"hey grumpy??

I just broke in my new 496 stroker big block chevy

My combo is 496 mahle 18 cc domes, AIR FLOW RESEARCH 265 cc heads, isky ez roll solid lifters, with a comp cams xr286r solid roller on billet core, air gap port matched to heads and hp 1000 made 625 hp and 623 ft lbs at 6200 with 32 degrees timing and the oil pressure goes up to 65 psi then starts bouncing between 60-65 psi if I run the car on a hard acceleration test run, the cars got a 6 quart oil pan and a tall oil filter that holds almost a full quart by its self any ideas"

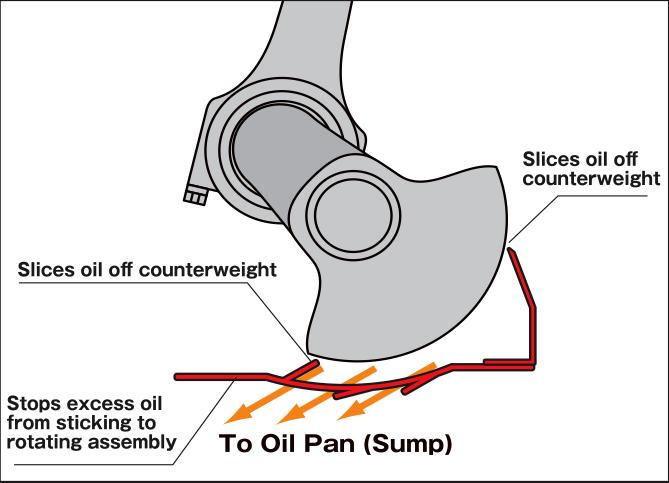

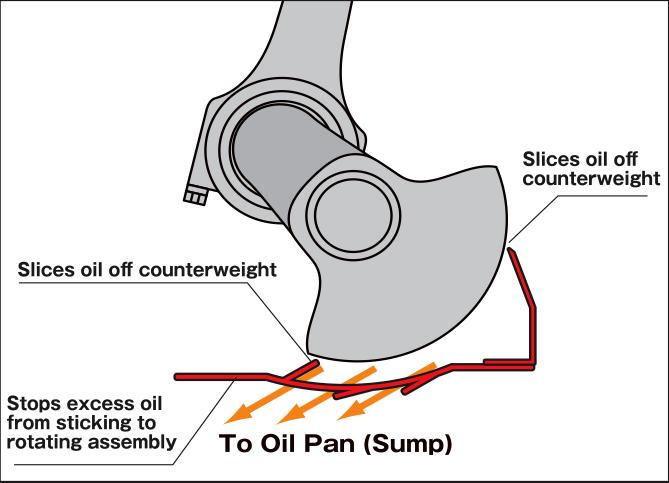

thats rather common in big block engines run in the higher rpm ranges if a stock oil pan or anything close to a stock 5-5 quart capacity oil pan is used, its mostly an oil control issue in most cases on a 454-496 bbc, if your not running a good windage screen that promotes rapid oil flow back to the sump,its USUALLY not really about the amount of oil as much as controlling the rapid return of oil to the sump so its constantly covering the oil pump pick-up.

just some info, you might need,

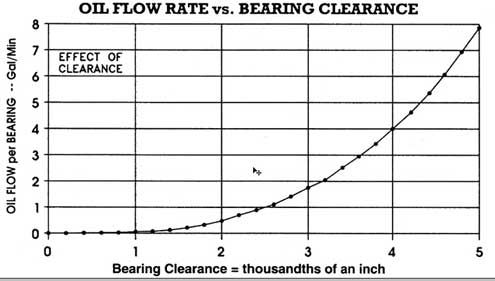

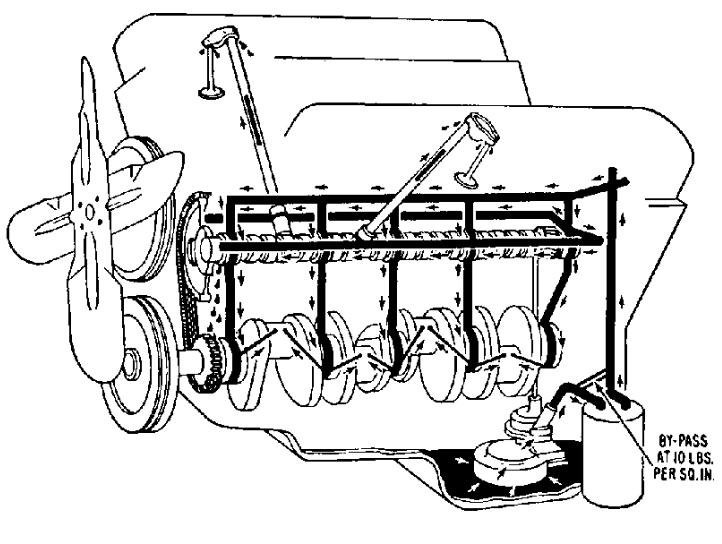

depending on the oil pump used, rpms and clearances a chevy V8 will generally push some where between 2 and 6 gallons a minute thru the oil passages, your average oil pan sump holds at most 3 quarts ,while the engines running, and theres generally about 2 or a bit more quarts in the upper engine, (lifter gallery, heads)while the engines running, so when you induce high inertial loads is common for the oil pump pick up to become uncovered even in a baffled oil pan for a few seconds as that 2-3 quarts in the sump slams forward and back in the sump, because remember , lets say your engines only pumping 3 gallons a minute, and theres got to be at least 2 quarts in the sump to keep the oil pump pick-up covered under high inertial loads, its only going to take a few seconds at most under those conditions to suck air into the oil pump. obviously having a baffled 7-8 quart oil pan has advantages under those conditions as theres a good deal larger (SAFETY MARGIN) in the amount of oil present over the oil pump pick-up is you use the higher capacity BAFFLED oil pan with its better oil control and larger sump capacity,, windage screen combo

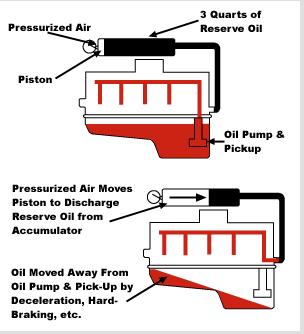

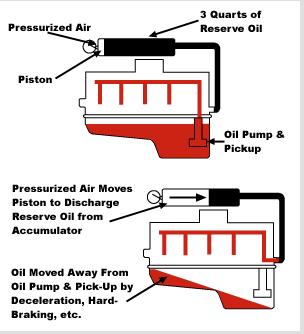

in some applications adding an oil accumulators a good idea

yes its annoying but its usually not instantly damaging to the engine, but over time it can cause wear. without a effective windage screen the longer stroke, can cause a good deal of problems with oil being whipped around in the lower engine being turned to a froth,

At high-rpm, about two-three quarts of oil are on top of the engine (out of the pan), and there is always close to a quart in the filter, and oil passages, leaving one more quart in the pan in a typical five-quart system,, on a high performance big block, a 6 quart oil pan is FREQUENTLY ONLY BARELY adequate under mild driving conditions, A vehicle used for high-performance (high-rpm operation) driving should have a larger 7-8 quart baffled oil pan with a windage screen.

pressure is the way that you commonly measure resistance to flow rates, obviously the bearing clearances can,t rapidly change back and forth so its more than likely caused by an intermittent oil flow into the oil pump, or a lack of consistent oil around the oil pump pick up, because air in the oil allows the pressure fluctuation, a constant supply of non-compresses able oil would not,it could be something simply like the oil bye-pass valve sticking at times

now obviously Id need a bit more info,about the oil pan,design, windage tray design your using,or lack of a windage tray, and where, and when during the run the oil pressure fluctuates, but the first thing Id personally try is adding a quart of oil to see it it changes anything.

if oil pressures bouncing between 60psi and 65 psi it might indicate the oil pumps sucking a bit of oil froth, (air/oil mix) caused by the rapidly spinning rotating assembly or oil rushing away from the oil pump pick-up due to inertia during either acceleration or braking inertia. it may be cured with adding an additional quart of oil, it may be a defective gauge or it may be the oil pump pick-ups either mounted too close to the oil pan floor or its come loose.

It might be an issue with oil return drainage being restricted, I know guys that have used common metal window screen , and epoxy on blocks as a shrapnel screen the holes are far to small and it restricts oil flow, your far better off using the perforated metal with the 1/8" minimum hole size or a muck courser screen grill size

spending the time too read through the links and sub-links will prevent a lot of wasted money and time and mistakes

http://garage.grumpysperformance.com/index.php?threads/another-496bbc.5123/

http://garage.grumpysperformance.co...alves-and-polishing-combustion-chambers.2630/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.com/index.php?threads/installing-an-oil-pump-pick-up-tube.1800/

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-72126

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-68850

http://garage.grumpysperformance.com/index.php?threads/big-block-chevy-info.710/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.co...402-bbc-with-a-4-454-crank-or-even-4-25.2165/

http://www.superchevy.com/how-to/148-0309-396-ci-chevrolet-chevelle-engine-rebuild/

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

https://www.summitracing.com/search...-5l-396/engine-family/chevy-big-block-mark-iv

https://www.themotorbookstore.com/how-to-rebuild-big-block-chevy-engines.html

http://garage.grumpysperformance.com/index.php?threads/bits-of-396-bbc-build-info.3968/

Last edited: Friday at 9:20 PM

reading thru these links should help

viewtopic.php?f=54&t=3536

viewtopic.php?f=54&t=64

viewtopic.php?f=54&t=1280&p=5430&hilit=accumulator#p5430

viewtopic.php?f=44&t=1518&p=12667&hilit=preforated#p12667

viewtopic.php?f=51&t=1458&p=3265&hilit=shrapnel#p3265

viewtopic.php?f=54&t=3194

viewtopic.php?f=54&t=1800

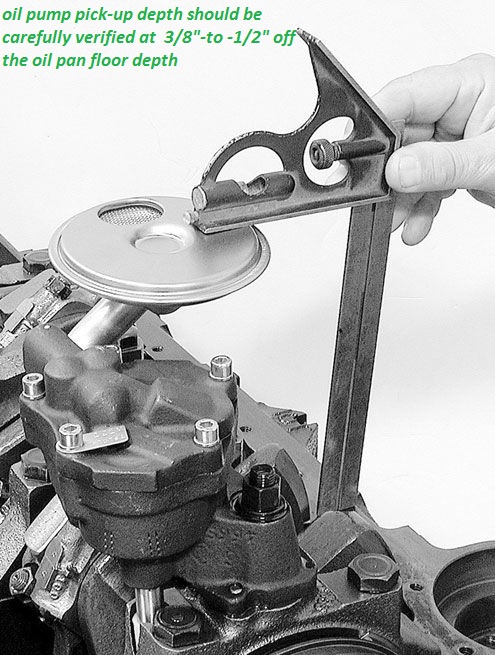

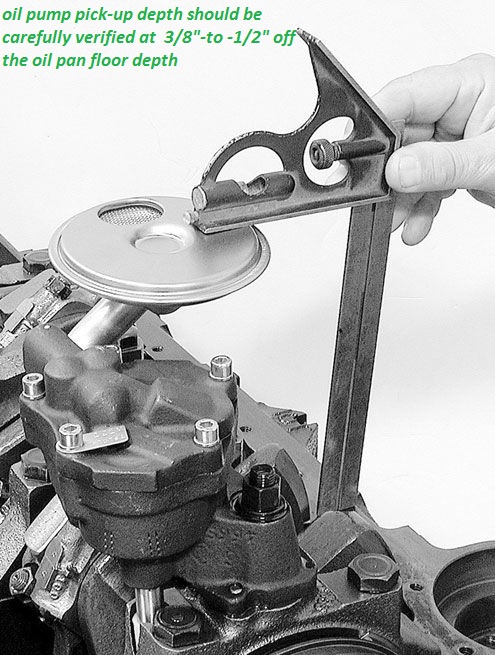

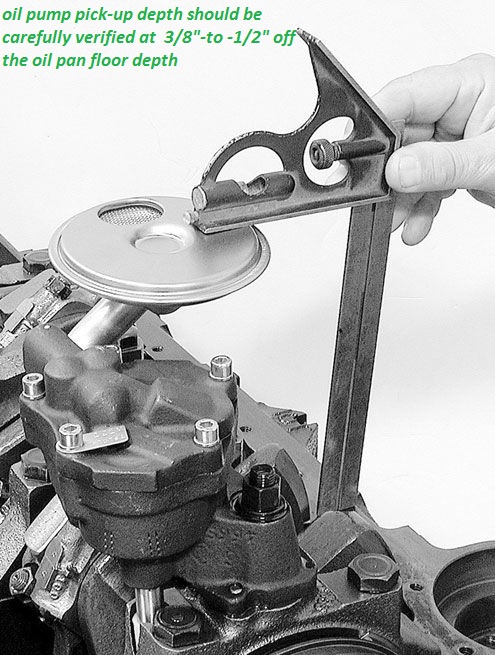

yes Ive seen several cases where guys failed to install the oil pump pick-up at the proper minimum 3/8"-to-1/2" off the oil pan floor clearance,

the result is the pump is starved for oil intake flow.

almost every mechanics tool box needs a few basic measuring tools and supplies

https://www.amazon.com/Claytoon-Set...d=1466872286&sr=8-17&keywords=plastilina+clay

https://www.amazon.com/Claytoon-Set...d=1466872286&sr=8-17&keywords=plastilina+clay

http://www.utrechtart.com/Plastalin...currency=USD&gclid=CN3G75zOw80CFQgaaQodKbgFjA

http://garage.grumpysperformance.co...m-sure-your-convinced-its-the-oil-pump.11085/

http://garage.grumpysperformance.co...m-oil-pump-installed-now-no-oil-pressure.525/

http://garage.grumpysperformance.com/index.php?threads/bbc-oil-pump-in-a-sbc.2598/

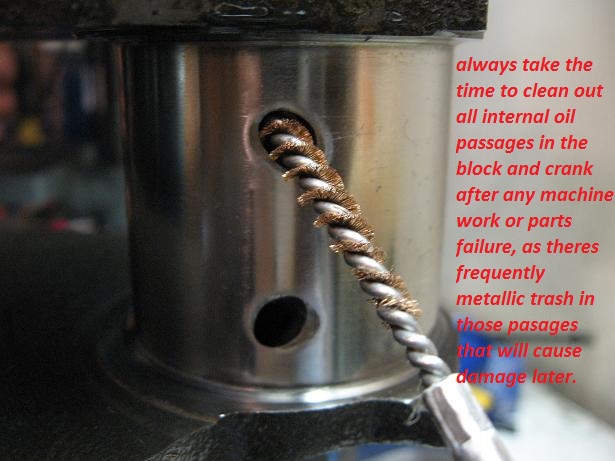

excess silicone trash clogging the oil pump pick-up and internal oil passages in the block,

from guys putting too much or improperly located silicone sealant on gaskets,

is a common source of problems when the excess crap gets into the oil passages

http://garage.grumpysperformance.co...oil-passages-and-improved-oil-flow-mods.3834/

http://garage.grumpysperformance.com/index.php?threads/metallic-debris-in-filter.12364/

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

Last edited: Sunday at 3:39 PM

I just broke in my new 496 stroker big block chevy

My combo is 496 mahle 18 cc domes, AIR FLOW RESEARCH 265 cc heads, isky ez roll solid lifters, with a comp cams xr286r solid roller on billet core, air gap port matched to heads and hp 1000 made 625 hp and 623 ft lbs at 6200 with 32 degrees timing and the oil pressure goes up to 65 psi then starts bouncing between 60-65 psi if I run the car on a hard acceleration test run, the cars got a 6 quart oil pan and a tall oil filter that holds almost a full quart by its self any ideas"

thats rather common in big block engines run in the higher rpm ranges if a stock oil pan or anything close to a stock 5-5 quart capacity oil pan is used, its mostly an oil control issue in most cases on a 454-496 bbc, if your not running a good windage screen that promotes rapid oil flow back to the sump,its USUALLY not really about the amount of oil as much as controlling the rapid return of oil to the sump so its constantly covering the oil pump pick-up.

just some info, you might need,

depending on the oil pump used, rpms and clearances a chevy V8 will generally push some where between 2 and 6 gallons a minute thru the oil passages, your average oil pan sump holds at most 3 quarts ,while the engines running, and theres generally about 2 or a bit more quarts in the upper engine, (lifter gallery, heads)while the engines running, so when you induce high inertial loads is common for the oil pump pick up to become uncovered even in a baffled oil pan for a few seconds as that 2-3 quarts in the sump slams forward and back in the sump, because remember , lets say your engines only pumping 3 gallons a minute, and theres got to be at least 2 quarts in the sump to keep the oil pump pick-up covered under high inertial loads, its only going to take a few seconds at most under those conditions to suck air into the oil pump. obviously having a baffled 7-8 quart oil pan has advantages under those conditions as theres a good deal larger (SAFETY MARGIN) in the amount of oil present over the oil pump pick-up is you use the higher capacity BAFFLED oil pan with its better oil control and larger sump capacity,, windage screen combo

in some applications adding an oil accumulators a good idea

yes its annoying but its usually not instantly damaging to the engine, but over time it can cause wear. without a effective windage screen the longer stroke, can cause a good deal of problems with oil being whipped around in the lower engine being turned to a froth,

At high-rpm, about two-three quarts of oil are on top of the engine (out of the pan), and there is always close to a quart in the filter, and oil passages, leaving one more quart in the pan in a typical five-quart system,, on a high performance big block, a 6 quart oil pan is FREQUENTLY ONLY BARELY adequate under mild driving conditions, A vehicle used for high-performance (high-rpm operation) driving should have a larger 7-8 quart baffled oil pan with a windage screen.

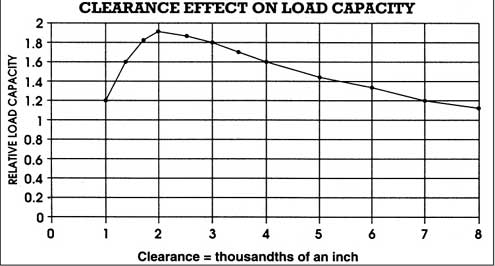

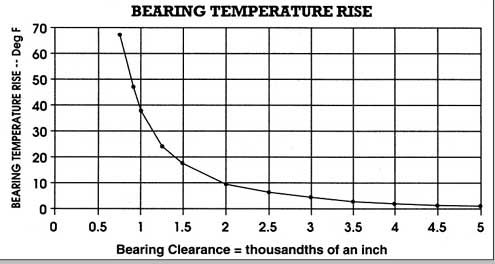

pressure is the way that you commonly measure resistance to flow rates, obviously the bearing clearances can,t rapidly change back and forth so its more than likely caused by an intermittent oil flow into the oil pump, or a lack of consistent oil around the oil pump pick up, because air in the oil allows the pressure fluctuation, a constant supply of non-compresses able oil would not,it could be something simply like the oil bye-pass valve sticking at times

now obviously Id need a bit more info,about the oil pan,design, windage tray design your using,or lack of a windage tray, and where, and when during the run the oil pressure fluctuates, but the first thing Id personally try is adding a quart of oil to see it it changes anything.

if oil pressures bouncing between 60psi and 65 psi it might indicate the oil pumps sucking a bit of oil froth, (air/oil mix) caused by the rapidly spinning rotating assembly or oil rushing away from the oil pump pick-up due to inertia during either acceleration or braking inertia. it may be cured with adding an additional quart of oil, it may be a defective gauge or it may be the oil pump pick-ups either mounted too close to the oil pan floor or its come loose.

It might be an issue with oil return drainage being restricted, I know guys that have used common metal window screen , and epoxy on blocks as a shrapnel screen the holes are far to small and it restricts oil flow, your far better off using the perforated metal with the 1/8" minimum hole size or a muck courser screen grill size

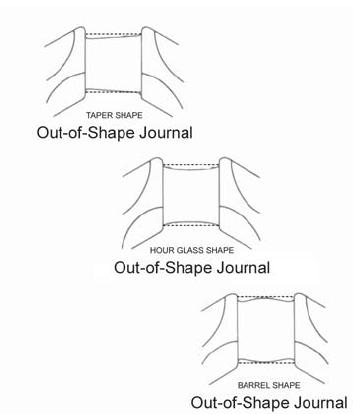

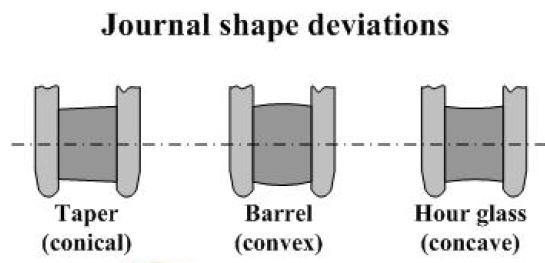

its always a good idea to verify machine work, theres always some machine shops that either do low quality or shoddy work, and you can,t expect an engine to operate correctly if the clearances or consistency of the bearing and lubrication surfaces are not correctly set, you would not bet the first or last guy to be told a crank was cut to a size that was not the true size or sold the wrong bearings for an application, you should always verify machine work, with both a precision measuring tool and plasti-gauge

MEASURE CAREFULLY

http://garage.grumpysperformance.com/index.php?threads/can-i-get-it-polished.9214/

http://garage.grumpysperformance.co...guess-on-clearances-and-journal-surface.9955/

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.com/index.php?threads/rotating-assembly-bearings.9527/

Grumpy, Friday at 4:05 PMEditDeleteIPReport

#3+ QuoteReply

Michel ResdiNew Member

Thank you very much for these explanations.

I already proceeded the way you suggest for the first steps: oil filter change ,oil filling to the high mark,use of another oil gage(mechanical),with the same results.

The pressure rises to 60psi,then falls down enough to turn the idiot light on...

I will take the mill out and search for the things you mentioned.

(I had the heads rebuilt with hardened seats,and new guides ,a few years ago.)

(By any chance,could the bypass valve on the oil filter housing cause this symptom?)

Michel Resdi, Friday at 4:26 PMEditDeleteSpamIPWarnReport

#4Like+ QuoteReply

GrumpyThe Grumpy Grease MonkeyStaff Member

thats a very common question but the answers no!

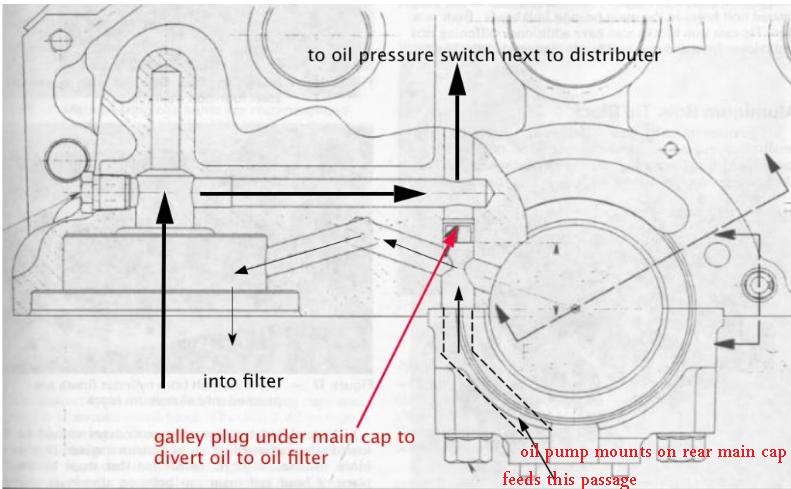

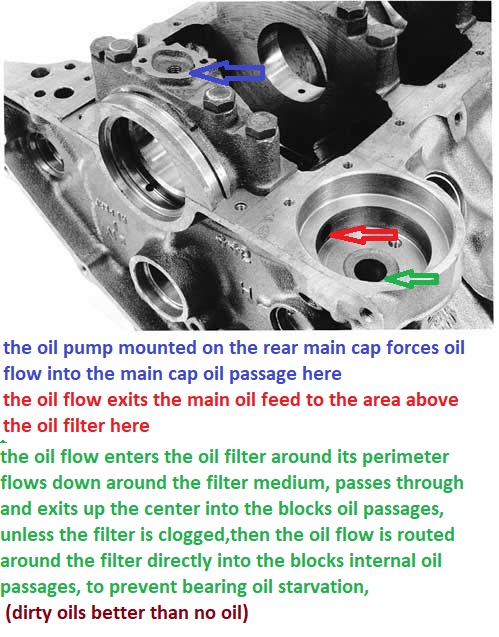

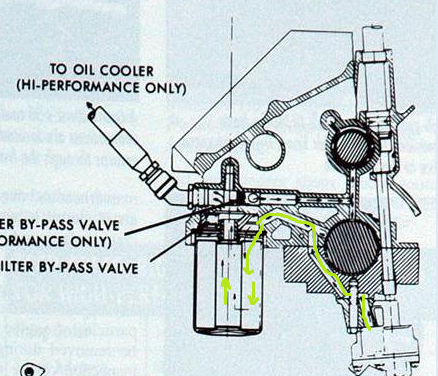

ALL THAT OIL FILTER BYE-PASS VALVE DOES IS ROUTE OIL FLOW PAST THE OIL FILTER

IF IT BECOMES SO CLOGGED WITH TRASH THAT THERES

A 10 PSI DIFFERENCE IN THE RESISTANCE TO OIL FLOW THROUGH THE FILTER

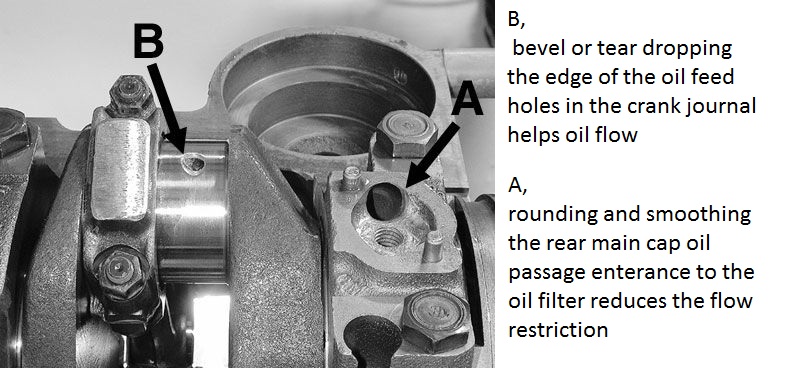

VS AROUND IT INTO THE BLOCKS OIL PASSAGES, oil enters the area over the oil filter in the block and is forced into the outer holes in the oil filter perimeter down through the case and filter element and up through the central hollow screw retention stud into the blocks oil passages, if the resistance too flow is too great the oil filter bye-pass valve routes oil around the filter directly from oil pump to the blocks oil passages.

MORE USEFUL INFO

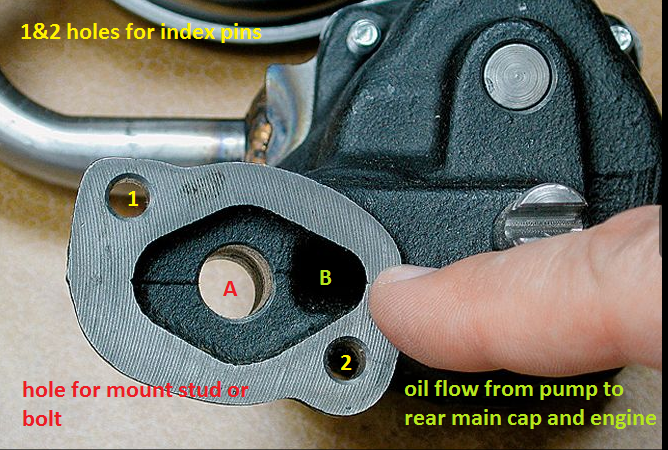

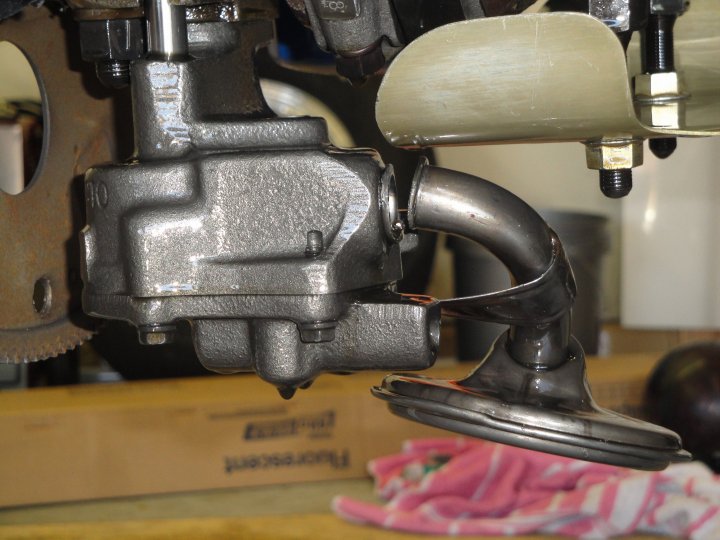

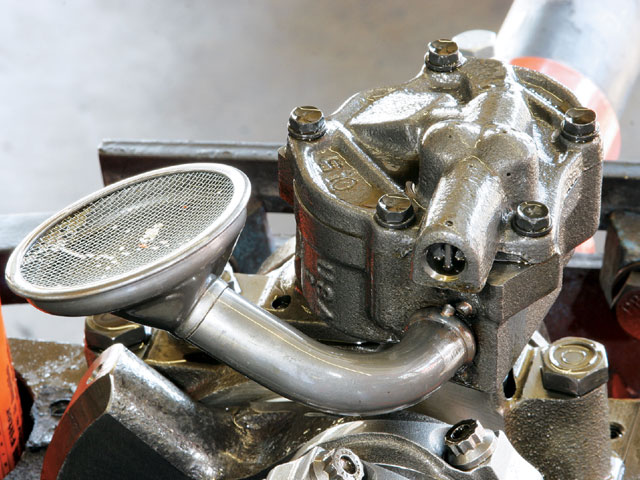

yes the oil flows around the mounting stud,from oil pump to main cap to reach the engine oil passages, thru the oil filter

failure to use the correct oil pump,mounting stud, bolt or nut or carefully check clearances when mounting an oil pump can cause problems

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP IT CAN AND WILL BIND ON THE BEARING AND LOCK OR RESTRICT, SMOOTH ROTATION

http://garage.grumpysperformance.co...-friction-and-pumping-losses.8966/#post-31978

obviously the first two steps in diagnosing any oil pressure problem you suspect is to check your dipstick for the proper oil level in the engine and then test the pressure with an independent test gauge to verify your cars gauge is correct, and you do have a problem , not a defective sensor or gauge

the oil pressure sensor location, is next to the distributor base,on most sbc engines on the rear of the block, but if your trying to track down an oil pressure issue it could be either a bad sensor, bad connection on the sensor or gauge, or a defective gauge, causing the high pressure reading OR it may be a defective oil pump, or bearing clearances or an oil passage plug, or the wrong oil viscosity, or a busted oil pump pick-up or incorrect installation of the oil pump or pick-up,defective oil filter or several other potential sources if its a low pressure issue as previously mentioned.

broken , or improperly installed oil pump pick-ups can cause several major oil pressure issues

Last edited: Saturday at 2:41 AM

spending the time too read through the links and sub-links will prevent a lot of wasted money and time and mistakes

http://garage.grumpysperformance.com/index.php?threads/another-496bbc.5123/

http://garage.grumpysperformance.co...alves-and-polishing-combustion-chambers.2630/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.com/index.php?threads/installing-an-oil-pump-pick-up-tube.1800/

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-72126

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-68850

http://garage.grumpysperformance.com/index.php?threads/big-block-chevy-info.710/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.co...402-bbc-with-a-4-454-crank-or-even-4-25.2165/

http://www.superchevy.com/how-to/148-0309-396-ci-chevrolet-chevelle-engine-rebuild/

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

https://www.summitracing.com/search...-5l-396/engine-family/chevy-big-block-mark-iv

https://www.themotorbookstore.com/how-to-rebuild-big-block-chevy-engines.html

http://garage.grumpysperformance.com/index.php?threads/bits-of-396-bbc-build-info.3968/

Last edited: Friday at 9:20 PM

reading thru these links should help

viewtopic.php?f=54&t=3536

viewtopic.php?f=54&t=64

viewtopic.php?f=54&t=1280&p=5430&hilit=accumulator#p5430

viewtopic.php?f=44&t=1518&p=12667&hilit=preforated#p12667

viewtopic.php?f=51&t=1458&p=3265&hilit=shrapnel#p3265

viewtopic.php?f=54&t=3194

viewtopic.php?f=54&t=1800

yes Ive seen several cases where guys failed to install the oil pump pick-up at the proper minimum 3/8"-to-1/2" off the oil pan floor clearance,

the result is the pump is starved for oil intake flow.

almost every mechanics tool box needs a few basic measuring tools and supplies

http://www.utrechtart.com/Plastalin...currency=USD&gclid=CN3G75zOw80CFQgaaQodKbgFjA

http://garage.grumpysperformance.co...m-sure-your-convinced-its-the-oil-pump.11085/

http://garage.grumpysperformance.co...m-oil-pump-installed-now-no-oil-pressure.525/

http://garage.grumpysperformance.com/index.php?threads/bbc-oil-pump-in-a-sbc.2598/

excess silicone trash clogging the oil pump pick-up and internal oil passages in the block,

from guys putting too much or improperly located silicone sealant on gaskets,

is a common source of problems when the excess crap gets into the oil passages

http://garage.grumpysperformance.co...oil-passages-and-improved-oil-flow-mods.3834/

http://garage.grumpysperformance.com/index.php?threads/metallic-debris-in-filter.12364/

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

Last edited: Sunday at 3:39 PM

Last edited by a moderator: