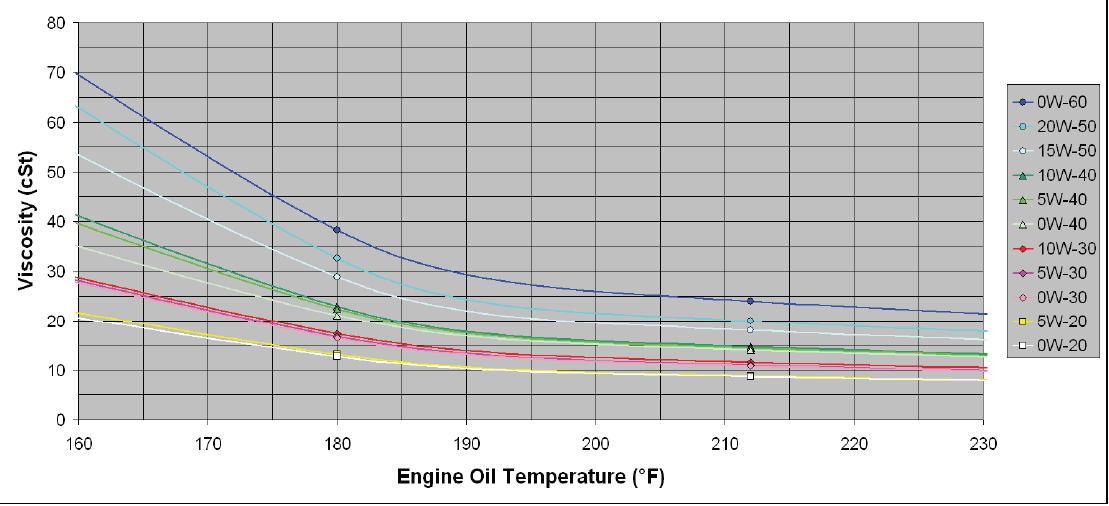

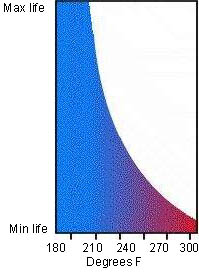

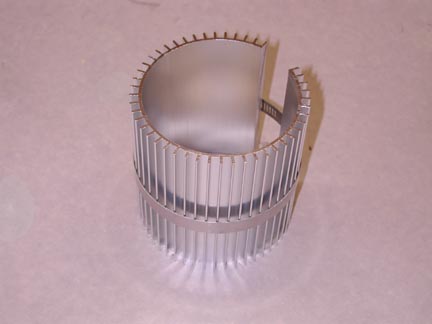

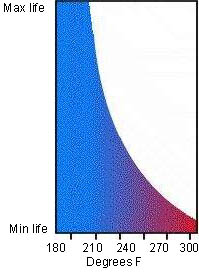

I was just over at a friends shop where he was working on a kids car giving him a tune up, after he finished the kid said let me try it out, and proceeded to back the car out on the street and do a 5000rpm tire smoking burn out without letting the engine come close to reaching operational temps first, as he pulled it back up the drive way I mentioned to my friend that the chances of that engine staying in one piece over the long term was about zero, look as kids we all did dumb stuff but if you insist on beating the hell out of an engine before temps stabilize and oil gets up to the correct temps its certainly going to take a toll in increased engine wear rates, theres always a compromise and on most engines the best oil temp range to reduce wear,emissions and get the best mileage is found when the oil temps kept in the 190F-215F range MOST OF THE TIME and it RARELY exceeds 220F

look up your fluid capacity

http://www.amsoil.com/lookup/auto-and-light-truck/?zo=531421&page=/products/application_guide.aspx

http://www.zddplus.com/TechBrief13%20-% ... cosity.pdf

www.pegasusautoracing.com

www.pegasusautoracing.com

viewtopic.php?f=57&t=9880&p=37712&hilit=t+stat#p37712

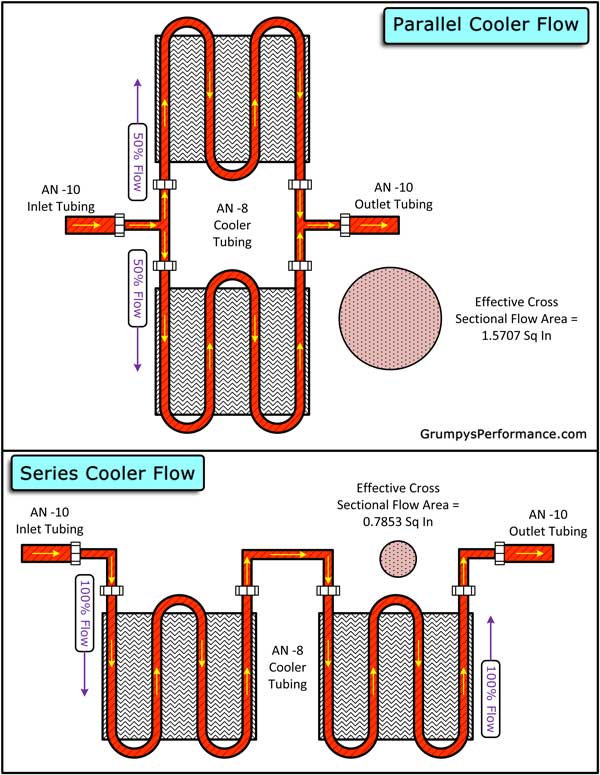

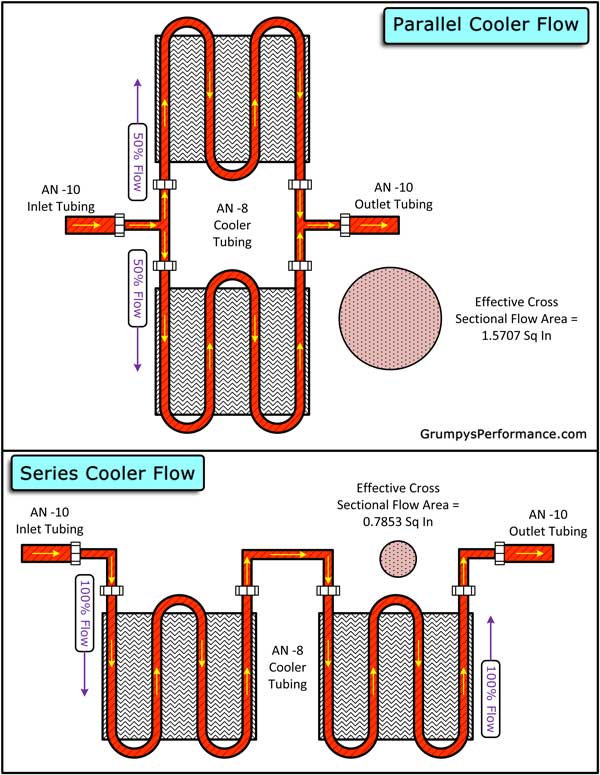

BTW HERES AN IMPORTANT TIP, IF YOUR INSTALLING A REMOTE OIL COOLER, IT is really common for guys to use lines that are far too small, that restrict flow oil flow or select a transmission or oil cooler that has to small of internal passages, shop carefully you want a MINIMUM of 1/2, or AN8 line size and 5/8" or AN10 is BETTER.

many guys don,t realize that adding an oil and/or a transmission fluid cooler, with its own fan and radiator that allows those liquids to be cooled separately, to your engine and drive train, significantly reduces the heat load on the radiator, and generally allows the engine temps to decline noticeably. in fact just adding a high volume oil pan and a transmission cooler can drop your engine coolant temps 20F-30F in many cases

a rather common issue with adding oil coolers, is that many of the coolers available can significantly restrict fluid flow because of the small restrictive internal cross section of the internal tubing, AN #6 and 3/8" tube coolers can be quite restrictive, the AN#8 are better but DUAL AN#8 coolers and AN#10 lines generally work the best, and there's also frequently limited space to position a cooler in the outside cool air flow mandating a powered fans.

the solution to both issues can and frequently does require use of two different oil coolers but placed in series this can further increase flow restrictions, the solution is in use of larger internal cross sectional area,transfer lines and mounting the twin coolers in parallel thus doubling the effective cross sectional area reducing the flow restriction the cooler potentially could produce if used in series

by Larry Gedney

This article is provided as a public service by the Geophysical Institute, University of Alaska Fairbanks, in cooperation with the UAF research community. Larry Gedney is a seismologist at the Institute.

Dr. Terry McFadden teaches a course at UAF called Arctic Engineering. It is a gold mine of tips, solid engineering, common sense and often little-known facts about coping with day-to-day problems encountered in cold climates.

If you don't like puzzles, skip the next paragraph, but I'm including it here to show the kind of problem that McFadden gives his class. It's a classic of basic engineering rationale, and requires only rudimentary mathematics and a little insight to solve. For malingerers, the answer is given at the end of this column. The problem reads:

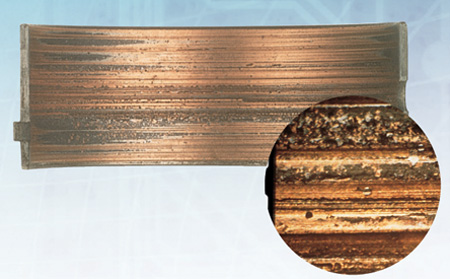

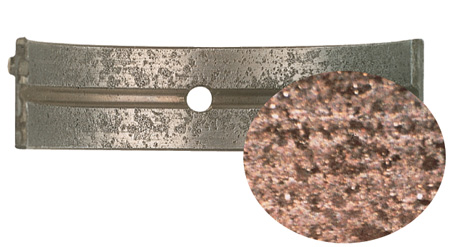

"Some experts estimate that the wear on the rings of an internal combustion engine is as high as 0.001" per 1000 miles of operation when the oil temperature is below 170 degrees F. If the maximum allowable wear is 0.006", how long can you run your engine when the oil temperature is below 170 degrees before you wear it out?" (A 6-to-1 engine-to-wheel reduction ratio, an average running speed of 3000 rpm, and 14-inch wheels 28 inches in diameter are assumed.)

The point of this problem is to stress that by far the greatest amount of engine wear takes place before the oil is warmed up. The amount of wear that occurs afterward is insignificant by comparison.

It can be appreciated, therefore, that it is important to warm the oil, as well as the engine block. An engine that is kept warm with a circulating heater or with one that is plugged into the block can usually be started easily, but the oil is not heated and it provides very little lubrication at first. Consequently, the most engine wear occurs during the few minutes immediately after starting.

The ideal situation, of course, is to have a heater for both the engine block and the oil pan. Owners of cars with air-cooled engines like the old Volkswagen beetle know that the oil pan heaters are the only kind of heater that the engine will take (aside from dipstick heaters, and the less said about them, the better).

The answer to the problem given above is that the engine would be technically worn out after just 144 hours of cold operation. Realistically though, those 144 hours represent an awful lot of cold starts.

As startup the engine is cold (pressure high, temperature low)

As the engine warms up (pressure low, temperature high)

As the rpms increase (pressure up, temperature up)

At some point the oil begins to thin (temperature up, pressure down)

Ideal oil temperature is between 180-220F

ZDDP:

Remember all my talk about the brand you choose not being so important? Times are a changing but it's not 100% clear what's happening and what is the best action to take.

Oil contains many performance enhancing additives:

Detergents - keep the engine parts clean

Dispersants - keep contaminant from clumping together

Friction Modifiers - reduce wear and improve fuel efficiency

Antioxidants

Rust Inhibitors - prevent corrosion by acids

Pour Point Depressants - keeps oil fluid at low temps

Antifoam Agents

Seal Conditioners - swell elastomeric engine seals

Metal Deactivators - reduce oxidation

Viscosity Modifiers - makes multi-grade oils possible

Antiwear/EP agents - compounds (like ZDDP) that bond to metal to prevent wear

READ THE LINKS, theres a ton of useful info

viewtopic.php?f=54&t=2187

http://garage.grumpysperformance.com/index.php?threads/which-oil-what-viscosity.1334/

http://transmissionrepairguy.com/transmission-cooler/

viewtopic.php?f=54&t=1334

viewtopic.php?f=54&t=5037

viewtopic.php?f=54&t=3536

http://www.classiccarmotoroil.com/articles.html

viewtopic.php?f=54&t=3519

viewtopic.php?f=54&t=64

viewtopic.php?f=54&t=615

http://autos.yahoo.com/maintain/repairq ... 120_2.html

http://www.ratwell.com/technical/OilSelection.html#tnp

http://www.elephantracing.com/techtopic ... rature.htm

http://www.upmpg.com/tech_articles/motoroil_viscosity/

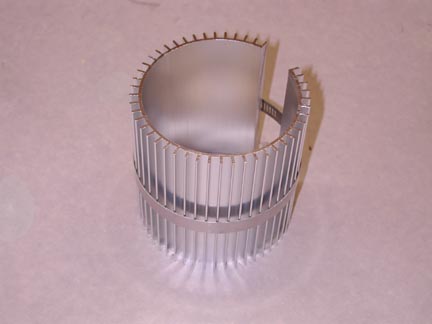

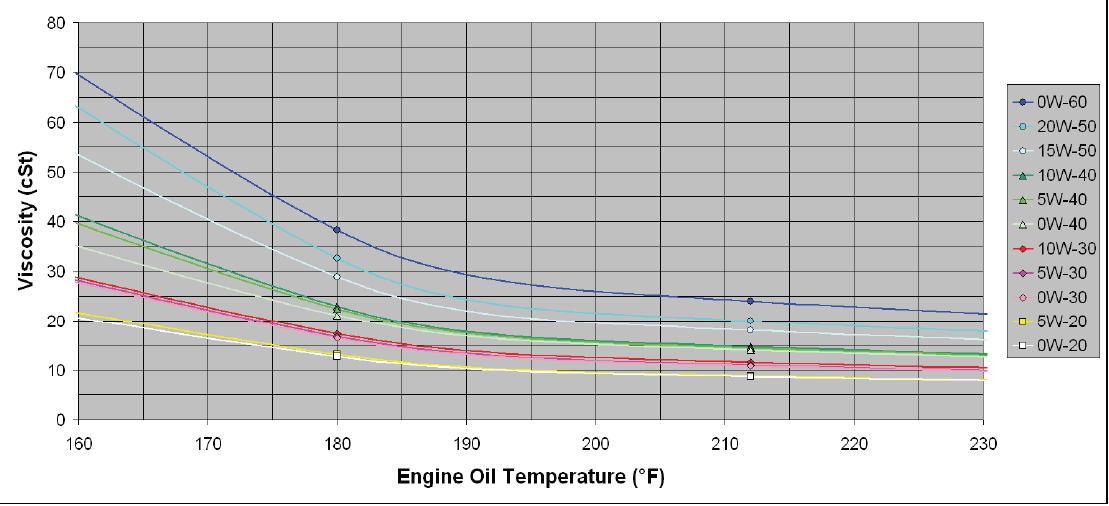

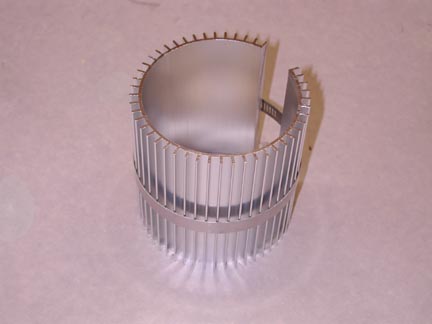

BTW I DON,T KNOW WHO SELLS THESE BUT IVE GOT TWO ON MY CORVETTES OIL FILTERS AND THEY EASILY REDUCE OIL TEMPS 7-15 DEGREES the ones I have are about 6" long and fit about 90% of the diam of the filter

they still sell these and you could modify them or use as designed

this lower designs what Ive used for decades

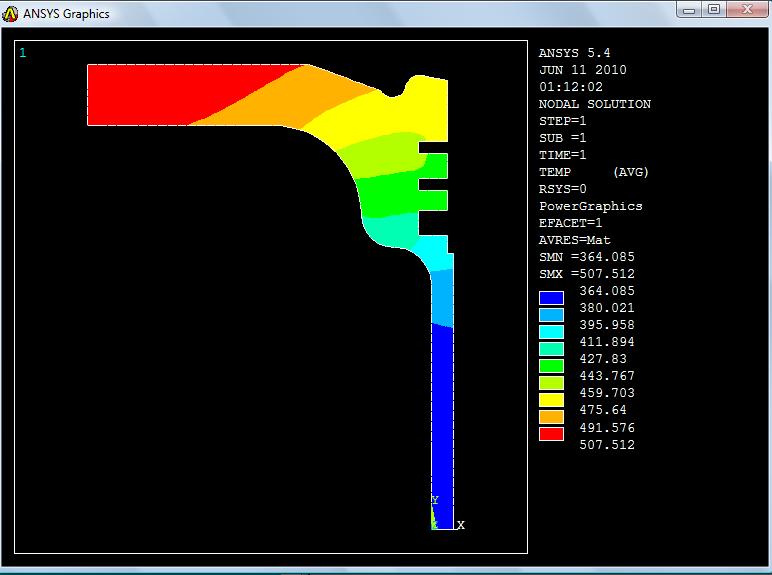

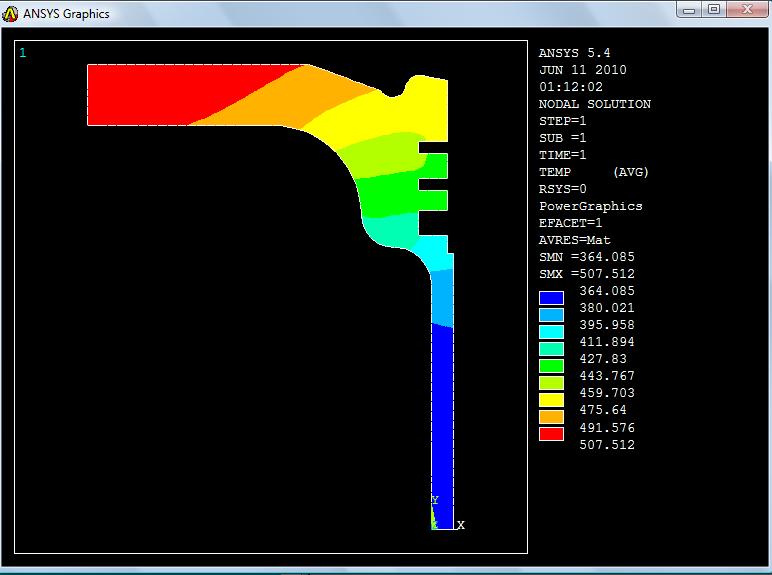

the t-stat controls COOLANT temps,

which are generally 15F-25F lower than peak oil temps,

obviously the coolant temps vary as the t-stat opens allowing flow ,

and closes as temps drop off.

your oil temp may read only 10F hotter than the coolant temps,

but its a fact that oil temps vary a great deal during the trip from sump,

oil pump, valve train,and bearings and back to the oil pan sump.

get out a high quality infrared temp gun, and scan the valve springs after 10 minutes of engine run time,

youll notice the oil temp on the rockers is significantly cooler than that flowing over the valve springs

this is the most consistently accurate I.R temp gun I've used for testing

http://www.testequipmentdepot.com/e...1100200223789&utm_content=All Extech Products

INFRARED TEMP GUN

Wide temperature range from -58 to 1832°F (-50 to 1000°C)

any time that your dealing with a potential temperature issue or a trouble issue where

, knowing the exact temperature vs what a gauge might say,

\it helps to have a handy and accurate infrared temp gun handy,

to locate and confirm heat, levels.

look up your fluid capacity

http://www.amsoil.com/lookup/auto-and-light-truck/?zo=531421&page=/products/application_guide.aspx

http://www.zddplus.com/TechBrief13%20-% ... cosity.pdf

Choosing and Using Engine Oil Coolers - Pegasus Auto Racing Supplies

Looking for information on Choosing and Using Engine Oil Coolers? Then come read about it at Pegasus Auto Racing Supplies!

viewtopic.php?f=57&t=9880&p=37712&hilit=t+stat#p37712

BTW HERES AN IMPORTANT TIP, IF YOUR INSTALLING A REMOTE OIL COOLER, IT is really common for guys to use lines that are far too small, that restrict flow oil flow or select a transmission or oil cooler that has to small of internal passages, shop carefully you want a MINIMUM of 1/2, or AN8 line size and 5/8" or AN10 is BETTER.

many guys don,t realize that adding an oil and/or a transmission fluid cooler, with its own fan and radiator that allows those liquids to be cooled separately, to your engine and drive train, significantly reduces the heat load on the radiator, and generally allows the engine temps to decline noticeably. in fact just adding a high volume oil pan and a transmission cooler can drop your engine coolant temps 20F-30F in many cases

hotrod said:For a dual-purpose car, engine oil needs to be at least 220 degrees F to burn off all the deposits and accumulated water vapor. For every pound of fuel burned in an engine, the combustion process also generates a pound of water! If engine sump temperatures rarely exceed 212 degrees (water’s boiling point), the water will mix with sulfur (another combustion by-product) and create acids that can eventually damage bearings.

As for ultimate power potential, the general consensus among most racers is that hot oil and cool water make more power in most engines. Cold engine oil causes excessive frictional drag on the bearings and cylinder walls. A quality conventional motor oil will tolerate oil sump temperatures of up to 250 degrees, but starts breaking down over 275 degrees. The traditional approach is to try to hold oil temperatures between 230 and 260 degrees. Even on a short-duration, drag-only combo where oil is frequently changed, I would not want to routinely see under-200-degree oil temps.

a rather common issue with adding oil coolers, is that many of the coolers available can significantly restrict fluid flow because of the small restrictive internal cross section of the internal tubing, AN #6 and 3/8" tube coolers can be quite restrictive, the AN#8 are better but DUAL AN#8 coolers and AN#10 lines generally work the best, and there's also frequently limited space to position a cooler in the outside cool air flow mandating a powered fans.

the solution to both issues can and frequently does require use of two different oil coolers but placed in series this can further increase flow restrictions, the solution is in use of larger internal cross sectional area,transfer lines and mounting the twin coolers in parallel thus doubling the effective cross sectional area reducing the flow restriction the cooler potentially could produce if used in series

by Larry Gedney

This article is provided as a public service by the Geophysical Institute, University of Alaska Fairbanks, in cooperation with the UAF research community. Larry Gedney is a seismologist at the Institute.

Dr. Terry McFadden teaches a course at UAF called Arctic Engineering. It is a gold mine of tips, solid engineering, common sense and often little-known facts about coping with day-to-day problems encountered in cold climates.

If you don't like puzzles, skip the next paragraph, but I'm including it here to show the kind of problem that McFadden gives his class. It's a classic of basic engineering rationale, and requires only rudimentary mathematics and a little insight to solve. For malingerers, the answer is given at the end of this column. The problem reads:

"Some experts estimate that the wear on the rings of an internal combustion engine is as high as 0.001" per 1000 miles of operation when the oil temperature is below 170 degrees F. If the maximum allowable wear is 0.006", how long can you run your engine when the oil temperature is below 170 degrees before you wear it out?" (A 6-to-1 engine-to-wheel reduction ratio, an average running speed of 3000 rpm, and 14-inch wheels 28 inches in diameter are assumed.)

The point of this problem is to stress that by far the greatest amount of engine wear takes place before the oil is warmed up. The amount of wear that occurs afterward is insignificant by comparison.

It can be appreciated, therefore, that it is important to warm the oil, as well as the engine block. An engine that is kept warm with a circulating heater or with one that is plugged into the block can usually be started easily, but the oil is not heated and it provides very little lubrication at first. Consequently, the most engine wear occurs during the few minutes immediately after starting.

The ideal situation, of course, is to have a heater for both the engine block and the oil pan. Owners of cars with air-cooled engines like the old Volkswagen beetle know that the oil pan heaters are the only kind of heater that the engine will take (aside from dipstick heaters, and the less said about them, the better).

The answer to the problem given above is that the engine would be technically worn out after just 144 hours of cold operation. Realistically though, those 144 hours represent an awful lot of cold starts.

As startup the engine is cold (pressure high, temperature low)

As the engine warms up (pressure low, temperature high)

As the rpms increase (pressure up, temperature up)

At some point the oil begins to thin (temperature up, pressure down)

Ideal oil temperature is between 180-220F

ZDDP:

Remember all my talk about the brand you choose not being so important? Times are a changing but it's not 100% clear what's happening and what is the best action to take.

Oil contains many performance enhancing additives:

Detergents - keep the engine parts clean

Dispersants - keep contaminant from clumping together

Friction Modifiers - reduce wear and improve fuel efficiency

Antioxidants

Rust Inhibitors - prevent corrosion by acids

Pour Point Depressants - keeps oil fluid at low temps

Antifoam Agents

Seal Conditioners - swell elastomeric engine seals

Metal Deactivators - reduce oxidation

Viscosity Modifiers - makes multi-grade oils possible

Antiwear/EP agents - compounds (like ZDDP) that bond to metal to prevent wear

READ THE LINKS, theres a ton of useful info

viewtopic.php?f=54&t=2187

http://garage.grumpysperformance.com/index.php?threads/which-oil-what-viscosity.1334/

http://transmissionrepairguy.com/transmission-cooler/

viewtopic.php?f=54&t=1334

viewtopic.php?f=54&t=5037

viewtopic.php?f=54&t=3536

http://www.classiccarmotoroil.com/articles.html

viewtopic.php?f=54&t=3519

viewtopic.php?f=54&t=64

viewtopic.php?f=54&t=615

http://autos.yahoo.com/maintain/repairq ... 120_2.html

http://www.ratwell.com/technical/OilSelection.html#tnp

http://www.elephantracing.com/techtopic ... rature.htm

http://www.upmpg.com/tech_articles/motoroil_viscosity/

BTW I DON,T KNOW WHO SELLS THESE BUT IVE GOT TWO ON MY CORVETTES OIL FILTERS AND THEY EASILY REDUCE OIL TEMPS 7-15 DEGREES the ones I have are about 6" long and fit about 90% of the diam of the filter

they still sell these and you could modify them or use as designed

this lower designs what Ive used for decades

the t-stat controls COOLANT temps,

which are generally 15F-25F lower than peak oil temps,

obviously the coolant temps vary as the t-stat opens allowing flow ,

and closes as temps drop off.

your oil temp may read only 10F hotter than the coolant temps,

but its a fact that oil temps vary a great deal during the trip from sump,

oil pump, valve train,and bearings and back to the oil pan sump.

get out a high quality infrared temp gun, and scan the valve springs after 10 minutes of engine run time,

youll notice the oil temp on the rockers is significantly cooler than that flowing over the valve springs

this is the most consistently accurate I.R temp gun I've used for testing

http://www.testequipmentdepot.com/e...1100200223789&utm_content=All Extech Products

INFRARED TEMP GUN

Wide temperature range from -58 to 1832°F (-50 to 1000°C)

any time that your dealing with a potential temperature issue or a trouble issue where

, knowing the exact temperature vs what a gauge might say,

\it helps to have a handy and accurate infrared temp gun handy,

to locate and confirm heat, levels.

Last edited by a moderator: