IF YOU DON,T READ THE SUB LINKS YOU'LL MISS LOTS OF INFO,.....info that might cure your particular problem, now or later, know what your looking for and what your doing before throwing parts randomly at a problem

Chevy V8 starters come in several variations but the main things you need to know is the flywheel size (flexplates & flywheels are either 14in diameter with 168 teeth, OR, about 12 3/4in) with 153 teeth.) and if your block used the strait across or off set mount bolt pattern, its usually the 168 tooth size.,

http://static.summitracing.com/global/i ... tarter.pdf

many 168 tooth starters will have staggered mounting bolt holes like this.

most 153 tooth starters will have the holes in a straight line.

153 tooth = 12-3/4" diameter

168 tooth = 14" diameter

10496870 Starter, heavy-duty, remanufactured for 12 3/4” diameter flywheel/flexplate

1876552 Starter, heavy-duty for 14” diameter flywheel/flexplate

14097278 Bolt, starter mounting, long, for heavy-duty starter

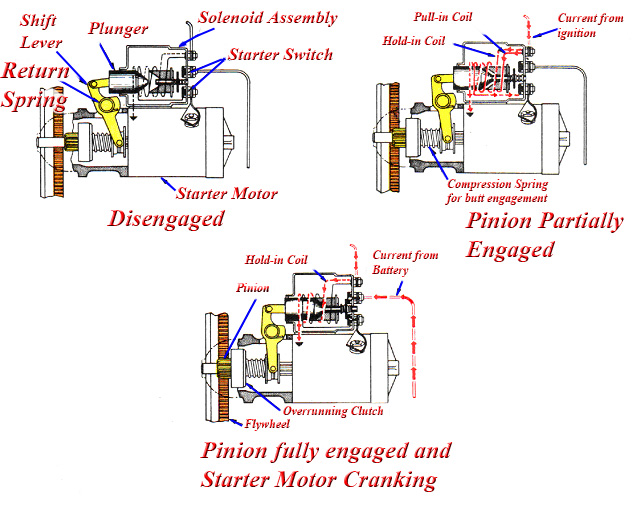

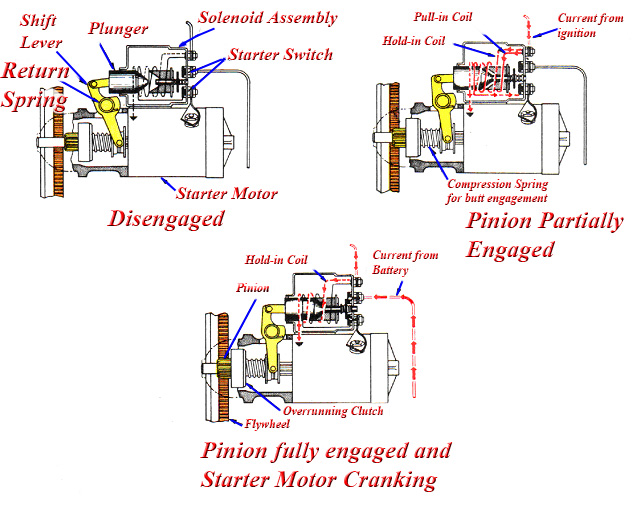

WATCH THE VIDEO,s ON STARTER OPERATION

http://www.youtube.com/watch?v=bx3xniNw ... re=related

http://www.youtube.com/watch?v=oCCTL3Gb ... re=related

http://www.youtube.com/watch?v=v1Vsx9Kl ... re=related

READ THRU THIS LINK IT MIGHT BE A VATS PROBLEM IF THE CAR WON<T START

viewtopic.php?f=36&t=520&p=645&hilit=vats+resistor#p645

IF IT SPINS BUT WON<T START READ THIS LINK AND SUB LINKS

viewtopic.php?f=32&t=1401&p=13764&hilit=terminals+cleaning+battery#p13764

IF YOUR GETTING ZERO FUEL PRESSURE READ THESE LINKS

viewtopic.php?f=32&t=33

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=1241

Description

http://www.harborfreight.com/5-in-1-dig ... 98674.html

Allows a single person to start or crank the engine from under the hood. Ideal for compression tests or for bumping engine onto TDC (top dead center) timing marks for valve, distributor or camshaft adjustment. Power tool-type trigger switch for regular use with medium currents. Most Specialty Tools products are available for in-store pickup...

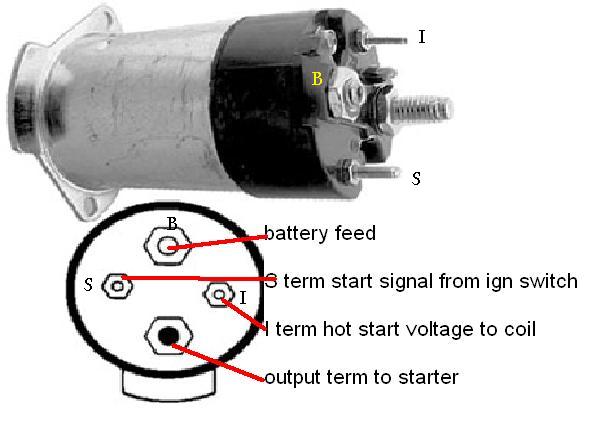

as always start with the basics and verify the battery has 13 volts,then verify the starter works when you jump the solenoid connections manually and the engines getting fuel pressure and ignition spark at the plugs

bypass the ignition and security with a manual starter test switch (look thru the link) starter test switches normally cost well under $20 and youll find them useful in the tool box

http://www.summitracing.com/parts/ANM-CP7853/

these test switches normally cost under $20 and easily test starter function along with a multi meter youll use to test battery voltage etc.

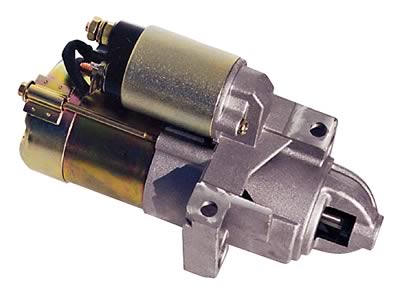

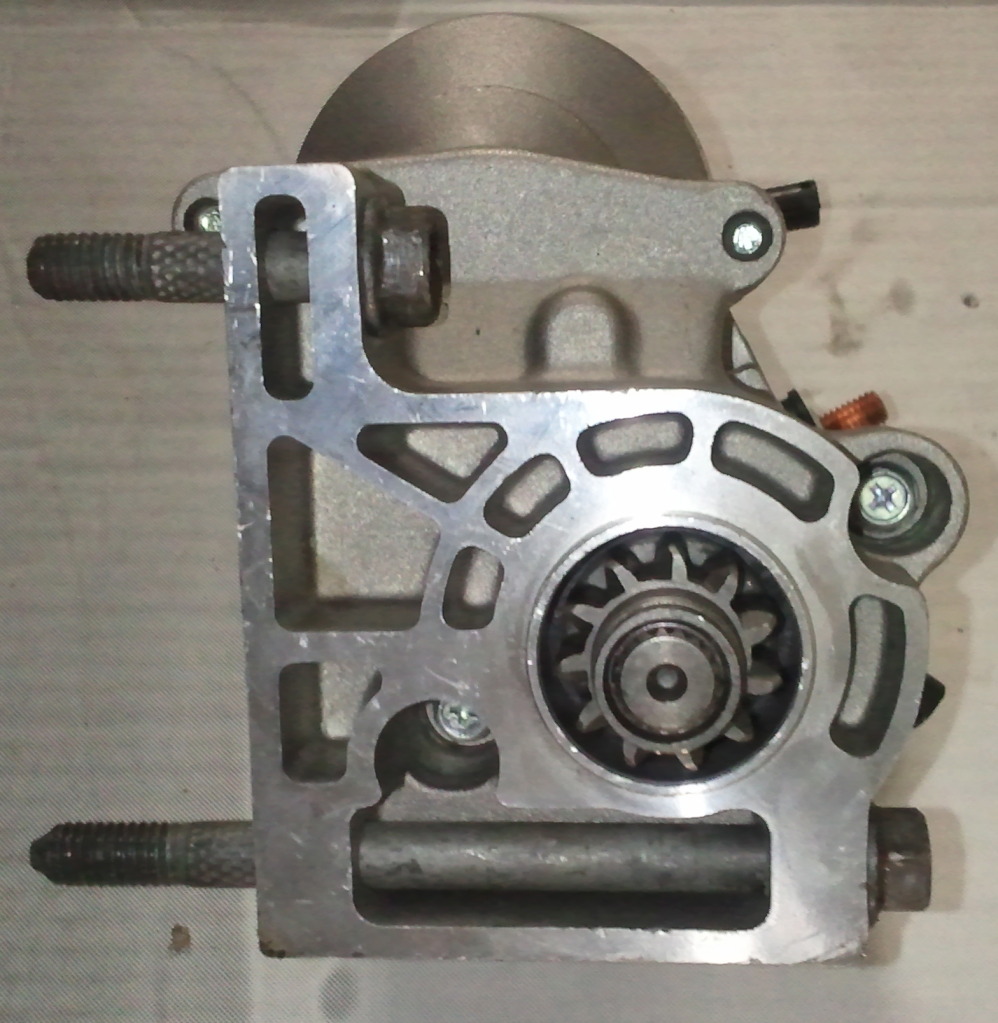

lt1 starters look a bit different

read thru these

http://www.jegs.com/i/JEGS-Performance- ... Id=1359671

you can buy standard chevy starters at a decent price

http://www.dbelectrical.com/p-1304-chev ... mt200.aspx

If it has 2 sets of mounting holes, it can usually be used on either a 153 or 168 tooth flywheel/flexplate.

viewtopic.php?f=70&t=299

viewtopic.php?f=70&t=1646&p=12717#p12717

http://www.tiltonracing.com/ins/98-095.pdf

http://www.circletrack.com/enginetech/c ... index.html

viewtopic.php?f=32&t=816&p=1201&hilit=+starter#p1201

http://www.chevyhiperformance.com/techa ... index.html

http://image.chevyhiperformance.com/f/8 ... t_07_z.jpg

viewtopic.php?f=36&t=676&p=937&hilit=+starter#p937

http://www.vetteweb.com/tech/vemp_0404_ ... index.html

http://www.novaresource.org/starter.htm

viewtopic.php?f=70&t=299&p=364&hilit=+starter#p364

http://www.chevyhiperformance.com/techa ... index.html

viewtopic.php?f=36&t=63&p=76&hilit=+starter#p76

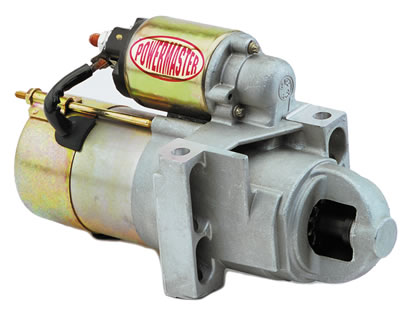

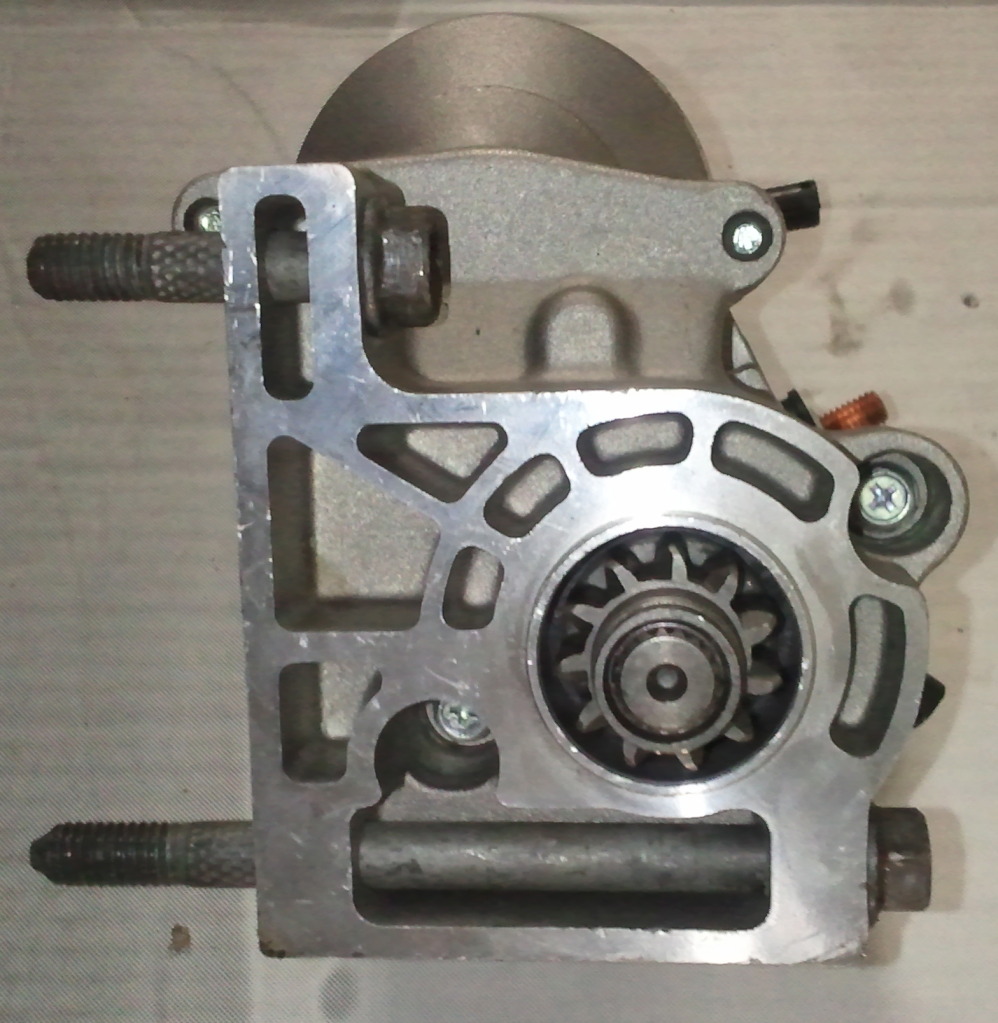

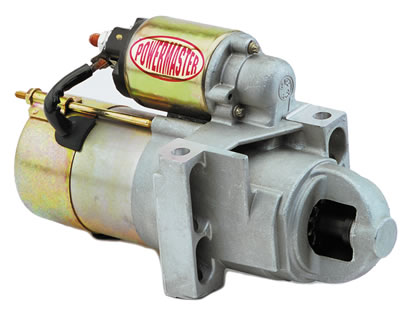

NOTICE THE DUAL MOUNT HOLES

http://store.summitracing.com/partdetail.asp?part=PWM-9000&autoview=sku

http://store.summitracing.com/partdetail.asp?part=PWM-9526&autoview=sku

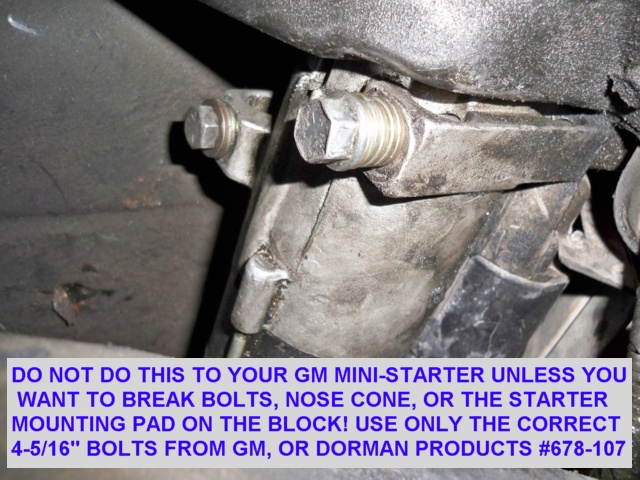

There ARE BOTH OFFSET and inline bolt mount patterns to consider also (depends on blocks used)

http://store.summitracing.com/partdetail.asp?autofilter=1&part=SUM-820323-OS&N=700+115&autoview=sku

these guys have a good product

http://www.dbelectrical.com/Starter%20M ... %20Motors/

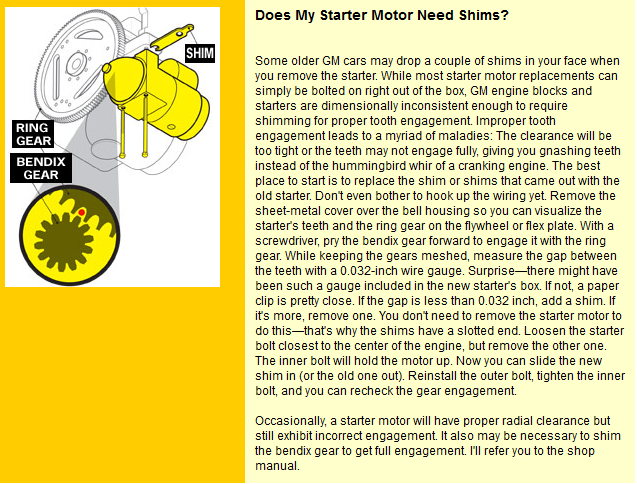

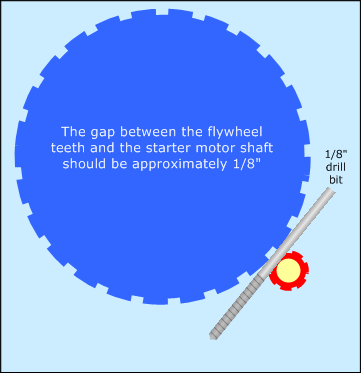

if your starter has both mount options you can move it closer in, if not youll need the correct starter, there's 153 and 168 tooth flywheel and flex plate diameters so you'll need to keep that in mind, the advantage of the better gear reduction starters is about 4:1 geared ratio so they are smaller lighter and many can be clocked or turned/ indexed, to access the max clearance to frame, headers, large oil pans,etc.

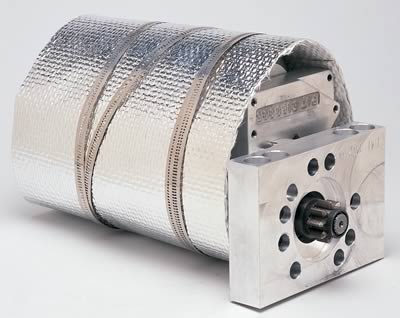

While OBVIOUSLY I’ve not used every brand or model available,

I’ve used several of each type over the years, Id also recommend the supported style

as I have seen more problems with the UN-supported starters , and you can use the mini-high torque starters on a street car, Ive had one on BOTH my 1985 and 1996 corvettes for years.... that being said, Id look into the guarantee of each brand and keep the shipping box ETC. as I know of several cases where mini-starters, and for that matter full size starters lasted under a week!, BTW your local area may have a shop that can build/sell you a quality mini starter for even less, and its always nice to have a local guy handy if you do have problems

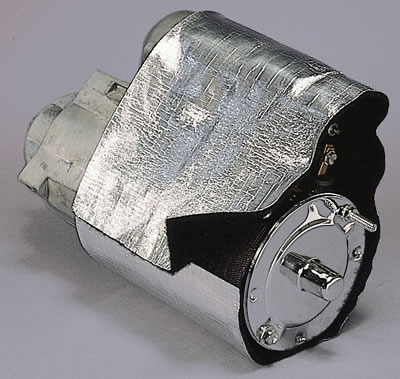

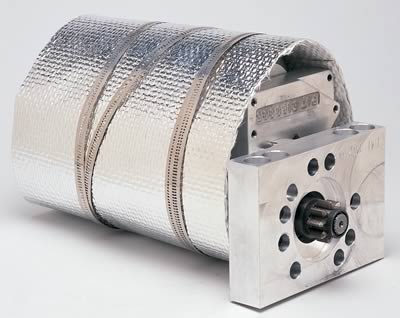

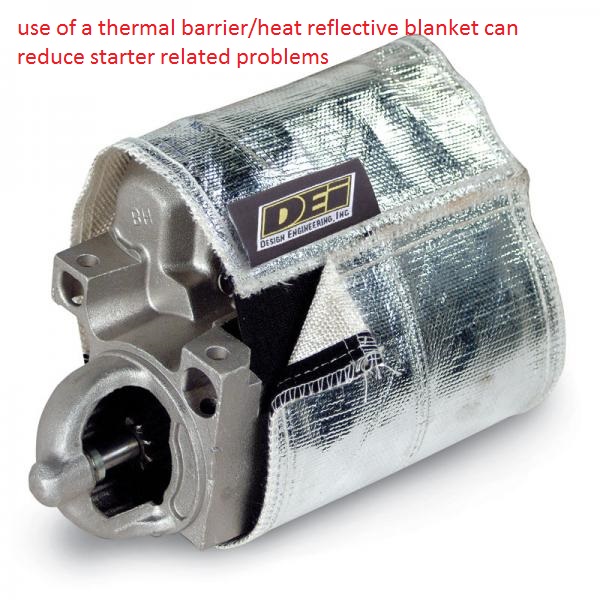

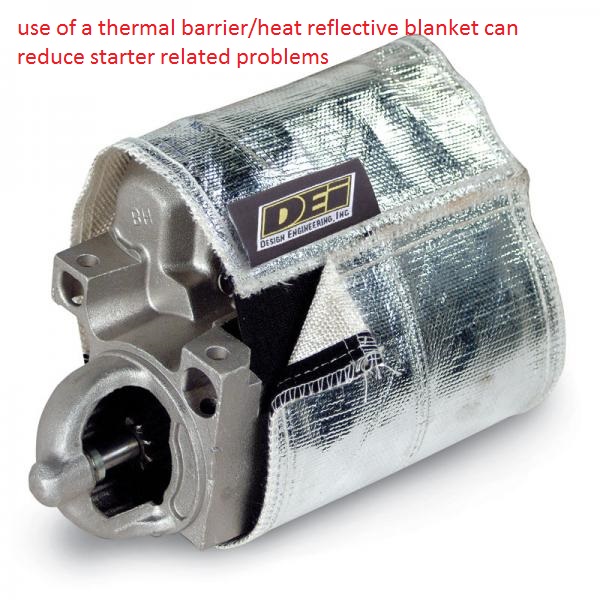

heat shielding can be a huge help

http://store.summitracing.com/partdetail.asp?autofilter=1&part=THE-14150&N=700+-118668+115&autoview=sku

you might want to look thru this info below also

viewtopic.php?f=70&t=299

viewtopic.php?f=70&t=514

occasionally you'll find damaged flywheel ring gears,

naturally you'll need to use the correct replacement parts from the original manufacturer in most cases,

viewtopic.php?f=53&t=5155&p=14949&hilit=ring+gear#p14949

http://www.thefind.com/cars/info-flywheel-ring-gear

http://www.tciauto.com/Products/Flywheels/

RING GEARS ARE CHEAPER THAN FLY WHEELS AND IN MOST CASES REPLACEABLE COMPONENTS

(1) Pull trans

(2) Remove flywheel

(3) HEAT WITH A PROPANE TORCH, THEN Tap ring gear off

(4)CLEAN AND INSPECT RING GEAR MOUNT SURFACE AND CLEAN IF REQUIRED, Heat new ring gear with torch, OR by placing in oven, place fly wheel in cardboard box covered with DRY ICE

once both are at correct temp.place flywheel on flat concrete floor

(5) Grab ring gear with pliers and drop onto flywheel, making sure its properly aligned

(6) Install flywheel back onto engine

(7) Bolt trans and flywheel/clutch back to engines drive train

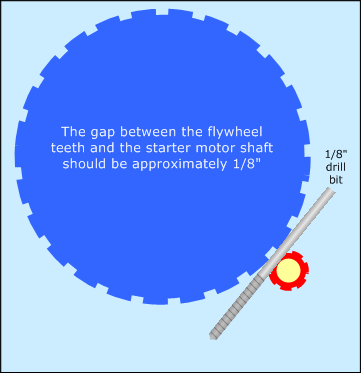

(8) Inspect old starter to make sure bendix gear alignment and clearance is still good

(9) Start engine

Chevy V8 starters come in several variations but the main things you need to know is the flywheel size (flexplates & flywheels are either 14in diameter with 168 teeth, OR, about 12 3/4in) with 153 teeth.) and if your block used the strait across or off set mount bolt pattern, its usually the 168 tooth size.,

http://static.summitracing.com/global/i ... tarter.pdf

many 168 tooth starters will have staggered mounting bolt holes like this.

most 153 tooth starters will have the holes in a straight line.

153 tooth = 12-3/4" diameter

168 tooth = 14" diameter

10496870 Starter, heavy-duty, remanufactured for 12 3/4” diameter flywheel/flexplate

1876552 Starter, heavy-duty for 14” diameter flywheel/flexplate

14097278 Bolt, starter mounting, long, for heavy-duty starter

WATCH THE VIDEO,s ON STARTER OPERATION

http://www.youtube.com/watch?v=bx3xniNw ... re=related

http://www.youtube.com/watch?v=oCCTL3Gb ... re=related

http://www.youtube.com/watch?v=v1Vsx9Kl ... re=related

READ THRU THIS LINK IT MIGHT BE A VATS PROBLEM IF THE CAR WON<T START

viewtopic.php?f=36&t=520&p=645&hilit=vats+resistor#p645

IF IT SPINS BUT WON<T START READ THIS LINK AND SUB LINKS

viewtopic.php?f=32&t=1401&p=13764&hilit=terminals+cleaning+battery#p13764

IF YOUR GETTING ZERO FUEL PRESSURE READ THESE LINKS

viewtopic.php?f=32&t=33

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=1241

Description

http://www.harborfreight.com/5-in-1-dig ... 98674.html

Allows a single person to start or crank the engine from under the hood. Ideal for compression tests or for bumping engine onto TDC (top dead center) timing marks for valve, distributor or camshaft adjustment. Power tool-type trigger switch for regular use with medium currents. Most Specialty Tools products are available for in-store pickup...

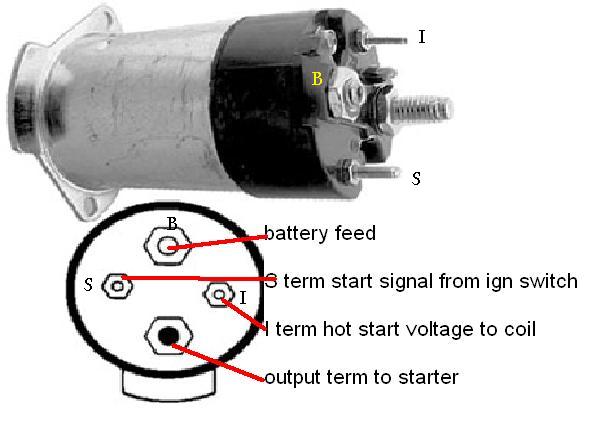

as always start with the basics and verify the battery has 13 volts,then verify the starter works when you jump the solenoid connections manually and the engines getting fuel pressure and ignition spark at the plugs

bypass the ignition and security with a manual starter test switch (look thru the link) starter test switches normally cost well under $20 and youll find them useful in the tool box

http://www.summitracing.com/parts/ANM-CP7853/

these test switches normally cost under $20 and easily test starter function along with a multi meter youll use to test battery voltage etc.

lt1 starters look a bit different

read thru these

http://www.jegs.com/i/JEGS-Performance- ... Id=1359671

you can buy standard chevy starters at a decent price

http://www.dbelectrical.com/p-1304-chev ... mt200.aspx

If it has 2 sets of mounting holes, it can usually be used on either a 153 or 168 tooth flywheel/flexplate.

viewtopic.php?f=70&t=299

viewtopic.php?f=70&t=1646&p=12717#p12717

http://www.tiltonracing.com/ins/98-095.pdf

http://www.circletrack.com/enginetech/c ... index.html

viewtopic.php?f=32&t=816&p=1201&hilit=+starter#p1201

http://www.chevyhiperformance.com/techa ... index.html

http://image.chevyhiperformance.com/f/8 ... t_07_z.jpg

viewtopic.php?f=36&t=676&p=937&hilit=+starter#p937

http://www.vetteweb.com/tech/vemp_0404_ ... index.html

http://www.novaresource.org/starter.htm

viewtopic.php?f=70&t=299&p=364&hilit=+starter#p364

http://www.chevyhiperformance.com/techa ... index.html

viewtopic.php?f=36&t=63&p=76&hilit=+starter#p76

NOTICE THE DUAL MOUNT HOLES

http://store.summitracing.com/partdetail.asp?part=PWM-9000&autoview=sku

http://store.summitracing.com/partdetail.asp?part=PWM-9526&autoview=sku

There ARE BOTH OFFSET and inline bolt mount patterns to consider also (depends on blocks used)

http://store.summitracing.com/partdetail.asp?autofilter=1&part=SUM-820323-OS&N=700+115&autoview=sku

these guys have a good product

http://www.dbelectrical.com/Starter%20M ... %20Motors/

if your starter has both mount options you can move it closer in, if not youll need the correct starter, there's 153 and 168 tooth flywheel and flex plate diameters so you'll need to keep that in mind, the advantage of the better gear reduction starters is about 4:1 geared ratio so they are smaller lighter and many can be clocked or turned/ indexed, to access the max clearance to frame, headers, large oil pans,etc.

While OBVIOUSLY I’ve not used every brand or model available,

I’ve used several of each type over the years, Id also recommend the supported style

as I have seen more problems with the UN-supported starters , and you can use the mini-high torque starters on a street car, Ive had one on BOTH my 1985 and 1996 corvettes for years.... that being said, Id look into the guarantee of each brand and keep the shipping box ETC. as I know of several cases where mini-starters, and for that matter full size starters lasted under a week!, BTW your local area may have a shop that can build/sell you a quality mini starter for even less, and its always nice to have a local guy handy if you do have problems

heat shielding can be a huge help

http://store.summitracing.com/partdetail.asp?autofilter=1&part=THE-14150&N=700+-118668+115&autoview=sku

you might want to look thru this info below also

viewtopic.php?f=70&t=299

viewtopic.php?f=70&t=514

occasionally you'll find damaged flywheel ring gears,

naturally you'll need to use the correct replacement parts from the original manufacturer in most cases,

viewtopic.php?f=53&t=5155&p=14949&hilit=ring+gear#p14949

http://www.thefind.com/cars/info-flywheel-ring-gear

http://www.tciauto.com/Products/Flywheels/

RING GEARS ARE CHEAPER THAN FLY WHEELS AND IN MOST CASES REPLACEABLE COMPONENTS

(1) Pull trans

(2) Remove flywheel

(3) HEAT WITH A PROPANE TORCH, THEN Tap ring gear off

(4)CLEAN AND INSPECT RING GEAR MOUNT SURFACE AND CLEAN IF REQUIRED, Heat new ring gear with torch, OR by placing in oven, place fly wheel in cardboard box covered with DRY ICE

once both are at correct temp.place flywheel on flat concrete floor

(5) Grab ring gear with pliers and drop onto flywheel, making sure its properly aligned

(6) Install flywheel back onto engine

(7) Bolt trans and flywheel/clutch back to engines drive train

(8) Inspect old starter to make sure bendix gear alignment and clearance is still good

(9) Start engine

Last edited by a moderator: