Michel Resdi

Member

I drive a 67 396/325 Impala sports coupe,that i brought from the USA to France ,in 1990.

135000 miles on the odometer.

The car has not been driven,for ten years,so i decided to give it some fresh stuff before going back to the road.

New timing chain and gears,and a pair of head gaskets,among other treats.

After initial start up everything seemed to be ok.

It ran fine,temp and oil pressure ok. (i have added some extra instruments)

I let it warm up and iddle ,drove aroud the block a few times: no issues .

Then ,after start up,i noticed a drop on the oil pressure meter,and the oil pressure idiot light went on.

I killed the engine,and checked the engine bay.

No leak whatsoever,the oil level was at the low mark,as i was planning to change the oil after a short time.

I replaced the oil filter: same thing.

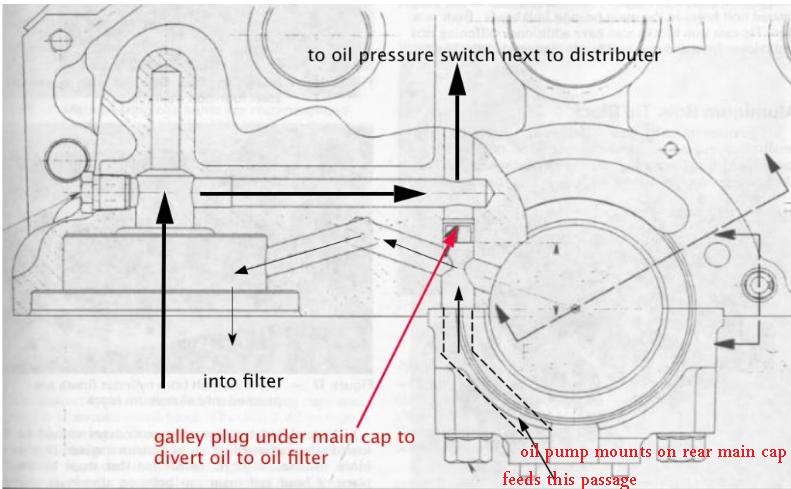

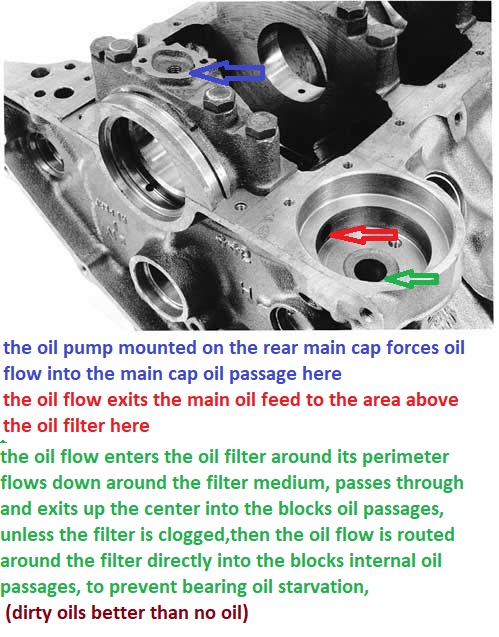

Oil pressure builds up on starting ,then falls down slowly to almost none...

I put a gage with an oil feed tube ,a new filter again ,and saw that pressure built up as the filter was filled then slowly falled down to zero.

This not temperature related,as the engine was cold.

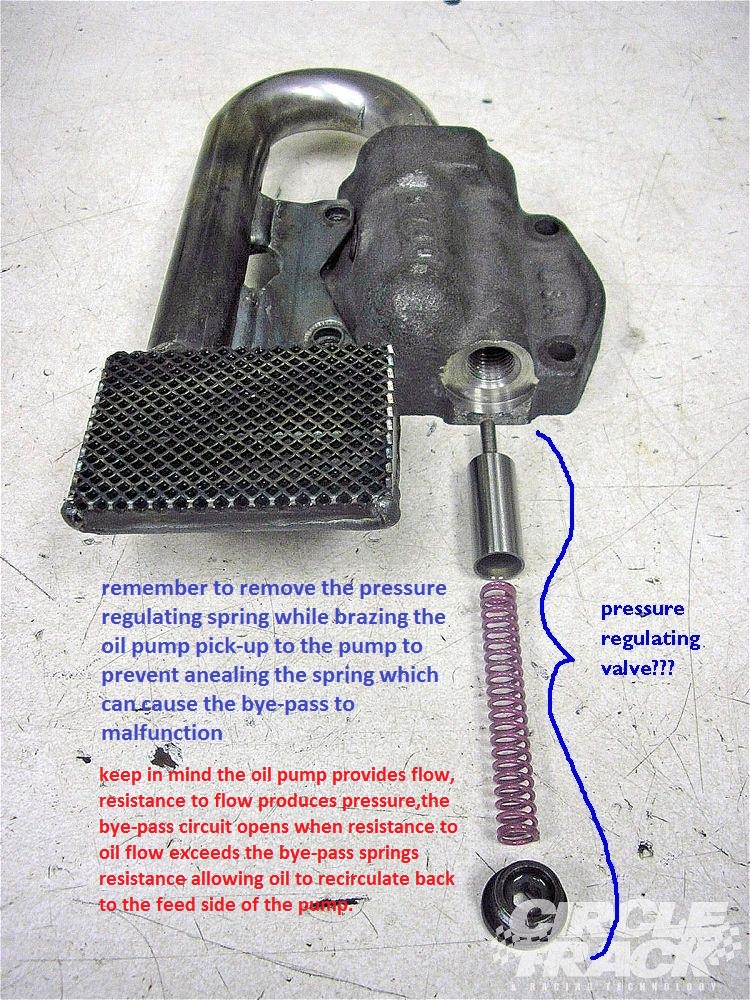

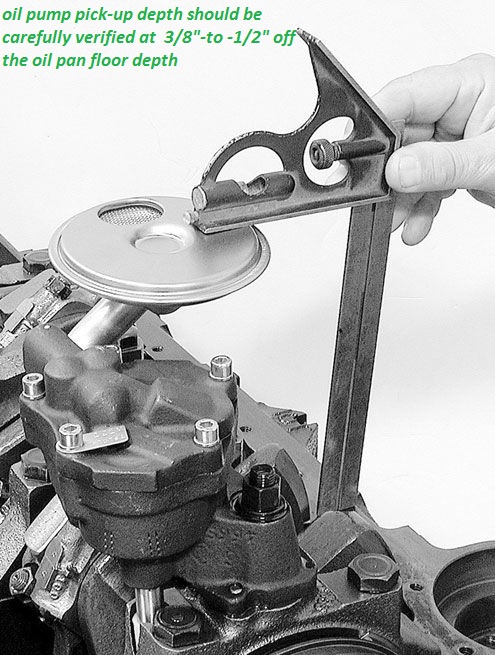

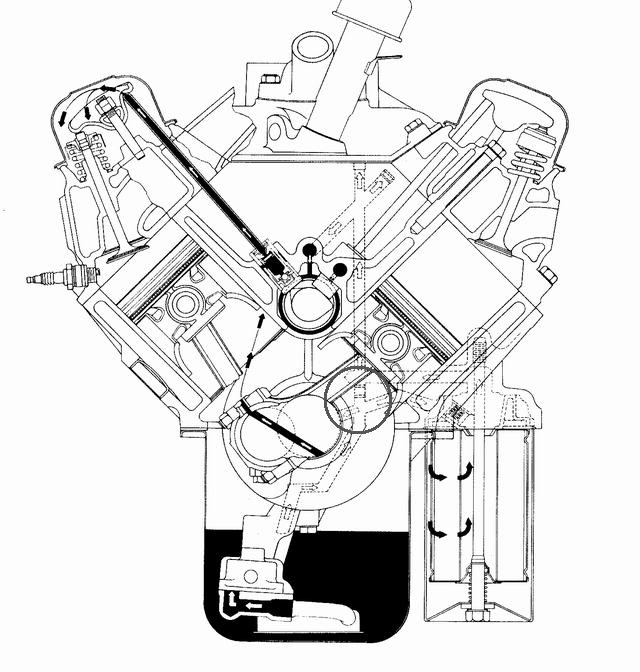

I took the oil sump out,and checked the pump : it seems ok to me.

What could cause this condition?

Thanks for reading so far. Any suggestion welcome.

135000 miles on the odometer.

The car has not been driven,for ten years,so i decided to give it some fresh stuff before going back to the road.

New timing chain and gears,and a pair of head gaskets,among other treats.

After initial start up everything seemed to be ok.

It ran fine,temp and oil pressure ok. (i have added some extra instruments)

I let it warm up and iddle ,drove aroud the block a few times: no issues .

Then ,after start up,i noticed a drop on the oil pressure meter,and the oil pressure idiot light went on.

I killed the engine,and checked the engine bay.

No leak whatsoever,the oil level was at the low mark,as i was planning to change the oil after a short time.

I replaced the oil filter: same thing.

Oil pressure builds up on starting ,then falls down slowly to almost none...

I put a gage with an oil feed tube ,a new filter again ,and saw that pressure built up as the filter was filled then slowly falled down to zero.

This not temperature related,as the engine was cold.

I took the oil sump out,and checked the pump : it seems ok to me.

What could cause this condition?

Thanks for reading so far. Any suggestion welcome.