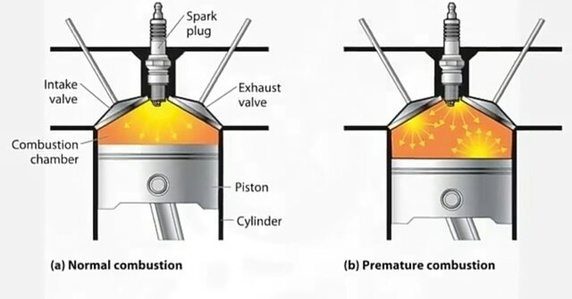

there are chances of pre-ignition and knocking, if temperature of the inlet air is higher than normal. As the temperature of the air will be higher, the temperature of air-fuel charge will also be higher (petrol engine) which means there are chances of ignition of air-fuel mixture even before the piston reaches its precise point during normal combustion.ricky said:grumpy I recently had a local guy rebuild my engine and I think its burning excessive oil, as it goes thru about a quart every 200 miles, where do I look for the cause, and yes i verified its not leaking oil and the spark plugs do show some oil being burnt.

The above picture gives a general idea about how knocking occurs.

theres several areas and Ill point out a few Ive seen. one of the first things ID suggest,is an old time test, have a buddy follow you in his car while you rapidly accelerate your car thru the first three gears then leave it in gear and pull your foot off the throttle and let the engine brake or drag the car to a lower speed. much more oil smoke on acceleration is generally related to high cylinder pressure and oil getting past the ring seal, much more oil smoke on engine braking generally related to high port vacuum levels and bad valve seals or valve guides, being worn, the next test,is to pull the intake and inspect carefully, you should easily see indications of a leaking intake gasket or bad valve guides under close visual inspection, thus you may find and determine if the oils entering the cylinders thru the heads or past the rings,it helps to know if the route the oil takes into the cylinders is thru the heads or past the rings,thus related to the heads or the rings

(1) rings need to seat to the cylinder walls this normally happens in the first 15 minutes of run time on a properly set up set of piston rings and a correctly honed cylinder wall. use of the wrong rings, or the wrong tension rings can increase oil burning

viewtopic.php?f=53&t=3897&p=26602&hilit=hone+plate#p26602

(2) FAILURE TO USE A TORQUE PLATE BEFORE HONING THE CYLINDER WALLS TENDS TO REDUCE THE CYLINDER WALL SEAL.

viewtopic.php?f=53&t=509&p=28226&hilit=hone+plate#p28226

(3)Ive seen guys who installed, new piston rings in the piston grooves either upside down in the ring grooves or installed the rings in the wrong grooves or in the pistons with more, or less than the ideal side clearance to the bore walls. if you install the rings incorrectly with the wrong side facing the top of the piston it results in an engine that basically pumps excess oil into the cylinders , you could burn 3 -4 quarts an hour if the compression rings are all upside down

Ive also seen piston grooves that were damaged or had the wrong back clearance or end gap cause problems.

viewtopic.php?f=53&t=1797&p=36469&hilit=piston+grooves#p36469

viewtopic.php?f=53&t=9490&p=34913&hilit=piston+grooves#p34913

(4) a defective p.v.c. valve or incorrectly installed valve cover baffles can cause excessive oil consumption.

viewtopic.php?f=52&t=2005&p=5328&hilit=positive+crank+case#p5328

(5)milled heads and intake surfaces must match, its common for guys to mill heads during a valve job but fail to have the intake machined to match., failure to do the machine work correctly frequently results in the intended to be mated, sealing gasket surfaces not seating and sealing correctly

viewtopic.php?f=51&t=5460&p=16311&hilit=mill+angle#p16311

viewtopic.php?f=50&t=2988&p=9055&hilit=mill+angle#p9055

(6) intake gaskets can be and frequently are sized to math intake ports on an engine, failure to match the port size to the gasket can cause leaks

viewtopic.php?f=52&t=5537&p=16750&hilit=1206+1207#p16750

(7) valve seals can be incorrectly installed, the wrong size or damaged due to use of the wrong valve train clearances

viewtopic.php?f=52&t=5306&hilit=valve+seals

(8) valve guides can be installed wrong, damaged or worn.

viewtopic.php?f=55&t=5081&p=14463&hilit=mill+angle#p14463

(9)the rocker stud threads can be a path into the intake port allowing oil to enter the intake port from the valve spring area in some heads

viewtopic.php?f=52&t=7979&p=27511&hilit=valve+guides#p27511

(10)excessively high oil levels in the crank case can cause excessive oil thrown on the cylinder walls to cause excessive oil burning

viewtopic.php?f=54&t=64

(11) in rare cases excessively high exhaust scavenging can cause you to burn a bit more oil

(12) verify your piston to valve clearance and valve train geometry,are correct and if you pull a cylinder head look carefully for detonation damage you won,t be the first guy to find a barely bent valve. or partly melted piston is the cause of excessive oil burning

viewtopic.php?f=52&t=399

http://garage.grumpysperformance.com/index.php?threads/oily-crud-on-intake-valves.12083/#post-57903

viewtopic.php?f=53&t=110&p=33300&hilit=detonation#p33300

viewtopic.php?f=50&t=2883&p=31942&hilit=detonation#p31942

viewtopic.php?f=50&t=8744&p=30912&hilit=detonation#p30912

viewtopic.php?f=87&t=332&p=30684&hilit=detonation#p30684

viewtopic.php?f=50&t=609&p=26934&hilit=detonation#p26934

viewtopic.php?f=44&t=1758&p=26252&hilit=detonation#p26252

Last edited by a moderator: