Ill BE WORKING ON THIS thread and adding too it,OFF AND ON FOR A WHILE, yeah a bit of wishful thinking, about what Id like to build, if I had the funds

I got an E-mail question asking me to put a bit of detail into the components Id select to build a kick-butt and take names BBC engine for a car that would be a week end toy,similar to RICK's T-bucket,or my Brother-in-laws COBRA and a brief explanation of WHY you would select those components ? IT would be matched to a full manual control 4l80e trans a 3200 rpm stall converter and a DANA 60 rear differential with a 3.55:1-3.73:1 rear gear with 29"-30" diameter treaded street tires in a car that weight's under 2500 lbs, the power goal will be not as important as high durability,a visually impressive combo,an engine designed for, low maintenance , semi reasonable cost, easy parts availability and a very impressive wide torque curve that allows the engine to perform well in the 3500rpm- 6200rpm power band. yeah Id build it to run on race octane fuel, and I would never subject it to the piss level octane swill the pumps at gas stations dispense, so Id be looking to build an engine that runs on about 105 octane if it was my toy, so I might consider E85 as its rated at 105 octane , but I would darn sure have a way to accurately test the true ethanol content and build the fuel system and injection to run efficiently on e85 if I went that route

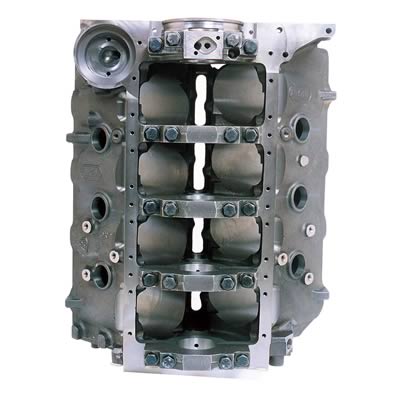

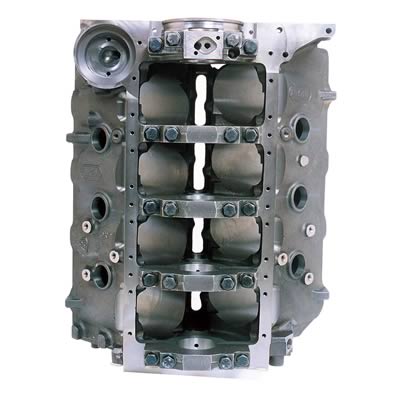

well Id start with a DART BIG M, TALL DECK block with a 4.5" bore as ID want the largest bore size I could reasonably get while still maintaining MAXIMUM bore wall rigidity

http://hotrodenginetech.com/dart-big-m- ... eparation/

http://www.dartheads.com/products/aitdo ... e_id/1663/

http://www.summitracing.com/parts/drt-31263454

ID select a 4340 forged steel , internally balanced SCAT crank with the 6.535" forged rods and pistons, with 7/16" ARP 2000 series rod bolts and have the pistons thermally coated, then have the assembly carefully balanced to a 1 gram, limit

572 4-454-4500-6535-C 2-454-6535-2200 4.500" 6.535" PREMIUM 4.500 DOME 12.5 11.8 11.3 1-43284 1-43284BI

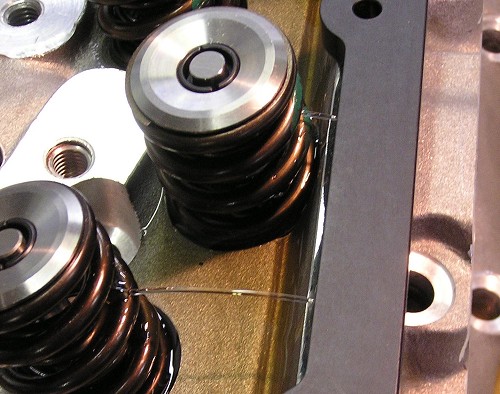

heres the roller cam,a crower solid roller

Performance level - High RPM-\

INT/EXH - Dur @ .050” Lift: 268°/279° RR: 1.7/1.7 Gross Lift: .706”/.700” LSA: 110° RPM: 2800 to 7200 Redline: 7700

and Id specify a BILLET cam core not a cast core as thats really mandatory on a serious solid roller lifter cam.

keep in mind with 572 displacement , and 12.5:1 compression,that durations going to support about 1100rpm lower

http://www.crower.com/camshafts/chevy-3 ... -7195.html

I'D HAVE THE BLOCKS LIFTER BORES MACHINED FOR THE LARGER DIAM. CHRYSLER .904 DIAM LIFTERS

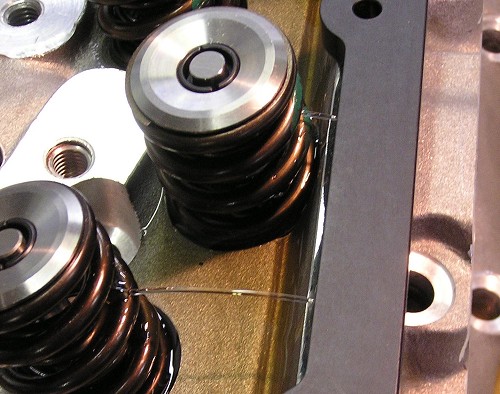

solid roller cam lifters are much cheaper and lighter in weight than hydraulic roller lifters and properly set up just as durable when used in an application that will have valve train spring load rates that will compliment the 6500 rpm max rpm limits the engine plan will be built to match

would I rather have individual runner stack injection? hell yes

but by the time I get the EFI controller, intake manifold injectors etc. the dual throttle body tunnel ram injection comes out $800-$1200 less so theres options

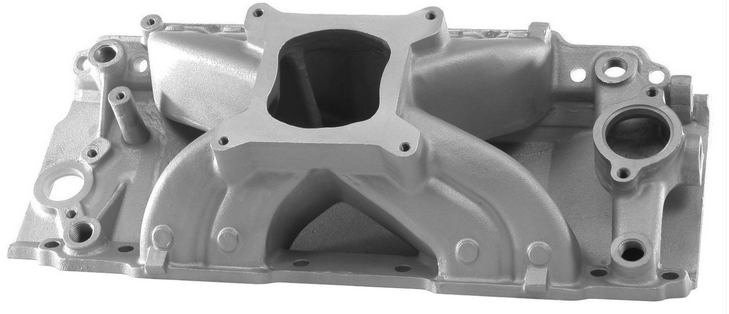

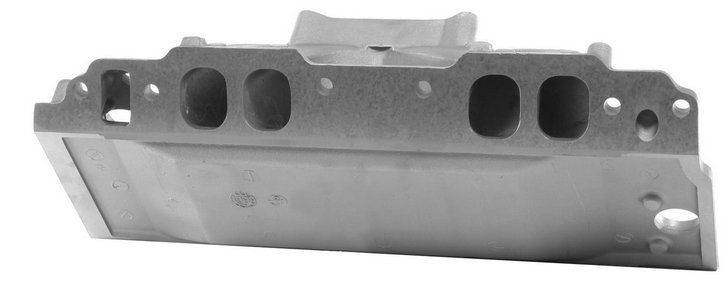

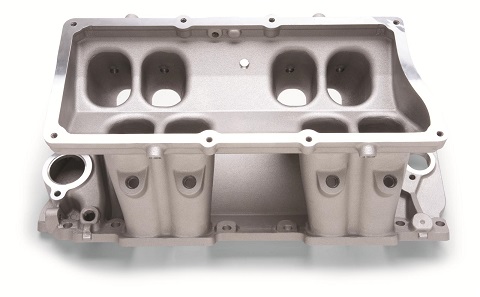

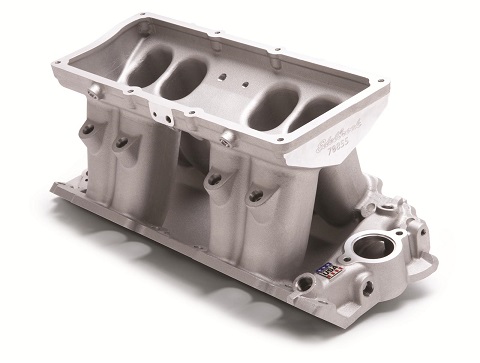

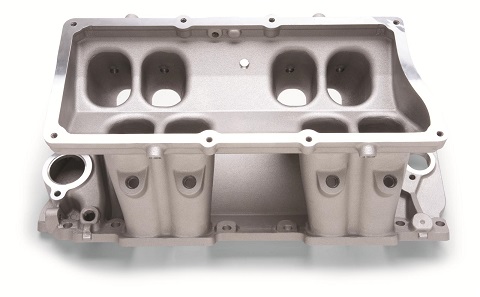

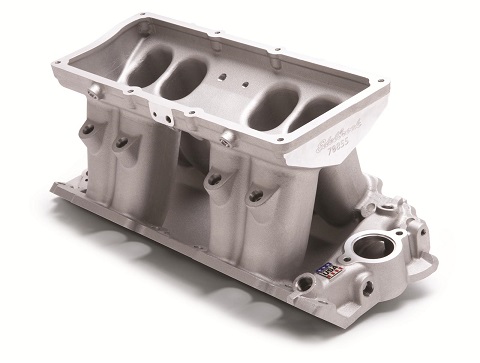

edelbrock recently came out with an improved tunnel ram designed to use throttle 4500 size bodys and injectors for the BBC rectangle port heads part #70855 for roughly $600 for the base

http://www.summitracing.com/parts/edl-70855 mainifold base $600

http://www.summitracing.com/parts/edl-7086 top plate $200

http://www.summitracing.com/parts/edl-3659 fuel rail kit $150

http://www.summitracing.com/parts/edl-7077 throttle linkage $140

http://www.summitracing.com/parts/edl-3879 DOMINATOR THROTTLE BODYS $500 EACH

youll still need a controller and sensors and a wire harness

85lb-95 lb injector sets should cost in the $400-450 range if you shop, and while that setup is not cheap its competitively priced..

but if the budget were not all that tight!

Id go the old school route in a heart beat

with EFI stack injection and a vertex max, without a seconds hesitation

Id run a 3 quart, oil accumulator and a 10 quart baffled oil pan with a custom windage tray, and a powered fan on a dual circuit transmission/oil cooler , (I doubt the oil cooler would be necessary)

Id select a individual coil on plug ignition with the proper crank, indexed spark timing

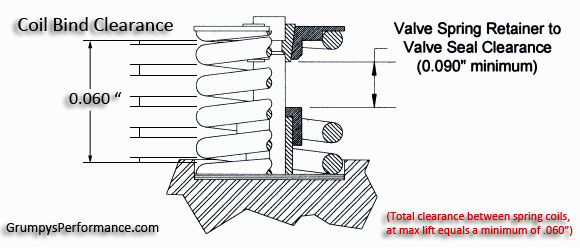

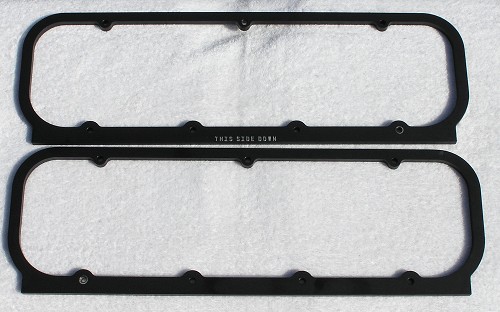

Id go for valve spring cooling oil squirters as they add durability

viewtopic.php?f=70&t=5916&p=18181&hilit=+ignition+coil+plug#p18181

yes the 365 CNC port trick flow heads ARE a bit larger than would be ideal, for the application, but IT been selected to provide more air flow than required for future use of a dual nitrous and E85 mix and to kill off a bit of UN- necessary lower rpm torque as this is NOT a true race engine, but rather a high power street strip toy that will seldom see rpm levels over about 4500rpm in real use!

properly assembled 800hp and 750 ft lbs at the flywheel should be easy to reach keep in mind this is not designed for all out power but impressive power with high durability and reasonable life expectancy, and Id set the rev limiter at 6000rpm.

http://www.summitracing.com/parts/tfs-4141t804-c02

http://www.trickflow.com/partdetail.asp ... toview=sku

http://www.summitracing.com/parts/tfs-4 ... /overview/

http://garage.grumpysperformance.co...hing-the-drive-train-to-the-engine-combo.741/

http://garage.grumpysperformance.co...electing-a-torque-converter-stall-speed.1715/

http://garage.grumpysperformance.co...late-gear-ratios-and-when-to-shift-calcs.555/

all it takes is a tiny bit of research and some math to calculate the ideal rear differential gearing, tires size etc. and transmission gear ratios, and you can certainly select the correct torque converter stall speed if you have a dyno graph of your engines power curve without much difficulty, an hour or so spent in reading and research will provide you with a great deal better performance from most cars.

and a couple days worth of research and doing some math on all of the power trains component parts will provide you with a wealth of info that can prevent you from making costly mistakes.

A SIMILAR BIT OF RELATED INFO

http://www.hotrod.com/how-to/engine/hrd ... vy-engine/

http://hotrodenginetech.com/540ci-all-m ... -screamer/

http://www.onallcylinders.com/2012/05/2 ... -assembly/

http://www.onallcylinders.com/2012/09/0 ... s-top-end/

http://www.onallcylinders.com/2012/10/1 ... o-results/

viewtopic.php?f=54&t=6491&p=20681&hilit=valve+spring+oiling#p20681

http://www.maliburacing.com/patrick_budd_article.htm

viewtopic.php?f=69&t=5123

http://garage.grumpysperformance.co...ing-a-cobra-replica-kit-car.10356/#post-48297

viewtopic.php?f=69&t=1474

I got an E-mail question asking me to put a bit of detail into the components Id select to build a kick-butt and take names BBC engine for a car that would be a week end toy,similar to RICK's T-bucket,or my Brother-in-laws COBRA and a brief explanation of WHY you would select those components ? IT would be matched to a full manual control 4l80e trans a 3200 rpm stall converter and a DANA 60 rear differential with a 3.55:1-3.73:1 rear gear with 29"-30" diameter treaded street tires in a car that weight's under 2500 lbs, the power goal will be not as important as high durability,a visually impressive combo,an engine designed for, low maintenance , semi reasonable cost, easy parts availability and a very impressive wide torque curve that allows the engine to perform well in the 3500rpm- 6200rpm power band. yeah Id build it to run on race octane fuel, and I would never subject it to the piss level octane swill the pumps at gas stations dispense, so Id be looking to build an engine that runs on about 105 octane if it was my toy, so I might consider E85 as its rated at 105 octane , but I would darn sure have a way to accurately test the true ethanol content and build the fuel system and injection to run efficiently on e85 if I went that route

well Id start with a DART BIG M, TALL DECK block with a 4.5" bore as ID want the largest bore size I could reasonably get while still maintaining MAXIMUM bore wall rigidity

http://hotrodenginetech.com/dart-big-m- ... eparation/

http://www.dartheads.com/products/aitdo ... e_id/1663/

http://www.summitracing.com/parts/drt-31263454

ID select a 4340 forged steel , internally balanced SCAT crank with the 6.535" forged rods and pistons, with 7/16" ARP 2000 series rod bolts and have the pistons thermally coated, then have the assembly carefully balanced to a 1 gram, limit

572 4-454-4500-6535-C 2-454-6535-2200 4.500" 6.535" PREMIUM 4.500 DOME 12.5 11.8 11.3 1-43284 1-43284BI

heres the roller cam,a crower solid roller

Performance level - High RPM-\

INT/EXH - Dur @ .050” Lift: 268°/279° RR: 1.7/1.7 Gross Lift: .706”/.700” LSA: 110° RPM: 2800 to 7200 Redline: 7700

and Id specify a BILLET cam core not a cast core as thats really mandatory on a serious solid roller lifter cam.

keep in mind with 572 displacement , and 12.5:1 compression,that durations going to support about 1100rpm lower

http://www.crower.com/camshafts/chevy-3 ... -7195.html

I'D HAVE THE BLOCKS LIFTER BORES MACHINED FOR THE LARGER DIAM. CHRYSLER .904 DIAM LIFTERS

solid roller cam lifters are much cheaper and lighter in weight than hydraulic roller lifters and properly set up just as durable when used in an application that will have valve train spring load rates that will compliment the 6500 rpm max rpm limits the engine plan will be built to match

would I rather have individual runner stack injection? hell yes

but by the time I get the EFI controller, intake manifold injectors etc. the dual throttle body tunnel ram injection comes out $800-$1200 less so theres options

edelbrock recently came out with an improved tunnel ram designed to use throttle 4500 size bodys and injectors for the BBC rectangle port heads part #70855 for roughly $600 for the base

http://www.summitracing.com/parts/edl-70855 mainifold base $600

http://www.summitracing.com/parts/edl-7086 top plate $200

http://www.summitracing.com/parts/edl-3659 fuel rail kit $150

http://www.summitracing.com/parts/edl-7077 throttle linkage $140

http://www.summitracing.com/parts/edl-3879 DOMINATOR THROTTLE BODYS $500 EACH

youll still need a controller and sensors and a wire harness

85lb-95 lb injector sets should cost in the $400-450 range if you shop, and while that setup is not cheap its competitively priced..

but if the budget were not all that tight!

Id go the old school route in a heart beat

with EFI stack injection and a vertex max, without a seconds hesitation

Id run a 3 quart, oil accumulator and a 10 quart baffled oil pan with a custom windage tray, and a powered fan on a dual circuit transmission/oil cooler , (I doubt the oil cooler would be necessary)

Id select a individual coil on plug ignition with the proper crank, indexed spark timing

Id go for valve spring cooling oil squirters as they add durability

viewtopic.php?f=70&t=5916&p=18181&hilit=+ignition+coil+plug#p18181

yes the 365 CNC port trick flow heads ARE a bit larger than would be ideal, for the application, but IT been selected to provide more air flow than required for future use of a dual nitrous and E85 mix and to kill off a bit of UN- necessary lower rpm torque as this is NOT a true race engine, but rather a high power street strip toy that will seldom see rpm levels over about 4500rpm in real use!

properly assembled 800hp and 750 ft lbs at the flywheel should be easy to reach keep in mind this is not designed for all out power but impressive power with high durability and reasonable life expectancy, and Id set the rev limiter at 6000rpm.

http://www.summitracing.com/parts/tfs-4141t804-c02

http://www.trickflow.com/partdetail.asp ... toview=sku

http://www.summitracing.com/parts/tfs-4 ... /overview/

http://garage.grumpysperformance.co...hing-the-drive-train-to-the-engine-combo.741/

http://garage.grumpysperformance.co...electing-a-torque-converter-stall-speed.1715/

http://garage.grumpysperformance.co...late-gear-ratios-and-when-to-shift-calcs.555/

all it takes is a tiny bit of research and some math to calculate the ideal rear differential gearing, tires size etc. and transmission gear ratios, and you can certainly select the correct torque converter stall speed if you have a dyno graph of your engines power curve without much difficulty, an hour or so spent in reading and research will provide you with a great deal better performance from most cars.

and a couple days worth of research and doing some math on all of the power trains component parts will provide you with a wealth of info that can prevent you from making costly mistakes.

A SIMILAR BIT OF RELATED INFO

http://www.hotrod.com/how-to/engine/hrd ... vy-engine/

http://hotrodenginetech.com/540ci-all-m ... -screamer/

http://www.onallcylinders.com/2012/05/2 ... -assembly/

http://www.onallcylinders.com/2012/09/0 ... s-top-end/

http://www.onallcylinders.com/2012/10/1 ... o-results/

viewtopic.php?f=54&t=6491&p=20681&hilit=valve+spring+oiling#p20681

http://www.maliburacing.com/patrick_budd_article.htm

viewtopic.php?f=69&t=5123

http://garage.grumpysperformance.co...ing-a-cobra-replica-kit-car.10356/#post-48297

viewtopic.php?f=69&t=1474

Last edited by a moderator: