Loves302Chevy

"One test is worth a thousand expert opinions."

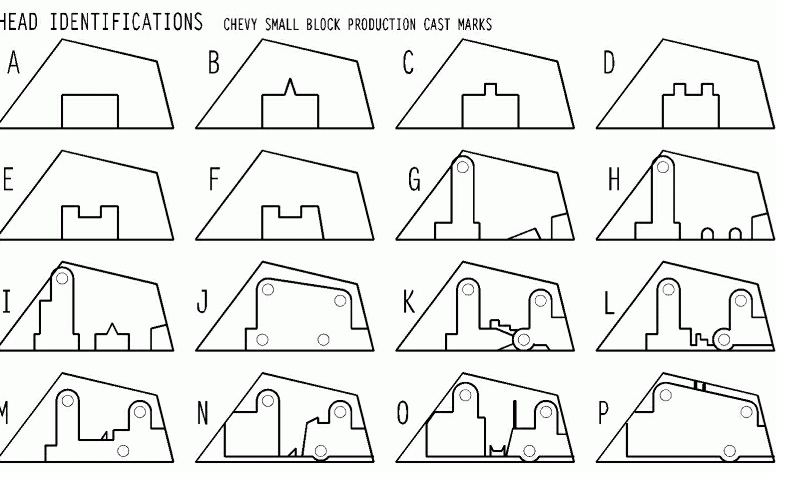

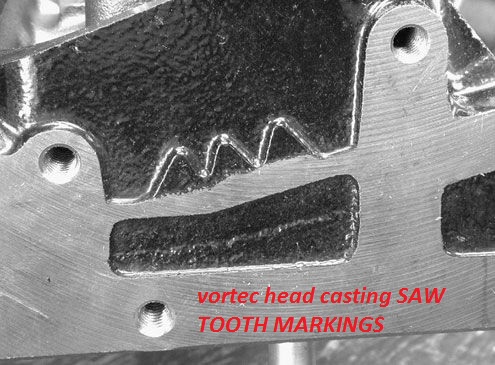

Are these heads big enough for a 383 Chevy daily driver street car? They came off of my trashed 334 (stroked 305) and I was hoping to re-use the rotating assembly with new pistons in a 350/383 block and also re-use the heads. I knew they were IRON World Products S/R Torquer 58cc for 305 Chevy (170cc intake runners). I was surprised to find out that they had 2.02/1.6 valves and the chambers overhung the bores. While I was cleaning them, I noticed that the choke points were unequal. They were gasket matched and bowl-blended by Racers' Head Service, and now (after 80+ hours of grinding by me) completely ported and smoothed and the choke points are equalized. Choke measures .95 x 1.90, which equals 1.805 sq in. and would allow only 5155 rpm in a 383 (5872 rpm for the 334). Brzezinski Racing has flow numbers for these ported heads: http://www.castheads.com/uc_flowfigures.php I would like to get them flow tested, but I don't know if there is anyone around me that does it. It would be nice if I could get close to the flow of AFR Super 23 175s with 56 cc chamber.

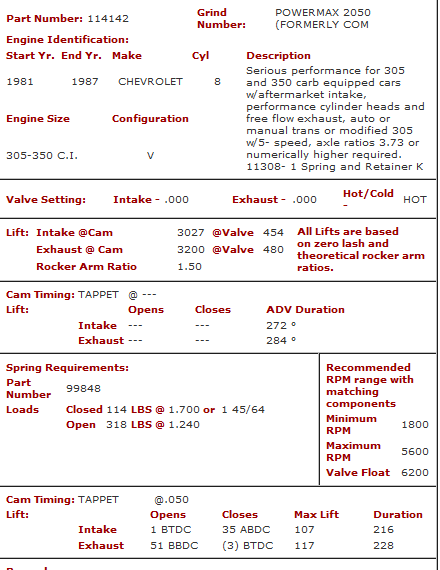

The 334 combo: .030 over 305 block (.005 deck), 2 pc seal Renegade 383 cast steel crank, Lunati LHA1 4340 5.7" bushed street/race rods (good for 450 HP @ 7000 rpm), Keith Black KB186 Hyperutectic 10 to1 pistons, TotalSeal TS1 STREET/RACE rings, 8" Streetdamper (external), and .035 thicker SFI 153 tooth flexplate with counter-balance plate added, Crane Powermax 2050 (formerly CompuCam) hydraulic flat-tappet: http://www.cranecams.com/product/cart.p ... il&p=23791, 1.6 roller-tip rockers, Weiand 8000 intake, and computer-controlled E4ME carb (modified).

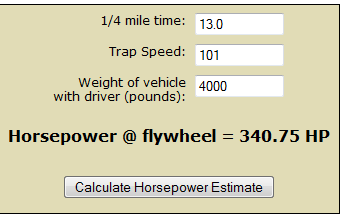

The car is a 1984 TransAm (4000#) with turbo 700R4, either a 2050 or 2200 rpm converter, 4.10 posi, and 28" tires.

Long story short: the rings never sealed, the engine developed what sounded like a lifter tick that I never could find, and eventually shavings from the failed camshaft and lifters went through the engine and chewed up the oil pump, imbedded in all of the bearings and pistons skirts, and put vertical grooves in the cylinder walls - causing the engine to spray oil out of the tailpipe. The crankshaft might take a polish and not have to be reground, and the connecting rods will have to be checked because the bearings fall out of cylinders 2-7 - only 1 and 8 still hold themselves in the rod. DETONATION IS THE CAUSE OF THE ROD BEARINGS LOSING THEIR CRUSH - ESPECIALLY ON THE UPPER (ROD) HALF. Also, all of the valve lock grooves were hammered, even on lifters & lobes that still look fine. I found that the retainers were hitting the valve seals.

I found a rear seal adapter to use a 2pc crank in a 1pc block that uses my 1984 oil pan for $90. I was planning to use a later model 350 1 pc 1996-2000 4 bolt main factory roller cam block with 22cc dished pistons to give a 9.8 to 1 compression ratio, the 334's crank, rods, and heads, and a CompCams XR270HR-10 roller cam: http://www.compcams.com/Company/CC/cam- ... d=158&sb=0 The intake would be a Performer RPM QJet along with a 1904 Quadrajet and the computer control will be GONE.

This would give me the benefit of a stronger factory roller cam block, but after spending hours browsing around this site, the info on cast iron cam cores has me more afraid of roller than flat-tappet. The added expense is a factor also.

Here is a link to this cam in a 356 chevy with S/R heads: http://www.compcams.com/v002/Pages/395/XR270HR-10.aspx

I am not allowed to attach the CamQuest and DD2000 files.

If the heads are too small for a 383, then I will rebuild the 334 correcting all of the problems I found and notch the tops of the bores. Thanks, Mike.

The 334 combo: .030 over 305 block (.005 deck), 2 pc seal Renegade 383 cast steel crank, Lunati LHA1 4340 5.7" bushed street/race rods (good for 450 HP @ 7000 rpm), Keith Black KB186 Hyperutectic 10 to1 pistons, TotalSeal TS1 STREET/RACE rings, 8" Streetdamper (external), and .035 thicker SFI 153 tooth flexplate with counter-balance plate added, Crane Powermax 2050 (formerly CompuCam) hydraulic flat-tappet: http://www.cranecams.com/product/cart.p ... il&p=23791, 1.6 roller-tip rockers, Weiand 8000 intake, and computer-controlled E4ME carb (modified).

The car is a 1984 TransAm (4000#) with turbo 700R4, either a 2050 or 2200 rpm converter, 4.10 posi, and 28" tires.

Long story short: the rings never sealed, the engine developed what sounded like a lifter tick that I never could find, and eventually shavings from the failed camshaft and lifters went through the engine and chewed up the oil pump, imbedded in all of the bearings and pistons skirts, and put vertical grooves in the cylinder walls - causing the engine to spray oil out of the tailpipe. The crankshaft might take a polish and not have to be reground, and the connecting rods will have to be checked because the bearings fall out of cylinders 2-7 - only 1 and 8 still hold themselves in the rod. DETONATION IS THE CAUSE OF THE ROD BEARINGS LOSING THEIR CRUSH - ESPECIALLY ON THE UPPER (ROD) HALF. Also, all of the valve lock grooves were hammered, even on lifters & lobes that still look fine. I found that the retainers were hitting the valve seals.

I found a rear seal adapter to use a 2pc crank in a 1pc block that uses my 1984 oil pan for $90. I was planning to use a later model 350 1 pc 1996-2000 4 bolt main factory roller cam block with 22cc dished pistons to give a 9.8 to 1 compression ratio, the 334's crank, rods, and heads, and a CompCams XR270HR-10 roller cam: http://www.compcams.com/Company/CC/cam- ... d=158&sb=0 The intake would be a Performer RPM QJet along with a 1904 Quadrajet and the computer control will be GONE.

This would give me the benefit of a stronger factory roller cam block, but after spending hours browsing around this site, the info on cast iron cam cores has me more afraid of roller than flat-tappet. The added expense is a factor also.

Here is a link to this cam in a 356 chevy with S/R heads: http://www.compcams.com/v002/Pages/395/XR270HR-10.aspx

I am not allowed to attach the CamQuest and DD2000 files.

If the heads are too small for a 383, then I will rebuild the 334 correcting all of the problems I found and notch the tops of the bores. Thanks, Mike.