My radiator has always had a problem with leaking in the upper left corner. I can get it

fixed, but then in a few weeks it's leaking again. I've had it fixed 4-5 times now and it

does the same thing every time.

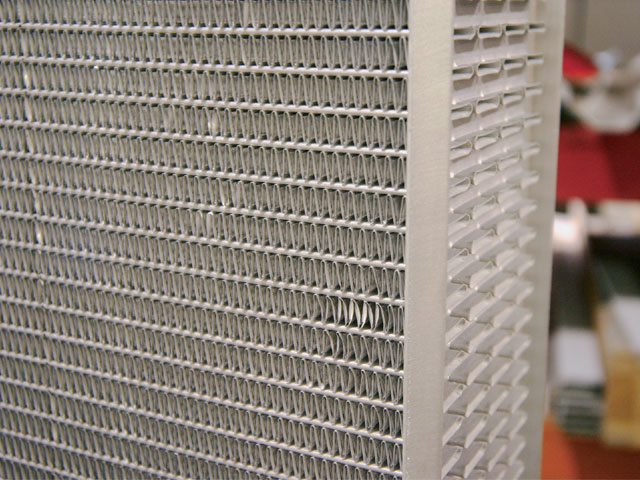

So I had the core replaced at a local shop here in town for $580. This core is the same

size, but should cool considerably better with the louvered fins that the other core did

not have. Now the other core had no problems cooling my engine and this new core does

to, so it's hard to say if it cools better. Today it's 92° F and the engine is running 175°

fixed, but then in a few weeks it's leaking again. I've had it fixed 4-5 times now and it

does the same thing every time.

So I had the core replaced at a local shop here in town for $580. This core is the same

size, but should cool considerably better with the louvered fins that the other core did

not have. Now the other core had no problems cooling my engine and this new core does

to, so it's hard to say if it cools better. Today it's 92° F and the engine is running 175°