x infektid x

New Member

OK here goes.

406 from Ohio crankshaft. forged everything and need a cam to make it all work ..

9.5 on comp 6 inch rods,dart 215 aluminum heads, and hydraulic rollers.

the first question is ring gap. its at .019 on the top and second is sat .015. ok for an sc or no?

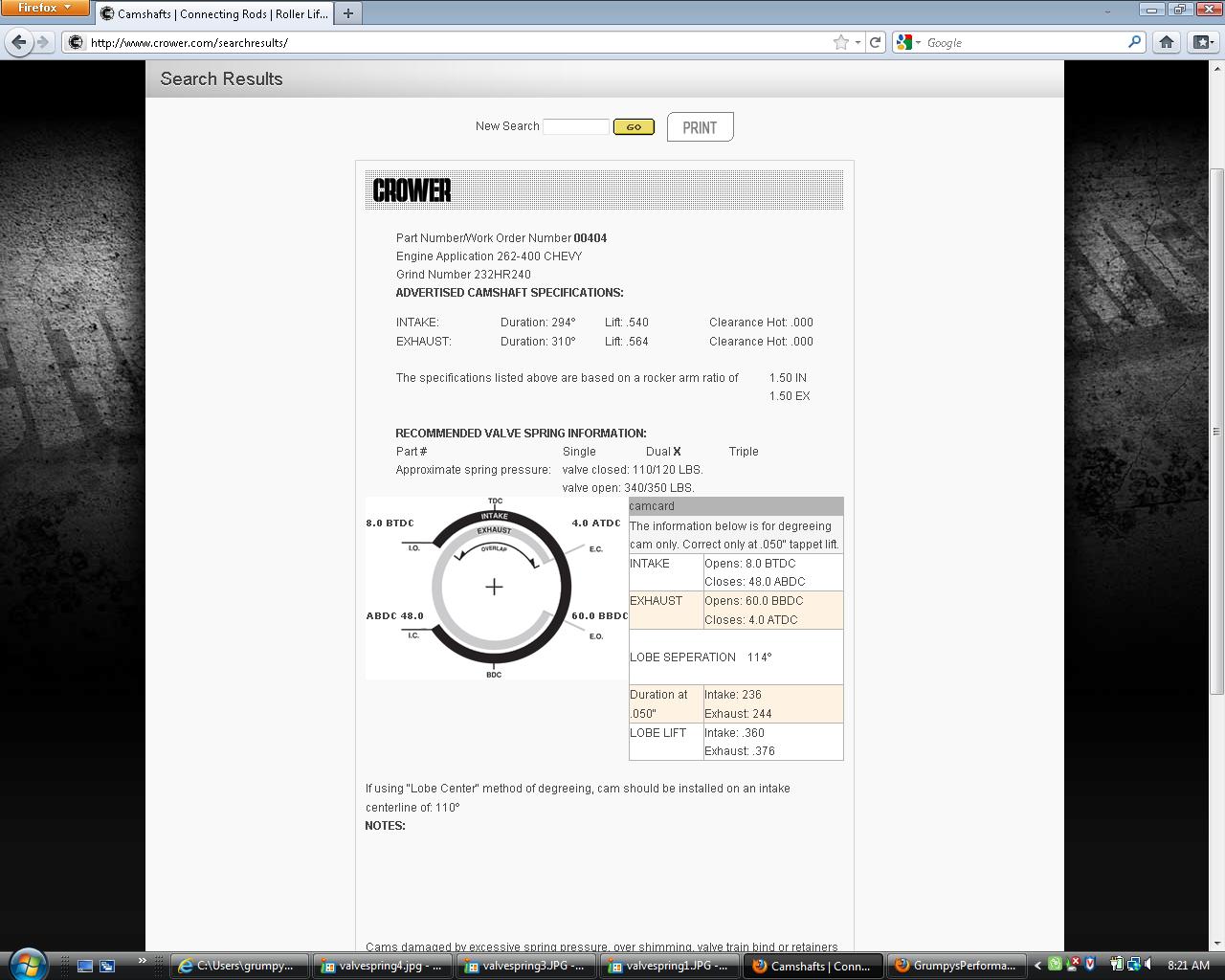

second is in cam selection . first sc engine and no idea as to what it needs to run right.

its a daily driven car and looking for all that i can get (within reason for a daily driver)

mileage is ot may be an issue but not really. hp needs gas to work i do understand that . i work 5 min from home .

700r4 tranny and stock everything else on a 85 Monte Carlo(peg leg rear end. dont ask me why ,i dunno)

ideas on cam is what i am really looking for.

pro-charger told me the d1scis what they recommend at 8 psi without an intercooler and 10 psi with one and a recommend lobe separation of 112-114 ,but call cam maker to be sure about whats best

i told pro-charger i want or am lookin at about 600 hp. do i want to much or is that easy to do on forced induction.(i know it is but there are always trade offs)

oh yeah its a standard dart shp block if that help. if u need info let me know as i have all the stuff they sent to me on hand

406 from Ohio crankshaft. forged everything and need a cam to make it all work ..

9.5 on comp 6 inch rods,dart 215 aluminum heads, and hydraulic rollers.

the first question is ring gap. its at .019 on the top and second is sat .015. ok for an sc or no?

second is in cam selection . first sc engine and no idea as to what it needs to run right.

its a daily driven car and looking for all that i can get (within reason for a daily driver)

mileage is ot may be an issue but not really. hp needs gas to work i do understand that . i work 5 min from home .

700r4 tranny and stock everything else on a 85 Monte Carlo(peg leg rear end. dont ask me why ,i dunno)

ideas on cam is what i am really looking for.

pro-charger told me the d1scis what they recommend at 8 psi without an intercooler and 10 psi with one and a recommend lobe separation of 112-114 ,but call cam maker to be sure about whats best

i told pro-charger i want or am lookin at about 600 hp. do i want to much or is that easy to do on forced induction.(i know it is but there are always trade offs)

oh yeah its a standard dart shp block if that help. if u need info let me know as i have all the stuff they sent to me on hand