You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

mig or TIG?

- Thread starter grumpyvette

- Start date

GREAT! we ALL START THAT WAY! and it HELPS to PRACTICE, so dive right in, but if you get a chance at getting some experienced welder to give you some tips and hands on training JUMP ON THE CHANCE!

Ive always felt that the brand name welder manufacturers should have made short ,very low cost classes on how to use their equipment available, at most dealers when you buy their equipment, because nothing sells welders as fast as having a buddy show you how well his new welder works.

and the one thing that keeps guys from BUYING a decent welder is not the cost because we all know that if you want something badly enough and its cost is less than a months pay, you'll eventually find a way to afford it!,But with most guys Ive talked with, its the idea that you'll spend the money and not be able to use the equipment, or use it often enough to justify its cost, but once they get some quality instruction it opens up a whole new world, and projects you've never dreamed of doing before start to look possible.

before you own a welder, you buy things like car trailers, welding tables, exhaust systems,accessory brackets,oil pans,traction bars,fence gates, etc. but once you own one you buy steel, aluminum,axles and detailed construction plans, and BUILD stuff better than you could buy,and to YOUR specifications

almost every guy I know that owns a welder bought that welder only after a buddy showed him how easy his welder was to use and how making things was not MAGIC but something almost anyone can do!

besides, theres a great deal of satisfaction in building your own custom oil pans,exhaust systems, accessory brackets or suspension components

TIG WELDERS generally cost a bit more, but once the skills mastered it is, at least in my opinion far superior, but noticeably slower than MIG welding

MIG welders are a bit less expensive but easier to learn on and use but not as versatile or precise

Cut Me Some Slag: Choosing Between MIG and TIG WeldersFROM SUMMIT RACING

As gearheads, we spend our fair share of time contemplating the important things: Ford vs. Chevy, carb’ed vs. fuel injected, skulls vs. flames. But if you’re shopping for a welder, there’s one brainteaser that trumps them all: MIG or TIG?

Whether you’re restoring a classic or prepping your car for the track, chances are good that you’ll need a welder along the way. But before you start stitching together body panels, fabricating custom brackets, or installing a one-off roll cage, you’ll need to pick a welder that’s right for you. Luckily, choosing the right welder is as simple as knowing what materials you’ll be working with and how much welding experience you have.

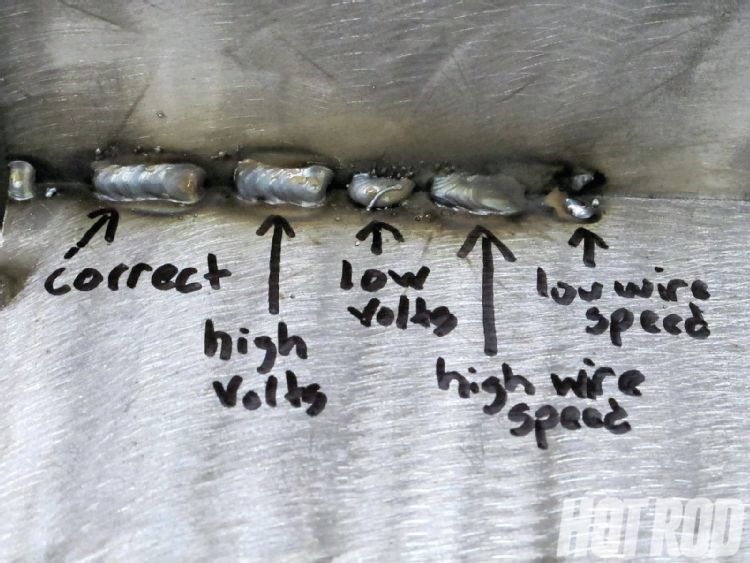

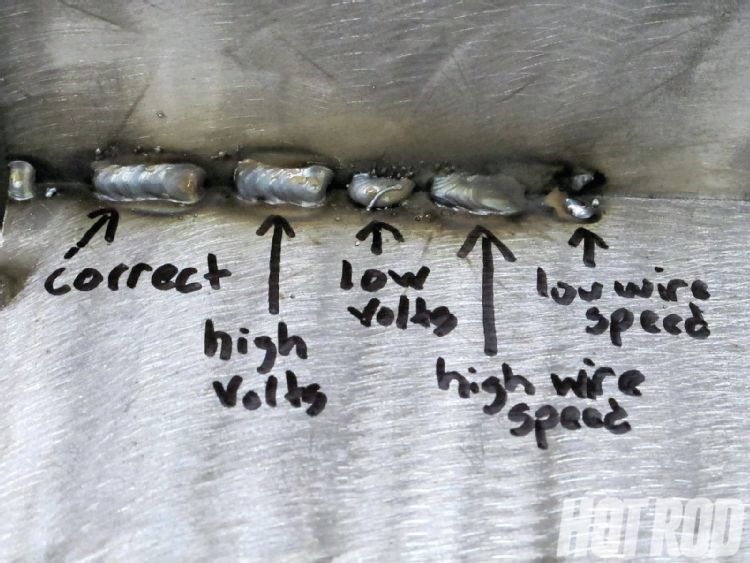

MIG (metal inert gas) welders are a good choice for beginners. They work by feeding a consumable wire electrode and a shielding gas—most commonly argon—through the welding gun and onto the surface to be welded. The wire acts as a filler metal and the gas protects the fresh weld from contamination as it cools.

MIG welders are capable of making strong, clean welds in a single pass but run the risk of creating spatter that’ll require some cleanup after you’re finished. Think of it as a hot glue gun for metal.

A portable 115V MIG welder can operate off of household current and can handle most metals up to 1/8" thick. For metals up to 5/8" thick, a 230V welder is the best choice. Due to temperature constraints, cast iron and aluminum should not be welded with a MIG welder.

For more tips on MIG welding, check out our in-depth tech article, Melding Metal.

TIG (tungsten inert gas) welders can produce a precise weld on any metal, although they’re generally slower and require more experience than a MIG welder. They heat the welding surface with an electric arc produced by a tungsten electrode. Unlike a MIG welder, they don’t require a filler metal, although it can be added by hand if needed. This produces a high-quality weld, free of spatter and smoke.

TIG welding offers an extremely hot, yet precise spark making it ideal for welding magnesium, aluminum, and stainless steel, as well as very thin materials. Just like a MIG welder, the TIG welding gun emits a shielding gas to keep the fresh weld clean.

And remember, whichever welder you choose, always be sure to use the proper safety precautions and equipment, including a helmet, gloves, apron, and blanket

Ive always felt that the brand name welder manufacturers should have made short ,very low cost classes on how to use their equipment available, at most dealers when you buy their equipment, because nothing sells welders as fast as having a buddy show you how well his new welder works.

and the one thing that keeps guys from BUYING a decent welder is not the cost because we all know that if you want something badly enough and its cost is less than a months pay, you'll eventually find a way to afford it!,But with most guys Ive talked with, its the idea that you'll spend the money and not be able to use the equipment, or use it often enough to justify its cost, but once they get some quality instruction it opens up a whole new world, and projects you've never dreamed of doing before start to look possible.

before you own a welder, you buy things like car trailers, welding tables, exhaust systems,accessory brackets,oil pans,traction bars,fence gates, etc. but once you own one you buy steel, aluminum,axles and detailed construction plans, and BUILD stuff better than you could buy,and to YOUR specifications

almost every guy I know that owns a welder bought that welder only after a buddy showed him how easy his welder was to use and how making things was not MAGIC but something almost anyone can do!

besides, theres a great deal of satisfaction in building your own custom oil pans,exhaust systems, accessory brackets or suspension components

TIG WELDERS generally cost a bit more, but once the skills mastered it is, at least in my opinion far superior, but noticeably slower than MIG welding

MIG welders are a bit less expensive but easier to learn on and use but not as versatile or precise

Cut Me Some Slag: Choosing Between MIG and TIG WeldersFROM SUMMIT RACING

As gearheads, we spend our fair share of time contemplating the important things: Ford vs. Chevy, carb’ed vs. fuel injected, skulls vs. flames. But if you’re shopping for a welder, there’s one brainteaser that trumps them all: MIG or TIG?

Whether you’re restoring a classic or prepping your car for the track, chances are good that you’ll need a welder along the way. But before you start stitching together body panels, fabricating custom brackets, or installing a one-off roll cage, you’ll need to pick a welder that’s right for you. Luckily, choosing the right welder is as simple as knowing what materials you’ll be working with and how much welding experience you have.

MIG (metal inert gas) welders are a good choice for beginners. They work by feeding a consumable wire electrode and a shielding gas—most commonly argon—through the welding gun and onto the surface to be welded. The wire acts as a filler metal and the gas protects the fresh weld from contamination as it cools.

MIG welders are capable of making strong, clean welds in a single pass but run the risk of creating spatter that’ll require some cleanup after you’re finished. Think of it as a hot glue gun for metal.

A portable 115V MIG welder can operate off of household current and can handle most metals up to 1/8" thick. For metals up to 5/8" thick, a 230V welder is the best choice. Due to temperature constraints, cast iron and aluminum should not be welded with a MIG welder.

For more tips on MIG welding, check out our in-depth tech article, Melding Metal.

TIG (tungsten inert gas) welders can produce a precise weld on any metal, although they’re generally slower and require more experience than a MIG welder. They heat the welding surface with an electric arc produced by a tungsten electrode. Unlike a MIG welder, they don’t require a filler metal, although it can be added by hand if needed. This produces a high-quality weld, free of spatter and smoke.

TIG welding offers an extremely hot, yet precise spark making it ideal for welding magnesium, aluminum, and stainless steel, as well as very thin materials. Just like a MIG welder, the TIG welding gun emits a shielding gas to keep the fresh weld clean.

And remember, whichever welder you choose, always be sure to use the proper safety precautions and equipment, including a helmet, gloves, apron, and blanket

heres some links to tig related info that may help

http://www.millerwelds.com/resources/te ... oting.html

http://www.millerwelds.com/resources/te ... _tips.html

http://www.millerwelds.com/resources/ar ... Ron-Covell

http://tractors.ucdavis.edu/TOMBELLTIGTIPS1.pdf

http://www.welding-direct.com/filler.html

36" Cut Lengths / Welding Filler Wire ER70S-6 Mild Steel, ER308L Stainless Steel or ER4043 & ER5356 Aluminum Available in 1 Lb. and 10 Lb. Cartons

Choose the filler wire for your application from the lists below. Other materials, special packaging and larger volume prices are available on request.

Tig Filler Rod ER70S6 Mild Steel 36" 1 Lb. BoxER70S6 filler rod is suitable for general shop applications with poor fit-up, oily or rusty plates, automotive, sheet metal or construction work.

Tig Filler Rod ER70S6 Mild Steel 36" 10 Lb. BoxER70S6 is suitable for general shop applications welding mild steel with poor fit-up, oily or rusty plates, automotive, sheet metal or construction work.

Tig Filler Rod ER308L Stainless Steel 36" 1 Lb. BoxER308L Stainless Steel filler rod is suitable for general stainless steel welding applications of all type 304, 304L, 308, 308L, 312 and 347 materials. Cut lengths are 36" long.

Tig Filler Rod ER308L Stainless Steel 10 Lb. BoxER308L Stainless Steel filler rod is suitable for general stainless steel welding applications of all type 304, 304L, 308, 308L, 312 and 347 materials.

Tig Filler Rod ER4043 or ER5356 Aluminum 1 Lb. BoxER4043, a good general purpose Aluminum filler with silicone additives for improved flow and reduces cracking. Bright weld finish.

Tig Filler Rod ER4043 or 5356 Aluminum 36" 10 Lb. BoxER4043, a good general purpose filler with silicone additives for improved flow and reduces cracking. Bright weld finish.

Tungsten Electrodes Rods & Wire Tungsten Electrodes Rods & Wire

http://www.millerwelds.com/resources/te ... oting.html

http://www.millerwelds.com/resources/te ... _tips.html

http://www.millerwelds.com/resources/ar ... Ron-Covell

http://tractors.ucdavis.edu/TOMBELLTIGTIPS1.pdf

http://www.welding-direct.com/filler.html

36" Cut Lengths / Welding Filler Wire ER70S-6 Mild Steel, ER308L Stainless Steel or ER4043 & ER5356 Aluminum Available in 1 Lb. and 10 Lb. Cartons

Choose the filler wire for your application from the lists below. Other materials, special packaging and larger volume prices are available on request.

Tig Filler Rod ER70S6 Mild Steel 36" 1 Lb. BoxER70S6 filler rod is suitable for general shop applications with poor fit-up, oily or rusty plates, automotive, sheet metal or construction work.

Tig Filler Rod ER70S6 Mild Steel 36" 10 Lb. BoxER70S6 is suitable for general shop applications welding mild steel with poor fit-up, oily or rusty plates, automotive, sheet metal or construction work.

Tig Filler Rod ER308L Stainless Steel 36" 1 Lb. BoxER308L Stainless Steel filler rod is suitable for general stainless steel welding applications of all type 304, 304L, 308, 308L, 312 and 347 materials. Cut lengths are 36" long.

Tig Filler Rod ER308L Stainless Steel 10 Lb. BoxER308L Stainless Steel filler rod is suitable for general stainless steel welding applications of all type 304, 304L, 308, 308L, 312 and 347 materials.

Tig Filler Rod ER4043 or ER5356 Aluminum 1 Lb. BoxER4043, a good general purpose Aluminum filler with silicone additives for improved flow and reduces cracking. Bright weld finish.

Tig Filler Rod ER4043 or 5356 Aluminum 36" 10 Lb. BoxER4043, a good general purpose filler with silicone additives for improved flow and reduces cracking. Bright weld finish.

Tungsten Electrodes Rods & Wire Tungsten Electrodes Rods & Wire

andysimmons

New Member

Great answers guys. Really comprehensive!

http://www.hotrod.com/techarticles/gene ... ing_guide/

worth the time to read thru

I got tired of buying crappy cheap migs, Ive owned 110 and 220 volt lincolns, and a 180 amp hobart and a couple off brands in the 140-180 amp range I bought dirt cheap at yard sales,all got sold off after being tested, none were exactly what I wanted. and I got fed up with not being able to weld simple stuff like 1/4 plate brackets to differentials or 3" tubing to differential housings , so I went down to the local miller dealer, I explained what I needed to do with the welder and he suggested the 211,for $1100 or the 252 for $2100, I bought the 252 for $2100 even thought it was almost twice the cost because I wanted to try MIG welding ALUMINUM and the 252 is more matched to that once you add the $1100 optional components (yeah thats almost $4k to weld 3/8" brackets in aluminum with a mig welder once you get the gas tanks wire, feed gun etc. and yes its faster than my tig,but Im rarely in a rush so the tig gets used more!)

AN NO! ITS NOT MY WELDING SKILL IVE BEEN WELDING FOR 40 PLUS YEARS and yes BOTH the 211 and 252 allow you to weld STEEL brackets and get good results

http://www.welders-direct.com/mm5/m...re_Code=WD&Product_Code=907422&Category_Code=

http://www.welders-direct.com/mm5/m...re_Code=WD&Product_Code=907321&Category_Code=

Ive used it and found it works great, but a buddy has recently purchased the 211 and while its not the same it does any thing youll ever need in steel welding

worth the time to read thru

I got tired of buying crappy cheap migs, Ive owned 110 and 220 volt lincolns, and a 180 amp hobart and a couple off brands in the 140-180 amp range I bought dirt cheap at yard sales,all got sold off after being tested, none were exactly what I wanted. and I got fed up with not being able to weld simple stuff like 1/4 plate brackets to differentials or 3" tubing to differential housings , so I went down to the local miller dealer, I explained what I needed to do with the welder and he suggested the 211,for $1100 or the 252 for $2100, I bought the 252 for $2100 even thought it was almost twice the cost because I wanted to try MIG welding ALUMINUM and the 252 is more matched to that once you add the $1100 optional components (yeah thats almost $4k to weld 3/8" brackets in aluminum with a mig welder once you get the gas tanks wire, feed gun etc. and yes its faster than my tig,but Im rarely in a rush so the tig gets used more!)

AN NO! ITS NOT MY WELDING SKILL IVE BEEN WELDING FOR 40 PLUS YEARS and yes BOTH the 211 and 252 allow you to weld STEEL brackets and get good results

http://www.welders-direct.com/mm5/m...re_Code=WD&Product_Code=907422&Category_Code=

http://www.welders-direct.com/mm5/m...re_Code=WD&Product_Code=907321&Category_Code=

Ive used it and found it works great, but a buddy has recently purchased the 211 and while its not the same it does any thing youll ever need in steel welding

I got tired of buying crappy cheap migs, Ive owned 110 and 220 volt lincolns, and a 180 amp hobart and a couple off brands in the 140-180 amp range I bought dirt cheap at yard sales,all got sold off after being tested, none were exactly what I wanted. and I got fed up with not being able to weld simple stuff like 1/4 plate brackets to differentials or 3" tubing to differential housings , so I went down to the local miller dealer, I explained what I needed to do with the welder and he suggested the 211,for $1100 or the 252 for $2100, I bought the 252 for $2100 even thought it was almost twice the cost because I wanted to try MIG welding ALUMINUM and the 252 is more matched to that once you add the $1100 optional components (yeah thats almost $4k to weld 3/8" brackets in aluminum with a mig welder once you get the gas tanks wire, feed gun etc. and yes its faster than my tig,but Im rarely in a rush so the tig gets used more!)

AN NO! ITS NOT MY WELDING SKILL IVE BEEN WELDING FOR 40 PLUS YEARS and yes BOTH the 211 and 252 allow you to weld STEEL brackets and get good results

http://www.welders-direct.com/mm5/merch ... gory_Code=

http://www.welders-direct.com/mm5/merch ... gory_Code=

Ive used it and found it works great, but a buddy has recently purchased the 211 and while its not the same it does any thing youll ever need in steel welding

I bought this miller 252 MIG for my shop, but I now see other options I was un-aware of at the time I purchased it

http://www.welders-direct.com/mm5/m...re_Code=WD&Product_Code=907321&Category_Code=

Never mind that the Millermatic 252 can weld material from 22 gauge to 1/2in thick in a single pass, or that it has the highest output in its class. You know a machine can pull its weight when it has infinate voltage control with self-calibrating digital meters.

Highest Output in its Class

(250 A at 28 VDC). Weld longer on high-end applications.

Auto Gun Detect

Miller's Auto Gun Detect allows operator to simply pull trigger on MIG gun, spool gun or push/pull gun. Automatically detects and recalls the voltage, wire feed speed and timer of the active gun.

Angled, Dual-Gear Driven, Cast Aluminum Drive System

Features no-tool, quick-change reversible drive rolls and an easy-to-set, scaled tension knob.

EZ-Access Consumable Compartment and Parameter Chart.

The Spoolmate 200 saves time for the operator by eliminating the need to go back to the machine to change wire feed speed.

Large, Digital Front Panel with Built-in Digital Timers Menu

Enables operator to preset voltage and wire feed speed. Standard run-in, pre/postflow, burnback, spot/delay (stitch) timer menu.

Push-Pull Gun Direct Connect

Compatible with Spoolmate 200 Series spool gun with wire feed speed control on the gun. This saves time by reducing trips back to the machine. Also compatible with more industrial Spoolmatic 15A or 30A spool gun.

EZ-Change Low Cylinder Rack

Allows users to easily roll cylinders on and off of rack - no need to lift cylinders.

Larger Work Area

Now with longer 15-ft M-25 MIG gun means you can reach more of your work without having to stop and move the machine.

Comes complete with:

• Millermatic 252 power source

• 10 ft (3 m) power cord and plug

• 15 ft (4.6 m), 250 amp M-25 MIG gun for .030/.035 in wire

• 10 ft (3 m) work cable and clamp

• Argon mix regulator/flow gauge and hose

• Extra contact tips

• Factory-installed running gear with EZ-Change Single Low Cylinder Rack

• .030/.035 in reversible drive rolls

youll find many welding schools and college trade schools etc. use LINCOLN welders, not MILLER

theres NOTHING WRONG WITH EITHER BRAND, BOTH, BRANDS have some good designs, BUT ID bet the schools getting a HEALTHY VOLUME discount on the price of the machines because the welding machine manufacturers KNOW that a high percentage of the weld school graduates tend to go out and buy the exact machine they were trained with has a great deal to do with the schools choice in machines

HERES MY ARC WELDER, I bought as its also an emergency shop generator, and easily converts to TIG with an accessory kit

http://www.welders-direct.com/mm5/merch ... de=K2382-4

Theres ALWAYS been and will likely always be a constantly expanding list of expensive shop tools most of us wish we could afford, but I don,t know anyone whose purchased a good TIG welder that regrets spending the cash. I went out and purchased a used tig decades ago, now Ill be the first guy to admit theres much better choices now, but at the time it seemed to be valid ,

I bought a ANCIENT 1980s TIG 330 amp welder used for a bit less than $1000 with a liquid cooled torch and accessories ,GAUGES , it may be old but it TIG welds just fine, and has paid for itself many time over in that length of time

http://garage.grumpysperformance.co...ng-to-water-cooled-tig-torch.8710/#post-30680

https://www.everlastgenerators.com/...MI_t-qjfTD5AIVmZOzCh1GswtsEAYYAyABEgKc8_D_BwE

AN NO! ITS NOT MY WELDING SKILL IVE BEEN WELDING FOR 40 PLUS YEARS and yes BOTH the 211 and 252 allow you to weld STEEL brackets and get good results

http://www.welders-direct.com/mm5/merch ... gory_Code=

http://www.welders-direct.com/mm5/merch ... gory_Code=

Ive used it and found it works great, but a buddy has recently purchased the 211 and while its not the same it does any thing youll ever need in steel welding

I bought this miller 252 MIG for my shop, but I now see other options I was un-aware of at the time I purchased it

http://www.welders-direct.com/mm5/m...re_Code=WD&Product_Code=907321&Category_Code=

Never mind that the Millermatic 252 can weld material from 22 gauge to 1/2in thick in a single pass, or that it has the highest output in its class. You know a machine can pull its weight when it has infinate voltage control with self-calibrating digital meters.

Highest Output in its Class

(250 A at 28 VDC). Weld longer on high-end applications.

Auto Gun Detect

Miller's Auto Gun Detect allows operator to simply pull trigger on MIG gun, spool gun or push/pull gun. Automatically detects and recalls the voltage, wire feed speed and timer of the active gun.

Angled, Dual-Gear Driven, Cast Aluminum Drive System

Features no-tool, quick-change reversible drive rolls and an easy-to-set, scaled tension knob.

EZ-Access Consumable Compartment and Parameter Chart.

The Spoolmate 200 saves time for the operator by eliminating the need to go back to the machine to change wire feed speed.

Large, Digital Front Panel with Built-in Digital Timers Menu

Enables operator to preset voltage and wire feed speed. Standard run-in, pre/postflow, burnback, spot/delay (stitch) timer menu.

Push-Pull Gun Direct Connect

Compatible with Spoolmate 200 Series spool gun with wire feed speed control on the gun. This saves time by reducing trips back to the machine. Also compatible with more industrial Spoolmatic 15A or 30A spool gun.

EZ-Change Low Cylinder Rack

Allows users to easily roll cylinders on and off of rack - no need to lift cylinders.

Larger Work Area

Now with longer 15-ft M-25 MIG gun means you can reach more of your work without having to stop and move the machine.

Comes complete with:

• Millermatic 252 power source

• 10 ft (3 m) power cord and plug

• 15 ft (4.6 m), 250 amp M-25 MIG gun for .030/.035 in wire

• 10 ft (3 m) work cable and clamp

• Argon mix regulator/flow gauge and hose

• Extra contact tips

• Factory-installed running gear with EZ-Change Single Low Cylinder Rack

• .030/.035 in reversible drive rolls

youll find many welding schools and college trade schools etc. use LINCOLN welders, not MILLER

theres NOTHING WRONG WITH EITHER BRAND, BOTH, BRANDS have some good designs, BUT ID bet the schools getting a HEALTHY VOLUME discount on the price of the machines because the welding machine manufacturers KNOW that a high percentage of the weld school graduates tend to go out and buy the exact machine they were trained with has a great deal to do with the schools choice in machines

HERES MY ARC WELDER, I bought as its also an emergency shop generator, and easily converts to TIG with an accessory kit

http://www.welders-direct.com/mm5/merch ... de=K2382-4

Theres ALWAYS been and will likely always be a constantly expanding list of expensive shop tools most of us wish we could afford, but I don,t know anyone whose purchased a good TIG welder that regrets spending the cash. I went out and purchased a used tig decades ago, now Ill be the first guy to admit theres much better choices now, but at the time it seemed to be valid ,

I bought a ANCIENT 1980s TIG 330 amp welder used for a bit less than $1000 with a liquid cooled torch and accessories ,GAUGES , it may be old but it TIG welds just fine, and has paid for itself many time over in that length of time

http://garage.grumpysperformance.co...ng-to-water-cooled-tig-torch.8710/#post-30680

https://www.everlastgenerators.com/...MI_t-qjfTD5AIVmZOzCh1GswtsEAYYAyABEgKc8_D_BwE

Last edited by a moderator:

IF your looking for a good TIG welder and are amazed at the price of a new tig welder that costs $2k-$7K you might want to look around for a used TIG welder, that will cost you less than 50% if you shop carefully, when I needed a tig welder I was certainly not in a financial position to pay $2K for a welder, but I started looking in the classified adds and found a good used commercial 330 amp tig that would run on 230 volt single phase with a liquid cooled torch, gauges, and a few extras for less than $1000, while it certainly was not state of the art it works fine.

now be aware that you will need to test weld with any used TIG before you buy it and youll need extras like a tank of shield gas, feeder wire, tig torch tungsten rods an electrical plug and cords, etc.

http://www.eastwood.com/tig200dc-and-ve ... o-kit.html

http://www.htpweld.com/products/tig_welders/tig201.html

http://www.welders-direct.com/mm5/merch ... ode=907460

viewtopic.php?f=60&t=295

viewtopic.php?f=60&t=8344

http://www.weldplus.com/tig-welders.htm

now be aware that you will need to test weld with any used TIG before you buy it and youll need extras like a tank of shield gas, feeder wire, tig torch tungsten rods an electrical plug and cords, etc.

http://www.eastwood.com/tig200dc-and-ve ... o-kit.html

http://www.htpweld.com/products/tig_welders/tig201.html

http://www.welders-direct.com/mm5/merch ... ode=907460

viewtopic.php?f=60&t=295

viewtopic.php?f=60&t=8344

http://www.weldplus.com/tig-welders.htm

a new miller multi use welder, converts from 110volt to 220 volt and from mig to tig use with accessory parts kit

while its not ideal for all applications it covers most shop needs, once you get the accessories and know how it works

https://www.youtube.com/watch?v=AwJvaq-OLYs#t=40

https://www.youtube.com/watch?v=3t0FNwuLcHY

https://www.youtube.com/watch?v=loJURx0SYIc

http://www.millerwelds.com/products/mul ... del=M00361

http://www.millerwelds.com/products/mul ... del=M00361

while its not ideal for all applications it covers most shop needs, once you get the accessories and know how it works

https://www.youtube.com/watch?v=AwJvaq-OLYs#t=40

https://www.youtube.com/watch?v=3t0FNwuLcHY

https://www.youtube.com/watch?v=loJURx0SYIc

http://www.millerwelds.com/products/mul ... del=M00361

http://www.millerwelds.com/products/mul ... del=M00361

8

87vette81big

Guest

Thanks for the Video Link Grumpy.

You have me thinking.....

Miller Multumatic 200.

Sell my Snap On MW120 (Tweeco built) MIG Welder.

Purchase a Miller MM200.

Like you can upgrade to a TIG, Accessorize.

I like Stick Welding still also at times. Can do also....

The Boy Jami (3-1/2 months watched with me)...

Quit crying & started Cooing & Laughing....All Smiles now.

He is checking out the used Rimac Valvespring Tester .

Came in. Didn't cost a small fortune.

You have me thinking.....

Miller Multumatic 200.

Sell my Snap On MW120 (Tweeco built) MIG Welder.

Purchase a Miller MM200.

Like you can upgrade to a TIG, Accessorize.

I like Stick Welding still also at times. Can do also....

The Boy Jami (3-1/2 months watched with me)...

Quit crying & started Cooing & Laughing....All Smiles now.

He is checking out the used Rimac Valvespring Tester .

Came in. Didn't cost a small fortune.

http://oppositelock.jalopnik.com/what-w ... 1455224176

a link you might care to read thru,discussing a shop welder

two TOOLS THAT GET CONSTANTLY USED, A DRILL PRESS AND MIG WELDER WOULD MAKE SHOPS MORE PRODUCTIVE

http://www.welders-direct.com/mm5/merch ... gory_Code=

a link you might care to read thru,discussing a shop welder

two TOOLS THAT GET CONSTANTLY USED, A DRILL PRESS AND MIG WELDER WOULD MAKE SHOPS MORE PRODUCTIVE

http://www.welders-direct.com/mm5/merch ... gory_Code=

Last edited by a moderator:

8

87vette81big

Guest

Have to obtain the Lincoln Ranger soon Grumpy.

Found a few within 400 miles.

All copper alternator windings.

Not aluminum as others.

Why Welding Arc Superior with a Lincoln.

I researched Hard.

You clued me in right direction.

Thanks.

Brian

Found a few within 400 miles.

All copper alternator windings.

Not aluminum as others.

Why Welding Arc Superior with a Lincoln.

I researched Hard.

You clued me in right direction.

Thanks.

Brian

George Madison

New Member

Here is one more nice welding tools shop.

Nice choise and prices, recommended.

The shop sells Arc, TIG and MIG welding helmets and many other welding tools.

https://ikraz.biz/tools-home-improvement/welding-soldering.html?p=2&product_list_limit=30

Nice choise and prices, recommended.

The shop sells Arc, TIG and MIG welding helmets and many other welding tools.

https://ikraz.biz/tools-home-improvement/welding-soldering.html?p=2&product_list_limit=30

thank you, that seems to be a good link and source for some items!

http://www.eastwood.com/mig-250.html

Did you see this?

I paid $2100 for my miller 252 mig

and this is rated at a similar level at less than 1/2 the price

http://www.eastwood.com/mig-250.html

Did you see this?

I paid $2100 for my miller 252 mig

and this is rated at a similar level at less than 1/2 the price

George Madison

New Member

You are welcome) I've spent a lot of time seeking for many tools, accessories... Everybody can just Google it, but not everybody can find his or her concrete GOAL =)