Faytmorgan

Member

I was sent here from Hyrbridz.org for help.

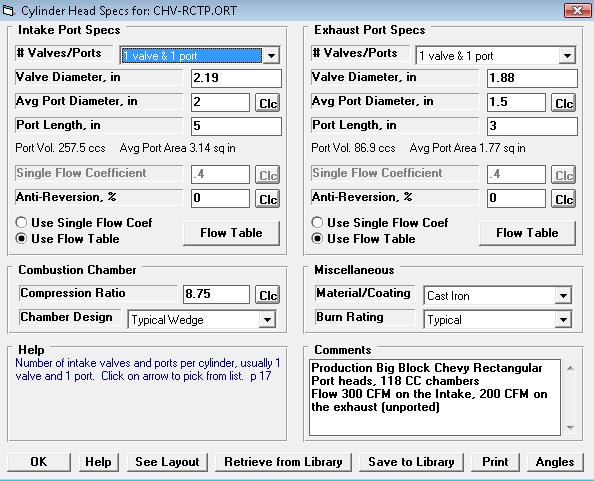

195cc intake runner, 64cc combustion chamber, aluminum, 2.02, and 1.60 valves

Superflow sf 600 flow com

air speed: 380-400FT, 375-410SC

Intake;

(.1)66

(.2)141

(.3)200

(.4)242

(.5)270

(.6)265

(.7)268

Exhaust;

(.1)55

(.2)107

(.3)139

(.4)167

(.5)192

(.6)209

2500lb car 245/50r16 street tires rated at 320aa by firestone (I don't really need tq the car is very light and I am limited on tire)

1978 280z long nose r200 diff. with stub axles

1987 700r4 trans

3.545 rear gear ratio

10.25:1 compression

chev 327 40 over now may end up 60 over soon

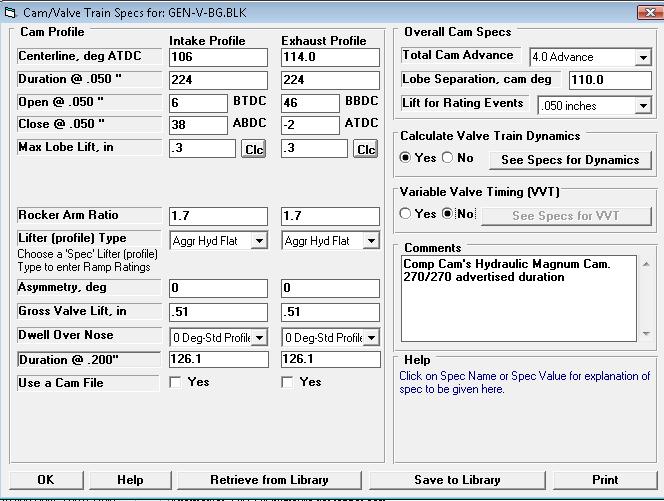

1.6:1 rocker ratio

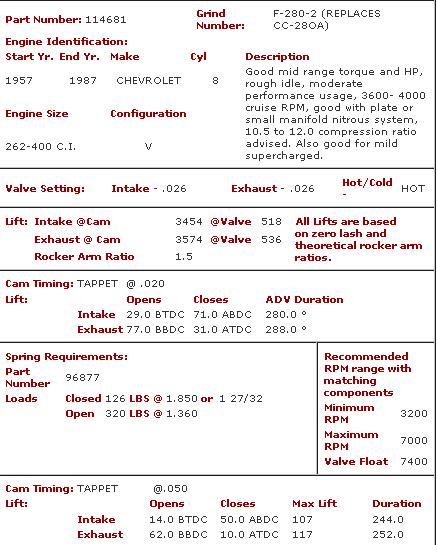

Looking for a solid flat tappet.

I'm looking to have a very WIDE rpm range, as much as possible. Comp claims the old duntov 30-30 is between 2300-6900. I'm talking that kind of wide. The issue with that cam is that the one they sell it for a 350, in a 327 that would bump my rpm past what I want it to be. The 30-30 does suck (compared to modern cam profiles), I am just pointing out that a wide powerband in a solid flat tappet can be done. Also when I was saying the difference between a 350 and a 327. The small crank throw will up the rpm a bit. Instead of being at 2300 it would be like 2500-2600, and instead of being 6900 it would be like 7200-7300. That is too peaky for me. 2300 to 6900 would be perfect if it was rated for the 327. When comp rates those numbers they are all done with a 350 base. Not a 3.25 but a 3.48 crank.

I'm looking for a 6700-7000 peak rpm, with it coming in as low as I can get it at.

One thing I have heard and read a lot of debate about is the fact that the 327 doesn't sit at top dead center for very long so a wide lsa (about a 112-114) would be beneficial. Also it would kill the tq down low. The other end of this opinion is that one could do a 110 lsa and advance it quite a bit. I don't honestly know what would be best. Some help/thoughts/advice would be great.

The car is intended for the road course at BIR in MN. Both the outer longer track and shorter center track.

http://www.brainerdraceway.com/

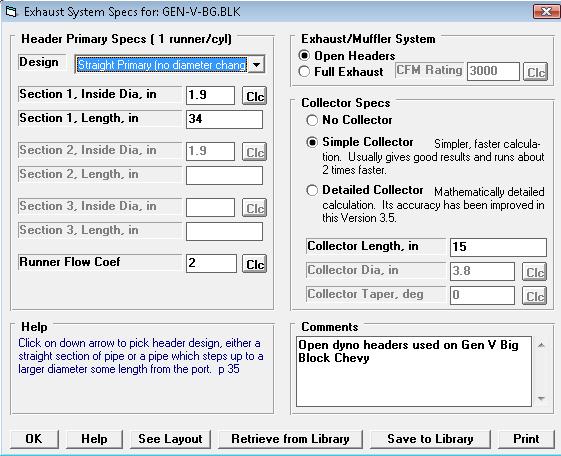

It looks like 1st gear is just to get going and 2nd gear should be about 33 mph at 2500 rpm and will be 80mph at 6000rpm. 3rd will go from 55mph @ 2500rpm to 130 @ 6000rpm or 140 @ 6500 rpm so 3rd should be a great gear for most of the high speed sections. 2nd should be enough for any tight stuff. Overdrive is 200mph + so that's good for a bit of extra pull down a straight if I'm able to go faster than 140mph before braking for the turn.

Looking at the Brainerd track it looks like a lot of high speed corners and long straightaways without too many tight corners. I have wide gearing so this should suit the track well but it means I need a wide powerband as well.

Help and advise or a point in the right direction would be great.

195cc intake runner, 64cc combustion chamber, aluminum, 2.02, and 1.60 valves

Superflow sf 600 flow com

air speed: 380-400FT, 375-410SC

Intake;

(.1)66

(.2)141

(.3)200

(.4)242

(.5)270

(.6)265

(.7)268

Exhaust;

(.1)55

(.2)107

(.3)139

(.4)167

(.5)192

(.6)209

2500lb car 245/50r16 street tires rated at 320aa by firestone (I don't really need tq the car is very light and I am limited on tire)

1978 280z long nose r200 diff. with stub axles

1987 700r4 trans

3.545 rear gear ratio

10.25:1 compression

chev 327 40 over now may end up 60 over soon

1.6:1 rocker ratio

Looking for a solid flat tappet.

I'm looking to have a very WIDE rpm range, as much as possible. Comp claims the old duntov 30-30 is between 2300-6900. I'm talking that kind of wide. The issue with that cam is that the one they sell it for a 350, in a 327 that would bump my rpm past what I want it to be. The 30-30 does suck (compared to modern cam profiles), I am just pointing out that a wide powerband in a solid flat tappet can be done. Also when I was saying the difference between a 350 and a 327. The small crank throw will up the rpm a bit. Instead of being at 2300 it would be like 2500-2600, and instead of being 6900 it would be like 7200-7300. That is too peaky for me. 2300 to 6900 would be perfect if it was rated for the 327. When comp rates those numbers they are all done with a 350 base. Not a 3.25 but a 3.48 crank.

I'm looking for a 6700-7000 peak rpm, with it coming in as low as I can get it at.

One thing I have heard and read a lot of debate about is the fact that the 327 doesn't sit at top dead center for very long so a wide lsa (about a 112-114) would be beneficial. Also it would kill the tq down low. The other end of this opinion is that one could do a 110 lsa and advance it quite a bit. I don't honestly know what would be best. Some help/thoughts/advice would be great.

The car is intended for the road course at BIR in MN. Both the outer longer track and shorter center track.

http://www.brainerdraceway.com/

It looks like 1st gear is just to get going and 2nd gear should be about 33 mph at 2500 rpm and will be 80mph at 6000rpm. 3rd will go from 55mph @ 2500rpm to 130 @ 6000rpm or 140 @ 6500 rpm so 3rd should be a great gear for most of the high speed sections. 2nd should be enough for any tight stuff. Overdrive is 200mph + so that's good for a bit of extra pull down a straight if I'm able to go faster than 140mph before braking for the turn.

Looking at the Brainerd track it looks like a lot of high speed corners and long straightaways without too many tight corners. I have wide gearing so this should suit the track well but it means I need a wide powerband as well.

Help and advise or a point in the right direction would be great.