nawlins-tim

Member

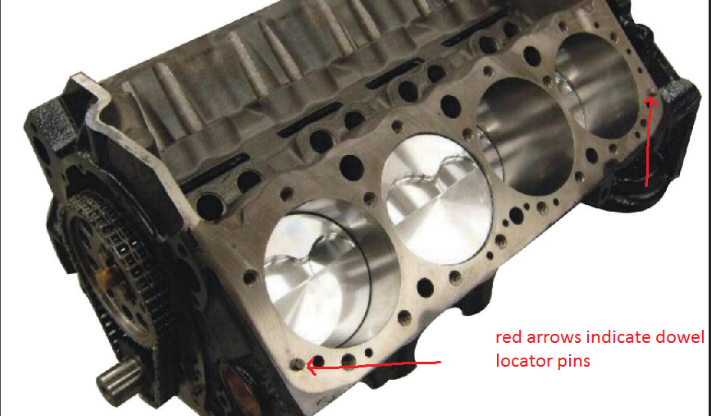

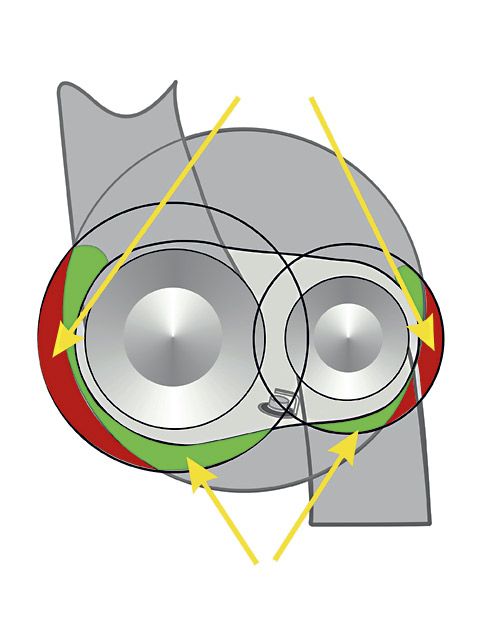

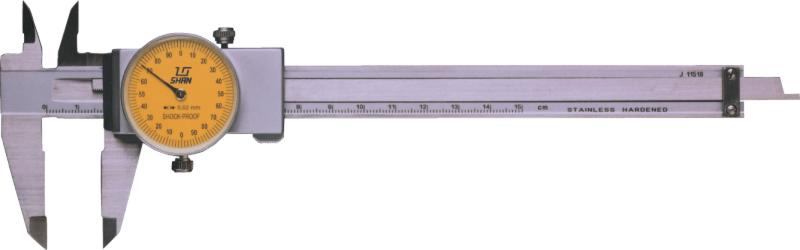

I have a fresh short block 400. Got a new set of Profiler heads and went to test fit and BOTH heads won't fit correctly over the left bank dowel pins. Its not much but the heads won't go on without a pounding. Anyone ever have this problem? I can't notice any mushrooming of the pins either. trying to decide what is the fix. Also the block was decked and squared.