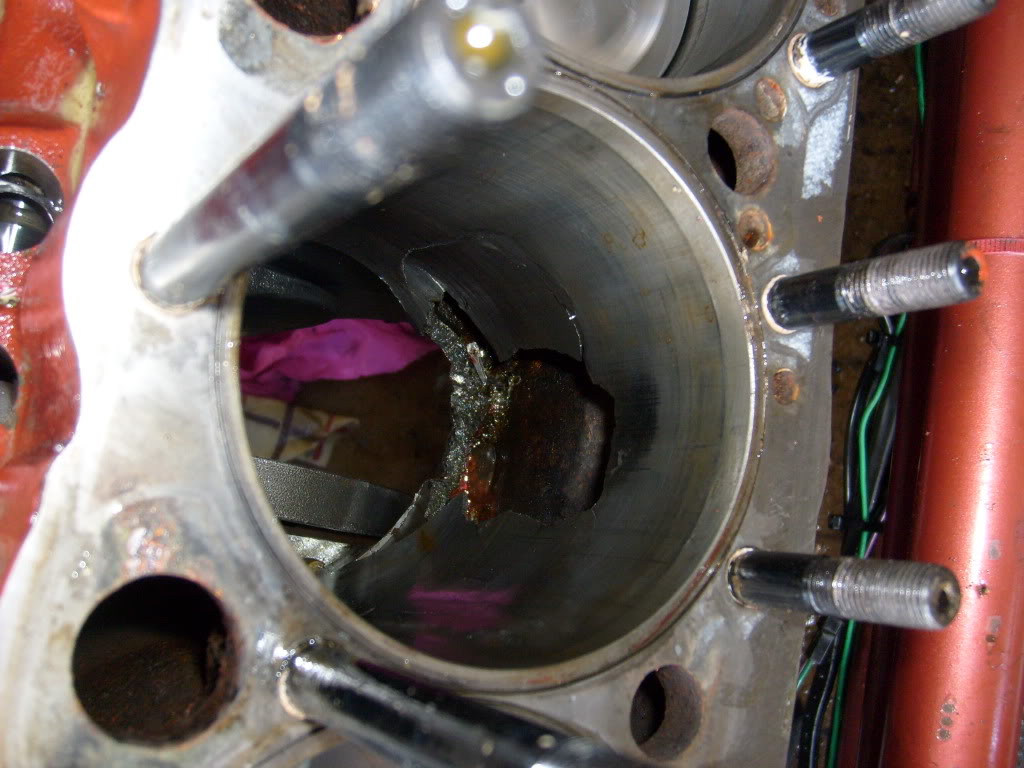

do you have any idea as to the actual cylinder wall thickness after a .060 bore & hone on YOUR block?

If you don,t ID ask the machine shop to sonic test each bore

if its under

.180 Id suggest filling the blocks coolant passage surrounding the bores up to the lower edge of the

BRASS freeze plugs as that helps cylinder wall rigidity and ring seal,

ID strongly suggest use of a 7-8 quart oil pan and windage screen, and arp main studs on the caps sure won,t cost all that much more before its line honed, ID suggest clevite (H) bearings, as they have a fairly hard surface and beveled edges designed for high loads, if its bore wall at any point is under

.120 I'd suggest looking for a different block,as its rather pointless to put hundreds of dollars in machine work and hours of prep work in a block that has a significant chance of eventually cracking under stress.

most guys who are just getting into hot rod engines use OEM production blocks and those work out reasonably well for the average guy who,s idea of a powerful engine is just adding a cam and intake and headers, but once you get into building a real race type engine that exceeds about 500 hp , you will quickly find the machine work costs,and block rigidity issues, with properly preparing a stock block, especially if you add splayed caps ,can easily approach or exceed the cost of the far stronger DART BLOCKS with their much thicker casting and more precise machine work

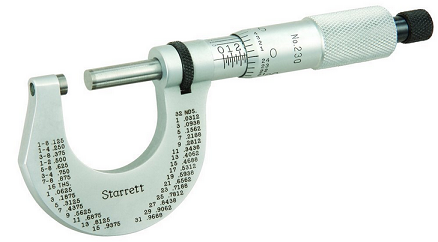

and before you dismiss this friendly advice get out a micrometer or feeler gauge and look at just how thin your sonic test results show your bore wall to be , and remember it will be hit with several hundred PSI pressure thousands of times an hour then think about how long it take you to bend a paper clip back and forth until it fails

these links and the pricing and info in them may help

read these two threads below first

viewtopic.php?f=50&t=321&p=2931&hilit=track+notes+pad#p2931

http://garage.grumpysperformance.co...piston-to-bore-clearance-on-your-block.14251/

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-52469

viewtopic.php?f=51&t=976&p=1706&hilit=epoxy+shot#p1706

http://www.rebelrebuilders.com/machine_work.htm

http://www.circletrack.com/howto/4661/index.html

http://www.rpmmachine.com/machine-work.shtml

http://www.steveschmidtracing.com/shop- ... rices.html

http://www.budsmachine.com/pdf/budspricesheet_0508.pdf

viewtopic.php?f=54&t=2187

viewtopic.php?f=51&t=125

viewtopic.php?f=54&t=65

I think youll find these are about ball park prices for labor, you may get better or worse pricing, but its the QUALITY of the work done more than the pricing thats the great concern, as you can get more money but careless machine work quickly ruins parts

Machine Shop - Labor Prices

Head Work

V-8 Valve Grind (Pr) $120.00

Pro Sportsman Valve Grind & Blend (Pr) $250.00

Competition Valve Grind (Pr) $350.00

Grind Valves (Set) $ 40.00

Back-Cut Valves (Set) $ 20.00

Surface Heads (up to .020) (Ea) $ 25.00

O-Ring Heads (.041 wire) (Pr) $120.00

Cut Heads for Loc-Wire (Pr) $120.00

Cut for Teflon Seals (Pr) $ 32.00

Cut for Large Springs (Pr) $ 32.00

Mill & CC Heads (Pr) $100.00

Clean Assemble Set Spring Height $ 80.00

Cut for Seats (1st seat) $ 30.00

Cut for Add'l Seats (2-7) (Per Head) $ 20.00

Hone Guides (Ea) $ 2.00

Install Guides (Ea) $ 5.00

Mill Int. or Ex. Side (Per Surface) $ 5.00

Angle Mill Head Correct Int. Side & Ream Head Bolt Holes $200.00

Clean Heads (Ea) $ 20.00

Custom Machine Work (Hr) $ 60.00

Head Repair - Aluminum Heads Per Quote

Block Work

Bore V-8 Block (up to .060) $120.00

Pro Sportsman Hone (with plate) $250.00

Competition Hone (with plate) $350.00

Finishing of Custom Unfinished Race Block Per Quote

Align Hone $125.00

Block True/Square Deck (up to .020) $185.00

Deck Heights over.020 Removed By Quote

Install 3 center 4 Bolts Caps $350.00

Install 5 Caps $500.00

Sleeve Cylinder Bores (Ea) $ 60.00

Install Cam Bearings $ 30.00

Machine / Align Bore for Big Ford Cam Bearings $600.00

Big Ford Bearings $125.00

Hone Small End to Float Pin (Ea) $ 5.00

Hone Big End to Resize (Ea) $ 6.00

Rebuild Rods (Ea) $ 10.00

Replace & Hone Pin Bushings (Ea) $ 10.00

Balancing V-8 Assemblies (Heavy Metal to Balance Additional Time & Material) $250.00

Balancing Flywheel & Pressure Plate $ 75.00

Pro Sportsman Porting Work

Gasket Match Intake Side (Pr) $125.00

Gasket Match Exhaust Side (Pr) $125.00

Bowl Blend (Pr) $150.00

Polish Chambers (Pr) $285.00

Intake Match, Bowl Blend, Polish Chamber& Exhaust Port (Pr) $650.00

Full Competition Port & Polish (Pr) $1,100.00

Port Welding to Reshape (Per Hr.) $ 80.00

Crank Grinding

Index Rods - Grind Mains $100.00

Polish Only $ 50.00

Offset Grind for Stroker $250.00

BTW heres some quoted cost another guy posted

Hello all, just got a call back from my machinist. The following are the prices for preping my 1988 454 4 bolt main BLOCK. Looking for opinions on his prices.

Freeze pugs brass $20.00

Freeze plug install $ 15.00

Hot tank block $75.00

Clean oil gallies $ 15.00

Bore .030 over & torque plate hone $350.00

Cam bearings $ 30.00

Cam bearing remove & install $75.00

Line bore inspection $25.00

Mill/deck block off mains if nec. $ 225.00

Remove one broken head bolt clean existing thread $35.00

Install insert if threads not good $50.00

Total $ 915.00 ??????