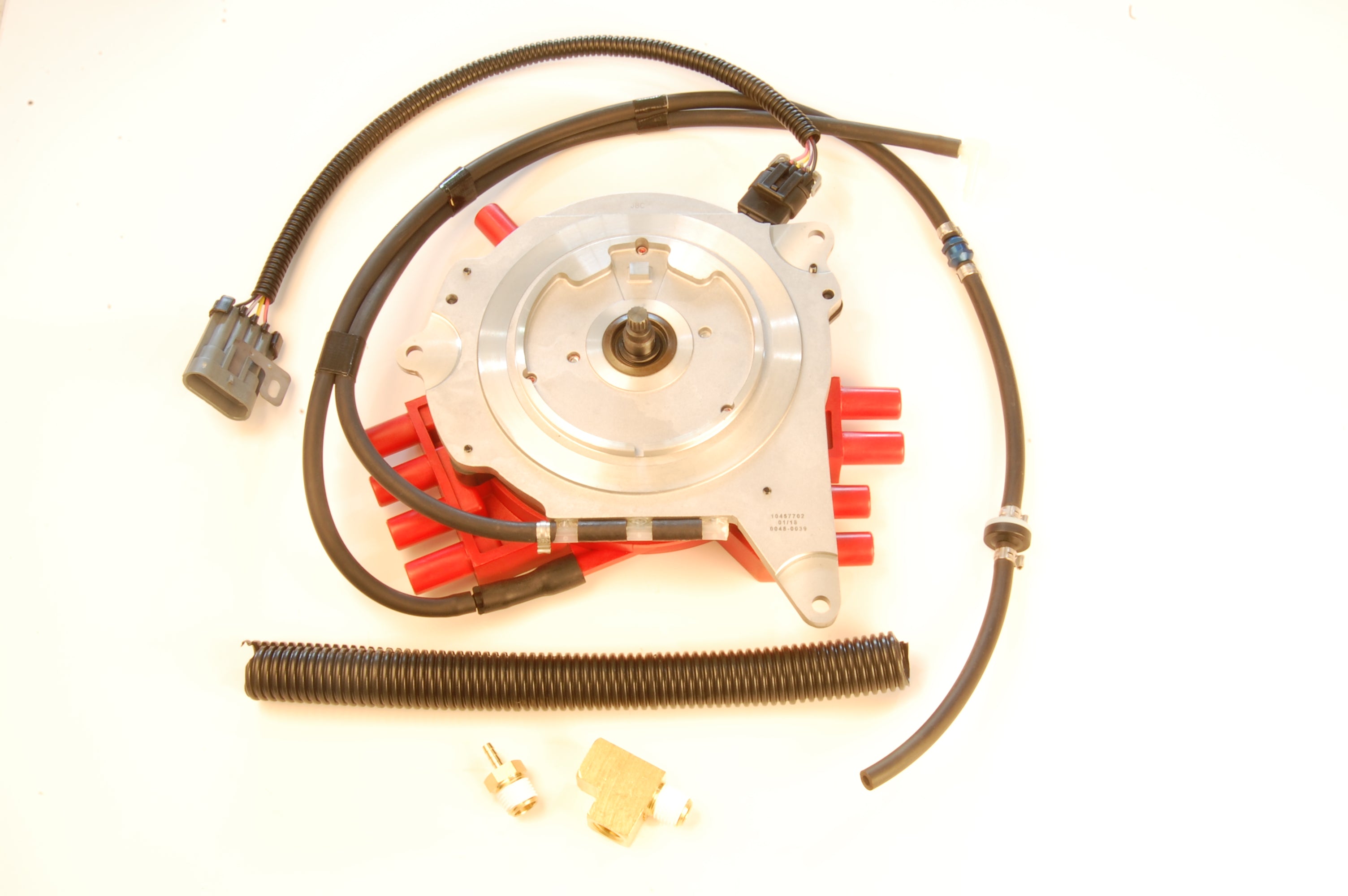

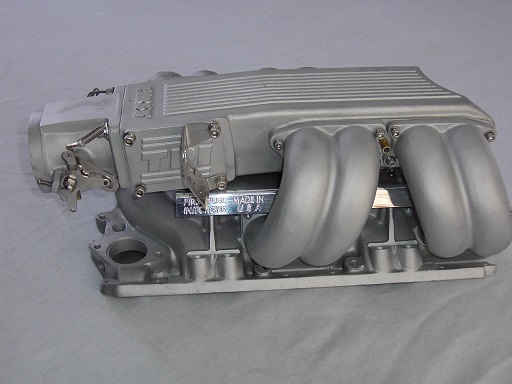

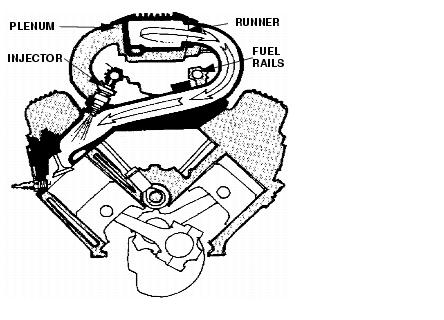

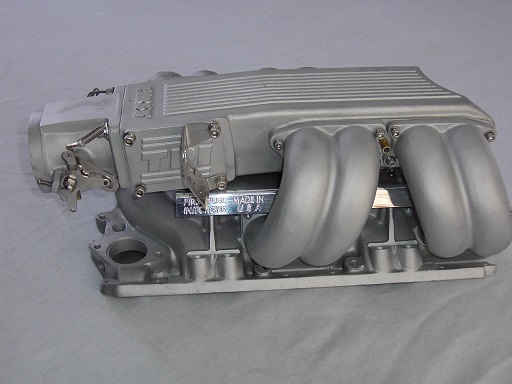

notice the short LT1 oil pump drive bolts under the intake to the block casting, these are available in metal or plastic, obviously plastic is weaker and there's NO HOLE IN THE LT1 INTAKE, for a distributor in most versions notice the full length mallory version is a direct distributor replacement REQUIRING the hole in the intake to be alined and bolted, into place

THE first intake WILL REQUIRE A BRASS FREEZE PLUG INSERT WHERE THE DISTRIBUTOR NORMALLY MOUNTS TO PREVENT LIFTER GALLERY OIL LOSS

http://garage.grumpysperformance.co...c-gen-1-parts-compatibility.13439/#post-69777

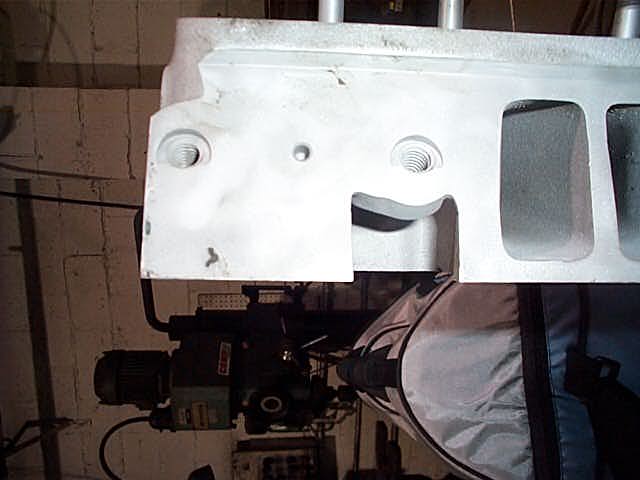

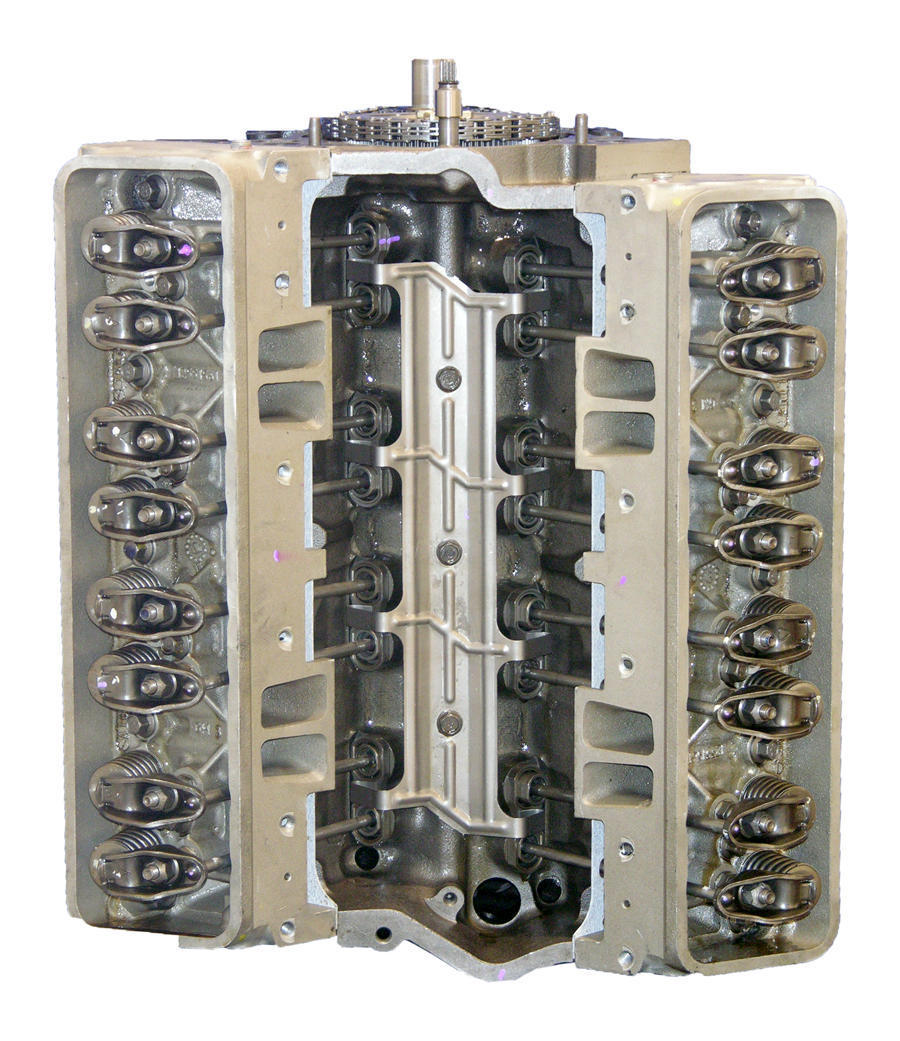

Pic one, is a Lt1 head, notice that the bolt angle is not flush with the intake face.

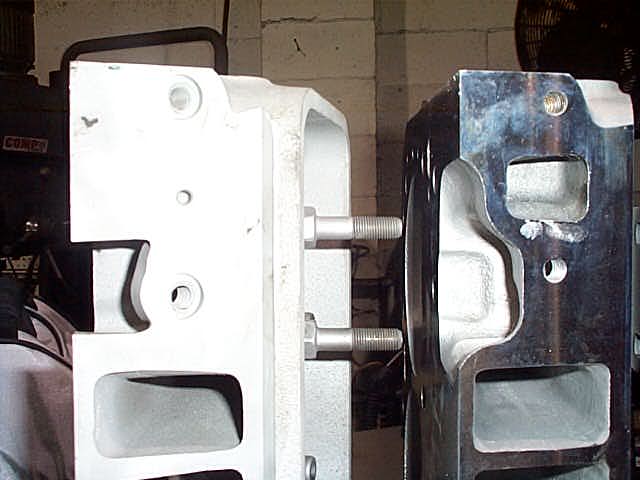

Now here is the same head next to a standard SBC head, notice the bolt angle as compared to the SBC gen 1 head, also notice the spacing is different between the two heads. LT1 head is on the left, SBC GEN1 head is on the right. Also notice there is no water jacket on the intake face of the LT1

Here is a SBC GEN1 head next to the LT1 head..This is the deck surface, notice all the water jacket openings are different..SBC Gen1 head is on the left, LT1 on the right

Now there two are for the vortec head, notice that the bolts are even more of an angle than the LT1, when you bolt this intake on, the bolts are facing straight down, also notice there are only 4 bolts per head on the intake, there isnt any bolt holes in the middle

http://www.corvetteactioncenter.com/specs/c4/1996/lt1lt4.html

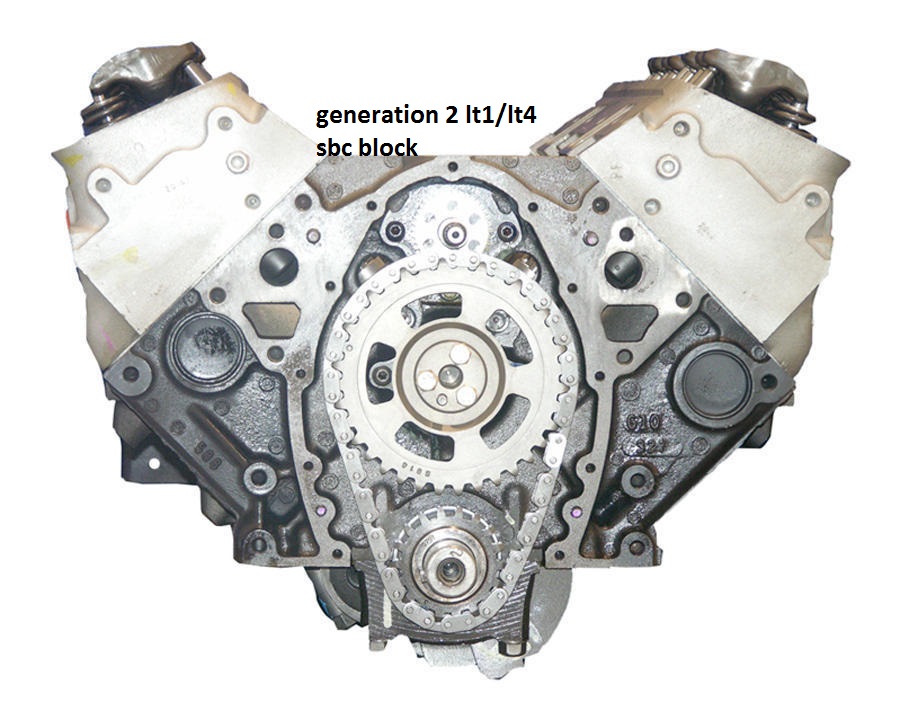

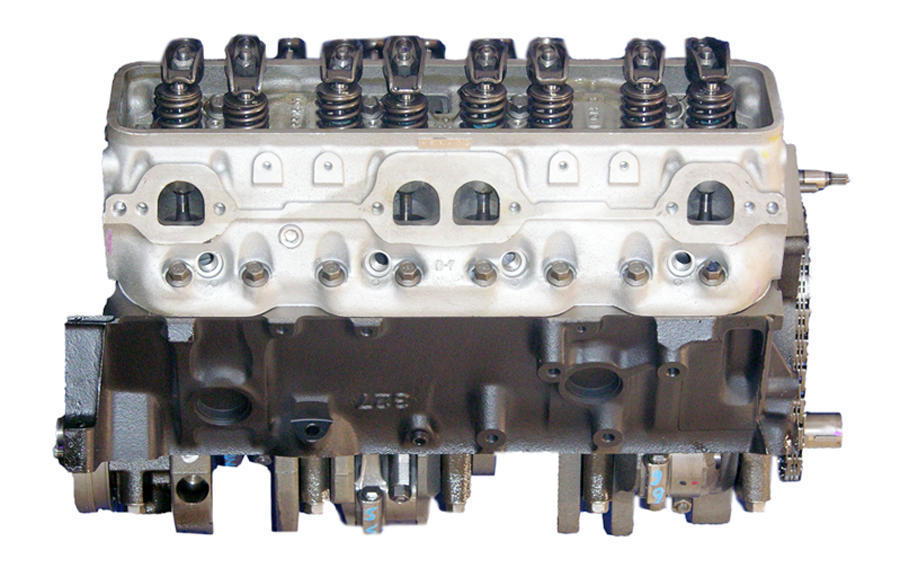

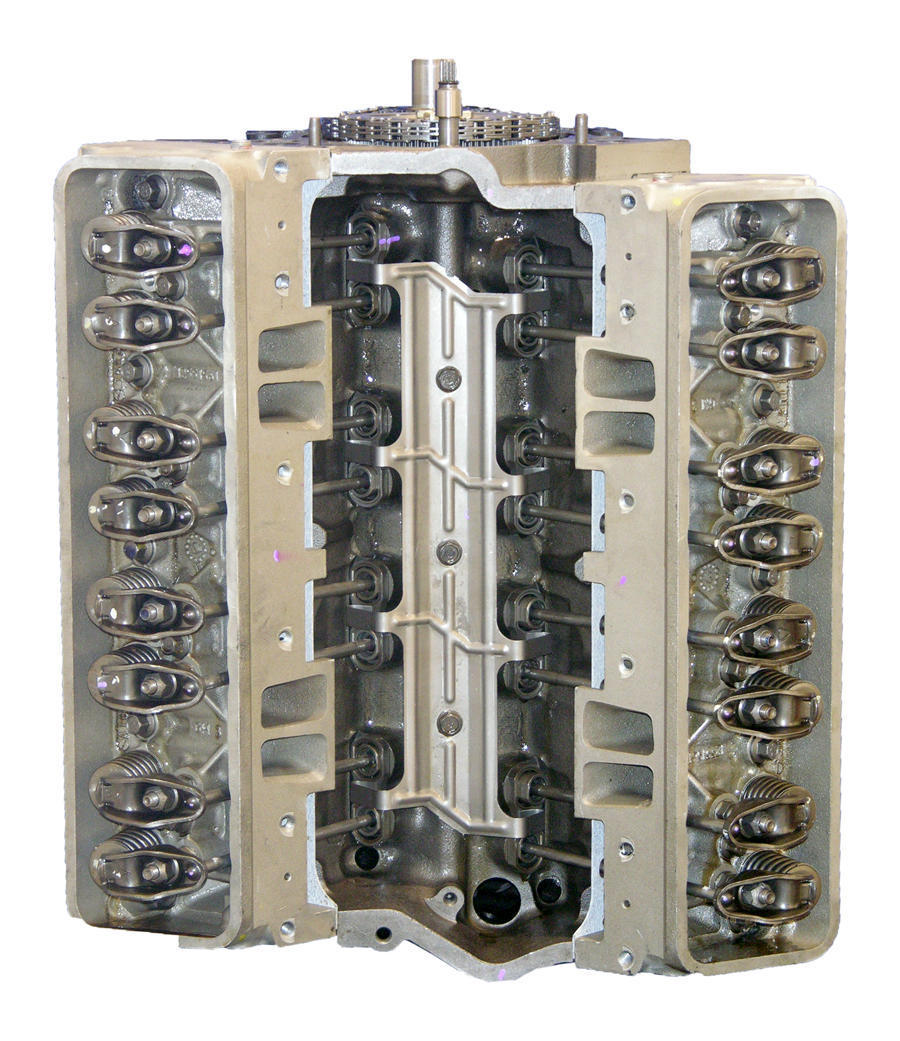

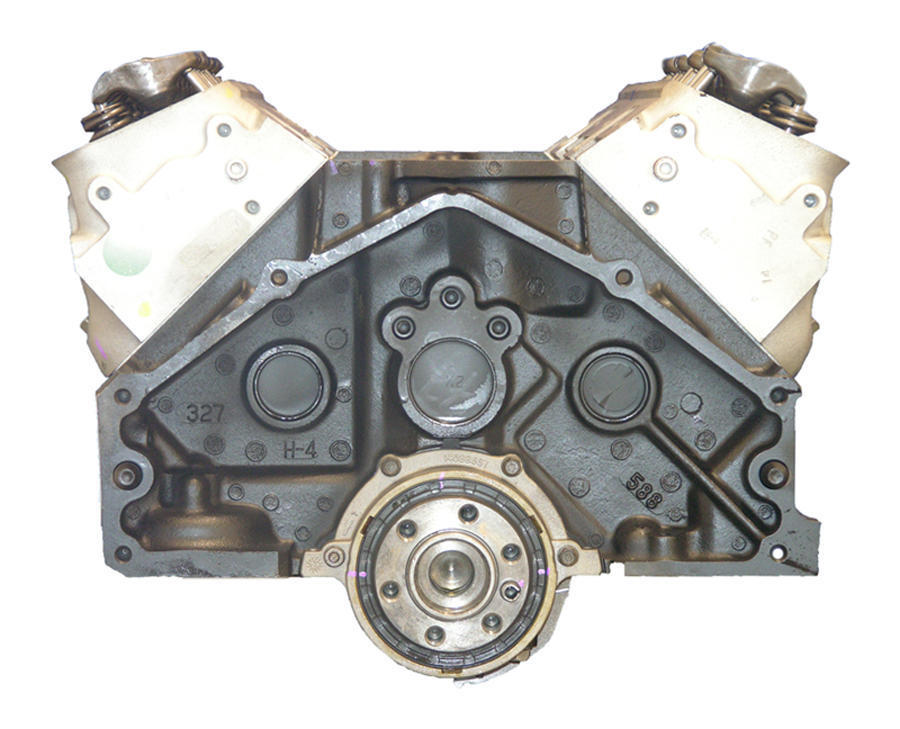

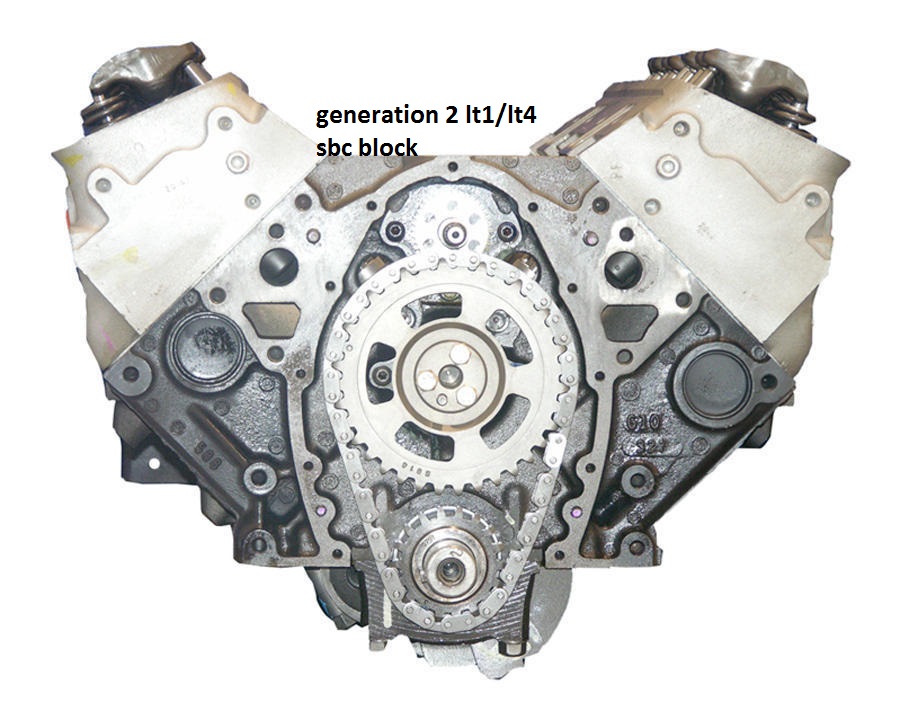

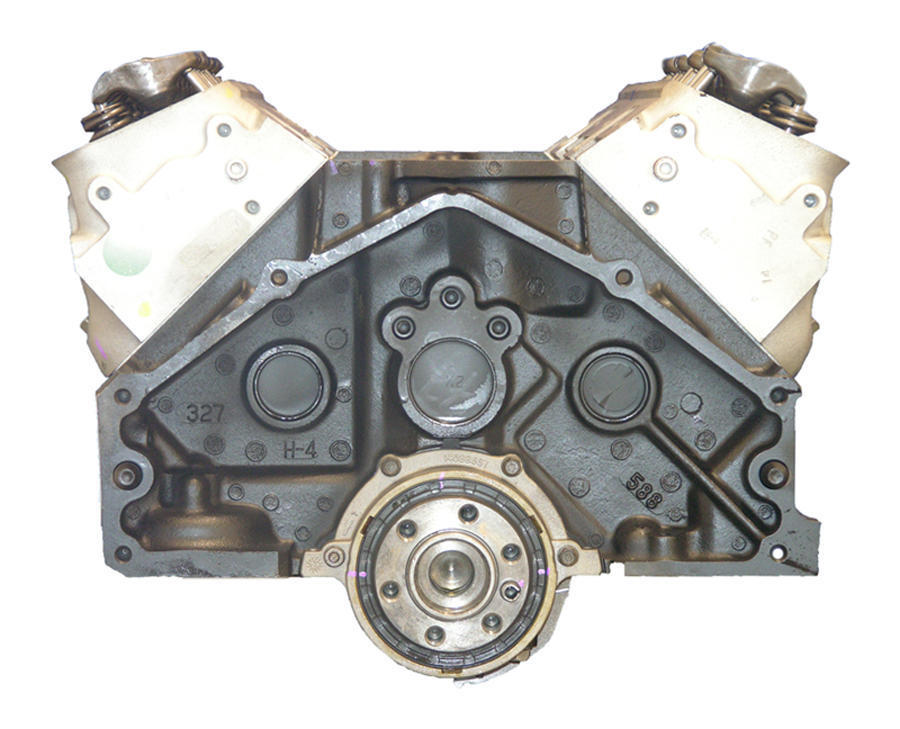

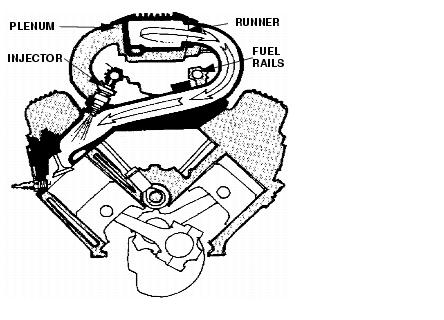

the later GEN2 LT!/LT4 reverse coolant flow block (ABOVE) differs from the first gen SBC

the LT1/LT4 second gen SBC engine was standard in the 1992-1996 corvette

(4)FIRST SELLS A LT1/4 LARGE PORT INTAKE IF YOU WANT LONGER INTAKE RUNNER INTAKE DESIGN

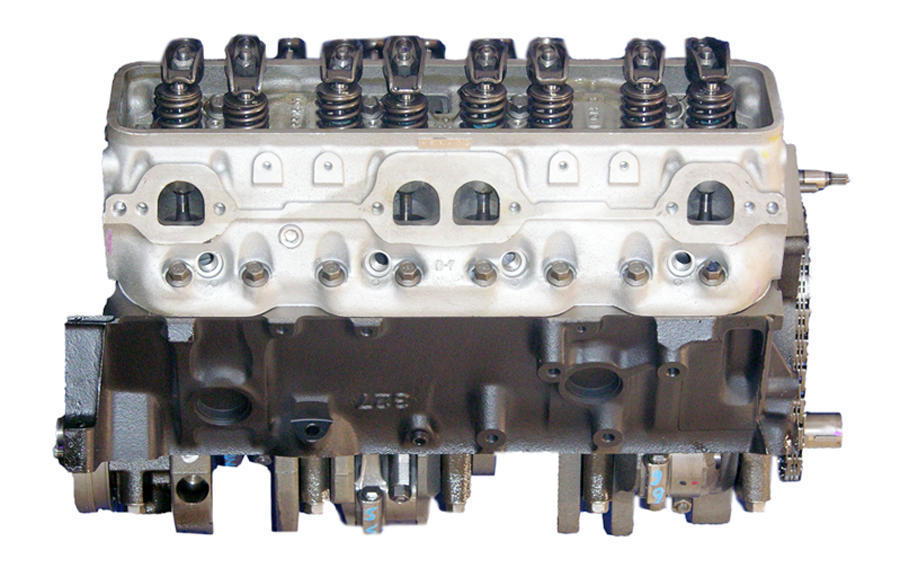

look carefully at the first gen SBC block below

increasing the lt1-lt4 350 displacement to 383-396 with a stroker crank is easily worth an additional 40-50 ft lbs and 50 hp , especially if youve added better flowing aftermarket heads and headers with a low restriction exhaust/

(6)http://www.melrosecorvette.com/1992-1996-lt1-lt4-corvette-header-system/

lt1mel.jpg

http://www.superchevy.com/how-to/en...t-1-aiming-for-600-plus-hp-with-a-396-gen-ii/

http://www.enginebuildermag.com/2000/04/rebuilding-the-chevrolet-lt1-engine/

https://corvetteparts.com/item/engine-cooling-system-rubber-hose-set-lt1-lt4-1995-1996

http://www.superchevy.com/how-to/en...-475-horsepower-lt4-powerhouse-engine-part-1/

http://www.superchevy.com/how-to/en...-475-horsepower-lt4-powerhouse-engine-part-2/

http://garage.grumpysperformance.co...t1-lt4-1992-96-corvette-engine-related.14574/

http://www.superchevy.com/how-to/en...no-testing-new-mods-for-the-lt1-motor-part-2/

http://www.enginebuildermag.com/1999/09/rebuilding-the-chevrolet-lt1-engine-2/

(5)https://www.crower.com/chevy-lt1-hydraulic-roller-cam-7025.html

http://hotrodenginetech.com/383-chevy-beyond-the-crate/

AIR FLOW RESEARCH SELLS SEVERAL much IMPROVED CYLINDER HEADS

the 210cc port size seems to have worked exceptionally well

if matched to a decent roller cam, and matching compression,

and yes to get the full benefit youll want a 3000-3200 rpm stall converter ,

add a trans fluid cooler and a 3.73:1 rear gear in the differential.

yes you'll need to swap too larger injectors and the size required can be accurately calculated based on the intended hp required.

Id suggest 1.6:1 roller rockers with 7/16" stud hole

https://www.injectorrx.com/fuel-inj...njector-calculators/injector-size-calculator/

because Id be trying for about 600-650 hp a 62 lb injector would be my choice on a supercharged 396 LT4

(1)http://www.airflowresearch.com/210cc-sbc-lt4-race-cylinder-head/

https://www.skipwhiteperformance.co...1pc-rms-king-bearings-included-lt1-kit_87489/

http://www.airflowresearch.com/chevy/sbc-eliminator-23-lt1-cylinder-head/

https://www.nookandtranny.com/Info_LT1.html

(3) http://garage.grumpysperformance.com/index.php?threads/first-intake-lt1-build.11781/

https://www.corvsport.com/1996-c4-corvette/

https://www.corvetteforum.com/forums/c4-tech-performance/3165200-supercharging-an-lt1-corvette.html

(2)

https://www.procharger.com/automoti...l-motors/corvette/1996-92-corvette-c4-lt1-lt4

http://www.grandsportregistry.com/lt1vslt4.htm

http://www.hotrod.com/articles/ccrp-0909-lt1-engine-build/

related printed reference info.

I was asked to propose a lt1-4 performance build

Id start with a 396 stroker kit, with a 4340 forged crank, and forged pistons and 210cc afr LT1 heads. Id use the melrose headers and exhaust, Id select 8:1 forged dished pistons because Id want to use a pro charger super charger and the crower roller cam linked below.

as with any corvette BUY THE CORRECT YEAR FACTORY SHOP MANUAL

1996 Corvette Shop Service Repair Manual Book Engine Drivetrain Electrical OEM | eBay

Body, Chassis, Engine, Drivetrain & Electrical. Physical Paper Manual! Loaded with diagrams & illustrations to help disassemble, repair & reassemble various components.

www.ebay.com

LT1 cooling info

READ THIS THREAD ALSO http://shbox.com/1/component_location_views.html http://garage.grumpysperformance.com/index.php?threads/convert-gen-i-sbc-to-reverse-flow-cooling.6099/ http://www.chevyhardcore.com/news/reverse-flow-cooling-is-changing-your-small-block-worth-the-effort/...

garage.grumpysperformance.com

lt1 vs lt4 corvette engine parts differences & useful links

failing to read through the links and sub-links on this web site is always a bad idea http://www.grandsportregistry.com/lt1vslt4.htm http://www.enginebuildermag.com/1999/09/rebuilding-the-chevrolet-lt1-engine-2/ http://www.hotrod.com/articles/ccrp-0909-lt1-engine-build/...

garage.grumpysperformance.com

related linked info,

read the links for related useful info

notice the short LT1 oil pump drive bolts under the intake to the block casting, these are available in metal or plastic, obviously plastic is weaker and there's NO HOLE IN THE LT1 INTAKE, for a distributor in most versions notice the full length mallory version is a direct distributor replacement REQUIRING the hole in the intake to be alined and bolted, into place

THE first intake WILL REQUIRE A BRASS FREEZE PLUG INSERT WHERE THE DISTRIBUTOR NORMALLY MOUNTS TO PREVENT LIFTER GALLERY OIL LOSS

http://garage.grumpysperformance.co...c-gen-1-parts-compatibility.13439/#post-69777

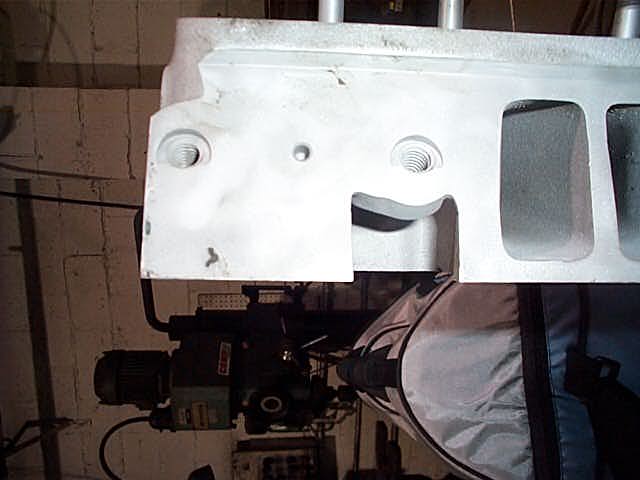

Pic one, is a Lt1 head, notice that the bolt angle is not flush with the intake face.

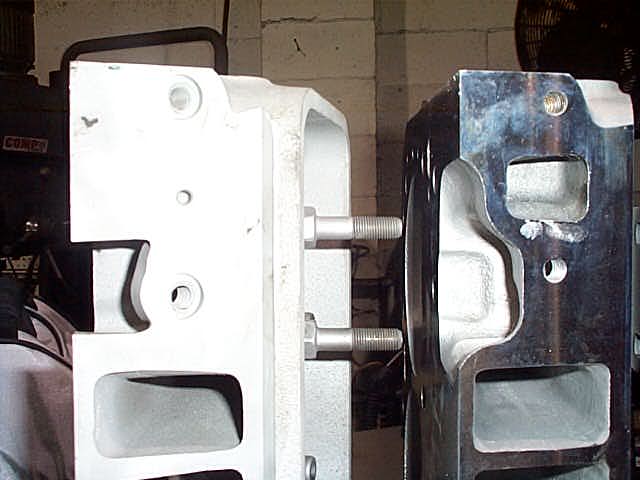

Now here is the same head next to a standard SBC head, notice the bolt angle as compared to the SBC gen 1 head, also notice the spacing is different between the two heads. LT1 head is on the left, SBC GEN1 head is on the right. Also notice there is no water jacket on the intake face of the LT1

Here is a SBC GEN1 head next to the LT1 head..This is the deck surface, notice all the water jacket openings are different..SBC Gen1 head is on the left, LT1 on the right

Now there two are for the vortec head, notice that the bolts are even more of an angle than the LT1, when you bolt this intake on, the bolts are facing straight down, also notice there are only 4 bolts per head on the intake, there isnt any bolt holes in the middle

http://www.corvetteactioncenter.com/specs/c4/1996/lt1lt4.html

the later GEN2 LT!/LT4 reverse coolant flow block (ABOVE) differs from the first gen SBC

the LT1/LT4 second gen SBC engine was standard in the 1992-1996 corvette

(4)FIRST SELLS A LT1/4 LARGE PORT INTAKE IF YOU WANT LONGER INTAKE RUNNER INTAKE DESIGN

look carefully at the first gen SBC block below

increasing the lt1-lt4 350 displacement to 383-396 with a stroker crank is easily worth an additional 40-50 ft lbs and 50 hp , especially if youve added better flowing aftermarket heads and headers with a low restriction exhaust/

(6)http://www.melrosecorvette.com/1992-1996-lt1-lt4-corvette-header-system/

lt1mel.jpg

http://www.superchevy.com/how-to/en...t-1-aiming-for-600-plus-hp-with-a-396-gen-ii/

http://www.enginebuildermag.com/2000/04/rebuilding-the-chevrolet-lt1-engine/

https://corvetteparts.com/item/engine-cooling-system-rubber-hose-set-lt1-lt4-1995-1996

http://www.superchevy.com/how-to/en...-475-horsepower-lt4-powerhouse-engine-part-1/

http://www.superchevy.com/how-to/en...-475-horsepower-lt4-powerhouse-engine-part-2/

http://garage.grumpysperformance.co...t1-lt4-1992-96-corvette-engine-related.14574/

http://www.superchevy.com/how-to/en...no-testing-new-mods-for-the-lt1-motor-part-2/

http://www.enginebuildermag.com/1999/09/rebuilding-the-chevrolet-lt1-engine-2/

(5)https://www.crower.com/chevy-lt1-hydraulic-roller-cam-7025.html

http://hotrodenginetech.com/383-chevy-beyond-the-crate/

AIR FLOW RESEARCH SELLS SEVERAL much IMPROVED CYLINDER HEADS

the 210cc port size seems to have worked exceptionally well

if matched to a decent roller cam, and matching compression,

and yes to get the full benefit youll want a 3000-3200 rpm stall converter ,

add a trans fluid cooler and a 3.73:1 rear gear in the differential.

yes you'll need to swap too larger injectors and the size required can be accurately calculated based on the intended hp required.

Id suggest 1.6:1 roller rockers with 7/16" stud hole

https://www.injectorrx.com/fuel-inj...njector-calculators/injector-size-calculator/

because Id be trying for about 600-650 hp a 62 lb injector would be my choice on a supercharged 396 LT4

(1)http://www.airflowresearch.com/210cc-sbc-lt4-race-cylinder-head/

https://www.skipwhiteperformance.co...1pc-rms-king-bearings-included-lt1-kit_87489/

http://www.airflowresearch.com/chevy/sbc-eliminator-23-lt1-cylinder-head/

https://www.nookandtranny.com/Info_LT1.html

(3) http://garage.grumpysperformance.com/index.php?threads/first-intake-lt1-build.11781/

https://www.corvsport.com/1996-c4-corvette/

https://www.corvetteforum.com/forums/c4-tech-performance/3165200-supercharging-an-lt1-corvette.html

(2)

https://www.procharger.com/automoti...l-motors/corvette/1996-92-corvette-c4-lt1-lt4

http://www.grandsportregistry.com/lt1vslt4.htm

http://www.hotrod.com/articles/ccrp-0909-lt1-engine-build/

Last edited: