a .032 end gap is nothing to worry about, generally most ring end gaps are that or larger

yes ring endgaps are suggested nearer to .020-.026 , even a .o45 end gap,

will have almost zero negative effect,

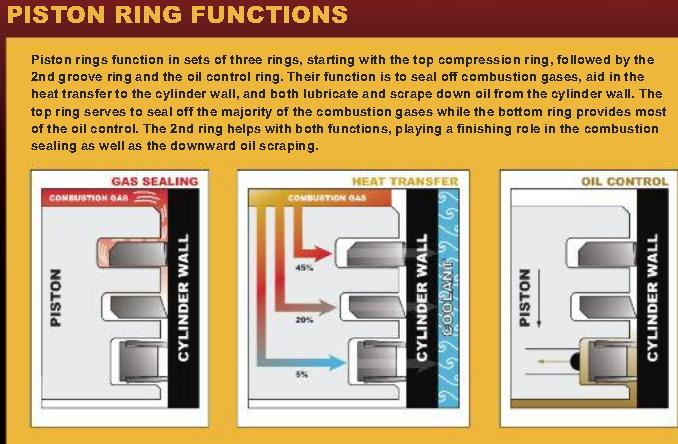

remember the compression and power stroke combined,

are accomplished a a very small fraction of a second,

and not much compressed gas can get through the gap between ring ends,

in that small fraction of a second, even if some does the second compression ring ,

also reduces combustion chamber potential leakage.

Id point out that a piston to bore side clearance is about .0017 or less at operating temps

the ring gap is there because piston rings run hot and expand, that .032 gap will be down under .020 once the engine warms up,

so youll have a potential leak past the rings smaller than a needle diameter ,

trying to pass gas about 9-60 times a second, and that micro volume must get past two more rings

on this web sites you'll find you'll get used to reading links,

in that process you'll learn a great deal,

it makes zero sense to answer

,endless revisions of similar questions, its easier to answer in depth,

and keep all the related info in a few closely related links ,

with sub links, this makes far better use of your time ,

than searching though hundreds of threads each having only bits of related info

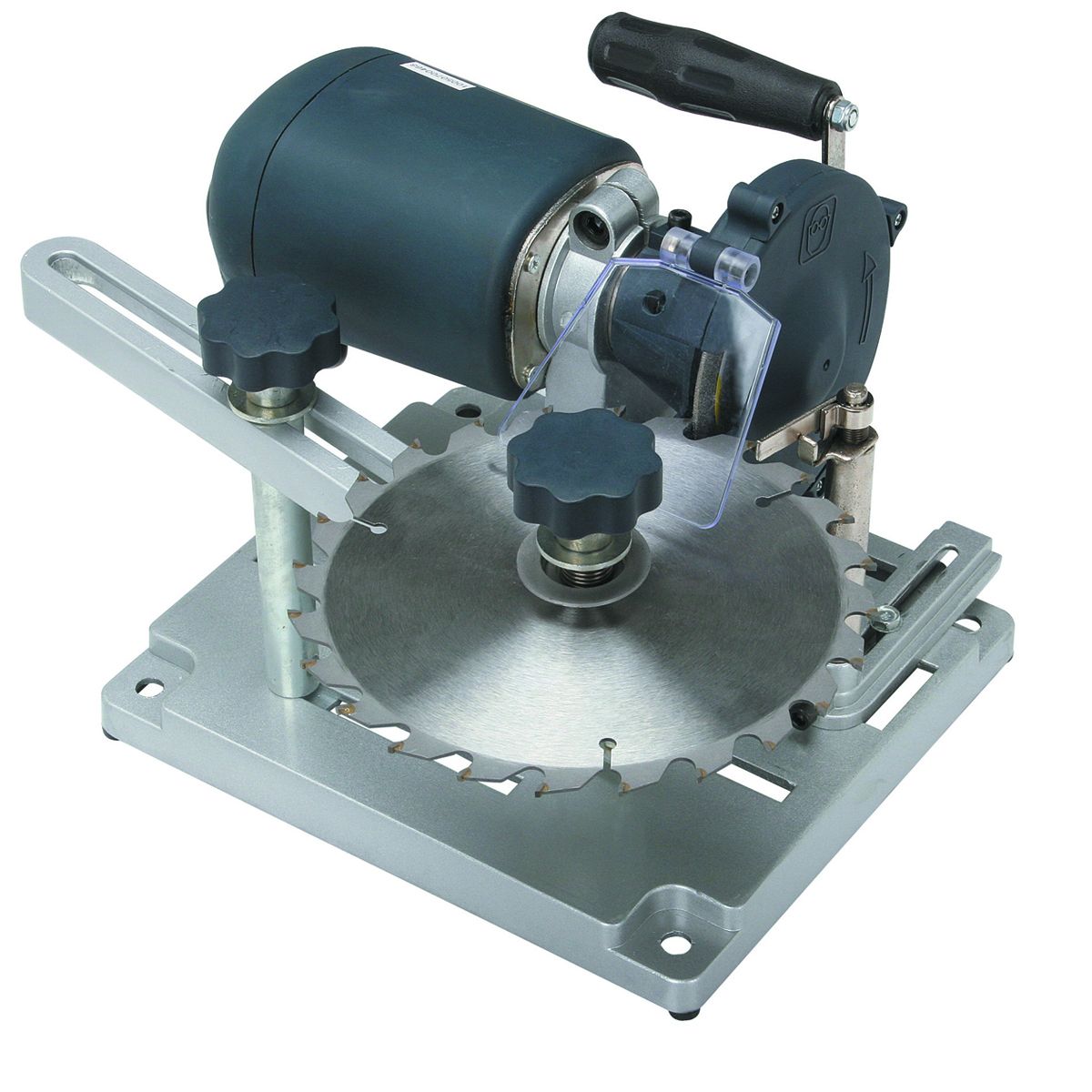

when I started building engines I purchased on of these hand crank, tools,

I rapidly found it had issues in keeping the ring end gaps parallel,

I found a carefully used DREMEL TOOL with cut off wheels and careful measuring to be a reliable route you can use obviously measure very carefully and polish off LESS on the ring end gaps than you think , you need too,

obviously measure very carefully and polish off LESS on the ring end gaps than you think , you need too,

and re-measure carefully and repeat, try to match the chart recommended end gaps

if your end gaps a tiny bit too large its no major issue ,but read and pay attention too the charts and work carefully

https://www.summitracing.com/parts/...MIpuDs0eDf9AIVGIiGCh3VKQvDEAQYAiABEgK8fPD_BwE

Amazing deals on this 120Volt Circular Saw Blade Sharpener at Harbor Freight. Quality tools & low prices.

www.harborfreight.com

This version works great. I added a fourth ring post and slots for all the posts. This lets me position the ring accurately against the grinding face. The platform is 1/4 thick HDPE and is very stiff with a "slippery" surface. Result is the ring can slide easily while still being held securely.

The line is indicative of the wheel face which is parallel to the end of the ring. It's not aligned with anything else like the ring centerline because the ring is not circular when it's in the machine. It becomes circular when it goes into the cylinder.

With this gizmo improvement the results are repeatable, and when the ring is compressed into the cylinder the gap is even.

Amazing deals on this 120Volt Circular Saw Blade Sharpener at Harbor Freight. Quality tools & low prices.

www.harborfreight.com

View attachment 16262View attachment 16263

proform sells a power upgrade tool,

now I work mostly on BBC engines and I built a custom ring square tool , out of cheap and easy to find PVC plumbing pipe adapters, (look at the pictures, rick posted,)remember it does not need to be a perfect bore diam. match too square the rings , but of course it must fit down the bore, too use when gapping rings,and on the big block engines you can build and use a custom tool like this without reducing the diam., but Rick went the extra step and built a very similar tool for his SBC projects engine

used carefully, and with some experience,

a dremel tool cut-off wheel can do a decent job at cutting ring end gaps

read thru these related threads, posted below, youll find a good deal of info, on installing pistons and rings.

http://garage.grumpysperformance.com/index.php?threads/another-rings-end-gap-question.14994/

http://garage.grumpysperformance.co...ng-and-basic-piston-ring-info-youll-need.509/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.co...piston-to-bore-clearance-on-your-block.14251/

http://garage.grumpysperformance.com/index.php?threads/maximizing-piston-to-bore-ring-seal.3897/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.co...ng-piston-ring-grooves-and-related-info.1797/

http://garage.grumpysperformance.com/index.php?threads/piston-rings-related-info.2795/