http://www.superchevy.com/how-to/90...e=cxrecs&cx_navSource=related-bottom#cxrecs_s

Nothing less than Sportsman Racing– forged dished pistons would do for this motor. The dish keeps the compression down to 9.8:1. The rods are Scat H-beam 4340 forgings with ARP bolts.

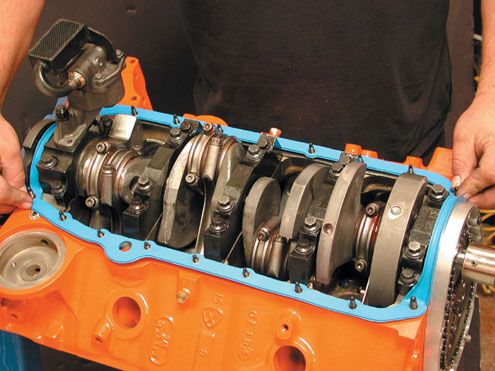

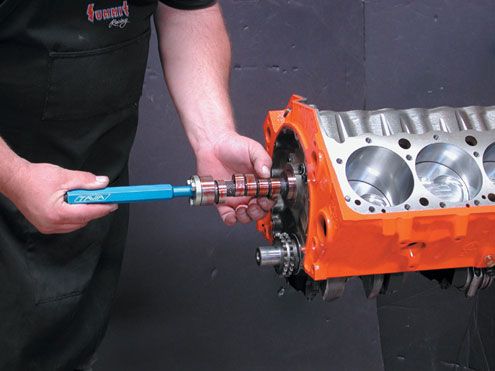

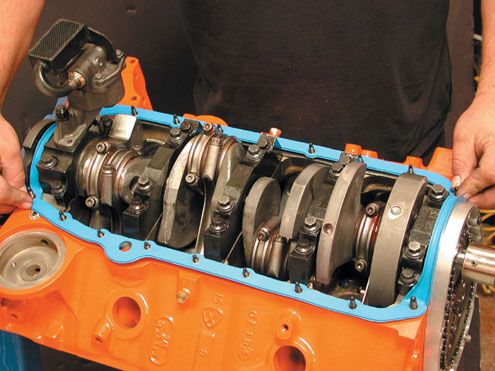

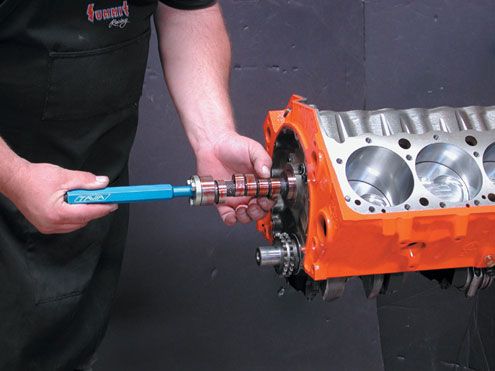

Scat also supplied the 4130 forged-steel internally balanced 3.75-inch stroke crank held in place with ARP fasteners.

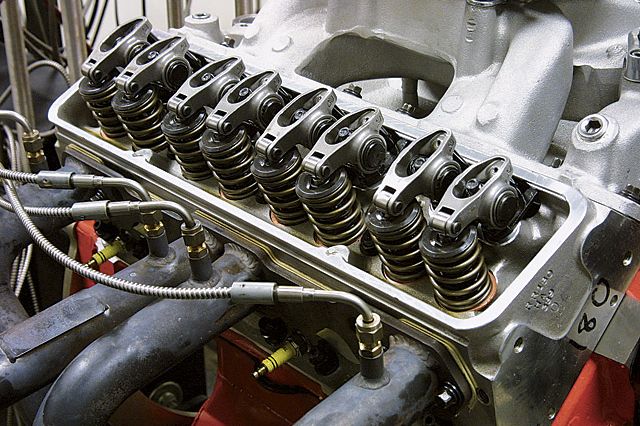

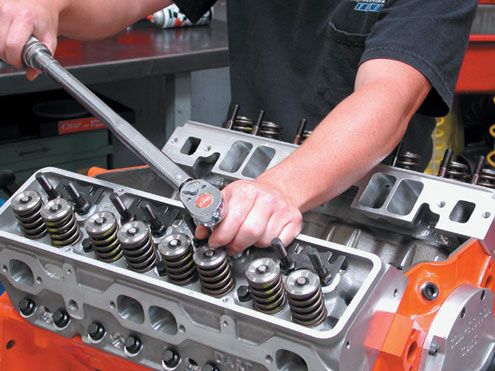

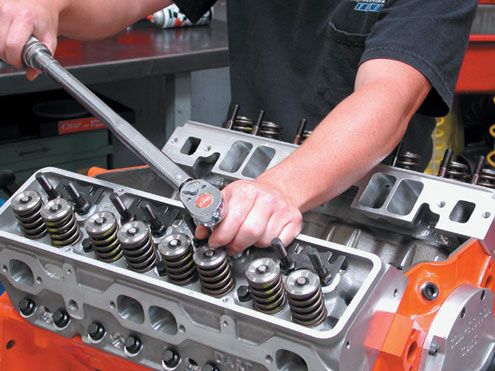

With a roller cam, it just makes sense to complete the system with a high-quality set of Pro Magnum roller rockers. We started with a set of 1.6 rockers to pump the valve lift to 0.614 inch on the intake and 0.620 inch on the exhaust.

We tested Son of Muscle Mouse on Ken Duttweiler’s dyno. After abusing the small-block for a couple of days, we managed to wring out as much as 515 hp at 6,300, and a stout 474 lb-ft of torque at 4,800 rpm. We made max horsepower with the larger 1-7/8-inch Hedman headers, while the 1-5/8-inch headers delivered the big torque numbers.

In a time not so long ago, CHP built a motor we called the Muscle Mouse. With a stock iron 400 block, Dart 215cc Iron Eagle heads, a Scat cast crank, and 4340 steel rods we had a winner on our hands. On Ken Duttweilers dyno, the small-block strong-armed its way to 455 hp at 5,500 and 498 lb-ft of torque at a streetable 3,800 rpm. We stuffed the motor in Bob Moores Camaro and took it to the track. Thats when it proceeded to eat itself alive.

The autopsy revealed that the engine had been improperly balanced, because we did not include the roll pin in the rear crank flange, and the externally balanced flexplate was positioned one bolt hole off during the balance procedure. When the flexplate was installed correctly in the car, the slight imbalance quickly destroyed the mains, killing the crank, block, and rods. After the memorial service, we vowed to build another small-block. This story is all about the Son of Muscle Mouse. In the gestation period, Ventura Motorsports engine builder Ed Taylor and the CHP staff decided to build this version with an emphasis on more muscle.

The Technology

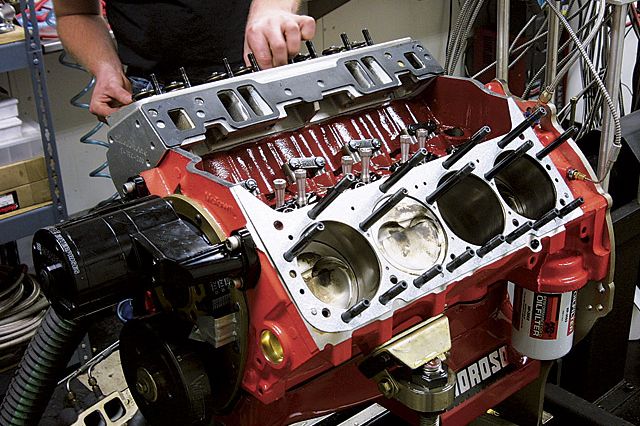

Foundations are the key to horsepower. We plan on supercharging this rascal at a later date, so we called Dart Machinery for one of the Little M blocks. With thicker siamesed cylinder walls and a 0.625-inch minimum deck thickness, the Dart Little M is one stout block. The pan rails are spread 0.400 inch while retaining the more popular two-piece rear-main seal. If desired, this block could be built as large as 455 ci using the 0.300-inch taller 9.325-inch deck height.

While we were sorely tempted to crank the displacement with a longer stroke, we stayed with the stock stroke but pumped the strength with a Scat 4130 steel forged crank. Matching the crank is a set of Scat 4340 steel H-beam–style rods pinned to Sportsman Racing Pistons (SRP) forged pistons with 21cc-dished pistons to limit the compression to 9.8:1. Along with the Speed-Pro 1/16-inch rings and the Federal-Mogul bearings, we also included a complete Moroso lubrication system.

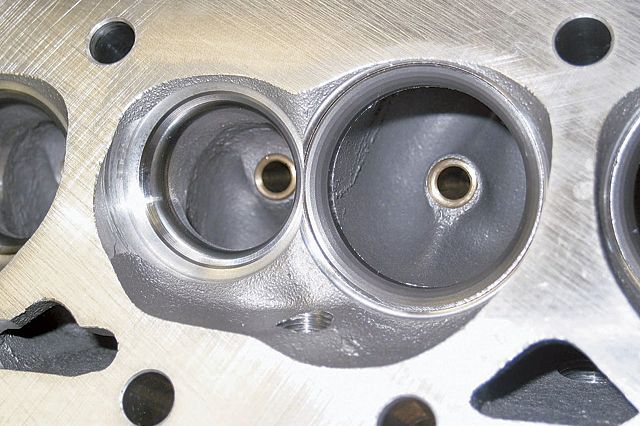

Our original 406 used Dart Iron Eagle 215cc heads, but we decided to step up to a set of Dart PRO-1 aluminum CNC-ported heads. These heads retain the standard 23-degree valve angle sitting in a 66cc CNC-machined combustion chamber using a 227cc intake port. The heads are finished off with a set of 2.08-/1.60-inch valves and 1.550-inch diameter roller cam springs and titanium retainers.

CHP’s flow testing revealed nearly 300 cfm of flow at 0.600-inch lift on the intake side, but more importantly, these heads crank out some impressive flow numbers at 0.300- and 0.400-inch lift. It is these mid-lift flow numbers that will support a strong torque curve as well as excellent peak power.

In keeping with our Dart theme, we also added Dart’s single-plane intake manifold mounted with a Barry Grant Race Demon 825-cfm double-pumper carburetor. The Race Demon also features removable venturis so we can experiment with various sizes to more accurately match the carb size to the engine.

Test Time

The Dart block required very little machine work other than boring to 4.155 inches and a torque-plate hone from Jim Grubbs Motorsports. Ed Taylor then had to do a minor amount of block massaging to notch the bottom of the bores to clear the big ends of the rods. Once he had completed the meticulous assembly, it was time to put our bruiser to the test.

After a quick break-in and some initial abuse, Taylor determined that the engine preferred 36 degrees of total timing and some minor jet changes with the Demon carburetor. He performed the first tests with the smaller 1-5/8-inch Hedman headers eventually produced 474 lb-ft of torque at 4,800 and 490 hp at 6,000. These primary pipes are actually a little small for a 406ci engine, so Taylor then swapped on a set of 1-7/8-inchers since a set of 1-¾-inch headers were not available at the time.

We assumed that the larger headers would lose a little torque down low and improve the horsepower above 5,000 rpm, which did occur. However, between 3,400 and 3,600 rpm, the larger headers actually delivered as much as 12 lb-ft more torque. We knew from the flowbench testing that the Dart PRO-1 exhaust port was extremely good, so this torque difference indicated that the smaller headers were over-scavenging the exhaust in this rpm range. The simple fix would be to change to a single-pattern cam that would improve the torque with the smaller headers and possibly peak horsepower as well.

Also, a set of 1-¾-inch headers would probably be the best overall choice for this engine even though time limitations prevented us from testing either the cam or header ideas. Clearly, there’s more left in this engine, especially if we combined a single-pattern cam with the 1-¾-inch headers. Ultimately, we plan to stuff this muscular Mouse in a Chevelle with a TCI TH400 trans and converter to test its dragstrip mettle. In a 3,650-pound car with 3.73 gears and decent traction, we conservatively estimate that this combination should run low 12s at 115 mph and possibly dip into the high 11s.

Muscle Mouse not only exceeded our expectations but also appears to be healthy and able to take on any challenge we put it up against. Stick with us—this promises to be fun.

Nothing less than Sportsman Racing– forged dished pistons would do for this motor. The dish keeps the compression down to 9.8:1. The rods are Scat H-beam 4340 forgings with ARP bolts.

Scat also supplied the 4130 forged-steel internally balanced 3.75-inch stroke crank held in place with ARP fasteners.

With a roller cam, it just makes sense to complete the system with a high-quality set of Pro Magnum roller rockers. We started with a set of 1.6 rockers to pump the valve lift to 0.614 inch on the intake and 0.620 inch on the exhaust.

We tested Son of Muscle Mouse on Ken Duttweiler’s dyno. After abusing the small-block for a couple of days, we managed to wring out as much as 515 hp at 6,300, and a stout 474 lb-ft of torque at 4,800 rpm. We made max horsepower with the larger 1-7/8-inch Hedman headers, while the 1-5/8-inch headers delivered the big torque numbers.

In a time not so long ago, CHP built a motor we called the Muscle Mouse. With a stock iron 400 block, Dart 215cc Iron Eagle heads, a Scat cast crank, and 4340 steel rods we had a winner on our hands. On Ken Duttweilers dyno, the small-block strong-armed its way to 455 hp at 5,500 and 498 lb-ft of torque at a streetable 3,800 rpm. We stuffed the motor in Bob Moores Camaro and took it to the track. Thats when it proceeded to eat itself alive.

The autopsy revealed that the engine had been improperly balanced, because we did not include the roll pin in the rear crank flange, and the externally balanced flexplate was positioned one bolt hole off during the balance procedure. When the flexplate was installed correctly in the car, the slight imbalance quickly destroyed the mains, killing the crank, block, and rods. After the memorial service, we vowed to build another small-block. This story is all about the Son of Muscle Mouse. In the gestation period, Ventura Motorsports engine builder Ed Taylor and the CHP staff decided to build this version with an emphasis on more muscle.

The Technology

Foundations are the key to horsepower. We plan on supercharging this rascal at a later date, so we called Dart Machinery for one of the Little M blocks. With thicker siamesed cylinder walls and a 0.625-inch minimum deck thickness, the Dart Little M is one stout block. The pan rails are spread 0.400 inch while retaining the more popular two-piece rear-main seal. If desired, this block could be built as large as 455 ci using the 0.300-inch taller 9.325-inch deck height.

While we were sorely tempted to crank the displacement with a longer stroke, we stayed with the stock stroke but pumped the strength with a Scat 4130 steel forged crank. Matching the crank is a set of Scat 4340 steel H-beam–style rods pinned to Sportsman Racing Pistons (SRP) forged pistons with 21cc-dished pistons to limit the compression to 9.8:1. Along with the Speed-Pro 1/16-inch rings and the Federal-Mogul bearings, we also included a complete Moroso lubrication system.

Our original 406 used Dart Iron Eagle 215cc heads, but we decided to step up to a set of Dart PRO-1 aluminum CNC-ported heads. These heads retain the standard 23-degree valve angle sitting in a 66cc CNC-machined combustion chamber using a 227cc intake port. The heads are finished off with a set of 2.08-/1.60-inch valves and 1.550-inch diameter roller cam springs and titanium retainers.

CHP’s flow testing revealed nearly 300 cfm of flow at 0.600-inch lift on the intake side, but more importantly, these heads crank out some impressive flow numbers at 0.300- and 0.400-inch lift. It is these mid-lift flow numbers that will support a strong torque curve as well as excellent peak power.

In keeping with our Dart theme, we also added Dart’s single-plane intake manifold mounted with a Barry Grant Race Demon 825-cfm double-pumper carburetor. The Race Demon also features removable venturis so we can experiment with various sizes to more accurately match the carb size to the engine.

Test Time

The Dart block required very little machine work other than boring to 4.155 inches and a torque-plate hone from Jim Grubbs Motorsports. Ed Taylor then had to do a minor amount of block massaging to notch the bottom of the bores to clear the big ends of the rods. Once he had completed the meticulous assembly, it was time to put our bruiser to the test.

After a quick break-in and some initial abuse, Taylor determined that the engine preferred 36 degrees of total timing and some minor jet changes with the Demon carburetor. He performed the first tests with the smaller 1-5/8-inch Hedman headers eventually produced 474 lb-ft of torque at 4,800 and 490 hp at 6,000. These primary pipes are actually a little small for a 406ci engine, so Taylor then swapped on a set of 1-7/8-inchers since a set of 1-¾-inch headers were not available at the time.

We assumed that the larger headers would lose a little torque down low and improve the horsepower above 5,000 rpm, which did occur. However, between 3,400 and 3,600 rpm, the larger headers actually delivered as much as 12 lb-ft more torque. We knew from the flowbench testing that the Dart PRO-1 exhaust port was extremely good, so this torque difference indicated that the smaller headers were over-scavenging the exhaust in this rpm range. The simple fix would be to change to a single-pattern cam that would improve the torque with the smaller headers and possibly peak horsepower as well.

Also, a set of 1-¾-inch headers would probably be the best overall choice for this engine even though time limitations prevented us from testing either the cam or header ideas. Clearly, there’s more left in this engine, especially if we combined a single-pattern cam with the 1-¾-inch headers. Ultimately, we plan to stuff this muscular Mouse in a Chevelle with a TCI TH400 trans and converter to test its dragstrip mettle. In a 3,650-pound car with 3.73 gears and decent traction, we conservatively estimate that this combination should run low 12s at 115 mph and possibly dip into the high 11s.

Muscle Mouse not only exceeded our expectations but also appears to be healthy and able to take on any challenge we put it up against. Stick with us—this promises to be fun.

Last edited: