I've tried to find the torque values for the 4 bolts that attach the pump cover, even going to Mellings

website. All I've found is someone posted 80 inch/lbs. I've sent an email to Melling, but don't

have much hope for a response. The pump is a Melling 10552.

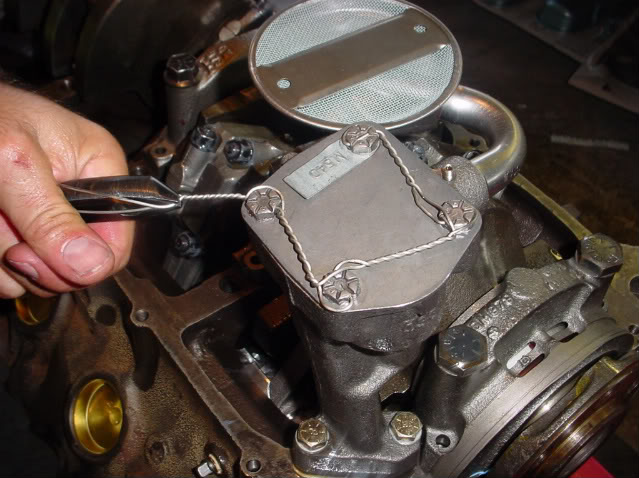

Even if the pickup is bolted like in the pic, does everyone still weld the pickup to the cover ???

What's the purpose of the threaded hole into the pump inlet passage ???

website. All I've found is someone posted 80 inch/lbs. I've sent an email to Melling, but don't

have much hope for a response. The pump is a Melling 10552.

Even if the pickup is bolted like in the pic, does everyone still weld the pickup to the cover ???

What's the purpose of the threaded hole into the pump inlet passage ???