LS7 Tech Specs Block Part Number:

17802854

Block Type:

Cast aluminum w/6-bolt steel main bearing caps

Bore x Stroke (in):

4.125 x 4.00 (104.8 mm x 101.6 mm)

Camshaft Duration:

211 degree intake / 230 degree exhaust

Camshaft lift (in):

.591" (15 mm) Intake and Exhaust

Camshaft Part Number:

Camshaft type(P/N 12571251

Camshaft type:

Hydraulic roller

Compression ratio:

11.0:1

Connecting Rod Part Number:

12586258):

Connecting rods Type:

Forged titanium

Crankshaft Part Number:

12568819

Crankshaft Type:

Forged steel

Cylinder head Part Number:

12578450

Cylinder head Type:

CNC Ported LS7 specific pattern 70 cc CNC combustion chambers

Displacement (cu in):

427 (7.0L)

Engine Name:

LS7:

Engine type:

Cam-in-block 90-degree V8

Maximum rpm:

7000

Piston Part Number:

89017774

Pistons Type:

Hypereutectic aluminum

Recommended fuel:

91 octane

Reluctor wheel:

58X

Rocker arm ratio:

1.8:1 (offset intake only)

Rocker arms Type:

Investment cast, roller trunnion

Valve size (in):

2.20" titanium intake, 1.61" sodium filled exhaust

LS7 engine

The Z06's LS7 7.0L engine delivers 505 horsepower (377 kW)in a 3,132-pound (1,421 kg) package - a combination that delivers 0-60performance of 3.7 seconds in first gear, quarter-mile times of 11.7seconds at 125 mph and a top speed of 198 mph (as recorded on Germany'sAutobahn). It also provides maximum lateral acceleration of 1.04 g and60-0 braking in 111.3 feet; it also circuited Germany's famedNuerburgring in a time of 7:43.

The LS7 reintroduced the 427-cubic-inch engine to the Corvette lineup.It is easily identified under the hood by red engine covers with blacklettering. The LS7 shares the same basic Gen IV V-8 architecture as theCorvette's 6.0-liter LS2, but it uses a different cylinder block castingwith pressed-in steel cylinder liners to accommodate the engine's largerdiameter, 4.125-inch (104.8 mm) cylinder bores.

Internally, the LS7's reciprocating components make use ofracing-derived lightweight technology, including titanium connectingrods and intake valves, to help boost horsepower and rpm capability. Therpm fuel shut-off limit is 7,100 rpm. The LS7's details include:

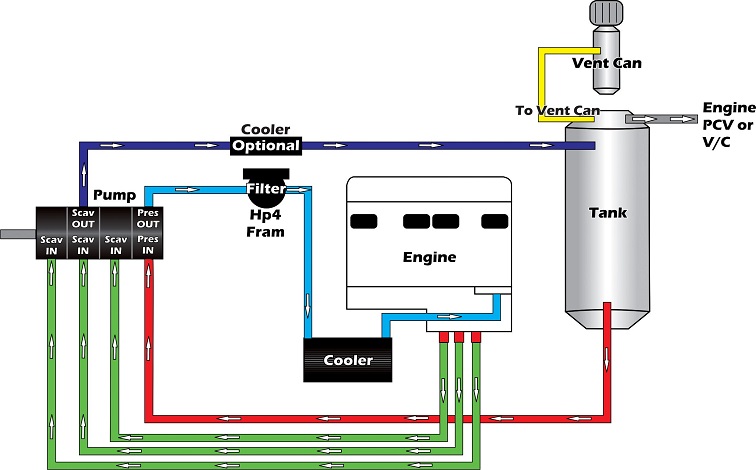

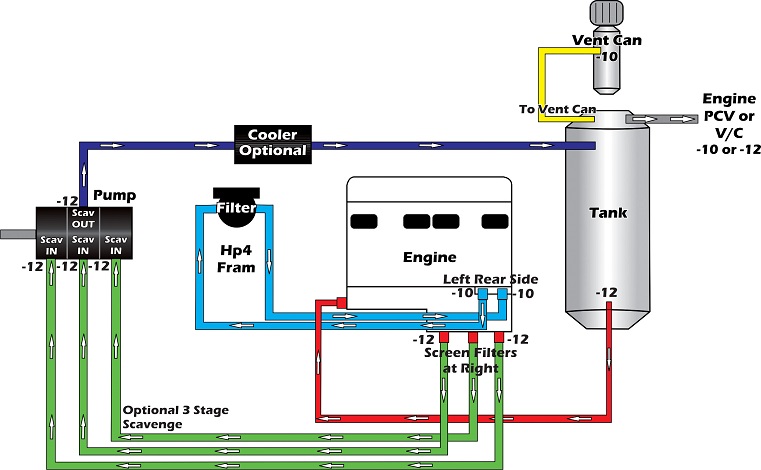

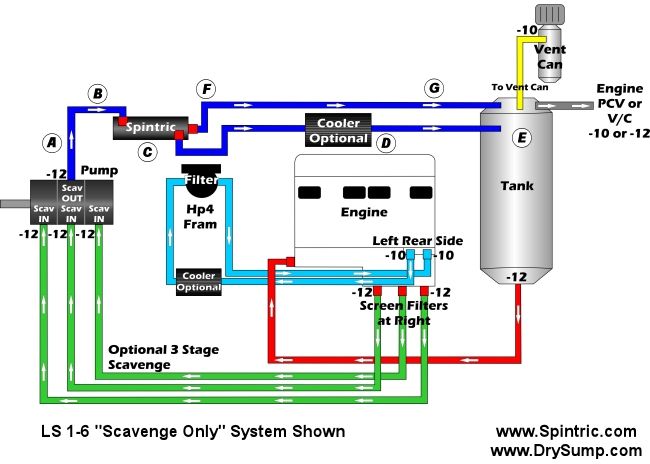

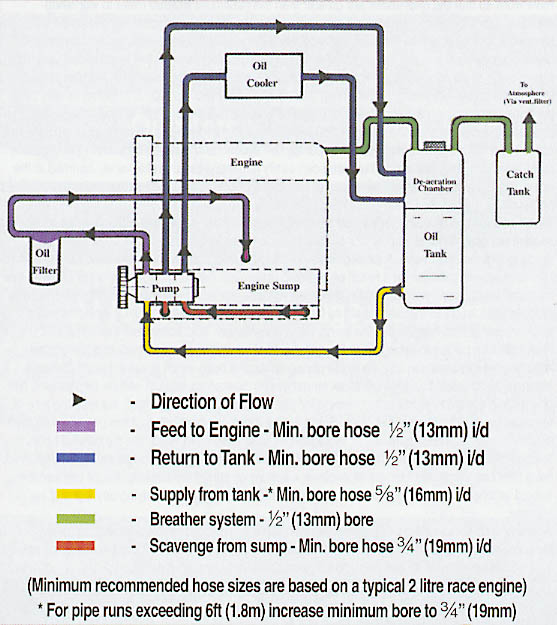

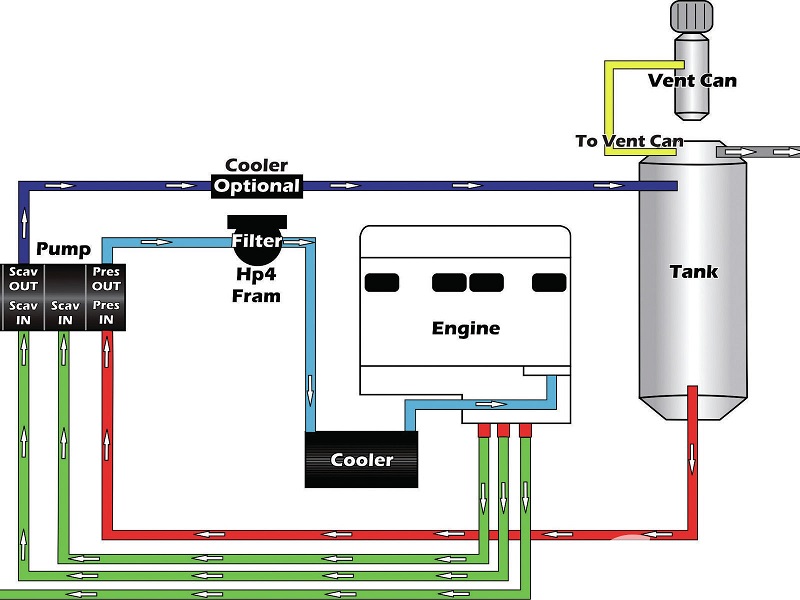

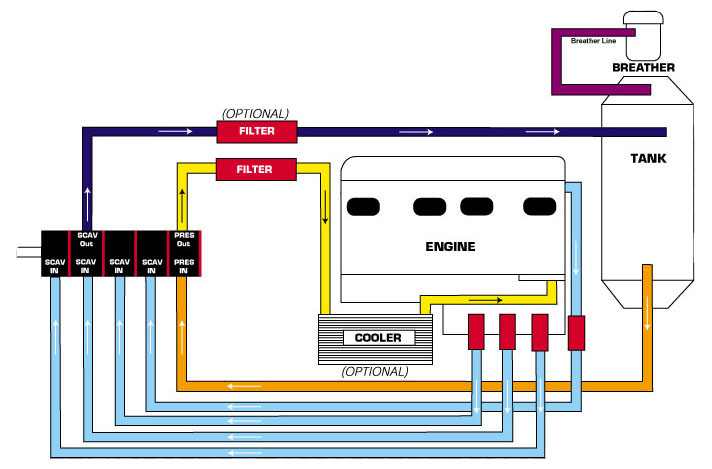

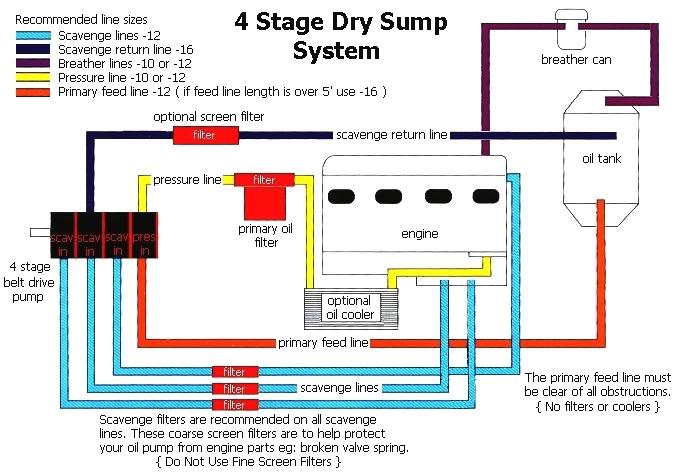

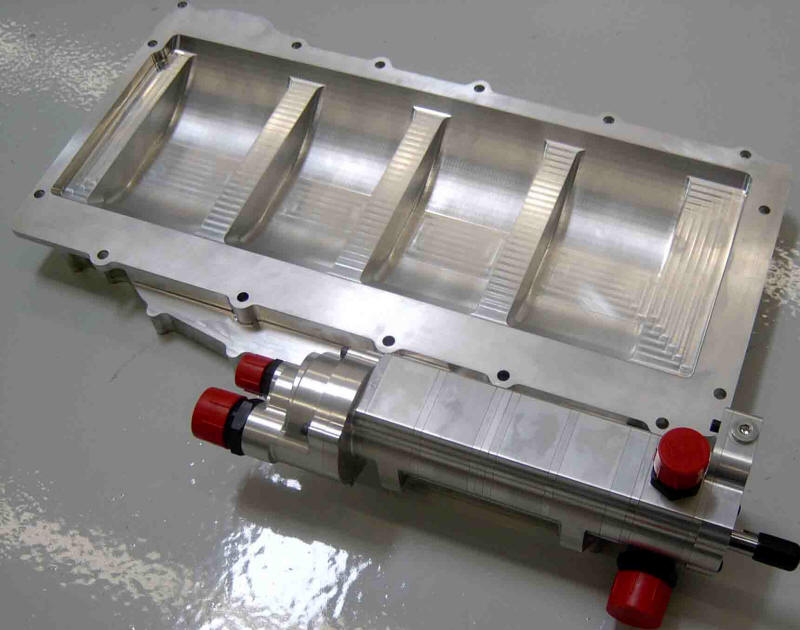

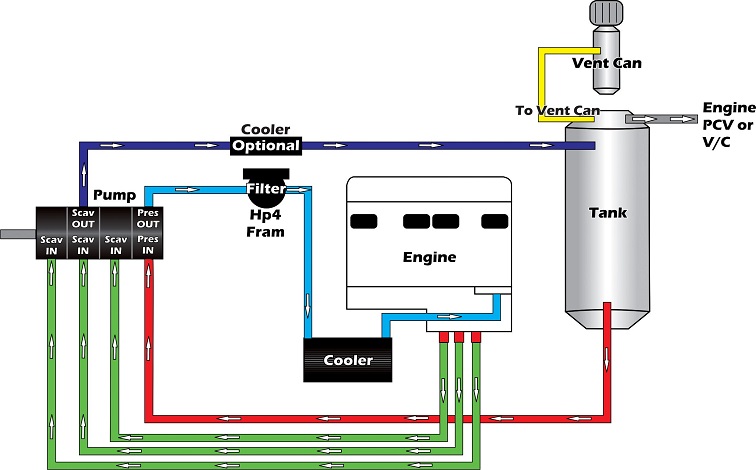

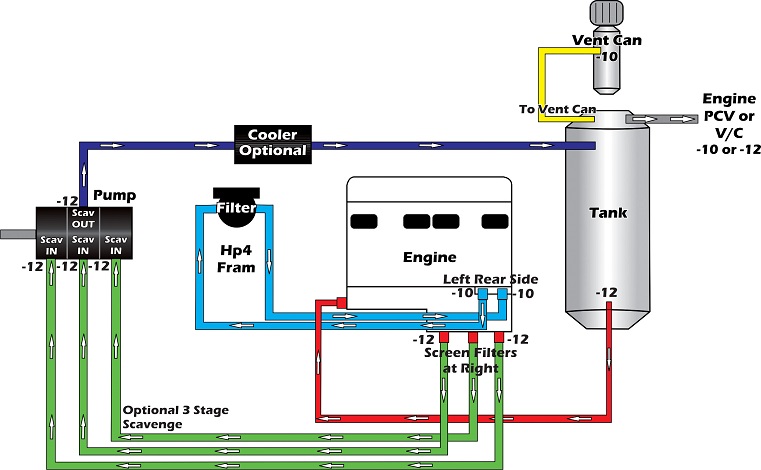

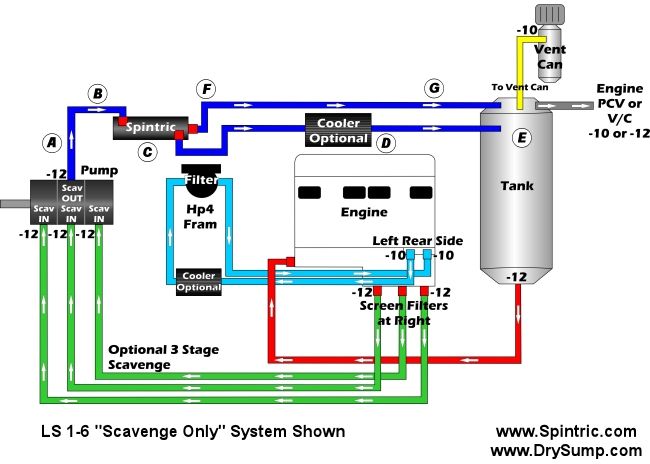

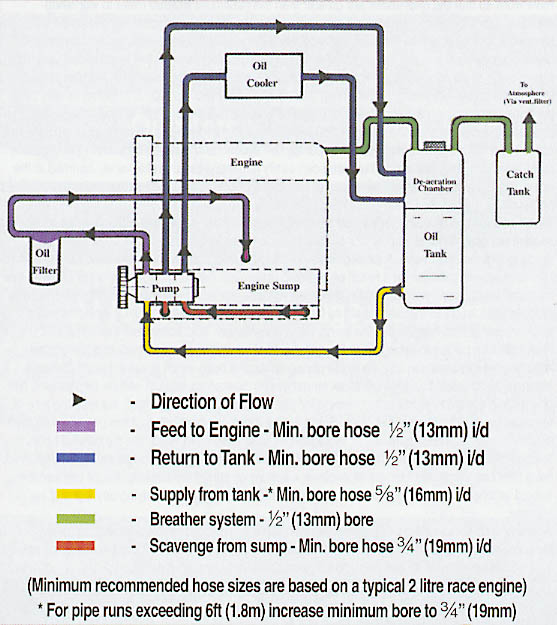

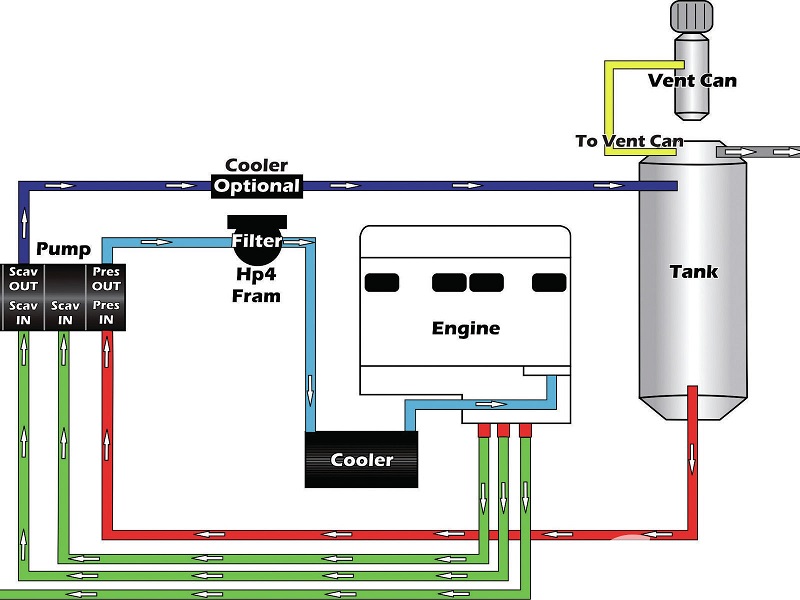

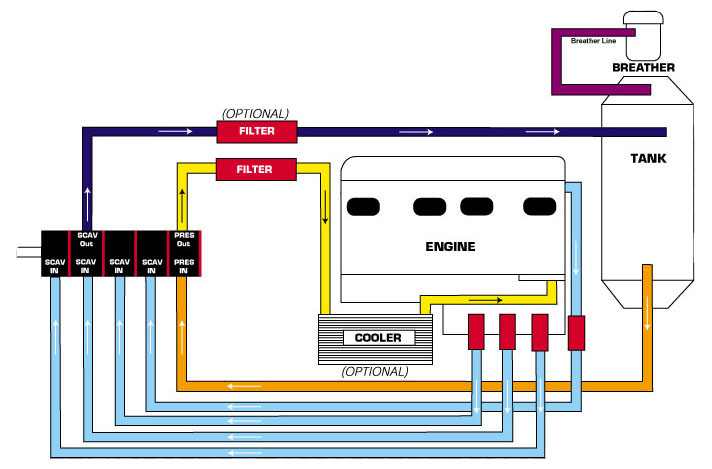

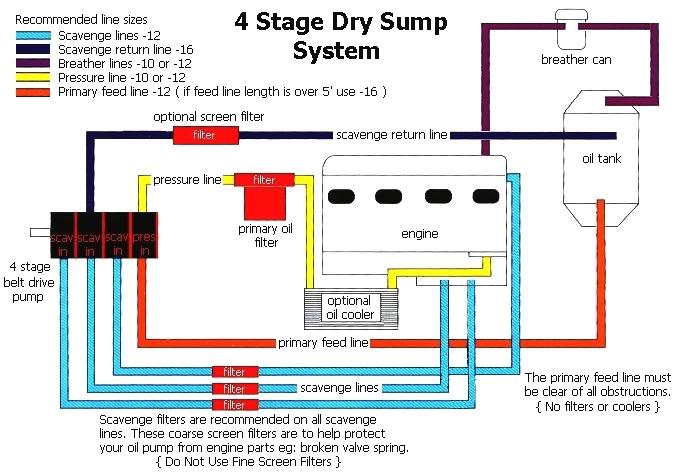

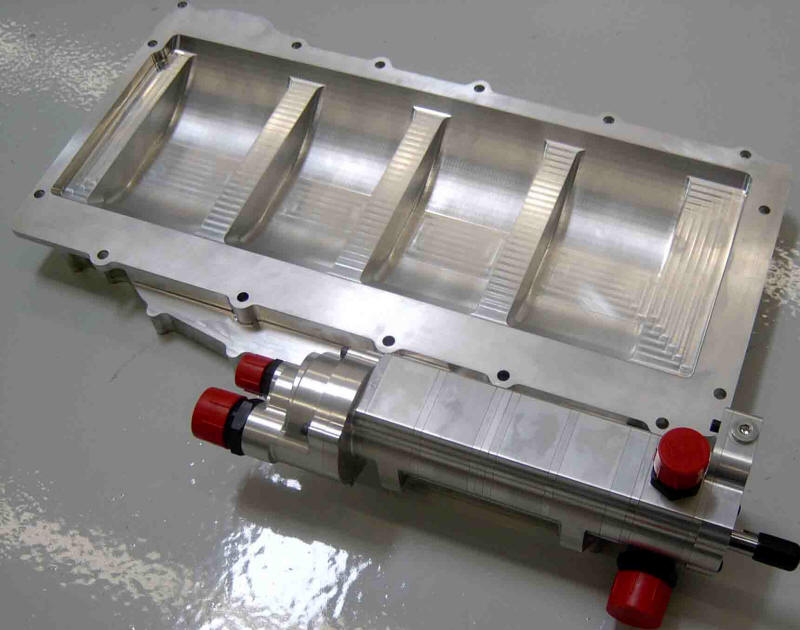

* Dry-sump oiling system

* Unique cylinder block casting with large, 104.8-mm bores and pressed-in cylinder liners

* Forged steel main bearing caps

* Forged steel crankshaft

* Titanium connecting rods with 101.6-mm stroke

* Cast aluminum flat-top pistons

* 11.0:1 compression

* High-lift camshaft

* Racing-derived CNC-ported aluminum cylinder heads with titanium intake valves and sodium-filled exhaust valves

* Low-restriction air intake system

* Hydroformed exhaust headers with unique "quad flow" collector flanges.

One of the clearest examples of the LS7's race-bred technology is itsuse of titanium connecting rods. They weigh just 464 grams apiece andbesides being lightweight, which enhances high-rpm performance and rpmrange, titanium makes the rods extremely durable.

The LS7's CNC-ported aluminum cylinder heads are designed to meet thehigh airflow demands of the engine's 7.0-liter displacement. A hydraulicroller camshaft with 0.588/0.593-inch valve lift is used to allow plentyof air to circulate in and out of the engine. To ensure optimal,uninterrupted airflow, the LS7's heads have straight, tunnel-like intakerunners. Very large by production-vehicle standards - even racingstandards - they are designed to maintain fast airflow velocity,providing excellent torque at low rpm and exhilarating horsepower athigh rpm. The heads feature 70-cc combustion chambers that are fed byhuge, 56-mm-diameter titanium intake valves. They are complemented by41-mm sodium-filled exhaust valves.

To accommodate the large valve face diameters, the heads' valve seatsare siamesed; and, taken from experience with the engines of C6.Rracecars, the LS7's valve angles are held at 12 degrees - vs. 15 degreesfor the LS2 - to enhance airflow through the ports.

The LS7 has a dry-sump oiling system designed to keep the engine fullylubricated during the high cornering loads the Corvette Z06 is capableof producing. An engine compartment-mounted 8-quart reservoir deliversoil at a constant pressure to a conventional-style oil pump pick-up atthe bottom of the engine. The pressurized oil feed keeps the oil pick-upcontinually immersed in oil at cornering loads exceeding 1 g.

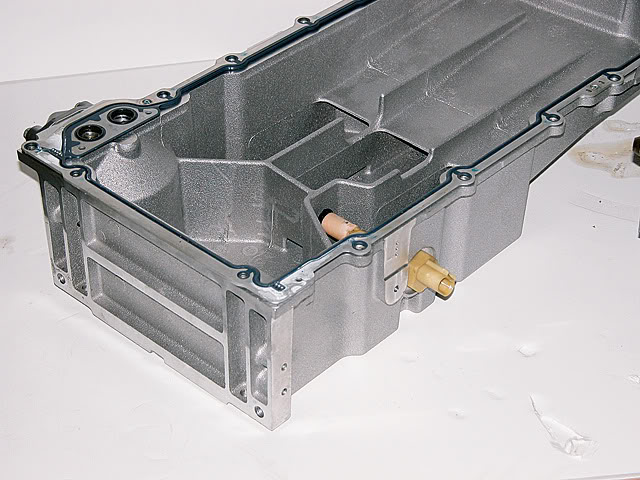

Oil circulates through the engine and down to the oil pan, where it issent back to the reservoir via a scavenge pump. The large-capacityreservoir, combined with a high efficiency air-to-oil cooler, providesnecessary engine oil cooling under the demands of the engine's poweroutput. With the dry-sump system, oil is added to the engine via thereservoir tank - which includes the oil level dipstick.

http://www.drysump.com/

http://www.drysump.com/Oil%20Pumps.htm

http://www.drysump.com/corvpan1.htm

http://www.drysump.com/ls1info.htm

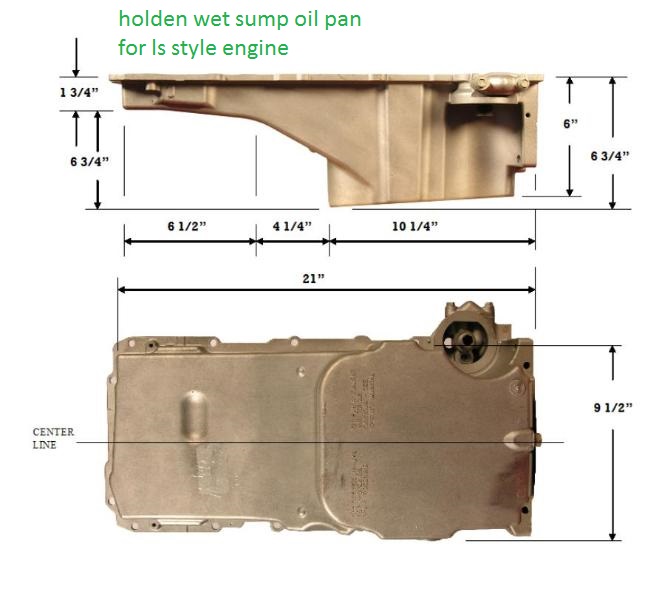

LS2 does not have a dry sump as standard equipment from the factory.

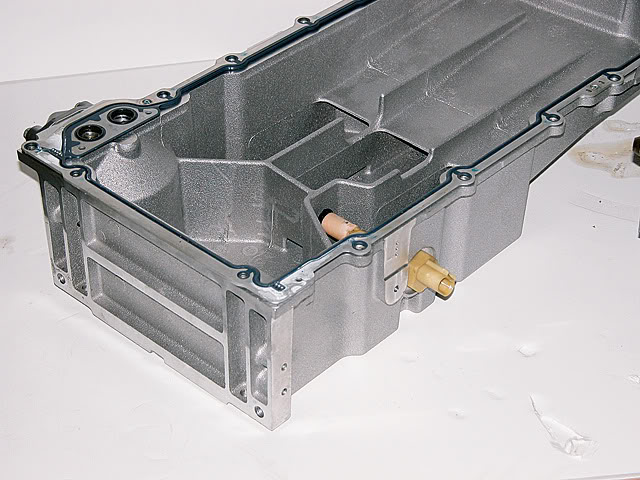

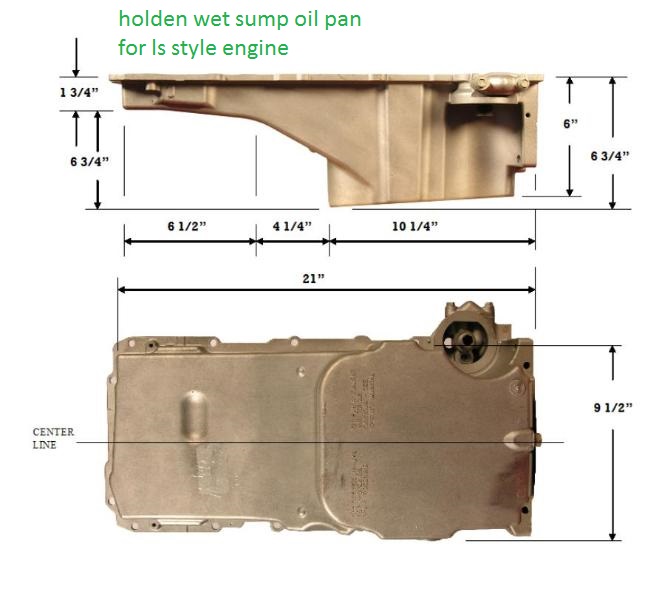

Any LS2 sump will bolt onto a LS1...LS1 sump gasket will fit... just need to use the oil pickup tube that belongs to the sump.

The LS2 sump to suit a C6 corvette has internal baffles to contain the oil better during cornering.....gone are the "batwings" seen on C5.

The LS2 sump to suit an 05 GTO looks identical externally to the LS1 GTO sump.

LS2 oil pump has better flow than LS1 but is in same position and at a glance looks the same externally. LS1 and LS2 oil pickup tubes may differ in length and position in the sump but have same tube size and O ring seal to the pump.

http://www.drysump.com/LS%20Plumbing%20Schematics.htm

17802854

Block Type:

Cast aluminum w/6-bolt steel main bearing caps

Bore x Stroke (in):

4.125 x 4.00 (104.8 mm x 101.6 mm)

Camshaft Duration:

211 degree intake / 230 degree exhaust

Camshaft lift (in):

.591" (15 mm) Intake and Exhaust

Camshaft Part Number:

Camshaft type(P/N 12571251

Camshaft type:

Hydraulic roller

Compression ratio:

11.0:1

Connecting Rod Part Number:

12586258):

Connecting rods Type:

Forged titanium

Crankshaft Part Number:

12568819

Crankshaft Type:

Forged steel

Cylinder head Part Number:

12578450

Cylinder head Type:

CNC Ported LS7 specific pattern 70 cc CNC combustion chambers

Displacement (cu in):

427 (7.0L)

Engine Name:

LS7:

Engine type:

Cam-in-block 90-degree V8

Maximum rpm:

7000

Piston Part Number:

89017774

Pistons Type:

Hypereutectic aluminum

Recommended fuel:

91 octane

Reluctor wheel:

58X

Rocker arm ratio:

1.8:1 (offset intake only)

Rocker arms Type:

Investment cast, roller trunnion

Valve size (in):

2.20" titanium intake, 1.61" sodium filled exhaust

LS7 engine

The Z06's LS7 7.0L engine delivers 505 horsepower (377 kW)in a 3,132-pound (1,421 kg) package - a combination that delivers 0-60performance of 3.7 seconds in first gear, quarter-mile times of 11.7seconds at 125 mph and a top speed of 198 mph (as recorded on Germany'sAutobahn). It also provides maximum lateral acceleration of 1.04 g and60-0 braking in 111.3 feet; it also circuited Germany's famedNuerburgring in a time of 7:43.

The LS7 reintroduced the 427-cubic-inch engine to the Corvette lineup.It is easily identified under the hood by red engine covers with blacklettering. The LS7 shares the same basic Gen IV V-8 architecture as theCorvette's 6.0-liter LS2, but it uses a different cylinder block castingwith pressed-in steel cylinder liners to accommodate the engine's largerdiameter, 4.125-inch (104.8 mm) cylinder bores.

Internally, the LS7's reciprocating components make use ofracing-derived lightweight technology, including titanium connectingrods and intake valves, to help boost horsepower and rpm capability. Therpm fuel shut-off limit is 7,100 rpm. The LS7's details include:

* Dry-sump oiling system

* Unique cylinder block casting with large, 104.8-mm bores and pressed-in cylinder liners

* Forged steel main bearing caps

* Forged steel crankshaft

* Titanium connecting rods with 101.6-mm stroke

* Cast aluminum flat-top pistons

* 11.0:1 compression

* High-lift camshaft

* Racing-derived CNC-ported aluminum cylinder heads with titanium intake valves and sodium-filled exhaust valves

* Low-restriction air intake system

* Hydroformed exhaust headers with unique "quad flow" collector flanges.

One of the clearest examples of the LS7's race-bred technology is itsuse of titanium connecting rods. They weigh just 464 grams apiece andbesides being lightweight, which enhances high-rpm performance and rpmrange, titanium makes the rods extremely durable.

The LS7's CNC-ported aluminum cylinder heads are designed to meet thehigh airflow demands of the engine's 7.0-liter displacement. A hydraulicroller camshaft with 0.588/0.593-inch valve lift is used to allow plentyof air to circulate in and out of the engine. To ensure optimal,uninterrupted airflow, the LS7's heads have straight, tunnel-like intakerunners. Very large by production-vehicle standards - even racingstandards - they are designed to maintain fast airflow velocity,providing excellent torque at low rpm and exhilarating horsepower athigh rpm. The heads feature 70-cc combustion chambers that are fed byhuge, 56-mm-diameter titanium intake valves. They are complemented by41-mm sodium-filled exhaust valves.

To accommodate the large valve face diameters, the heads' valve seatsare siamesed; and, taken from experience with the engines of C6.Rracecars, the LS7's valve angles are held at 12 degrees - vs. 15 degreesfor the LS2 - to enhance airflow through the ports.

The LS7 has a dry-sump oiling system designed to keep the engine fullylubricated during the high cornering loads the Corvette Z06 is capableof producing. An engine compartment-mounted 8-quart reservoir deliversoil at a constant pressure to a conventional-style oil pump pick-up atthe bottom of the engine. The pressurized oil feed keeps the oil pick-upcontinually immersed in oil at cornering loads exceeding 1 g.

Oil circulates through the engine and down to the oil pan, where it issent back to the reservoir via a scavenge pump. The large-capacityreservoir, combined with a high efficiency air-to-oil cooler, providesnecessary engine oil cooling under the demands of the engine's poweroutput. With the dry-sump system, oil is added to the engine via thereservoir tank - which includes the oil level dipstick.

http://www.drysump.com/

http://www.drysump.com/Oil%20Pumps.htm

http://www.drysump.com/corvpan1.htm

http://www.drysump.com/ls1info.htm

LS2 does not have a dry sump as standard equipment from the factory.

Any LS2 sump will bolt onto a LS1...LS1 sump gasket will fit... just need to use the oil pickup tube that belongs to the sump.

The LS2 sump to suit a C6 corvette has internal baffles to contain the oil better during cornering.....gone are the "batwings" seen on C5.

The LS2 sump to suit an 05 GTO looks identical externally to the LS1 GTO sump.

LS2 oil pump has better flow than LS1 but is in same position and at a glance looks the same externally. LS1 and LS2 oil pickup tubes may differ in length and position in the sump but have same tube size and O ring seal to the pump.

http://www.drysump.com/LS%20Plumbing%20Schematics.htm