Is there a way to circulate the oil before start-up for an engine that has not run for 4 years (stored in climate controlled garage) without removing the distributor and using a drill on the oil pump gear? Approximately how long sitting before a 'dry-start" condition exists, or is this a moot issue on an engine of moderate use and mileage? One more - Do the lifters drain out oil when sitting?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oil drain off & Circulation

- Thread starter chromebumpers

- Start date

http://www.melling.com/Aftermarket/High ... -Lube-Tank

http://www.mellingengine.com/Portals/5/ ... ricing.pdf

viewtopic.php?f=54&t=3144&p=16458&hilit=remote+filter#p16458

re-Lube Engine Oiler Tank

New Pre-Lube Engine Oiler tank tool now available!

Part # MPL-101

A MUST HAVE TOOL TO PRE-LUBE ENGINES

• Eliminates dry starts after engine rebuilds

• Eliminates initial wear on engine components

• Can be used on all internal combustion engines

Click here to Download FULL PDF Product Release

Additional Info:

The newest addition to Melling’s offering is a pre-lube tank. This design is necessary because of the inability to prime the oiling system in today’s modern engine with the oil pump mounted over the crankshaft. We did not need this in older engines because you could use the tools provided by Melling and a common drill to turn the pump and prime the system.

Here is some more details about the tank:

The size of the whole unit is about ½ the size of your gas grill propane tank.

Normal engine oil is used to fill the tank. (use the oil that will be used to break in the engine)

The tank will hold 4 quarts maximum. Usually 3 quarts is sufficient to fill the engine. The tank even has a dipstick.

The tank is then pressurized using your air compressor.

Included with the unit are the most popular two adaptors to fit most engines. 1/8th x 1/8th and 1/8th x ¼ are the two sizes included.

The adaptor is installed on the engine and then screwed to the hose from the tank.

The fill vale is turned and in a very short period of time oil will be flowing from the valvetrain area of the engine. The prime is complete. Fill the engine with oil, complete the build and start an engine that will live for a long time. You will not suffer from dry

http://www.mellingengine.com/Portals/5/ ... ricing.pdf

viewtopic.php?f=54&t=3144&p=16458&hilit=remote+filter#p16458

re-Lube Engine Oiler Tank

New Pre-Lube Engine Oiler tank tool now available!

Part # MPL-101

A MUST HAVE TOOL TO PRE-LUBE ENGINES

• Eliminates dry starts after engine rebuilds

• Eliminates initial wear on engine components

• Can be used on all internal combustion engines

Click here to Download FULL PDF Product Release

Additional Info:

The newest addition to Melling’s offering is a pre-lube tank. This design is necessary because of the inability to prime the oiling system in today’s modern engine with the oil pump mounted over the crankshaft. We did not need this in older engines because you could use the tools provided by Melling and a common drill to turn the pump and prime the system.

Here is some more details about the tank:

The size of the whole unit is about ½ the size of your gas grill propane tank.

Normal engine oil is used to fill the tank. (use the oil that will be used to break in the engine)

The tank will hold 4 quarts maximum. Usually 3 quarts is sufficient to fill the engine. The tank even has a dipstick.

The tank is then pressurized using your air compressor.

Included with the unit are the most popular two adaptors to fit most engines. 1/8th x 1/8th and 1/8th x ¼ are the two sizes included.

The adaptor is installed on the engine and then screwed to the hose from the tank.

The fill vale is turned and in a very short period of time oil will be flowing from the valvetrain area of the engine. The prime is complete. Fill the engine with oil, complete the build and start an engine that will live for a long time. You will not suffer from dry

now that you know such a product/tool exists I can,t see any reason a 3" diam. 3 foot long section of schedule 80 PVC pipe , with a screw on cap on the upper end and a glued on lower cap, with a couple adapter fittings and hoses could not be partly filled with new oil and have an air fitting on the upper cap set up so you could first fill the pipe with several quarts of oil, screw on the cap, apply 10-12 psi of air pressure with a compressor to the area over the oil, too force oil into all the interior oil passages and bearings thru one of the oil sensor connection threaded holes in the block, thru a lower drain hose and adapters you bought at a local hardware or hydraulic supply shop.

Thanks Grumpy. I will make this one first since it's so simple, cheap and easy to use.

I do remember many years back there was an interior switch operated pump. All set up and when you jumped into the car you could hit the switch, wait until oil pressure went up, shut it off and you're ready to start the engine. Any knowledge of that one?

I do remember many years back there was an interior switch operated pump. All set up and when you jumped into the car you could hit the switch, wait until oil pressure went up, shut it off and you're ready to start the engine. Any knowledge of that one?

http://garage.grumpysperformance.com/index.php?threads/oil-accumulator.1280/#post-48139

viewtopic.php?f=54&t=4537&p=12073#p12073

viewtopic.php?f=54&t=3144&p=16458&hilit=remote+filter#p16458

http://garage.grumpysperformance.co...king-how-other-people-might.11959/#post-56957

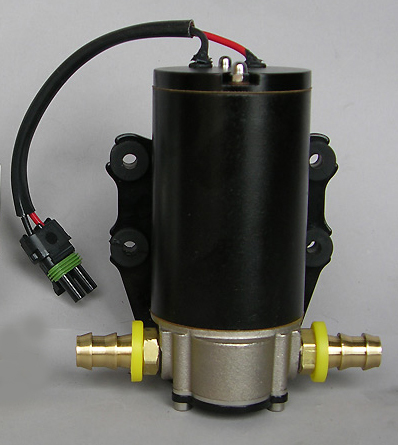

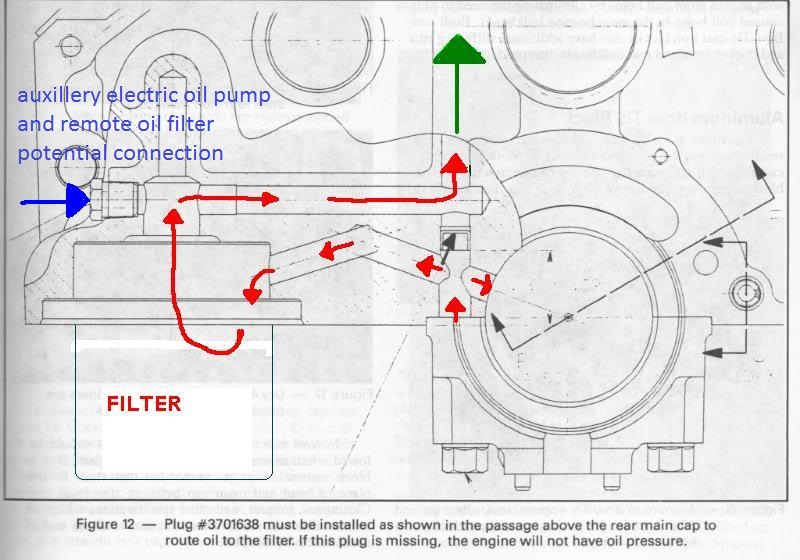

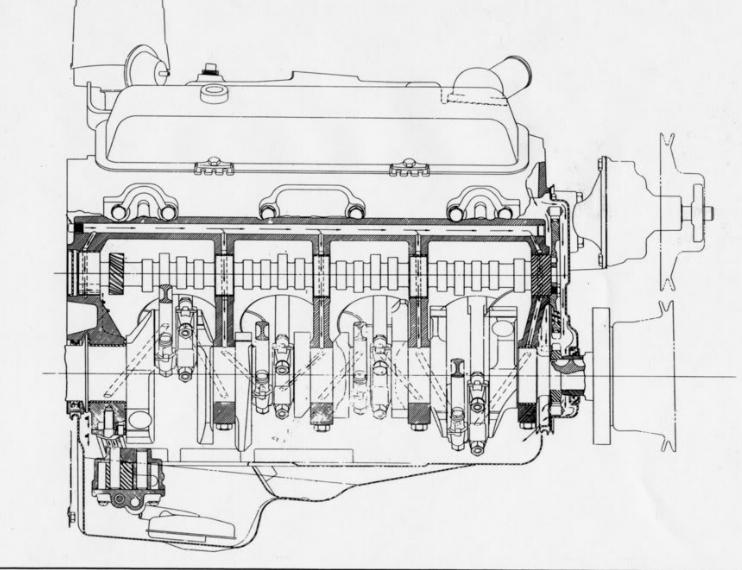

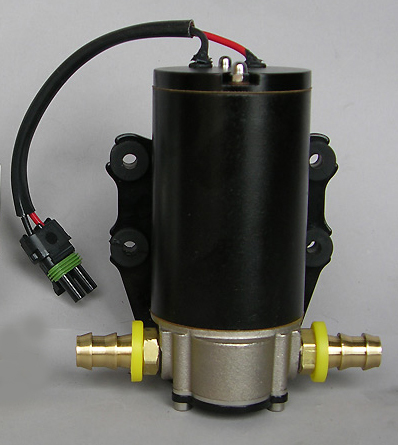

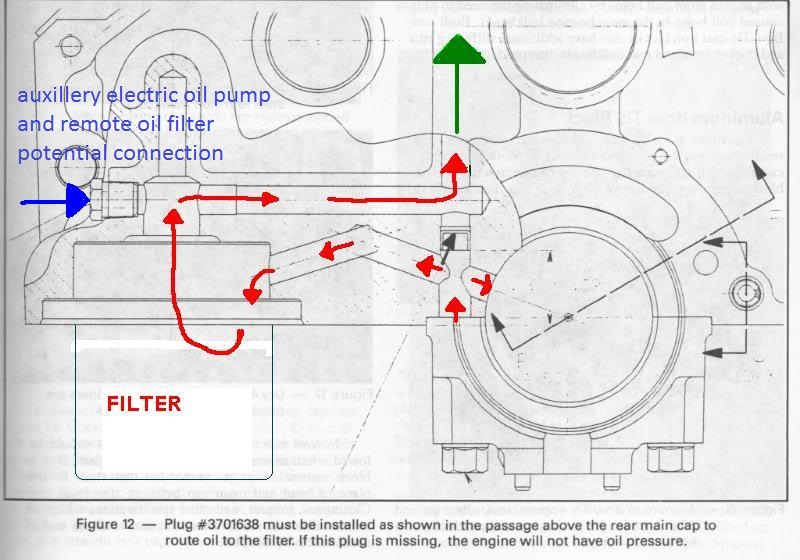

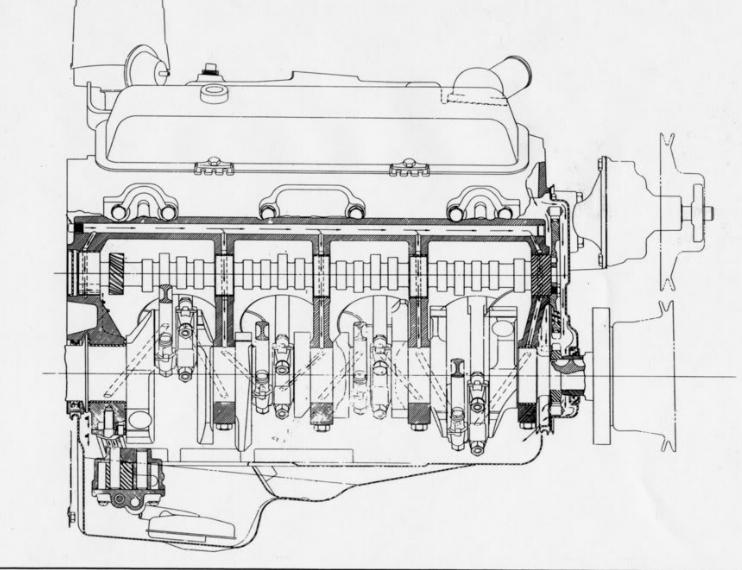

OBVIOUSLY you have the option of installing an oil accumulator or a separate auxiliary electric powered oil pump to pre-prime the engine and pressurize the bearings prior to start up, and because most engine wear occurs during the first 60 seconds under low oil flow conditions adding a pre-presurized oil flow system should in theory add to the engine durability

http://www.thinkauto.com/oilpumps.htm

http://www.rbracing-rsr.com/oilsystems.htm

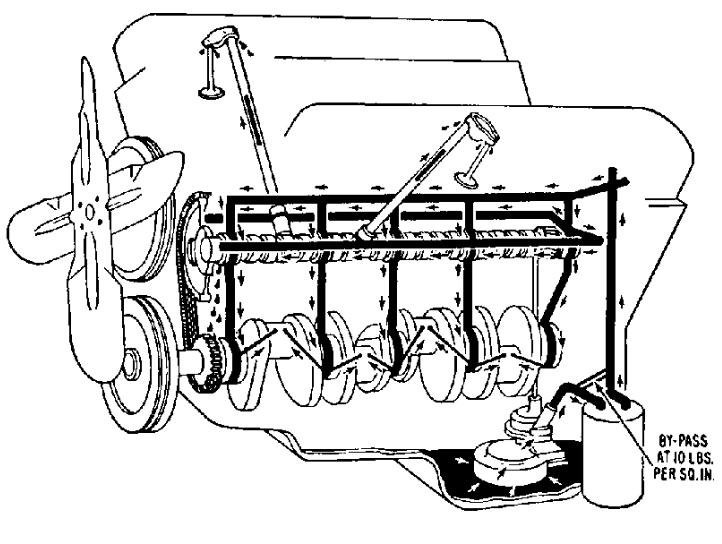

as a general rule as your engine oil viscosity is reduced the effort required to pump the oil thru clearances is lower and the pressure reading on the gauge drops, thats not necessarily an indication of lower bearing protection, as thats generally a function of oil quality and its formula, and basic components used, in its design, and generally its increased flow rate increases bearing cooling, a good quality 10w30 should ideally provide 20-22 psi at 800rpm idle (anything over 15-17 psi at 800rpm is fine) and 60-65psi by 5000rpm which is all you can use

Ive had several guys bring in c4 corvettes with both flat tappet and roller cams that had sticky or only semi functional hydraulic lifters.

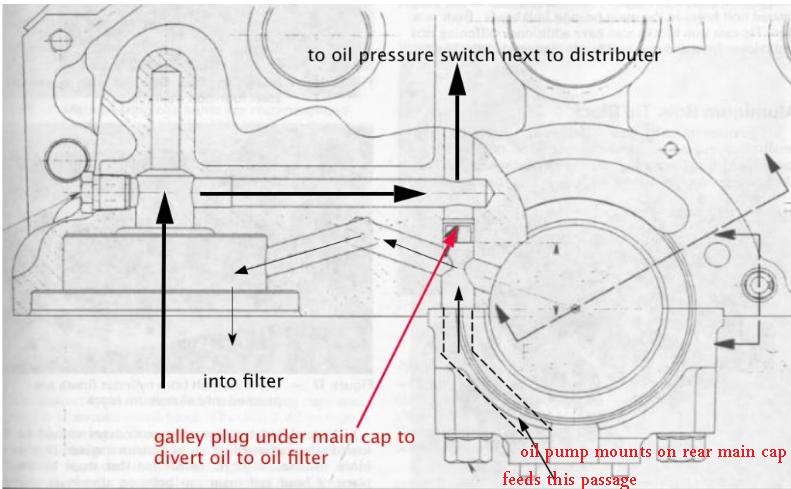

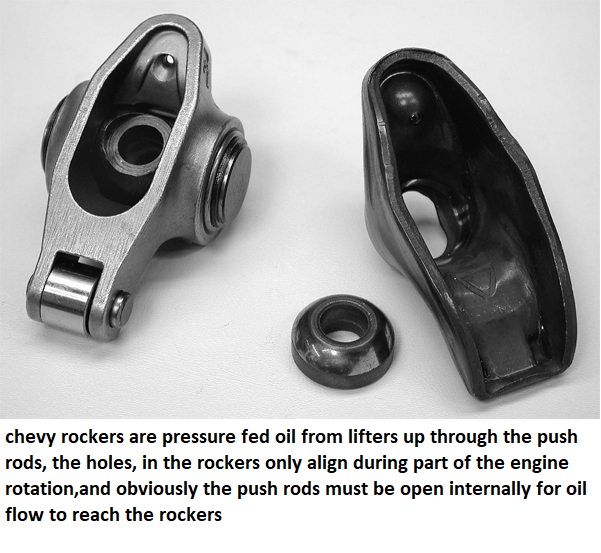

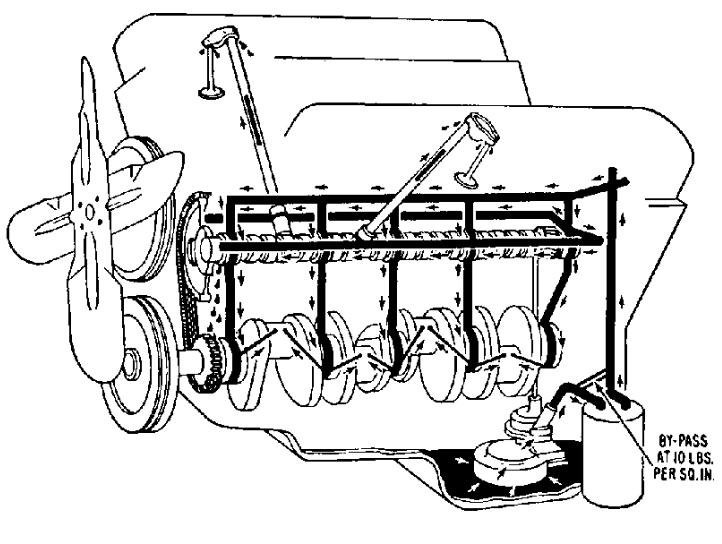

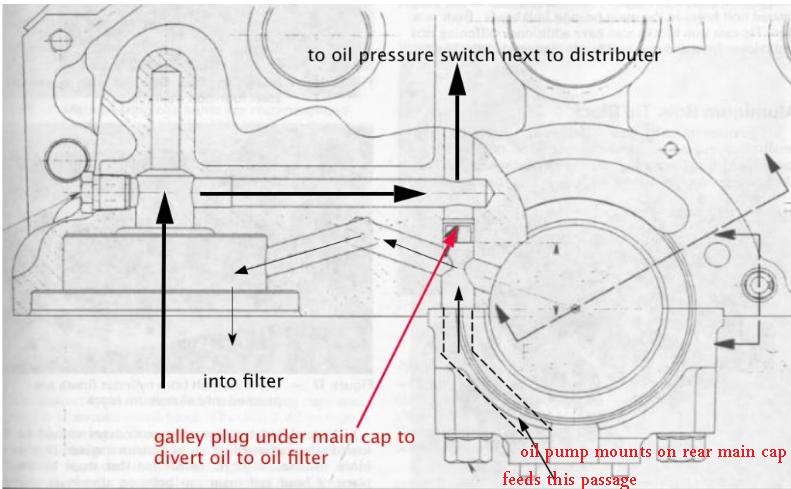

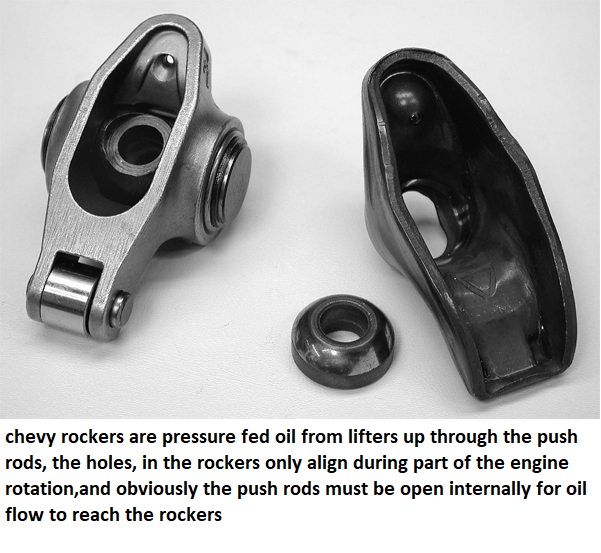

the first symptom is both noise in the valve train and little or no oil flow out of the push rods feeding oil flow too the rocker but you've got good oil pressure

this seems too be rather common in cars where for one reason or another the engines not been started for several months or years.

now obviously you might have mechanical issues or parts failure,

but in many cases its simply built up varnish or sludge,

or minor rust from moisture trapped in the engine during longer term storage.

first step is always doing an oil change to a good brand of high detergent 10w30 oil and a new WIX or PUREOLATOR or similar quality oil filter.

STEP TWO

remove each push rod and soak it briefly (10-15 minutes)in a can of 50% gas and 50% carb cleaner, then use a compressor and high velocity air nozzle to blow out and verify the push rods completely clean and free of internal debris, or sludge.

https://www.harborfreight.com/catalog/product/view/id/13295/

to get the best results I found loosening the valve lash 1/2 turn out so the lifters click almost like solid lifters speeds up the process of getting stuck lifter internals on hydraulic lifters to free up and driving the car for a couple hours tends to do a great deal of good

adding a quart of MMO

and a can of liquid moly

https://www.amazon.com/Liqui-Moly-20004-Hydraulic-Additive/dp/B0096Y6XPC/?tag=newcarpassionate-20

seafoam engine additives all help

additive's with solvents and detergents and added lubricants certainly won,t hurt the process of removing contaminants , and temporarily allowing a few extra thousands clearance in the valve train seems to speed up the process, after youve driven the car for an hour or so with the fresh oil, new oil filter and additives youll generally find the lifters have freed up unless theres a mechanical wear issue like a damaged cam lobe or defective or worn lifter, so you can re-adjust the valves correctly

youll generally want to install hydraulic roller lifter's with the oil feed holes pointing to the rear of the engine,

but its not super critical as hydraulic pressure in the blocks lifter gallery,

oil feed passages ,

insures the roller lifters get sufficient oil flow facing in either direction.

you should read these posted link's, and sub links

http://garage.grumpysperformance.co...ter-pumps-oil-and-traps-oil.15555/#post-92843

http://garage.grumpysperformance.co...er-lifter-install-direction.11398/#post-52208

http://garage.grumpysperformance.com/index.php?threads/correctly-adjusting-valves.196/#post-90731

http://garage.grumpysperformance.com/index.php?threads/can-t-adjust-the-valve-lash.15404/#post-90613

http://garage.grumpysperformance.co...ulic-lifters-mystery-solved.12263/#post-60159

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.com/index.php?threads/oil-pump-priming.15211/

viewtopic.php?f=54&t=4537&p=12073#p12073

viewtopic.php?f=54&t=3144&p=16458&hilit=remote+filter#p16458

http://garage.grumpysperformance.co...king-how-other-people-might.11959/#post-56957

OBVIOUSLY you have the option of installing an oil accumulator or a separate auxiliary electric powered oil pump to pre-prime the engine and pressurize the bearings prior to start up, and because most engine wear occurs during the first 60 seconds under low oil flow conditions adding a pre-presurized oil flow system should in theory add to the engine durability

http://www.thinkauto.com/oilpumps.htm

http://www.rbracing-rsr.com/oilsystems.htm

as a general rule as your engine oil viscosity is reduced the effort required to pump the oil thru clearances is lower and the pressure reading on the gauge drops, thats not necessarily an indication of lower bearing protection, as thats generally a function of oil quality and its formula, and basic components used, in its design, and generally its increased flow rate increases bearing cooling, a good quality 10w30 should ideally provide 20-22 psi at 800rpm idle (anything over 15-17 psi at 800rpm is fine) and 60-65psi by 5000rpm which is all you can use

Ive had several guys bring in c4 corvettes with both flat tappet and roller cams that had sticky or only semi functional hydraulic lifters.

the first symptom is both noise in the valve train and little or no oil flow out of the push rods feeding oil flow too the rocker but you've got good oil pressure

this seems too be rather common in cars where for one reason or another the engines not been started for several months or years.

now obviously you might have mechanical issues or parts failure,

but in many cases its simply built up varnish or sludge,

or minor rust from moisture trapped in the engine during longer term storage.

first step is always doing an oil change to a good brand of high detergent 10w30 oil and a new WIX or PUREOLATOR or similar quality oil filter.

STEP TWO

remove each push rod and soak it briefly (10-15 minutes)in a can of 50% gas and 50% carb cleaner, then use a compressor and high velocity air nozzle to blow out and verify the push rods completely clean and free of internal debris, or sludge.

https://www.harborfreight.com/catalog/product/view/id/13295/

to get the best results I found loosening the valve lash 1/2 turn out so the lifters click almost like solid lifters speeds up the process of getting stuck lifter internals on hydraulic lifters to free up and driving the car for a couple hours tends to do a great deal of good

adding a quart of MMO

and a can of liquid moly

https://www.amazon.com/Liqui-Moly-20004-Hydraulic-Additive/dp/B0096Y6XPC/?tag=newcarpassionate-20

seafoam engine additives all help

additive's with solvents and detergents and added lubricants certainly won,t hurt the process of removing contaminants , and temporarily allowing a few extra thousands clearance in the valve train seems to speed up the process, after youve driven the car for an hour or so with the fresh oil, new oil filter and additives youll generally find the lifters have freed up unless theres a mechanical wear issue like a damaged cam lobe or defective or worn lifter, so you can re-adjust the valves correctly

youll generally want to install hydraulic roller lifter's with the oil feed holes pointing to the rear of the engine,

but its not super critical as hydraulic pressure in the blocks lifter gallery,

oil feed passages ,

insures the roller lifters get sufficient oil flow facing in either direction.

you should read these posted link's, and sub links

http://garage.grumpysperformance.co...ter-pumps-oil-and-traps-oil.15555/#post-92843

http://garage.grumpysperformance.co...er-lifter-install-direction.11398/#post-52208

http://garage.grumpysperformance.com/index.php?threads/correctly-adjusting-valves.196/#post-90731

http://garage.grumpysperformance.com/index.php?threads/can-t-adjust-the-valve-lash.15404/#post-90613

http://garage.grumpysperformance.co...ulic-lifters-mystery-solved.12263/#post-60159

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.com/index.php?threads/oil-pump-priming.15211/

Last edited by a moderator: