Hi,

Electrical is not my thing,.. and am having an issue wondering is someone can help me with?

In short, I installed an electric fuel pump and an oil pressure switch. I won't list all my wiring details, but let's just say that due to my confidence level, I checked and double-checked all the wires matched the instructions.

The only item I did slightly different was instead of wiring the oil pressure switch into the ignition switch, I wired into the fuse box on an ignition-hot probe.

Now, when I turn the ignition on, I blow the ignition fuse. I have traced it down to that the ignition fuse only blows when I plug in that particular wire.

However, I cannot seem to find a short anywhere.

Any ideas as to what check next? Thanks!

(sorry if a stupid question.... this isn't my strength for sure)

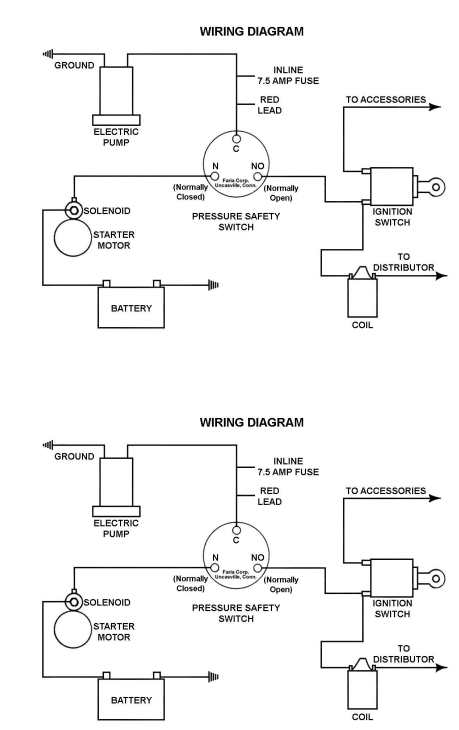

this may help

keep in mind the idea here is to cut off fuel and choke or kill the engine,

if oil pressure drops below minimal levels

to

potentially reduce the chances for catastrophic and expensive engine failures

that would rapidly result due to very low oil pressure

Relay:

30 - to power at fuse box

85 - to ground

87A - not used

87 - to electric fuel pump

86 - to oil pressure switch

https://www.holley.com/products/fue...nd_service/fuel_pump_accessories/parts/12-810

https://www.amazon.com/Holley-12-810-Electric-Safety-Pressure/dp/B00029JC7G

https://documents.holley.com/199r9680-1rev.pdf

HOLLEY PRESSURE SAFETY SWITCH INSTALLATION P/N 12-810 Congratulations on your purchase of the Holley Pressure Safety Switch! If you have any questions about the product or installation, please call Holley Technical Support at 1-270-781-9741. Follow the instructions as outlined below, using the wiring diagram (on back) as a guide. 1. Disconnect the ground cable from the battery. 2. Remove the original equipment oil pressure switch and retain. 3. Screw a 1/8” pipe nipple into the hole from which the pressure switch was removed. Use any suitable thread sealant on all fittings, taking care to avoid an excess which might contaminate the engine. 4. Screw a 1/8” pipe tee onto the nipple and position it in a manner to facilitate the installation of the original pressure switch and the new pressure safety switch in the remaining two holes. 5. Screw in the two switches and reconnect the lead to the original equipment oil pressure switch. NOTE: The pressure safety switch will normally have three terminals marked: C (common), N (normally closed), and NO (normally open). 6. Connect the fuel pump (RED lead) to the terminal marked “C”. In this line, add an in-line fuse holder and a 7.5 amp fuse. 7. Connect the terminal marked “NO” on the ON terminal of the ignition switch. 8. Connect the terminal marked “N” to the starter motor circuit (should have power only while cranking). 9. To complete the installation, connect the ground cable to the battery. NOTE: Use a minimum of 14 gauge wire. Be sure to crimp all the electrical connectors securely. Clean any area where ground leads will be fastened. WIRING: If the pressure switch is omitted from the wiring circuit, the pump may be wired directly to the ignition source and grounded at the frame or battery. 199R9680-1 Date: 2-19-10 HOLLEY PRESSURE SAFETY SWITCH INSTALLATION P/N 12-810 Congratulations on your purchase of the Holley Pressure Safety Switch! If you have any questions about the product or installation, please call Holley Technical Support at 1-270-781-9741. Follow the instructions as outlined below, using the wiring diagram (on back) as a guide. 1. Disconnect the ground cable from the battery. 2. Remove the original equipment oil pressure switch and retain. 3. Screw a 1/8” pipe nipple into the hole from which the pressure switch was removed. Use any suitable thread sealant on all fittings, taking care to avoid an excess which might contaminate the engine. 4. Screw a 1/8” pipe tee onto the nipple and position it in a manner to facilitate the installation of the original pressure switch and the new pressure safety switch in the remaining two holes. 5. Screw in the two switches and reconnect the lead to the original equipment oil pressure switch. NOTE: The pressure safety switch will normally have three terminals marked: C (common), N (normally closed), and NO (normally open). 6. Connect the fuel pump (RED lead) to the terminal marked “C”. In this line, add an in-line fuse holder and a 7.5 amp fuse. 7. Connect the terminal marked “NO” on the ON terminal of the ignition switch. 8. Connect the terminal marked “N” to the starter motor circuit (should have power only while cranking). 9. To complete the installation, connect the ground cable to the battery. NOTE: Use a minimum of 14 gauge wire. Be sure to crimp all the electrical connectors securely. Clean any area where ground leads will be fastened. WIRING: If the pressure switch is omitted from the wiring circuit, the pump may be wired directly to the ignition source and grounded at the frame or battery.

Last edited: