bboman said:Hi All,

I have a friend's '63 Bonneville for a project: replaced original tired 389+hydramatic with sbc400+th350.

The engine+tranny+accessories setup was purchased from a reliable looking guy, and was on his car on the street until last fall.

The engine had a light overhaul: new bottom bearings, piston rings, chain, oil pump, cam+lifters+pushrods, aluminium heads, headers, removed mech fuel pump, etc. No part was carried to machine shop. While engine apart everything seemed to be ok, just normal wear.

I got poncho engine out and the chevy setup adapted to the car; 1st fire up there was a loud knock from somewhere the sbc. The friend team's mutual verdict was a rod bearing. At that time the car did not have oil pressure gauge to verify.

Engine came out to fix rod bearings and crank. There was wear and scrathes on two new rod bearings, some debris was loosed off from the oil channel. The scratches were enough to think that's the root cause, and no other engine part came out at that time, to save money and labor on the gaskets etc. Rod journals were turned to 0.01" at machine shop, mains polished. Put it all together with new bearings.

The knock is still there. Please see and hear the youtube-video. Now we have oil pressure gauge with good readings, on the video the engine is warm.

a knock sound was and is there from the very first start up, from the first second. And the sound is there cold or hot, all the time.

Since the simplicity of these dinosaur era v8's there shouldn't be many places left to hunt... lifters, pushrods, cam, cam bearings...?

Would not want to spend another 20h pulling and tearing the engine again if not necessary... ideas and comments are welcome..

thanks.

like in most cases its a case of isolate and test,

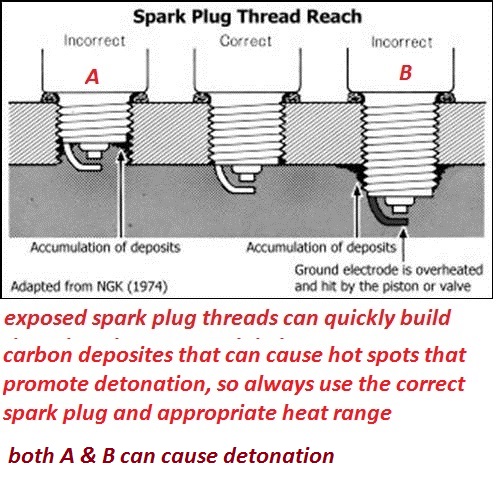

Id suggest you turn the engine OFF and pull the spark plugs out and check that they are not the wrong ones for the application, showing indications they extend too far into the combustion chambers, the pistons may be touching the plug threads at TDC

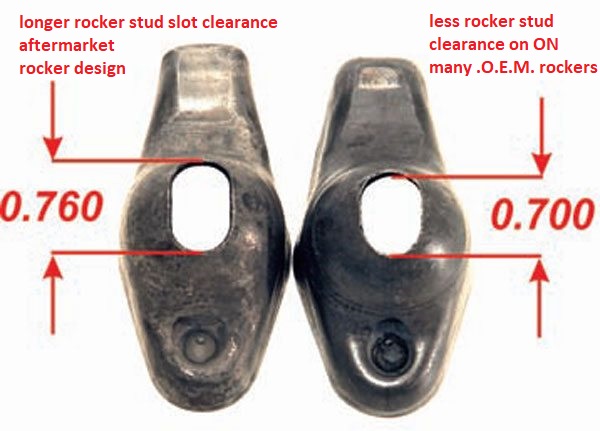

first quick test, push down on each rocker with the heel of your hand as it idles and listen and feel for a change in sound and less than smooth rocker movement, you could be dealing with a burnt rocker ball, or rocker binding on the rocker stud due to clearance issues or even several, lets verify or eliminate that possibility.

second test

get rubber gloves and individually pull each spark plug wire off, listen for a noticeable change in sound to locate defective cylinder (s)

third test

do a compression test to verify you have not bent one or more valves

fourth test

if you have access to a decent INFRARED THERMOMETER

get it out and use it too check each exhaust for temp differences

infrared thermometers are a very useful tool to track down issues with tuning, or mal functioning sensors , without verified facts your guessing.

this is the most consistently accurate I.R temp gun I've used for testing[/img]

http://www.testequipmentdepot.com/e...1100200223789&utm_content=All Extech Products

INFRARED TEMP GUN

FIFTH TEST

rotate the crank before you pull the oil pan, and see if it shows and tendency to bind, and once the oil pans off, very closely inspect it,internally,

and check the dip stick and oil pump pick-up,and windage tray,

for evidence of contact with rotating assembly

Id sure try removing the oil pan, too verify the crank rotating assembly,

is not hitting the oil pan ,windage screen, oil pump pick-up,or dip stick

GOOGLE PV-618 and PV-636

a visual inspection tool can be used through spark plug holes and oil pan drain holes

SIXTH TEST

check your flywheel , or FLEX PLATE, clutch,BELL HOUSING and or torque converter bolts are tight and theres nothing hitting the spinning components

related

http://garage.grumpysperformance.com/index.php?threads/infrared-temp-guns.11444/#post-60146

Last edited: