here this might help, and ID suggest reading thru the sub-linked info is well worth the effort

viewtopic.php?f=54&t=150

viewtopic.php?f=54&t=3536&p=9372#p9372

viewtopic.php?f=54&t=1837

viewtopic.php?f=36&t=63&p=6049&hilit=switch+sensor+oil#p6049

viewtopic.php?f=54&t=1281

viewtopic.php?f=54&t=64

viewtopic.php?f=54&t=6445

viewtopic.php?f=53&t=2726&p=7077#p7077

viewtopic.php?f=53&t=88

http://www.mobil.com/USA-English/MotorO ... _Guide.pdf

viewtopic.php?f=54&t=52

viewtopic.php?f=54&t=525

viewtopic.php?f=54&t=2187

http://www.mellingengine.com/TechnicalS ... etins.aspx

http://www.mobiloil.com/USA-English/Mot ... _Guide.pdf

viewtopic.php?f=54&t=615

viewtopic.php?f=54&t=2187

for the BBC guys

http://www.cartechbooks.com/vstore/show ... apter=7587

failure to use the correct oil pump,mounting stud, bolt or nut or

carefully check clearances when mounting an oil pump can cause problems

carefully check clearances when mounting an oil pump can cause problems

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT ,

THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP,

IT CAN AND WILL BIND ON THE BEARING ,

AND LOCK OR RESTRICT, SMOOTH ROTATION

read this over carefully

IVE POSTED MOST OF THIS BEFORE BUT IT FITS HERE AS A SOURCE OF INFO FOR THE NEWER GUYS

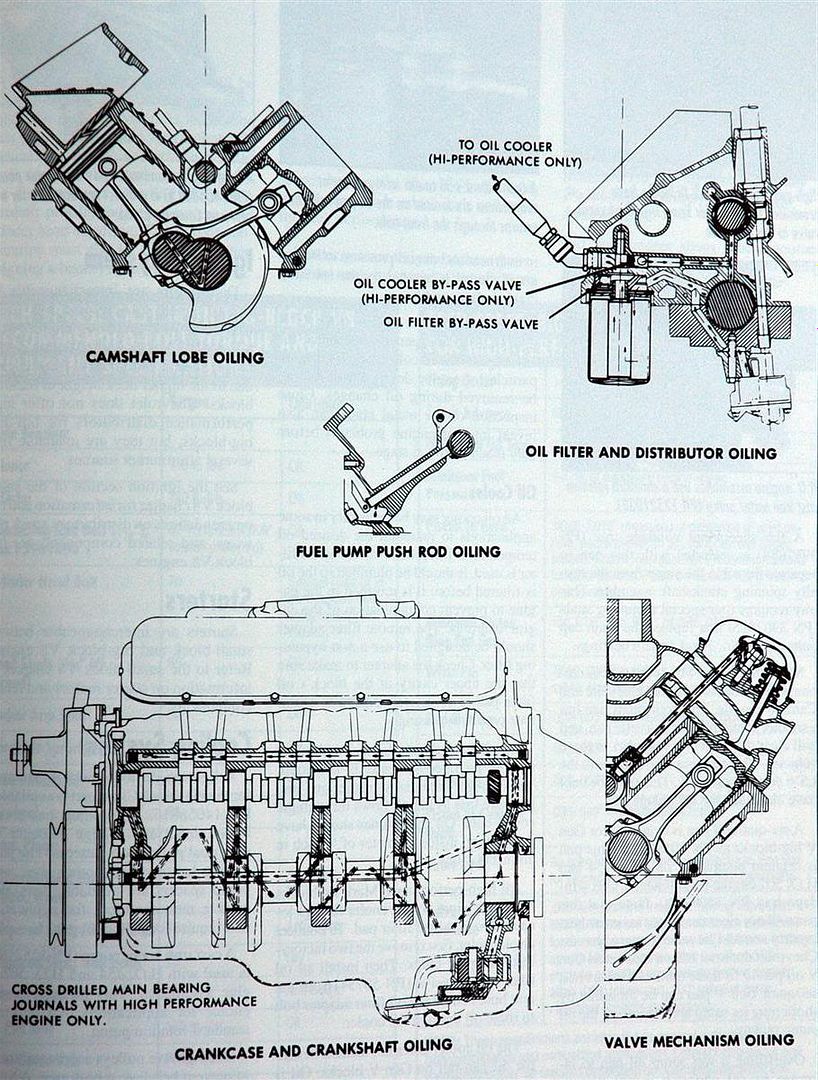

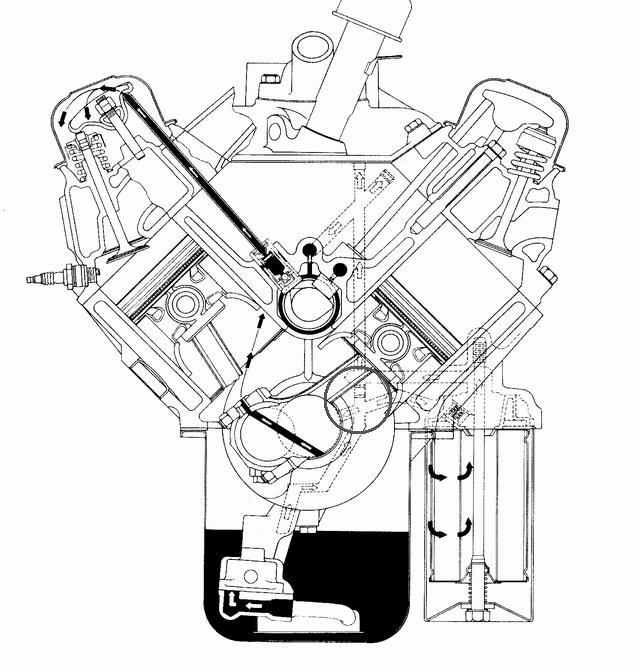

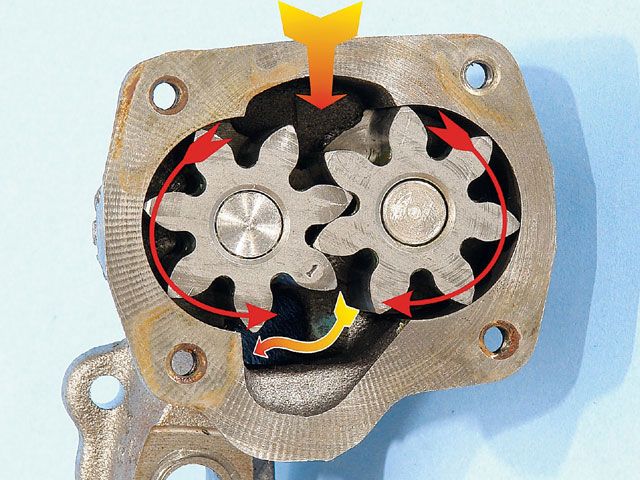

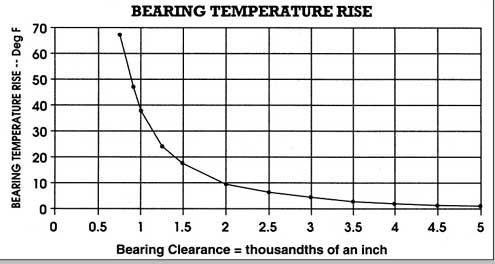

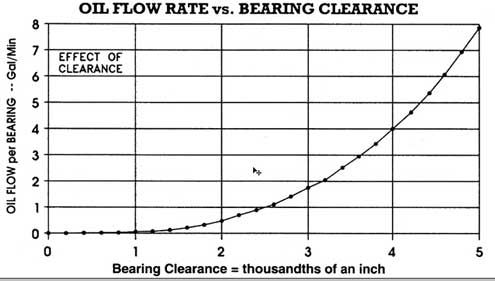

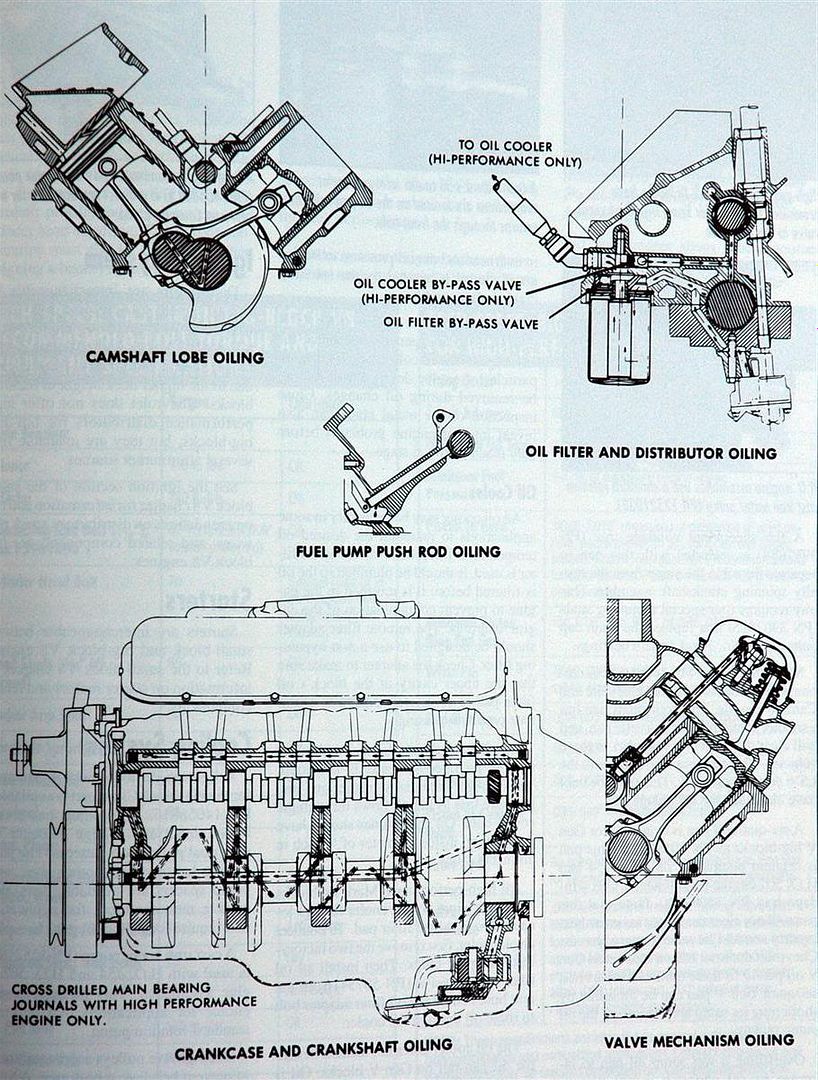

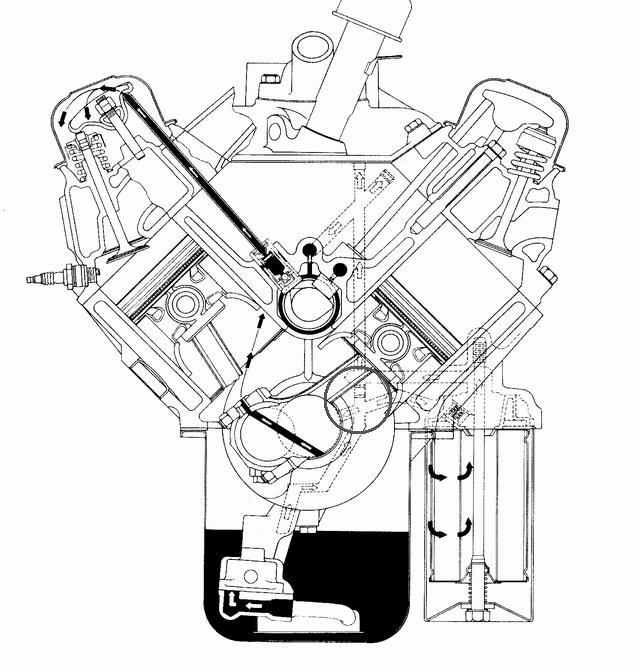

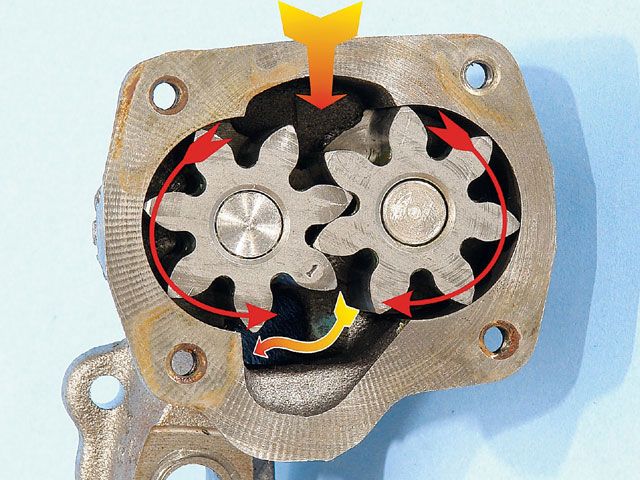

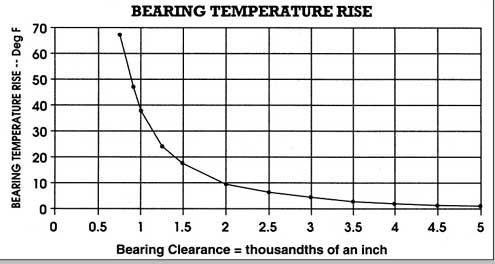

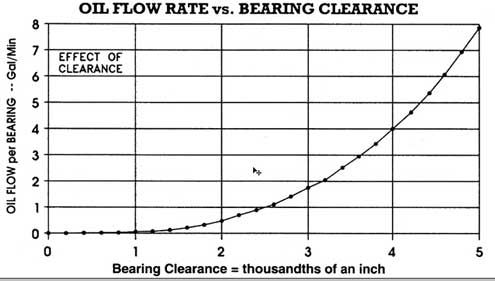

ok lets look at a few things, pressure is the result of a resistance to flow , no matter how much oil is put out by the oil pump there is almost no pressure unless there is a resistance to that oil flow and the main resistance is from oil trying to flow through the bearing surface clearances and once the pumps output pressure exceeds the engines ability to accept the oilflow at the max pressure the oil return system/bypass spring allows the oil circles back through the pump ,now the amount of oil flow necessary to reach the furthest parts in the engine from the oil pump does not go up in direct relation to rpm, but it instead increases with rpm at a steadily increasing rate that increases faster than the engine rpm due to centrifugal force draining the oil from the rods as they swing faster and faster since energy increases with the square of the velocity the rate of oil use goes up quite a bit faster due to the greatly increased (G-FORCES) pulling oil from the rod bearings over 5000rpm going to 8000rpm than the rate of oil flow increases from 2000 rpm to 5000rpm (the same 3000rpm spread) and remember the often stated (10 lbs per 1000rpm)needs to be measured at the furthest rod and main bearing from the pump not at the pump itself, next lets look at the oil flow itself, you have about 5-6 quarts in an average small block now the valve covers never get and hold more than about 1/3 to 2/3 of a quart each even at 8000 rpm (high speed photography by SMOKEY YUNICK doing stock car engine research with clear plastic valve covers prove that from what Ive read) theres about 1 quart in the lifter gallery at max and theres about 1 quart in the filter and in the oil passages in the block, that leaves at least 2 quarts in the pan at all times and for those that want to tell me about oil wrapped around the crankshaft at high rpms try squirting oil on a spinning surface doing even 2000rpm (yes that's right its thrown off as fast as it hits by centrifugal force, yes its possible for the crankshaft WITHOUT A WINDAGE SCREEN to keep acting like a propeller and pulling oil around with it in the crank case but that's what the wrap around style milodon type windage screen is designed to stop)the only way to run out of oil is to start with less than 4 quarts or to plug the oil return passages in the lifter gallery with sludge or gasket material! now add a good windage tray and a crank scrapper and almost all the oil is returned to the sump as it enters the area of the spinning crankshaft! forming a more or less endless supply to the oil pump, BTW almost all pro teams now use DRY SUMP SYSTEMS WITH POSITIVE DISPLACEMENT GEARATOR PUMPS that are 3,4,or 5 stage pumps each section of which has more volume than a standard volume oil pump because its been found total oil control is necessary at high rpms to keep bearings cool and lubed

NOW I POSTED THIS BEFORE BUT IT Need's REPEATING

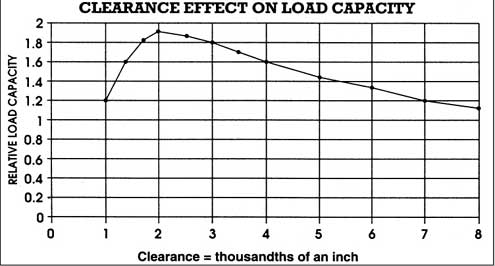

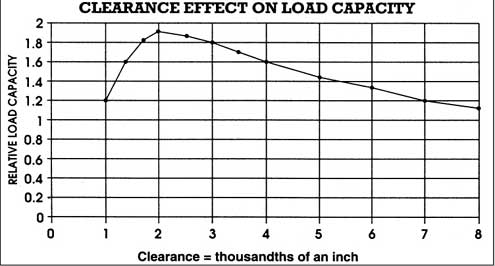

ok look at it this way,what your trying to do here is keep an pressurized oil film on the surface of all the bearings to lube and cool them and have enough oil spraying from the rod and main bearing clearances to lube the cam and cylinder walls/rings. now a standard pump does a good job up to 5000rpm and 400 hp but above 6000rpm and 400hp the bearings are under more stress and need more oil flow to cool and because the pressure on the bearings is greater you need higher pressures to maintain that oil film.lets look at the flow versus pressure curve. [color:"red"] since oil is a liquid its non-compressible and flow will increase with rpm up to the point where the bypass circuit starts to re-route the excess flow at the point were the pressure exceeds the bypass spring pressure. but the volume will be equal to the pumps sweep volume times the rpm of the pump, since the high volume pump has a sweep volume 1.3-1.5 times the standard pump volume it will push 1.3-1.5 times the volume of oil up to the bypass circuit cut in point,that means that since the engine bearings leakage rate increases faster as the rpms increase because the clearances don,t change but the bleed off rate does that the amount of oil and the pressure that it is under will increase faster and reach the bypass circuit pressure faster with the high volume pump. the advantage here is that the metal parts MUST be floated on that oil film to keep the metal parts from touching/wearing and the more leakage points the oil flows by the less the volume of oil that's available for each leakage point beyond it and as the oil heats up it becomes easier to push through the clearances.now as the rpms and cylinder pressures increase in your goal to add power the loads trying to squeeze that oil out of those clearances also increase. ALL mods that increase power either increase rpms,cylinder pressures or reduce friction or mechanical losses. there are many oil leakage points(100) in a standard Chevy engine.

16 lifter to push rod points

16 pushrod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines [/color] that have an oil pressure feed distributor shaft bearing.)

so the more oil volume the better,(AS LONG AS ITS TOTALLY UNDER CONTROL ON BOTH THE PRESSURE AND RETURN/SCAVENGING SIDES OF THE SYSTEMChevy did an excellent job in the design but as the stresses increase the cooling volume of the extra oil available from the larger pump helps to prevent lubrication delivery failure, do you need a better pump below 5000rpm or 400hp (no) above that level the extra oil will definitely help possible deficient oil flow and bearing cooling and a simple increase in pressure does not provide a big increase in volume that may be necessary to keep that oil film in the correct places at the correct volume at all times.the stock system was designed for a 265cid engine in a passenger car turning a max of about 6000 rpm but only having the stress of under 300hp transmitted to the bearings, I'm sure the original designers never thought that the sbc or bbc would someday be asked to on occasion hold up to 450-800hp and 6000-8000 rpm.nor did they for see valve springs that placed 500lbs and up loads on the lifters and the use of over 9 to 1 compression ratios in the original design so the oil volumes and pressures necessary to cool those valve springs and bearings at those stress levels were never taken into account for that either.

Continued (oil Pan/pump)

the oil pump can only pump as much oil as the engine clearances allow at the max pressure that the oil pump bye -pass circuit will allow, and no more. for your idea to be correct (which it could be under some conditions)the oil flow through the engine clearances would need to be so great that the pump turning at 3500rpm,7000rpm engine speed(remember the pump spins 1/2 the speed the crank does)and most likely pumping at max pressure could lower the oil level to the point that the pick-up becomes uncovered or a vortex as you call it forms and the pump starts sucking air.

now under hard acceleration it is very possible for the pickup on ANY oil pump to to become uncovered in a oil pan that has less than 5qt capacity and with no oil control baffles as the oil rushes to the rear of the oil pan if the pick-up is located in mid pan or under hard braking if the pick-up is located at the rear of the pan on a non- oil baffle controlled pan.

I will grant you that it is possible for ANY oil pump to pump a good amount of oil into the lifter gallery at high rpms IF THE OIL RETURN PASSAGES IN THE HEADS AND LIFTER GALLERY ARE BLOCKED, preventing its normal return to the crankcase

, but running a high volume oil pump will have little or nothing to do with how much oil is in the pan if the engines drain back holes are clear and your using a milodon style windage screen. I have several times had that same complaint about lack of oil pressure under acceleration but it is caused by a non-baffled pan or the pickup mounted so close to the pan bottom that the pump cant get a good intake flow, if you carefully check you'll find that on a dyno runs it seldom happens,because the oil is constantly removed by the windage screen is returned to the sump, most of the oil pumped into the system exits at the rod and main bearing clearances or at the cam bearings and from the lifter bores lower ends, its not the constant oil flow or lack of oil into the rocker arms that has the big effect on total oil flow as SMOKEY YUNICKS PHOTOGRAPHIC RESEARCH PROVED YEARS AGO,its the oil flowing from the bearings and lifters and that oil flow is quickly returned to the sump by a windage screen scraping it off the spinning crank and rods as the spinning assembly passes over the windage screen. in effect most of the oil in an engine works like your timing chain in that it constantly cycles top to bottom and back never getting higher than the cam bearing lifter area.

keep in mind the distributor base forms one wall of the lifter gallery oil passage

so grooving the lower oil band helps spray extra oil on the distributor/cam gears contact area

use a good 7-8 quart baffled oil pan

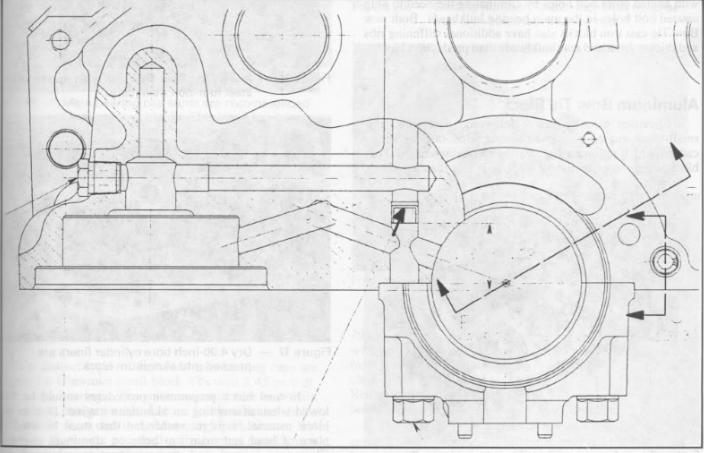

now what does quite frequently happen is that the guys installing a high volume oil pump just swap out the standard pump, reinstall the stock or similar pick-up and bolt on the pan with the pick-up in the stock position on the oil pump. the stock pick-up is mounted about 3/8" off the pan bottom,the high volume pump is normally equipped with impeller gears about .3 inches longer than stock, the high volume pump body is that much lower in the pan, resulting in the pick-up being only about 1/8" from the pan bottom. the result is that on a normal Chevy oil pump pick-up this leaves a space of about 1/8" x 2.5" for oil to flow into the pump. at low rpms this works but as the rpms climb the pick-up that can,t get any oil to pump is significantly restricted as it spins and fails to pump oil, result oil pressure drops until rpms are lowered no matter how much oil is over the pick-up. simply checking to make sure that about 3/8"-1/2" of space is under the pick-up when the pan is installed cures that problem (a simple trick is to weld a 1/2" thick nut to the oil pump Pick-up base and test fitting the pan BEFORE WELDING THE PICK-UP TO THE PUMP BODY)

Ive had this discussion dozens of times and every time the guys are willing to bet me the hv pumps pumping the pan empty and every time I pull the pan, suggest strongly they install a 8 qt baffled oil pan with the correct windage screen and throw the same 5-6 qts of oil into the engine as a test,and when they do the problem vanished, I then suggest they run the 8 qt pan with 7qts as its always better to cool the engine.what it comes down too in every case that Ive looked into so far is a improperly positioned pick-up or a non- baffled oil pan without a windage screen or less than 5 qts of oil in the system, not a problem of all available oil being pumped into the lifter gallery and valve covers like some people would like you to think.

the MELLING COMPANY HAS THIS TO SAY

Most of the stock automobile engines are designed to operate from idle to 4500 RPM. The original volume and pressure oil pump will work fine in this type of application. As the demands on the engine increase so does the demands on the oiling system and pump.

The oil pump's most difficult task is to supply oil to the connecting rod bearing that is the farthest from the pump. To reach this bearing, the oil travels from three to four feet, turns numerous square corners thru small holes in the crankshaft to the rod bearing. The rod bearing doesn't help matters. It is traveling in a circle which means centrifugal force is pulling the oil out of the bearing.

A 350 Chevy has a 3.4811 stroke and a 2.111 rod journal. The outer edge of the journal travels 17.5311 every revolution. At 1000 RPM, the outer edge is traveling at 16.6 MPH and 74.7 MPH at 4500 RPM. If we take this engine to 6500 the outer edge is up to 107.9 and at 8500 it is 141.1 MPH. Now imagine driving a car around a curve at those speeds and you can feel the centrifugal force. Now imagine doing it around a circle with a 5.581, diameter.

The size of the gears or rotors determines the amount of oil a pump can move at any given RPM. Resistance to this movement creates the pressure. If a pump is not large enough to meet the demands of the engine, there will not be any pressure. Or if the demands of the engine are increased beyond the pumps capabilities there will be a loss of oil pressure. This is where high volume pumps come in; they take care of any increased demands of the engine.

Increases in the engine's oil requirements come from higher RPM, being able to rev faster, increased bearing clearances, remote oil cooler and/or filter and any combination of these. Most high volume pumps also have a increase in pressure to help get the oil out to the bearings faster.

That is what a high volume pump will do. Now let Is consider what it will not do.

It will not replace a rebuild in a worn-out engine. It may increase pressure but the engine is still worn-out.

It will not pump the oil pan dry. Both solid and hydraulic lifters have metering valves to limit flow of the oil to the top of the engine. If a pan is pumped dry, it is because the holes that drain oil back to the pan are plugged. If the high volume pump is also higher pressure, there will be a slight increase in flow to the top.

brazing the oil pump pick-up tube to the pump body after carefully checking clearances will usually prevent the oil pump pick-up from vibrating loose over time

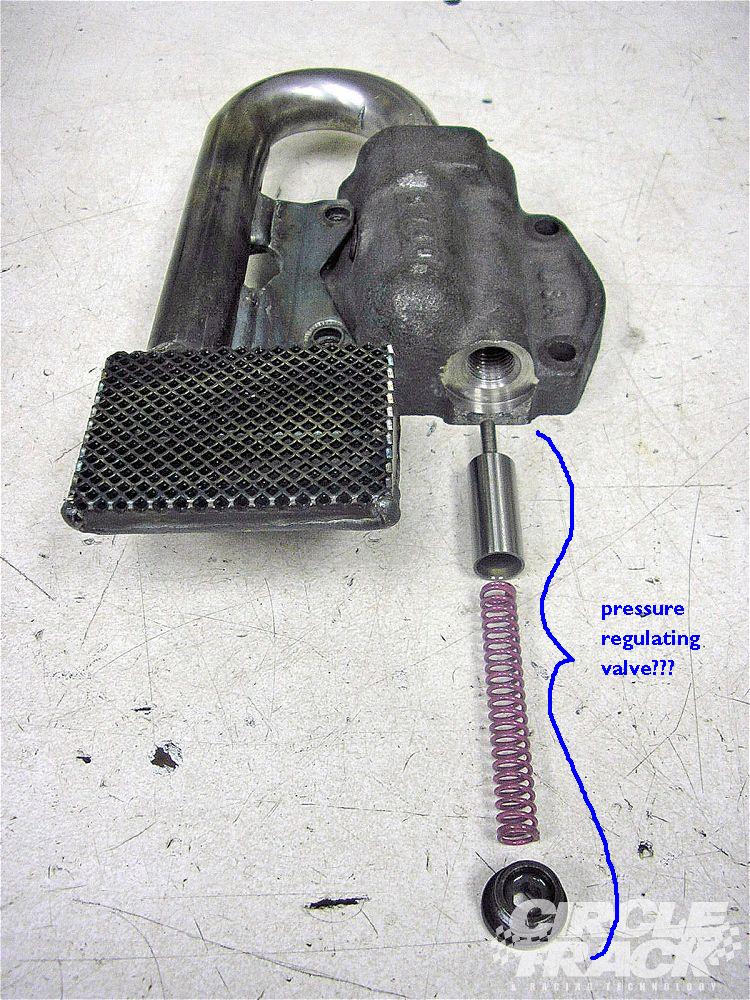

BRAZING the pick-up to the pump is a good idea but remember to remove the pressure regulator valve first and oil and replace it after the pumps cooled

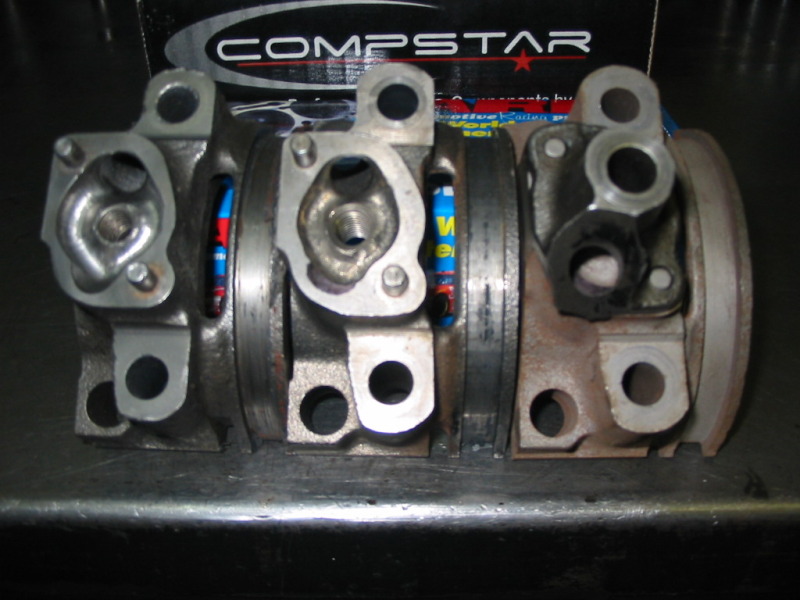

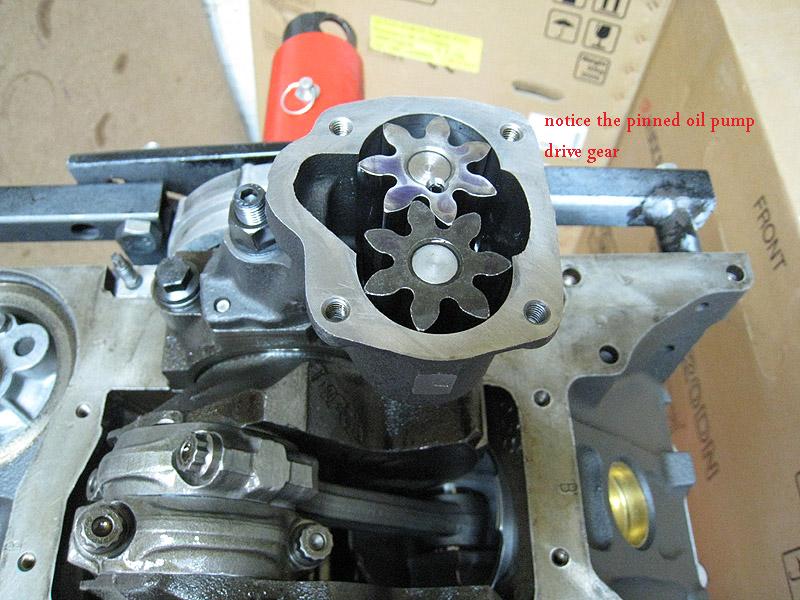

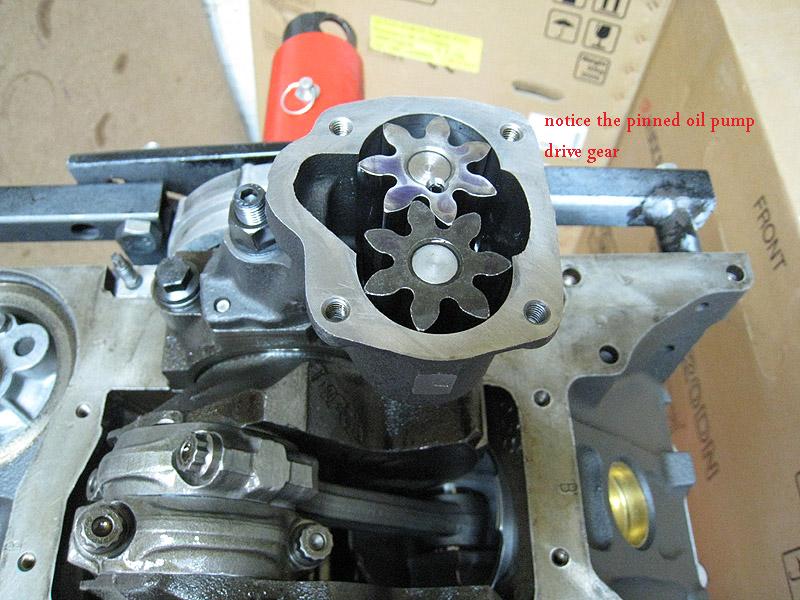

keep in mind the sbc oil pump has 7 tooth gears and the big block pumps have 12 teeth making the oil flow smoother and less pulsed, plus having larger gears they tend to supply more oil at lower rpms

look closely and youll see the big block oil pump has a 5 bolt lower cover and the oil pump pick-up with its 3/4" feed seats into the main pump casting while the small block oil pump has a 4 bolt cover and the sbc oil pump pick-up with its 5/8" feed seats into the pumps cover plate

heres other info,

http://www.babcox.com/editorial/ar/ar10180.htm

http://www.thirskauto.net/BearingPics.html

http://www.chevyhiperformance.com/techa ... index.html

http://www.waynesgarage.com/docs/oil.htm

http://www.jimcookperformance.com/TechNotes/TN 23.html

viewtopic.php?f=54&t=64

http://www.cryoeng.com/images/EngineDurabilitySecrets.htm

http://members.aol.com/carleyware/library/engine2t.htm

HERES more info on oil and filters HERE READ THESE

http://www.babcox.com/editorial/us/uhs69720.htm

http://www.co.broward.fl.us/aqi03202.htm

http://www.motoroilbible.com/five.html

http://www.motoroilbible.com/two.html

http://www.motoroilbible.com/six.html

http://www.exxon.com/exxon_lubes/tigerbytes/documents/brochures/bro0020.htm

http://www.atis.net/oil_faq.html

http://www.chevyhiperformance.com/techa ... index.html

http://www.triumphspitfire.com/Oiltest.html

http://minimopar.net/oilfilterstudy.html

http://www.melling.com/engoil.html

http://www.geocities.com/MotorCity/Downs/3837/oilprime.html

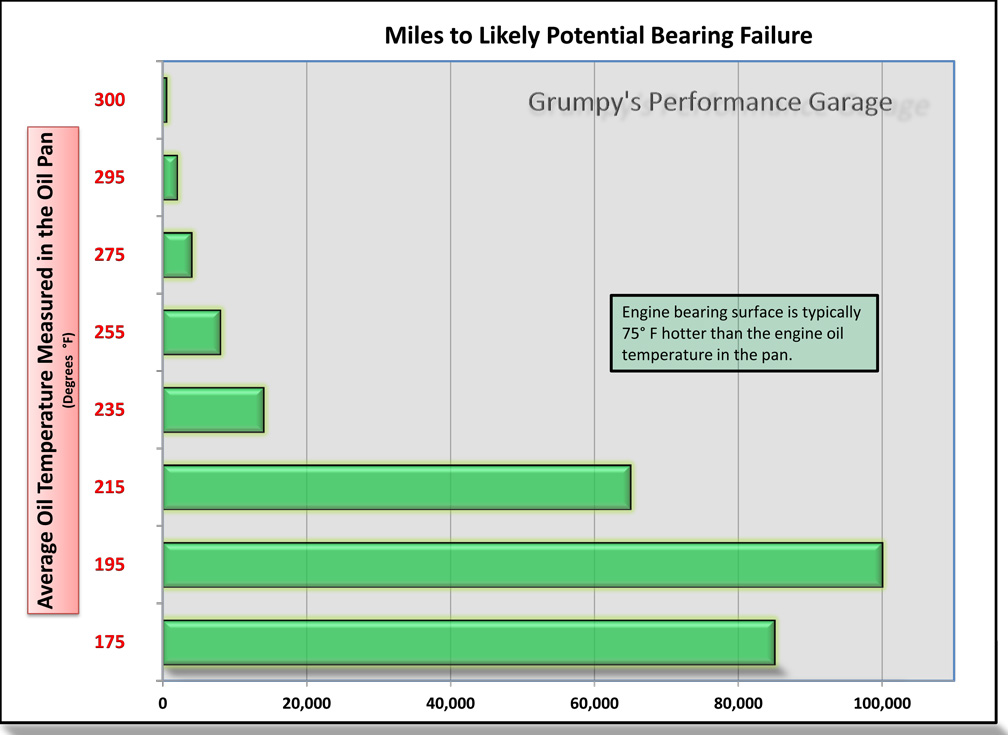

AND FOR THOSE OF YOU THAT DON,T WANT TO READ THROUGH THE LINKS THE SHORT ANSWER IS

(1)MOST OILS AVAILABLE TODAY ARE VERY GOOD QUALITY AND FAR EXCEED WHAT WAS AVAILABLE EVEN TEN YEARS AGO.

(2)CHANGING YOUR OIL AND FILTER OFTEN AND NEVER RUNNING LOW ON OIL IS THE KEY TO LONG ENGINE LIFE

(3)SYNTHETIC OILS DO HAVE A SIGNIFICANT ADVANTAGE AS FAR AS HEAT RESISTANCE AND HIGH HEAT LUBRICATION

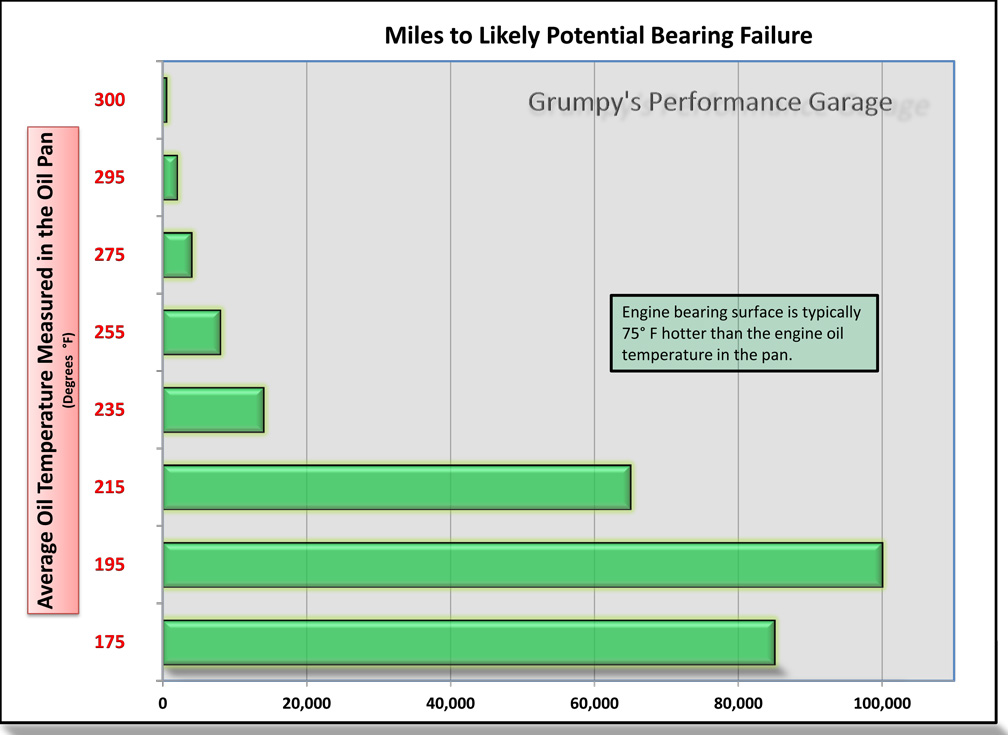

(4) IF YOU DON,T ABUSE OR OVERHEAT YOUR ENGINE THERE'S LITTLE DISADVANTAGE TO USING GOOD DINO BASE OIL UNDER 240 DEGREES OF ENGINE TEMP AS LONG AS YOU CHANGE OIL OFTEN

(5)SYNTHETIC OIL DOES HAVE A BIG ADVANTAGE WHEN ENGINE OIL TEMPS EXCEED 260 DEGREES (F)

oil info

heres what consumer reports says about the better oils available

http://www.unofficialbmw.com/all/misc/all_oilfaq.html

All of the oils above meet current SG/CD ratings and all vehicle

manufacture's warranty requirements in the proper viscosity. All are "good

enough", but those with the better numbers are icing on the cake.

The synthetics offer the only truly significant differences, due to their

superior high temperature oxidation resistance, high film strength, very

low tendency to form deposits, stable viscosity base, and low temperature

flow characteristics. Synthetics are superior lubricants compared to

traditional petroleum oils. You will have to decide if their high cost is

justified in your application.

I use puralator pure 1 filters or mobile 1 filters and mobile 1 synthetic oil 90%-95% and 10%-5% marvel mystery oil. ALL APPLICATIONS, read this,

http://www.fernblatt.com/longhurst/engineoil_bible.html

http://www.melling.com/engoil.html

http://www.melling.com/highvol.html

http://www.aa1car.com/library/us1097.htm

https://dallnd6.dal.mobil.com/GIS/M...61638dff7d0453b085256b8400618b40?OpenDocument

http://www.shotimes.com/SHO3oilfilter.html

now think it thru,

(1)pressure is the resistance to oil flow

(2) the high volume pump can push about 25% more oil

(3) the oil pump bye-pass circuit limits the max pressure in either size pump to about 65lbs-75 lbs MAXIMUM before it BYE-PASSES all additional oil volume

(4) the engine can accept and use only the max flow volume that the engine passages can flow at the max pressure the pump provides , at any point less than max pressure the passages can flow only what the pressure and volume provided by the pump supplies

(5)if the bearing clearances can flow more than the pump provides in volume and pressure at any rpm level the film of cooling oil that provides a cushion between the bearing surfaces are at risk of not being supported and separated by that cushion of oil

(6) now since the sweep volume is greater with the high volume pump it will reach that bye-pass circuits max pressure at about 25% lower rpms and supply a POTENTIALLY higher volume of oil to the supply passages/bearings

(7)SO... all a high volume pump does is provide the maximum oil flow the engine can use up to the max pressure allowed by the bye-pass circuit at a 25% lower rpm level if the system can reach max pressure, but it also supplies 25% more oil at every rpm level below that point to provide additional cooling and protection for the engine. and if the engine can flow more than the stock pump can provide the high volume pump helps fill the need faster

(8)oil flow through the bearing clearances INCREASES at a faster rate as the rpms increase

(9) in most engines the oil flow can be provided by the stock pump IF the clearances are close to stock AND THE RPM LEVELS ARE KEPT IN ABOUT THE idle-6000rpm range but if rpm levels exceed ABOUT 6000rpm,or if bearing loads greatly exceed the stock hp levels, or the clearances are greater than stock, the high volume pump is a good idea , simply because it potentially provides that extra volume of oil.

any less than about a 1/4" tends to restrict oil flow into the pick-up on many oil pump pick-up pan combo designs and more than about 3/8" to about 1/2 MAX tends to allow air to be sucked under some hard braking or acceleration with some pan and pick up designs so a 3/8"-1/2" pick-up to pan floor clearance is what I tend to try for, Ive seen numerous cases where a high volume pump was installed without checking the clearances (and of course the pick-up moved closer to the oil pan floor simply because the oil pump itself is longer and the pick ups deeper in the pan if its reused from the old pump)and the engine SEEMED to run out of oil pressure almost instantly on accelleration, (im sure this is what leads to the myth of pumping the pan dry, but simply swapping pick-ups and verifying the pan floor to pick-up clearances cured the lack of oil flow into the pump and restriction that was the true cause of the low oil pressure condition.

remember the high voluum pumps have a deeper body to fit the longer impeller gears. this places the oil pump pickup closer to the oil pan floor if no other changes are made when swapping to a high voluum pump from the standard pump and can restrict oil flow into the pump

if you choose to install a high volume oil pump you should SERIOUSLY consider the fact that the pump is only a small part of the whole oil system,(which includes a high volume BAFFLED oil pan (7qts or more is ideal) and a windage screen, which is necessary to quickly return that extra oil to the sump, and doing the distributor mod is a big help, as it prevents any potential for cam/gear wear (something already almost non-existent with synthetic oil and the proper distributor gear material.)

the bye-pass spring only limits the pressure at which the bye-pass OPENS thus it only effects the upper pressure limit and has NOTHING to do with oil pressures or flow BELOW that level

BTW heres an old post that will answer several questions

I just got asked

" I just installed a new oil pump and have no oil pressure over about 1500rpm. but IM pulling about 24 psi at IDLE?? whats wrong GRUMPY"

the oil pick-up needs to be mounted between 3/8-1/2" from the oil pan floor.MOUNT THE PUMPS INTAKE TOO CLOSE TOO THE PAN FLOOR AND YOU'LL GET THE RESULTS YOUR SEEING! THE reason is that at low rpms the pumps pick-up can feed enough oil but speed up the pump, the flow requirement goes up and since the pick-up can,t supply the pumps needs, it cavitates and oil pressure falls rapidly to near ZERO ..until the rpms drop back to the point where the pick-up CAN supply the pumps needs

HERES MORE OIL INFO

small block oil pumps generally but not in all cases have 5/8" pickup tube dia. while BIG blocks generally but not in all cases have 3/4" pickup tube diam.

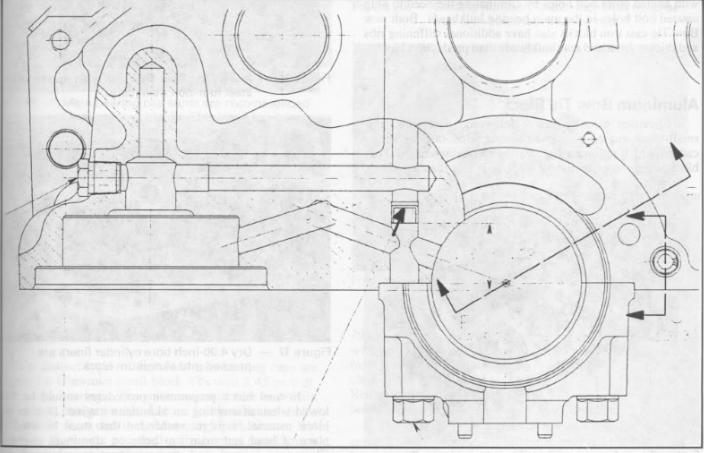

keep in mind that in many cases the big block pump can be bolted onto and used on the small block engine (a common mod) and that you need to carefully check clearances on the oil pump,oil pump drive shaft to distributor length and pan to pickup clearances in all oil pump installations

braze the pick-up tube to the pump body so the pick up is 3/8" MINIMUM, 1/2" maximum from the oil pan floor and use a large lump of MODELING CLAY (every mechanic should have some its great for checking clearances)on the pickup then install the pan temp. with no gasket and remove to measure the thickness of the clay

your local arts/craft store sells it in 1 lb blocks I usually use brite blue or black but suit your self, a digital caliper or even a ruler will get you the thickness measurement your looking for)

»http://store.yahoo.com/teacher-parent-store/modelingclay.html

http://www.guildcraftinc.com/ProductInfo.aspx?productid=102-500

once its correctly positioned ,remove the bye pass spring and gears from the oil pump,and have the pick-up brazed or welded to the pump body, then after it SLOWLY AIR cools (DON,T DROP IT IN WATER LET IT AIR COOL)replace the bye-pass spring and gears, lube the pump,with assembly lube on the gears, check the clearances, check clearances again! and install! just be damn sure its brazed or welded in the correct location as that 3/8"-1/2" is critical to good oil volume feeding the pick-up

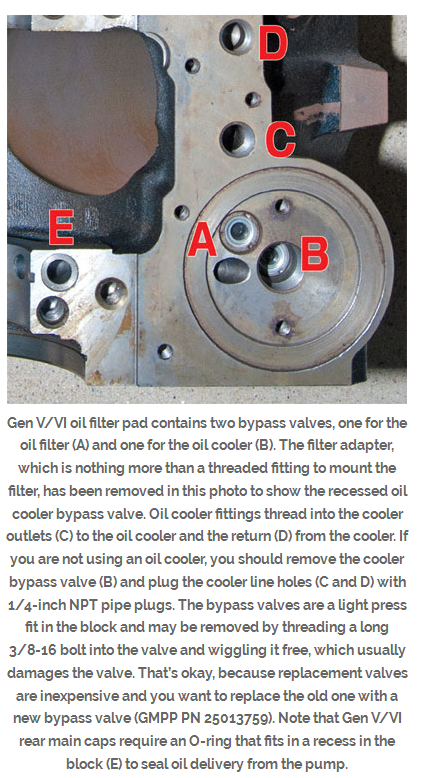

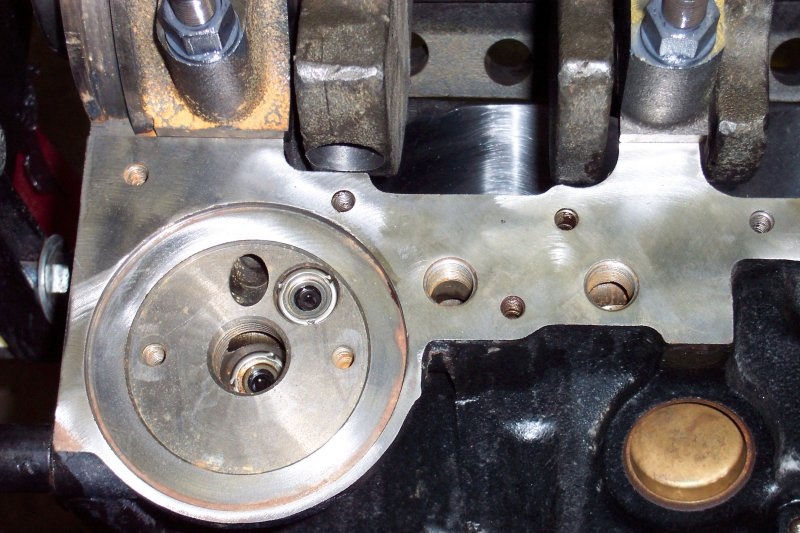

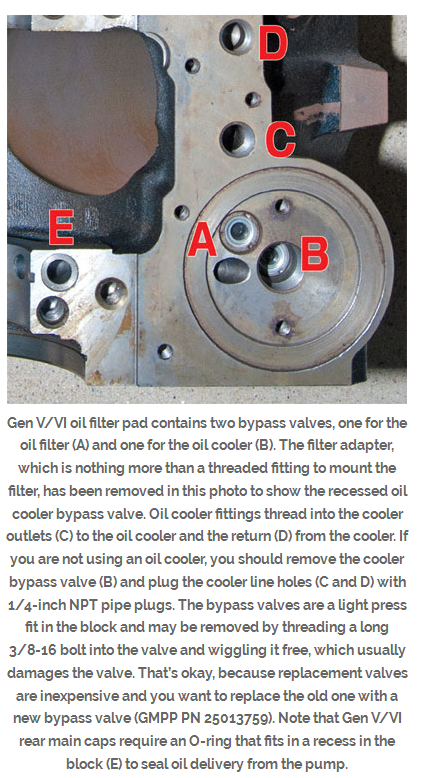

Don’t forget the “forgotten†plug. If you don’t remove it before the block is cleaned, debris can hide in the main oil passages. And if you forget to reinstall it before the rear main cap is bolted on, oil will not be directed through the oil filter!

BTW THAT INFO ON THE PLUG PICTURES NOT TOTALLY TRUE! YOU STILL HAVE SOME OIL PRESSURE BUT MOST OF THE OIL BYE_PASSES THE OIL FILTER

BTW THATS NOT TOTALLY TRUE! YOU STILL HAVE SOME OIL PRESSURE BUT MOST OF THE OIL BYE_PASSES THE OIL FILTER

http://users.erols.com/jyavins/solder.htm«

http://www.tinmantech.com/html/faq_brazing_versus_soldering.html

http://www.epemag.wimborne.co.uk/solderfaq.htm

http://www.aa1car.com/library/2005/us020516.htm

http://www.aa1car.com/library/2004/eb10445.htm

silver soldering is basically lower temp brazing , the soldering metal flows over the surface and into micro cracks in the surface of the other metal forming a almost un-removeable bond to the other metals surface it allows you to stick iron to steel or brass to steel, it works more or less like normal solder does on copper but at higher temps and has a much stronger grip in addition too working on iron and steel

from chevy high performance mag

I vastly prefer the 5 BOLT BBC style pumps with the 12 tooth gears and their larger 3/4" pick-up VS the small 4 bolt pumps with their 5/8" pick-ups and 7 tooth gears. the oil flow is both higher pressure at low rpms and smoother in pulse pressure spread,no! you don,t need it on a non-race combo, or even on some race combos but its nice to have and I willingly will loose a few hp pumping oil for better engine lubrication

most common question I get? "will a high volume oil pump help or hurt my engine?" followed by some guy saying

"If you're using a stock capacity pan, the high volume oil pump could actually suck out all the oil from the pan before it is drained back in, thus creating bad, bad problems"

absolutely proven false bye SMOKE YUNICK with HIGH SPEED PHOTOGRAPHY and CLEAR WINDOWS IN ROCKER COVERS AND OIL PAN but what can and does happen is the oil pump pickup can and does get mounted or moved too high or low in the oil pan,restricting access to the oil supply, sometimes the pickup comes loose or under hard acceleration or braking the oil in a non-baffled pan can rush away from the pickup under (G) forces, this is not pumping the pan dry, a baffled pan with a windage screen with the same oil supply volume would work perfectly

ok lets look at a few things, pressure is the result of a resistance to flow , no matter how much oil is put out by the oil pump there is almost no pressure unless there is a resistance to that oil flow and the main resistance is from oil trying to flow through the bearing surface clearances and once the pumps output pressure exceeds the engines ability to accept the oil flow at the max pressure the oil return system/bypass spring allows the oil circles back through the pump ,now the amount of oil flow necessary to reach the furthest parts in the engine from the oil pump does not go up in direct relation to rpm, but it instead increases with rpm at a steadily increasing rate that increases faster than the engine rpm due to centrifugal force draining the oil from the rods as they swing faster and faster since energy increases with the square of the velocity the rate of oil use goes up quite a bit faster due to the greatly increased (G-FORCES) pulling oil from the rod bearings over 5000rpm going to 8000rpm than the rate of oil flow increases from 2000 rpm to 5000rpm (the same 3000rpm spread) and remember the often stated (10 lbs per 1000rpm)needs to be measured at the furthest rod and main bearing from the pump not at the pump itself, next lets look at the oil flow itself, you have about 5-6 quarts in an average small block now the valve covers never get and hold more than about 1/3 to 2/3 of a quart each even at 8000 rpm (high speed photography by SMOKEY YUNICK doing stock car engine research with clear plastic valve covers prove that from what Ive read) theres about 1 quart in the lifter gallery at max and theres about 1 quart in the filter and in the oil passages in the block, that leaves at least 2 quarts in the pan at all times and for those that want to tell me about oil wrapped around the crankshaft at high rpms try squirting oil on a spinning surface doing even 2000rpm (yes that's right its thrown off as fast as it hits by centrifugal force, yes its possible for the crankshaft WITHOUT A WINDAGE SCREEN to keep acting like a propeller and pulling oil around with it in the crank case but that's what the wrap around style milodon type windage screen is designed to stop)the only way to run out of oil is to start with less than 4 quarts or to plug the oil return passages in the lifter gallery with sludge or gasket material! now add a good windage tray and a crank scrapper and almost all the oil is returned to the sump as it enters the area of the spinning crankshaft! forming a more or less endless supply to the oil pump, BTW almost all pro teams now use DRY SUMP SYSTEMS WITH POSITIVE DISPLACEMENT GERATOR PUMPS that are 3,4,or 5 stage pumps each section of which has more volume than a standard volume oil pump because its been found total oil control is necessary at high rpms to keep bearings cool and lube

the standard volume pump gears are about 1.2" long the high volume pump gears are about 1.5 inches long (depends on manufacturer)

heres the descriptions right from chevy

12555884

SBC Oil Pump, High Pressure Z28/LT1. Production high-pressure oil pump with 1.20" gears.Will produce 60-70 psi oil pressure. Does not include screen. The pickup tube dia. is 5/8" for this pump.

62.17

14044872

SBC Oil Pump, High-Volume. This high-volume pump has1.50" long gears.It has approximately 25% more capacity than a production pump at standard pressure. Does not include screen.

and yes I commonly build small blocks using bbc oil pumps like the ls7 pump, it has 1.3" gears but they are bigger in diam. and have 12 not 7 teeth like the small block pumps (many standard sbc pickups use 5/8" diam. pickups) (the ls7 pump is best used on 8qt-9qt road racing oil pans as the larger 3/4" pickup flows lots of oil for extreme high rpm engines with a multi baffled pan using windage screens, scrappers and cut outs for extreme (G) loads where a dry sump can,t be used or cost makes you stick to a wet sump pan. these LS7 pumps don't fit most sbc oil pans so your stuck using the high volume sbc oil pump if your not using a true racing 8-9 qt style oil pan in some cases

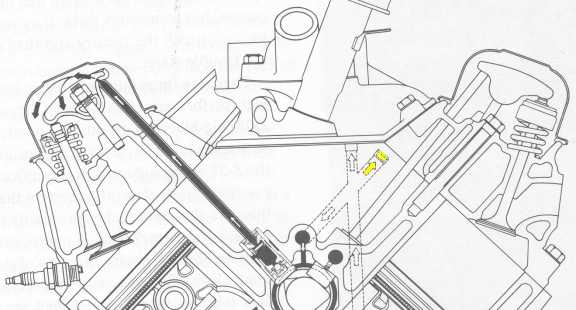

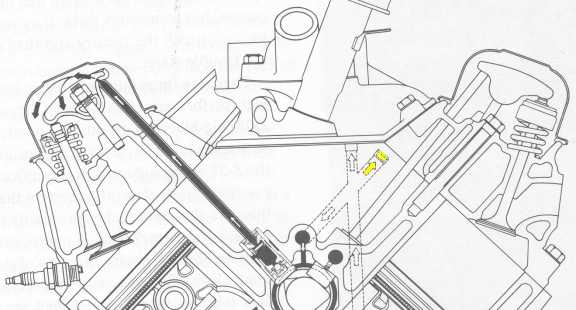

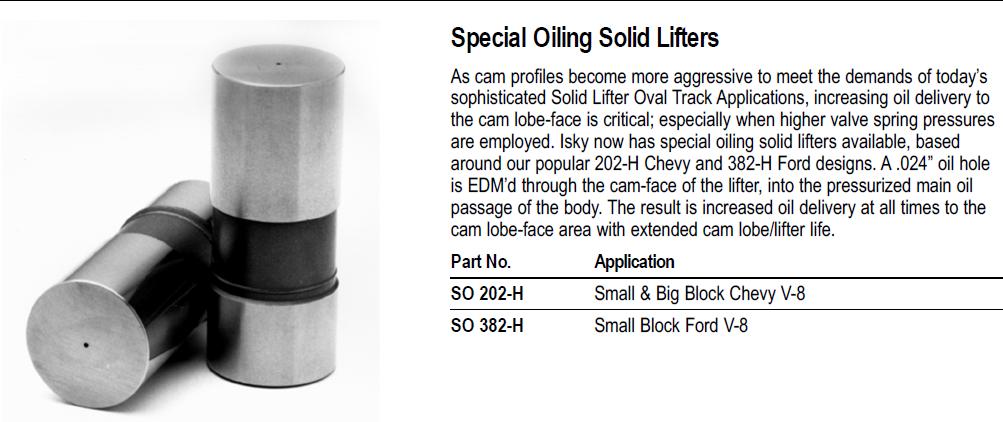

since I just got an E-MAIL about what mods are necessary or at least a good idea when running a high volume oil pump, and concern over possible extra gear wear caused by the slightly and I do mean slightly increased pressure on the gears, guys Im getting the idea here that most of you are not aware that your normally suppose to cut a .060 wide x .005-9 deep grouve in the lower band on the distributor houseing so that extra oil sprays constantly on the contact point between the cam and distributor gears and that a ARP style drive shaft with a steel collar to hold the dirveshaft alignment on true center is mandatory for long high rpm use. look at this picture:

The groove is cut under the bottom (O)ring in the band just above the gear (look at the picture above, (BTW the pic shows a smaller groove than ideal)) and in line with the gears so that oil sprays on the gear contact points at all times, this is a mod most old time racers know about and use, but Im getting the idea the new guys have not picked up on it! (those two bands form the side of an oil passage in the block and the distributor shaft seals that passage, cutting the groove sends a spray of high pressure oil onto the contact point at all times, if you don't cut the groove your relieing on returning zero pressure oil flowing down the rear lifter gallery drain holes to lube the gears

BTW the other way to do this is to groove the block in the distributors lower band area as this keeps the location of the oil jet constant as the distributor is turned, for a full contact spray on the gears so I generally do BOTH

btw

heres more OIL info

http://motorcycleinfo.calsci.com/Oils1.html

http://minimopar.knizefamily.net/oilfilterstudy.html

http://www.unofficialbmw.com/all/misc/all_oilfaq.html

http://www.bobistheoilguy.com/

http://www.babcox.com/editorial/ar/ar10180.htm

http://www.melling.com/support/bulletins/default.asp

http://www.melling.com/select/oil_pumps_gm_chevy_small_block.asp

one or at the most two of outer plugs for the oil passages plugs above the cam, drill a .030-.038 hole in one or both , naturally the one on the left is preferred as the rotation favors that side for spraying oil everywhere under the timing cover

BTW DRILL the removed oil passage plugs, while they are clamped between a couple boards with a drill press If you can, you don,t want metallic shavings in the engine

don,t get too wrapped up in worrying about which oil is superior, keep in mind oils main function is to provide a lubricating film and transfer absorbed heat,away from the moving parts, almost ANY of the name brand oils do that well and ALMOST ANY oil will last at least 5000 miles without significant loss of its abilities to do that if the filters used keep the metallic dust in it minimized AND the temp stays in the 190F-250F range. but like I stated earlier, oil needs to get up to 215F at least for a short time to burn off moisture, and above about 240F it slowly brakes down, its the regular replacement with clean oil , to remove the crud from the engine and good filters that's the key!

If a gasoline engine is tuned correctly AND it is allowed to warm up completely each time it is started, there will be very little contamination in the oil.if the cars driven frequently as the frequent heat cycles tend to remove moisture and acids, its that moisture and acids and bits of abrasive debris that cause much of the bearing wear issues, most wear occurs during the first 2 minutes before oils circulating under pressure and starting to warm up, Reasonably frequent oil changes are good insurance, i.e. 3000-5000 miles for a hard-driven street/strip car and every 4 to 5 events for a drag car. If the vehicle is stored for long periods of time, ideally the oil should be changed after its taken out of storage and changed to some cheap standard 10w30 before putting it into storage,once its out of storage run the engine long enough, till its up to temp and drain it hot, to remove moisture and acids that form in used oils and remove any moisture the engine may accumulate in storage,before swapping to a good quality oil

EVEN if you had the best oil in the world, that could easily last 30K-35K miles the CRUD & acids trapped in the oil from combustion,would cause wear and reduce its lucubration abilities over time, if the filters don,t remove the majority of that crud the oils life expectancy is still limited regardless of the oil quality itself ,so don,t buy into advertizing suggesting the better synthetic oils last nearly forever with just filter changes , Id strongly suggest even the better synthetics get changed at a minimum of every 15,000 miles and a new oil filter every 5000 miles ,regular replacement is the key

a few pictures above may help

http://www.digitalcorvettes.com/forums/showthread.php?t=80781

while its true that pumping oil, falling from the lifter gallery , around the crankcase with the rotating assembly, adds some drag and costs some hp, adding a correctly fitted windage screen and high capacity baffled oil pan to route that draining oil back to the sump efficiently minimizes the loss, and your forgetting that oil spray helps lube the rings and cam and cools the pistons, Ive seen more problems caused than solved restricting oil drain back.

I don,t restrict oil drain back, I use a windage screen and high capacity baffled oil pan designed to route the oil efficiently back to the sump, in theory at least the vast majority of the return oil flow will only make it dragged around about 240 degrees of the cranks rotational arc ONCE, but then Ive always prized absolute durability and dependability over getting the last possible 4-5 hp from an engine if it might lower that dependability

a high volume pump has slightly longer gears, usually about 10%-20% longer, that build the volume of oil pushed thru the engines oil passages,and engines clearances 10%-20% faster at any given rpm, PRESSURE is a measure of resistance to oil flow thru those clearances, theres a bye-pass circuit in the pump designed to open and limit the pressure at a set pressure level, thats usually 60-65 psi in a high volume pump and at 65-70 psi in a high pressure pump, theres no real disadvantage unless the pumps bye-pass circuit is not functioning correctly and starts to restrict the flow and the pressure builds to higher levels than intended resulting in resistance to the pump which adds drag and eats hp.

theres no lubrication increase past about 55-60 psi of oil flow thru the bearing clearances so the idea is to match the oils viscosity to the engine clearances at the engines operational temperature and to use an oil cooler and the engines oil bye-pass circuit to maintain the pressure and temperature within known, and predicted limits.

generally a high volume oil pump is used in conjunction with a windage screen, crank scraper and high capacity baffled oil pan to control the extra oil flow rates and per mote increase oil cooling and flow control

viewtopic.php?f=54&t=150

viewtopic.php?f=54&t=3536&p=9372#p9372

viewtopic.php?f=54&t=1837

viewtopic.php?f=36&t=63&p=6049&hilit=switch+sensor+oil#p6049

viewtopic.php?f=54&t=1281

viewtopic.php?f=54&t=64

viewtopic.php?f=54&t=6445

viewtopic.php?f=53&t=2726&p=7077#p7077

viewtopic.php?f=53&t=88

http://www.mobil.com/USA-English/MotorO ... _Guide.pdf

viewtopic.php?f=54&t=52

viewtopic.php?f=54&t=525

viewtopic.php?f=54&t=2187

http://www.mellingengine.com/TechnicalS ... etins.aspx

http://www.mobiloil.com/USA-English/Mot ... _Guide.pdf

viewtopic.php?f=54&t=615

viewtopic.php?f=54&t=2187

for the BBC guys

http://www.cartechbooks.com/vstore/show ... apter=7587

failure to use the correct oil pump,mounting stud, bolt or nut or

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT ,

THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP,

IT CAN AND WILL BIND ON THE BEARING ,

AND LOCK OR RESTRICT, SMOOTH ROTATION

read this over carefully

IVE POSTED MOST OF THIS BEFORE BUT IT FITS HERE AS A SOURCE OF INFO FOR THE NEWER GUYS

ok lets look at a few things, pressure is the result of a resistance to flow , no matter how much oil is put out by the oil pump there is almost no pressure unless there is a resistance to that oil flow and the main resistance is from oil trying to flow through the bearing surface clearances and once the pumps output pressure exceeds the engines ability to accept the oilflow at the max pressure the oil return system/bypass spring allows the oil circles back through the pump ,now the amount of oil flow necessary to reach the furthest parts in the engine from the oil pump does not go up in direct relation to rpm, but it instead increases with rpm at a steadily increasing rate that increases faster than the engine rpm due to centrifugal force draining the oil from the rods as they swing faster and faster since energy increases with the square of the velocity the rate of oil use goes up quite a bit faster due to the greatly increased (G-FORCES) pulling oil from the rod bearings over 5000rpm going to 8000rpm than the rate of oil flow increases from 2000 rpm to 5000rpm (the same 3000rpm spread) and remember the often stated (10 lbs per 1000rpm)needs to be measured at the furthest rod and main bearing from the pump not at the pump itself, next lets look at the oil flow itself, you have about 5-6 quarts in an average small block now the valve covers never get and hold more than about 1/3 to 2/3 of a quart each even at 8000 rpm (high speed photography by SMOKEY YUNICK doing stock car engine research with clear plastic valve covers prove that from what Ive read) theres about 1 quart in the lifter gallery at max and theres about 1 quart in the filter and in the oil passages in the block, that leaves at least 2 quarts in the pan at all times and for those that want to tell me about oil wrapped around the crankshaft at high rpms try squirting oil on a spinning surface doing even 2000rpm (yes that's right its thrown off as fast as it hits by centrifugal force, yes its possible for the crankshaft WITHOUT A WINDAGE SCREEN to keep acting like a propeller and pulling oil around with it in the crank case but that's what the wrap around style milodon type windage screen is designed to stop)the only way to run out of oil is to start with less than 4 quarts or to plug the oil return passages in the lifter gallery with sludge or gasket material! now add a good windage tray and a crank scrapper and almost all the oil is returned to the sump as it enters the area of the spinning crankshaft! forming a more or less endless supply to the oil pump, BTW almost all pro teams now use DRY SUMP SYSTEMS WITH POSITIVE DISPLACEMENT GEARATOR PUMPS that are 3,4,or 5 stage pumps each section of which has more volume than a standard volume oil pump because its been found total oil control is necessary at high rpms to keep bearings cool and lubed

NOW I POSTED THIS BEFORE BUT IT Need's REPEATING

ok look at it this way,what your trying to do here is keep an pressurized oil film on the surface of all the bearings to lube and cool them and have enough oil spraying from the rod and main bearing clearances to lube the cam and cylinder walls/rings. now a standard pump does a good job up to 5000rpm and 400 hp but above 6000rpm and 400hp the bearings are under more stress and need more oil flow to cool and because the pressure on the bearings is greater you need higher pressures to maintain that oil film.lets look at the flow versus pressure curve. [color:"red"] since oil is a liquid its non-compressible and flow will increase with rpm up to the point where the bypass circuit starts to re-route the excess flow at the point were the pressure exceeds the bypass spring pressure. but the volume will be equal to the pumps sweep volume times the rpm of the pump, since the high volume pump has a sweep volume 1.3-1.5 times the standard pump volume it will push 1.3-1.5 times the volume of oil up to the bypass circuit cut in point,that means that since the engine bearings leakage rate increases faster as the rpms increase because the clearances don,t change but the bleed off rate does that the amount of oil and the pressure that it is under will increase faster and reach the bypass circuit pressure faster with the high volume pump. the advantage here is that the metal parts MUST be floated on that oil film to keep the metal parts from touching/wearing and the more leakage points the oil flows by the less the volume of oil that's available for each leakage point beyond it and as the oil heats up it becomes easier to push through the clearances.now as the rpms and cylinder pressures increase in your goal to add power the loads trying to squeeze that oil out of those clearances also increase. ALL mods that increase power either increase rpms,cylinder pressures or reduce friction or mechanical losses. there are many oil leakage points(100) in a standard Chevy engine.

16 lifter to push rod points

16 pushrod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines [/color] that have an oil pressure feed distributor shaft bearing.)

so the more oil volume the better,(AS LONG AS ITS TOTALLY UNDER CONTROL ON BOTH THE PRESSURE AND RETURN/SCAVENGING SIDES OF THE SYSTEMChevy did an excellent job in the design but as the stresses increase the cooling volume of the extra oil available from the larger pump helps to prevent lubrication delivery failure, do you need a better pump below 5000rpm or 400hp (no) above that level the extra oil will definitely help possible deficient oil flow and bearing cooling and a simple increase in pressure does not provide a big increase in volume that may be necessary to keep that oil film in the correct places at the correct volume at all times.the stock system was designed for a 265cid engine in a passenger car turning a max of about 6000 rpm but only having the stress of under 300hp transmitted to the bearings, I'm sure the original designers never thought that the sbc or bbc would someday be asked to on occasion hold up to 450-800hp and 6000-8000 rpm.nor did they for see valve springs that placed 500lbs and up loads on the lifters and the use of over 9 to 1 compression ratios in the original design so the oil volumes and pressures necessary to cool those valve springs and bearings at those stress levels were never taken into account for that either.

Continued (oil Pan/pump)

the oil pump can only pump as much oil as the engine clearances allow at the max pressure that the oil pump bye -pass circuit will allow, and no more. for your idea to be correct (which it could be under some conditions)the oil flow through the engine clearances would need to be so great that the pump turning at 3500rpm,7000rpm engine speed(remember the pump spins 1/2 the speed the crank does)and most likely pumping at max pressure could lower the oil level to the point that the pick-up becomes uncovered or a vortex as you call it forms and the pump starts sucking air.

now under hard acceleration it is very possible for the pickup on ANY oil pump to to become uncovered in a oil pan that has less than 5qt capacity and with no oil control baffles as the oil rushes to the rear of the oil pan if the pick-up is located in mid pan or under hard braking if the pick-up is located at the rear of the pan on a non- oil baffle controlled pan.

I will grant you that it is possible for ANY oil pump to pump a good amount of oil into the lifter gallery at high rpms IF THE OIL RETURN PASSAGES IN THE HEADS AND LIFTER GALLERY ARE BLOCKED, preventing its normal return to the crankcase

, but running a high volume oil pump will have little or nothing to do with how much oil is in the pan if the engines drain back holes are clear and your using a milodon style windage screen. I have several times had that same complaint about lack of oil pressure under acceleration but it is caused by a non-baffled pan or the pickup mounted so close to the pan bottom that the pump cant get a good intake flow, if you carefully check you'll find that on a dyno runs it seldom happens,because the oil is constantly removed by the windage screen is returned to the sump, most of the oil pumped into the system exits at the rod and main bearing clearances or at the cam bearings and from the lifter bores lower ends, its not the constant oil flow or lack of oil into the rocker arms that has the big effect on total oil flow as SMOKEY YUNICKS PHOTOGRAPHIC RESEARCH PROVED YEARS AGO,its the oil flowing from the bearings and lifters and that oil flow is quickly returned to the sump by a windage screen scraping it off the spinning crank and rods as the spinning assembly passes over the windage screen. in effect most of the oil in an engine works like your timing chain in that it constantly cycles top to bottom and back never getting higher than the cam bearing lifter area.

keep in mind the distributor base forms one wall of the lifter gallery oil passage

so grooving the lower oil band helps spray extra oil on the distributor/cam gears contact area

use a good 7-8 quart baffled oil pan

now what does quite frequently happen is that the guys installing a high volume oil pump just swap out the standard pump, reinstall the stock or similar pick-up and bolt on the pan with the pick-up in the stock position on the oil pump. the stock pick-up is mounted about 3/8" off the pan bottom,the high volume pump is normally equipped with impeller gears about .3 inches longer than stock, the high volume pump body is that much lower in the pan, resulting in the pick-up being only about 1/8" from the pan bottom. the result is that on a normal Chevy oil pump pick-up this leaves a space of about 1/8" x 2.5" for oil to flow into the pump. at low rpms this works but as the rpms climb the pick-up that can,t get any oil to pump is significantly restricted as it spins and fails to pump oil, result oil pressure drops until rpms are lowered no matter how much oil is over the pick-up. simply checking to make sure that about 3/8"-1/2" of space is under the pick-up when the pan is installed cures that problem (a simple trick is to weld a 1/2" thick nut to the oil pump Pick-up base and test fitting the pan BEFORE WELDING THE PICK-UP TO THE PUMP BODY)

Ive had this discussion dozens of times and every time the guys are willing to bet me the hv pumps pumping the pan empty and every time I pull the pan, suggest strongly they install a 8 qt baffled oil pan with the correct windage screen and throw the same 5-6 qts of oil into the engine as a test,and when they do the problem vanished, I then suggest they run the 8 qt pan with 7qts as its always better to cool the engine.what it comes down too in every case that Ive looked into so far is a improperly positioned pick-up or a non- baffled oil pan without a windage screen or less than 5 qts of oil in the system, not a problem of all available oil being pumped into the lifter gallery and valve covers like some people would like you to think.

the MELLING COMPANY HAS THIS TO SAY

Most of the stock automobile engines are designed to operate from idle to 4500 RPM. The original volume and pressure oil pump will work fine in this type of application. As the demands on the engine increase so does the demands on the oiling system and pump.

The oil pump's most difficult task is to supply oil to the connecting rod bearing that is the farthest from the pump. To reach this bearing, the oil travels from three to four feet, turns numerous square corners thru small holes in the crankshaft to the rod bearing. The rod bearing doesn't help matters. It is traveling in a circle which means centrifugal force is pulling the oil out of the bearing.

A 350 Chevy has a 3.4811 stroke and a 2.111 rod journal. The outer edge of the journal travels 17.5311 every revolution. At 1000 RPM, the outer edge is traveling at 16.6 MPH and 74.7 MPH at 4500 RPM. If we take this engine to 6500 the outer edge is up to 107.9 and at 8500 it is 141.1 MPH. Now imagine driving a car around a curve at those speeds and you can feel the centrifugal force. Now imagine doing it around a circle with a 5.581, diameter.

The size of the gears or rotors determines the amount of oil a pump can move at any given RPM. Resistance to this movement creates the pressure. If a pump is not large enough to meet the demands of the engine, there will not be any pressure. Or if the demands of the engine are increased beyond the pumps capabilities there will be a loss of oil pressure. This is where high volume pumps come in; they take care of any increased demands of the engine.

Increases in the engine's oil requirements come from higher RPM, being able to rev faster, increased bearing clearances, remote oil cooler and/or filter and any combination of these. Most high volume pumps also have a increase in pressure to help get the oil out to the bearings faster.

That is what a high volume pump will do. Now let Is consider what it will not do.

It will not replace a rebuild in a worn-out engine. It may increase pressure but the engine is still worn-out.

It will not pump the oil pan dry. Both solid and hydraulic lifters have metering valves to limit flow of the oil to the top of the engine. If a pan is pumped dry, it is because the holes that drain oil back to the pan are plugged. If the high volume pump is also higher pressure, there will be a slight increase in flow to the top.

brazing the oil pump pick-up tube to the pump body after carefully checking clearances will usually prevent the oil pump pick-up from vibrating loose over time

BRAZING the pick-up to the pump is a good idea but remember to remove the pressure regulator valve first and oil and replace it after the pumps cooled

keep in mind the sbc oil pump has 7 tooth gears and the big block pumps have 12 teeth making the oil flow smoother and less pulsed, plus having larger gears they tend to supply more oil at lower rpms

look closely and youll see the big block oil pump has a 5 bolt lower cover and the oil pump pick-up with its 3/4" feed seats into the main pump casting while the small block oil pump has a 4 bolt cover and the sbc oil pump pick-up with its 5/8" feed seats into the pumps cover plate

heres other info,

http://www.babcox.com/editorial/ar/ar10180.htm

http://www.thirskauto.net/BearingPics.html

http://www.chevyhiperformance.com/techa ... index.html

http://www.waynesgarage.com/docs/oil.htm

http://www.jimcookperformance.com/TechNotes/TN 23.html

viewtopic.php?f=54&t=64

http://www.cryoeng.com/images/EngineDurabilitySecrets.htm

http://members.aol.com/carleyware/library/engine2t.htm

HERES more info on oil and filters HERE READ THESE

http://www.babcox.com/editorial/us/uhs69720.htm

http://www.co.broward.fl.us/aqi03202.htm

http://www.motoroilbible.com/five.html

http://www.motoroilbible.com/two.html

http://www.motoroilbible.com/six.html

http://www.exxon.com/exxon_lubes/tigerbytes/documents/brochures/bro0020.htm

http://www.atis.net/oil_faq.html

http://www.chevyhiperformance.com/techa ... index.html

http://www.triumphspitfire.com/Oiltest.html

http://minimopar.net/oilfilterstudy.html

http://www.melling.com/engoil.html

http://www.geocities.com/MotorCity/Downs/3837/oilprime.html

AND FOR THOSE OF YOU THAT DON,T WANT TO READ THROUGH THE LINKS THE SHORT ANSWER IS

(1)MOST OILS AVAILABLE TODAY ARE VERY GOOD QUALITY AND FAR EXCEED WHAT WAS AVAILABLE EVEN TEN YEARS AGO.

(2)CHANGING YOUR OIL AND FILTER OFTEN AND NEVER RUNNING LOW ON OIL IS THE KEY TO LONG ENGINE LIFE

(3)SYNTHETIC OILS DO HAVE A SIGNIFICANT ADVANTAGE AS FAR AS HEAT RESISTANCE AND HIGH HEAT LUBRICATION

(4) IF YOU DON,T ABUSE OR OVERHEAT YOUR ENGINE THERE'S LITTLE DISADVANTAGE TO USING GOOD DINO BASE OIL UNDER 240 DEGREES OF ENGINE TEMP AS LONG AS YOU CHANGE OIL OFTEN

(5)SYNTHETIC OIL DOES HAVE A BIG ADVANTAGE WHEN ENGINE OIL TEMPS EXCEED 260 DEGREES (F)

oil info

heres what consumer reports says about the better oils available

http://www.unofficialbmw.com/all/misc/all_oilfaq.html

All of the oils above meet current SG/CD ratings and all vehicle

manufacture's warranty requirements in the proper viscosity. All are "good

enough", but those with the better numbers are icing on the cake.

The synthetics offer the only truly significant differences, due to their

superior high temperature oxidation resistance, high film strength, very

low tendency to form deposits, stable viscosity base, and low temperature

flow characteristics. Synthetics are superior lubricants compared to

traditional petroleum oils. You will have to decide if their high cost is

justified in your application.

I use puralator pure 1 filters or mobile 1 filters and mobile 1 synthetic oil 90%-95% and 10%-5% marvel mystery oil. ALL APPLICATIONS, read this,

http://www.fernblatt.com/longhurst/engineoil_bible.html

http://www.melling.com/engoil.html

http://www.melling.com/highvol.html

http://www.aa1car.com/library/us1097.htm

https://dallnd6.dal.mobil.com/GIS/M...61638dff7d0453b085256b8400618b40?OpenDocument

http://www.shotimes.com/SHO3oilfilter.html

now think it thru,

(1)pressure is the resistance to oil flow

(2) the high volume pump can push about 25% more oil

(3) the oil pump bye-pass circuit limits the max pressure in either size pump to about 65lbs-75 lbs MAXIMUM before it BYE-PASSES all additional oil volume

(4) the engine can accept and use only the max flow volume that the engine passages can flow at the max pressure the pump provides , at any point less than max pressure the passages can flow only what the pressure and volume provided by the pump supplies

(5)if the bearing clearances can flow more than the pump provides in volume and pressure at any rpm level the film of cooling oil that provides a cushion between the bearing surfaces are at risk of not being supported and separated by that cushion of oil

(6) now since the sweep volume is greater with the high volume pump it will reach that bye-pass circuits max pressure at about 25% lower rpms and supply a POTENTIALLY higher volume of oil to the supply passages/bearings

(7)SO... all a high volume pump does is provide the maximum oil flow the engine can use up to the max pressure allowed by the bye-pass circuit at a 25% lower rpm level if the system can reach max pressure, but it also supplies 25% more oil at every rpm level below that point to provide additional cooling and protection for the engine. and if the engine can flow more than the stock pump can provide the high volume pump helps fill the need faster

(8)oil flow through the bearing clearances INCREASES at a faster rate as the rpms increase

(9) in most engines the oil flow can be provided by the stock pump IF the clearances are close to stock AND THE RPM LEVELS ARE KEPT IN ABOUT THE idle-6000rpm range but if rpm levels exceed ABOUT 6000rpm,or if bearing loads greatly exceed the stock hp levels, or the clearances are greater than stock, the high volume pump is a good idea , simply because it potentially provides that extra volume of oil.

any less than about a 1/4" tends to restrict oil flow into the pick-up on many oil pump pick-up pan combo designs and more than about 3/8" to about 1/2 MAX tends to allow air to be sucked under some hard braking or acceleration with some pan and pick up designs so a 3/8"-1/2" pick-up to pan floor clearance is what I tend to try for, Ive seen numerous cases where a high volume pump was installed without checking the clearances (and of course the pick-up moved closer to the oil pan floor simply because the oil pump itself is longer and the pick ups deeper in the pan if its reused from the old pump)and the engine SEEMED to run out of oil pressure almost instantly on accelleration, (im sure this is what leads to the myth of pumping the pan dry, but simply swapping pick-ups and verifying the pan floor to pick-up clearances cured the lack of oil flow into the pump and restriction that was the true cause of the low oil pressure condition.

remember the high voluum pumps have a deeper body to fit the longer impeller gears. this places the oil pump pickup closer to the oil pan floor if no other changes are made when swapping to a high voluum pump from the standard pump and can restrict oil flow into the pump

if you choose to install a high volume oil pump you should SERIOUSLY consider the fact that the pump is only a small part of the whole oil system,(which includes a high volume BAFFLED oil pan (7qts or more is ideal) and a windage screen, which is necessary to quickly return that extra oil to the sump, and doing the distributor mod is a big help, as it prevents any potential for cam/gear wear (something already almost non-existent with synthetic oil and the proper distributor gear material.)

the bye-pass spring only limits the pressure at which the bye-pass OPENS thus it only effects the upper pressure limit and has NOTHING to do with oil pressures or flow BELOW that level

BTW heres an old post that will answer several questions

I just got asked

" I just installed a new oil pump and have no oil pressure over about 1500rpm. but IM pulling about 24 psi at IDLE?? whats wrong GRUMPY"

the oil pick-up needs to be mounted between 3/8-1/2" from the oil pan floor.MOUNT THE PUMPS INTAKE TOO CLOSE TOO THE PAN FLOOR AND YOU'LL GET THE RESULTS YOUR SEEING! THE reason is that at low rpms the pumps pick-up can feed enough oil but speed up the pump, the flow requirement goes up and since the pick-up can,t supply the pumps needs, it cavitates and oil pressure falls rapidly to near ZERO ..until the rpms drop back to the point where the pick-up CAN supply the pumps needs

HERES MORE OIL INFO

small block oil pumps generally but not in all cases have 5/8" pickup tube dia. while BIG blocks generally but not in all cases have 3/4" pickup tube diam.

keep in mind that in many cases the big block pump can be bolted onto and used on the small block engine (a common mod) and that you need to carefully check clearances on the oil pump,oil pump drive shaft to distributor length and pan to pickup clearances in all oil pump installations

braze the pick-up tube to the pump body so the pick up is 3/8" MINIMUM, 1/2" maximum from the oil pan floor and use a large lump of MODELING CLAY (every mechanic should have some its great for checking clearances)on the pickup then install the pan temp. with no gasket and remove to measure the thickness of the clay

your local arts/craft store sells it in 1 lb blocks I usually use brite blue or black but suit your self, a digital caliper or even a ruler will get you the thickness measurement your looking for)

»http://store.yahoo.com/teacher-parent-store/modelingclay.html

http://www.guildcraftinc.com/ProductInfo.aspx?productid=102-500

once its correctly positioned ,remove the bye pass spring and gears from the oil pump,and have the pick-up brazed or welded to the pump body, then after it SLOWLY AIR cools (DON,T DROP IT IN WATER LET IT AIR COOL)replace the bye-pass spring and gears, lube the pump,with assembly lube on the gears, check the clearances, check clearances again! and install! just be damn sure its brazed or welded in the correct location as that 3/8"-1/2" is critical to good oil volume feeding the pick-up

Don’t forget the “forgotten†plug. If you don’t remove it before the block is cleaned, debris can hide in the main oil passages. And if you forget to reinstall it before the rear main cap is bolted on, oil will not be directed through the oil filter!

BTW THAT INFO ON THE PLUG PICTURES NOT TOTALLY TRUE! YOU STILL HAVE SOME OIL PRESSURE BUT MOST OF THE OIL BYE_PASSES THE OIL FILTER

BTW THATS NOT TOTALLY TRUE! YOU STILL HAVE SOME OIL PRESSURE BUT MOST OF THE OIL BYE_PASSES THE OIL FILTER

http://users.erols.com/jyavins/solder.htm«

http://www.tinmantech.com/html/faq_brazing_versus_soldering.html

http://www.epemag.wimborne.co.uk/solderfaq.htm

http://www.aa1car.com/library/2005/us020516.htm

http://www.aa1car.com/library/2004/eb10445.htm

silver soldering is basically lower temp brazing , the soldering metal flows over the surface and into micro cracks in the surface of the other metal forming a almost un-removeable bond to the other metals surface it allows you to stick iron to steel or brass to steel, it works more or less like normal solder does on copper but at higher temps and has a much stronger grip in addition too working on iron and steel

from chevy high performance mag

I vastly prefer the 5 BOLT BBC style pumps with the 12 tooth gears and their larger 3/4" pick-up VS the small 4 bolt pumps with their 5/8" pick-ups and 7 tooth gears. the oil flow is both higher pressure at low rpms and smoother in pulse pressure spread,no! you don,t need it on a non-race combo, or even on some race combos but its nice to have and I willingly will loose a few hp pumping oil for better engine lubrication

most common question I get? "will a high volume oil pump help or hurt my engine?" followed by some guy saying

"If you're using a stock capacity pan, the high volume oil pump could actually suck out all the oil from the pan before it is drained back in, thus creating bad, bad problems"

absolutely proven false bye SMOKE YUNICK with HIGH SPEED PHOTOGRAPHY and CLEAR WINDOWS IN ROCKER COVERS AND OIL PAN but what can and does happen is the oil pump pickup can and does get mounted or moved too high or low in the oil pan,restricting access to the oil supply, sometimes the pickup comes loose or under hard acceleration or braking the oil in a non-baffled pan can rush away from the pickup under (G) forces, this is not pumping the pan dry, a baffled pan with a windage screen with the same oil supply volume would work perfectly

ok lets look at a few things, pressure is the result of a resistance to flow , no matter how much oil is put out by the oil pump there is almost no pressure unless there is a resistance to that oil flow and the main resistance is from oil trying to flow through the bearing surface clearances and once the pumps output pressure exceeds the engines ability to accept the oil flow at the max pressure the oil return system/bypass spring allows the oil circles back through the pump ,now the amount of oil flow necessary to reach the furthest parts in the engine from the oil pump does not go up in direct relation to rpm, but it instead increases with rpm at a steadily increasing rate that increases faster than the engine rpm due to centrifugal force draining the oil from the rods as they swing faster and faster since energy increases with the square of the velocity the rate of oil use goes up quite a bit faster due to the greatly increased (G-FORCES) pulling oil from the rod bearings over 5000rpm going to 8000rpm than the rate of oil flow increases from 2000 rpm to 5000rpm (the same 3000rpm spread) and remember the often stated (10 lbs per 1000rpm)needs to be measured at the furthest rod and main bearing from the pump not at the pump itself, next lets look at the oil flow itself, you have about 5-6 quarts in an average small block now the valve covers never get and hold more than about 1/3 to 2/3 of a quart each even at 8000 rpm (high speed photography by SMOKEY YUNICK doing stock car engine research with clear plastic valve covers prove that from what Ive read) theres about 1 quart in the lifter gallery at max and theres about 1 quart in the filter and in the oil passages in the block, that leaves at least 2 quarts in the pan at all times and for those that want to tell me about oil wrapped around the crankshaft at high rpms try squirting oil on a spinning surface doing even 2000rpm (yes that's right its thrown off as fast as it hits by centrifugal force, yes its possible for the crankshaft WITHOUT A WINDAGE SCREEN to keep acting like a propeller and pulling oil around with it in the crank case but that's what the wrap around style milodon type windage screen is designed to stop)the only way to run out of oil is to start with less than 4 quarts or to plug the oil return passages in the lifter gallery with sludge or gasket material! now add a good windage tray and a crank scrapper and almost all the oil is returned to the sump as it enters the area of the spinning crankshaft! forming a more or less endless supply to the oil pump, BTW almost all pro teams now use DRY SUMP SYSTEMS WITH POSITIVE DISPLACEMENT GERATOR PUMPS that are 3,4,or 5 stage pumps each section of which has more volume than a standard volume oil pump because its been found total oil control is necessary at high rpms to keep bearings cool and lube

the standard volume pump gears are about 1.2" long the high volume pump gears are about 1.5 inches long (depends on manufacturer)

heres the descriptions right from chevy

12555884

SBC Oil Pump, High Pressure Z28/LT1. Production high-pressure oil pump with 1.20" gears.Will produce 60-70 psi oil pressure. Does not include screen. The pickup tube dia. is 5/8" for this pump.

62.17

14044872

SBC Oil Pump, High-Volume. This high-volume pump has1.50" long gears.It has approximately 25% more capacity than a production pump at standard pressure. Does not include screen.

and yes I commonly build small blocks using bbc oil pumps like the ls7 pump, it has 1.3" gears but they are bigger in diam. and have 12 not 7 teeth like the small block pumps (many standard sbc pickups use 5/8" diam. pickups) (the ls7 pump is best used on 8qt-9qt road racing oil pans as the larger 3/4" pickup flows lots of oil for extreme high rpm engines with a multi baffled pan using windage screens, scrappers and cut outs for extreme (G) loads where a dry sump can,t be used or cost makes you stick to a wet sump pan. these LS7 pumps don't fit most sbc oil pans so your stuck using the high volume sbc oil pump if your not using a true racing 8-9 qt style oil pan in some cases

since I just got an E-MAIL about what mods are necessary or at least a good idea when running a high volume oil pump, and concern over possible extra gear wear caused by the slightly and I do mean slightly increased pressure on the gears, guys Im getting the idea here that most of you are not aware that your normally suppose to cut a .060 wide x .005-9 deep grouve in the lower band on the distributor houseing so that extra oil sprays constantly on the contact point between the cam and distributor gears and that a ARP style drive shaft with a steel collar to hold the dirveshaft alignment on true center is mandatory for long high rpm use. look at this picture:

The groove is cut under the bottom (O)ring in the band just above the gear (look at the picture above, (BTW the pic shows a smaller groove than ideal)) and in line with the gears so that oil sprays on the gear contact points at all times, this is a mod most old time racers know about and use, but Im getting the idea the new guys have not picked up on it! (those two bands form the side of an oil passage in the block and the distributor shaft seals that passage, cutting the groove sends a spray of high pressure oil onto the contact point at all times, if you don't cut the groove your relieing on returning zero pressure oil flowing down the rear lifter gallery drain holes to lube the gears

BTW the other way to do this is to groove the block in the distributors lower band area as this keeps the location of the oil jet constant as the distributor is turned, for a full contact spray on the gears so I generally do BOTH

btw

heres more OIL info

http://motorcycleinfo.calsci.com/Oils1.html

http://minimopar.knizefamily.net/oilfilterstudy.html

http://www.unofficialbmw.com/all/misc/all_oilfaq.html

http://www.bobistheoilguy.com/

http://www.babcox.com/editorial/ar/ar10180.htm

http://www.melling.com/support/bulletins/default.asp

http://www.melling.com/select/oil_pumps_gm_chevy_small_block.asp

one or at the most two of outer plugs for the oil passages plugs above the cam, drill a .030-.038 hole in one or both , naturally the one on the left is preferred as the rotation favors that side for spraying oil everywhere under the timing cover

BTW DRILL the removed oil passage plugs, while they are clamped between a couple boards with a drill press If you can, you don,t want metallic shavings in the engine

don,t get too wrapped up in worrying about which oil is superior, keep in mind oils main function is to provide a lubricating film and transfer absorbed heat,away from the moving parts, almost ANY of the name brand oils do that well and ALMOST ANY oil will last at least 5000 miles without significant loss of its abilities to do that if the filters used keep the metallic dust in it minimized AND the temp stays in the 190F-250F range. but like I stated earlier, oil needs to get up to 215F at least for a short time to burn off moisture, and above about 240F it slowly brakes down, its the regular replacement with clean oil , to remove the crud from the engine and good filters that's the key!

If a gasoline engine is tuned correctly AND it is allowed to warm up completely each time it is started, there will be very little contamination in the oil.if the cars driven frequently as the frequent heat cycles tend to remove moisture and acids, its that moisture and acids and bits of abrasive debris that cause much of the bearing wear issues, most wear occurs during the first 2 minutes before oils circulating under pressure and starting to warm up, Reasonably frequent oil changes are good insurance, i.e. 3000-5000 miles for a hard-driven street/strip car and every 4 to 5 events for a drag car. If the vehicle is stored for long periods of time, ideally the oil should be changed after its taken out of storage and changed to some cheap standard 10w30 before putting it into storage,once its out of storage run the engine long enough, till its up to temp and drain it hot, to remove moisture and acids that form in used oils and remove any moisture the engine may accumulate in storage,before swapping to a good quality oil

EVEN if you had the best oil in the world, that could easily last 30K-35K miles the CRUD & acids trapped in the oil from combustion,would cause wear and reduce its lucubration abilities over time, if the filters don,t remove the majority of that crud the oils life expectancy is still limited regardless of the oil quality itself ,so don,t buy into advertizing suggesting the better synthetic oils last nearly forever with just filter changes , Id strongly suggest even the better synthetics get changed at a minimum of every 15,000 miles and a new oil filter every 5000 miles ,regular replacement is the key

a few pictures above may help

http://www.digitalcorvettes.com/forums/showthread.php?t=80781

while its true that pumping oil, falling from the lifter gallery , around the crankcase with the rotating assembly, adds some drag and costs some hp, adding a correctly fitted windage screen and high capacity baffled oil pan to route that draining oil back to the sump efficiently minimizes the loss, and your forgetting that oil spray helps lube the rings and cam and cools the pistons, Ive seen more problems caused than solved restricting oil drain back.

I don,t restrict oil drain back, I use a windage screen and high capacity baffled oil pan designed to route the oil efficiently back to the sump, in theory at least the vast majority of the return oil flow will only make it dragged around about 240 degrees of the cranks rotational arc ONCE, but then Ive always prized absolute durability and dependability over getting the last possible 4-5 hp from an engine if it might lower that dependability

a high volume pump has slightly longer gears, usually about 10%-20% longer, that build the volume of oil pushed thru the engines oil passages,and engines clearances 10%-20% faster at any given rpm, PRESSURE is a measure of resistance to oil flow thru those clearances, theres a bye-pass circuit in the pump designed to open and limit the pressure at a set pressure level, thats usually 60-65 psi in a high volume pump and at 65-70 psi in a high pressure pump, theres no real disadvantage unless the pumps bye-pass circuit is not functioning correctly and starts to restrict the flow and the pressure builds to higher levels than intended resulting in resistance to the pump which adds drag and eats hp.

theres no lubrication increase past about 55-60 psi of oil flow thru the bearing clearances so the idea is to match the oils viscosity to the engine clearances at the engines operational temperature and to use an oil cooler and the engines oil bye-pass circuit to maintain the pressure and temperature within known, and predicted limits.

generally a high volume oil pump is used in conjunction with a windage screen, crank scraper and high capacity baffled oil pan to control the extra oil flow rates and per mote increase oil cooling and flow control

Last edited by a moderator: