I can,t tell you the number of times I see guys with chevelles,camaros, etc, that have problems with a 10 bolt rear. and the first thing you hear is get a 12 bolt, well, a decent 12 bolt is ok, but pro built it can easily cost over $3K, and if your swapping to a stronger rear differential anyway look over your options,

damage like this is common, when the 10 bolt rear differentials subjected to high stress loads

IF your dead set on running a 10 bolt differential in a serious performance application with 500 ft lbs of torque or more the clear plastic rear cover ,is a great idea.. that way you can see the shreaded internals without even pulling the rear cover

ok I just got to ask, why would anyone pay $3200 plus for a 12 bolt when theres bolt in rears based on a hybrid dana 60 available with its 9.75" rear gears that are darn near bullet proof,that are significantly stronger, and depending on options ,costs less vs the chevy 8.7/8" gears and lower strength assembly

yes the chevys 25 lbs lighter but that 25 lbs is all steel that makes the dana 60 hybrid significantly stronger

http://www.strangeengineering.net/catalog/index.html

I destroyed several 12 bolts before swapping to a dana 60 with a nitrous BBC in a camaro, I installed a dana 60 and never had another problem

a ford 9" is a decent option , especially if you get a deal, at a local salvage yard, on a differential with disc brakes

http://www.kevinstang.com/Ninecase.htm

the reason I bring this up, is that theres DOZENS of options

and if you have a 10 bolt G.M. rear you may want to upgrade to add a good bit more strenth, and durability, ID certainly look into the local salvage yards for a rear differential of aproximately your cars current width, and look for a rear differential with disc brakes If I had a camaro or nova or similar 10 bolt differential car once the G.M. 10 bolt failed rather than sinking cash into a 10 bolt rebuild, the parts size and mass is just not there to withstand long term abuse!

http://www.mustangsandmore.com/ubb/FordRearDimensions.html

FORD READ DIFFERENTIALS ARE JUST NOT VERY HARD TO FIND, NOR ARE MOST OVERLY EXPENSIVE (especially compared to the cost of rebuilding a G.M. 10 bolt with top quality components) that could easily exceed $1200)

1965-1966 Mustang 57.25 inches

1967-1970 Mustang 59.25 inches

1971-1973 Mustang 61.25 inches

1977-1981 Versailles 58.50 inches

1967-1973 Mustang, Torino, Ranchero, Fairlane 59.25 inches to

61.25 inches

1957-1959 Ranchero and station wagon 57.25 inches

1966-1977 Bronco 58 inches

1977-1981 Granada/Versailles 58 inches

1967-1971 Comet, Cougar, Mustang, Fairlane 59.25 inches

1971-1973 Mustang 61.25 inches

1964 Falcon 58 inches

1967 Cougar 60 inches

1967 Fairlane 63.50 inches coil springs

1972 Ford Van 3/4 ton 68 inches

1973-1986 Ford Van 3/4 ton 65.25 inches

1957-1959 Ranchero and station wagon

57.25 inches

narrowest 9" housing

1966-1977 Bronco 58 inches 5-on-5 1/2 inch diameter bolt circle

1967-1973 Torinos, Rancheros, Fairlanes 59.25 inches or

61.25 inches

1967-1971 Comets, Cougars, Fairlanes 59.25 inches

http://dfwmotorsport.com/Fairlane/9inchrearends.htm

http://www.superchevy.com/how-to/148-02 ... r-install/

http://www.kevinstang.com/Ninecase.htm

http://www.ford-trucks.com/article/idx/ ... build.html

http://www.off-road.com/trucks4x4/artic ... ?id=198404

http://www.carcraft.com/techarticles/cc ... ewall.html

http://www.autohobbydigest.com/dana.html

http://www.pirate4x4.com/tech/billavist ... Rea%20Axle).PDF

http://www.offroaders.com/directory/axles/dana60.htm

http://www.currieenterprises.com/CESTORE/alldana60.aspx

the ford 9" and dana 60 rear were used for years in trucks and a few cars, theres still plenty out there in salvage yards and many are also reasonably priced

http://wallaceracing.com/axledata2.htm

http://tech.oldsgmail.com/axle_useage.php

http://www.oldsmobility.com/old/10bolt-tech.htm

http://chevellestuff.net/qd/rear_axle_info.htm

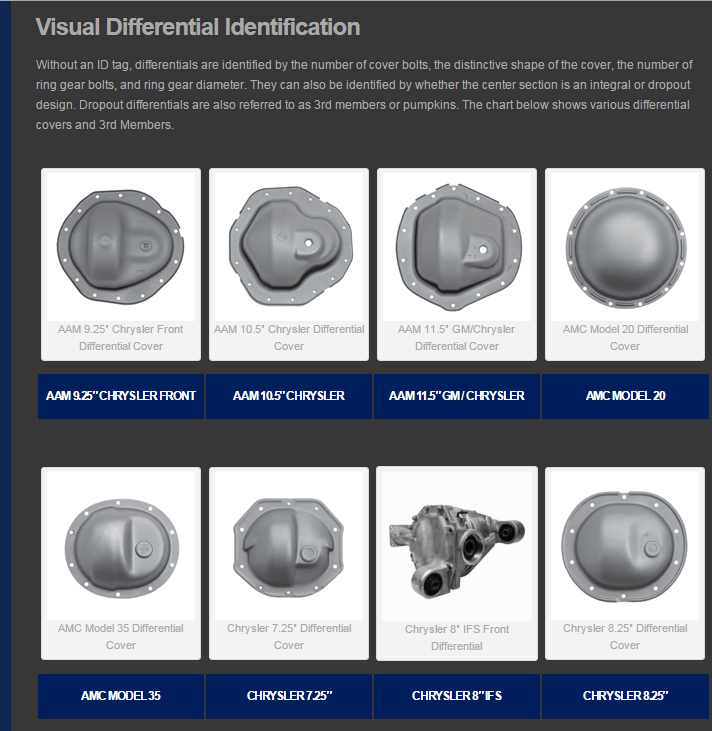

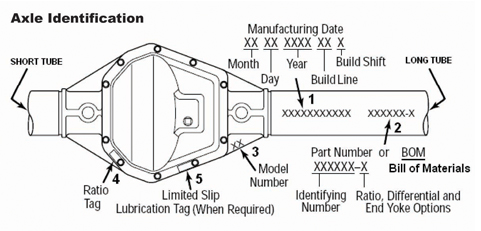

http://www.differentials.com/technical-help/differential-identification

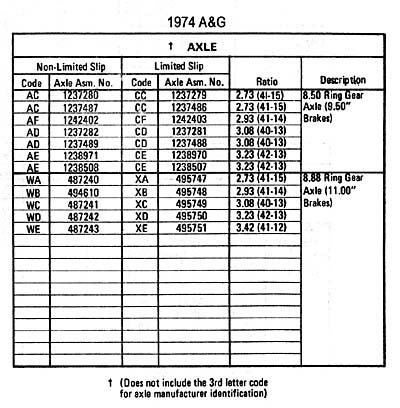

http://www.differentials.com/gm-axle-ratio-identification-codes

http://www.differentials.com/technical-help/differential-identification

http://www.fourwheeler.com/how-to/transmission-drivetrain/1312-10-bolt-builder-s-guide/

damage like this is common, when the 10 bolt rear differentials subjected to high stress loads

IF your dead set on running a 10 bolt differential in a serious performance application with 500 ft lbs of torque or more the clear plastic rear cover ,is a great idea.. that way you can see the shreaded internals without even pulling the rear cover

ok I just got to ask, why would anyone pay $3200 plus for a 12 bolt when theres bolt in rears based on a hybrid dana 60 available with its 9.75" rear gears that are darn near bullet proof,that are significantly stronger, and depending on options ,costs less vs the chevy 8.7/8" gears and lower strength assembly

yes the chevys 25 lbs lighter but that 25 lbs is all steel that makes the dana 60 hybrid significantly stronger

http://www.strangeengineering.net/catalog/index.html

I destroyed several 12 bolts before swapping to a dana 60 with a nitrous BBC in a camaro, I installed a dana 60 and never had another problem

a ford 9" is a decent option , especially if you get a deal, at a local salvage yard, on a differential with disc brakes

http://www.kevinstang.com/Ninecase.htm

the reason I bring this up, is that theres DOZENS of options

and if you have a 10 bolt G.M. rear you may want to upgrade to add a good bit more strenth, and durability, ID certainly look into the local salvage yards for a rear differential of aproximately your cars current width, and look for a rear differential with disc brakes If I had a camaro or nova or similar 10 bolt differential car once the G.M. 10 bolt failed rather than sinking cash into a 10 bolt rebuild, the parts size and mass is just not there to withstand long term abuse!

http://www.mustangsandmore.com/ubb/FordRearDimensions.html

FORD READ DIFFERENTIALS ARE JUST NOT VERY HARD TO FIND, NOR ARE MOST OVERLY EXPENSIVE (especially compared to the cost of rebuilding a G.M. 10 bolt with top quality components) that could easily exceed $1200)

1965-1966 Mustang 57.25 inches

1967-1970 Mustang 59.25 inches

1971-1973 Mustang 61.25 inches

1977-1981 Versailles 58.50 inches

1967-1973 Mustang, Torino, Ranchero, Fairlane 59.25 inches to

61.25 inches

1957-1959 Ranchero and station wagon 57.25 inches

1966-1977 Bronco 58 inches

1977-1981 Granada/Versailles 58 inches

1967-1971 Comet, Cougar, Mustang, Fairlane 59.25 inches

1971-1973 Mustang 61.25 inches

1964 Falcon 58 inches

1967 Cougar 60 inches

1967 Fairlane 63.50 inches coil springs

1972 Ford Van 3/4 ton 68 inches

1973-1986 Ford Van 3/4 ton 65.25 inches

1957-1959 Ranchero and station wagon

57.25 inches

narrowest 9" housing

1966-1977 Bronco 58 inches 5-on-5 1/2 inch diameter bolt circle

1967-1973 Torinos, Rancheros, Fairlanes 59.25 inches or

61.25 inches

1967-1971 Comets, Cougars, Fairlanes 59.25 inches

http://dfwmotorsport.com/Fairlane/9inchrearends.htm

http://www.superchevy.com/how-to/148-02 ... r-install/

http://www.kevinstang.com/Ninecase.htm

http://www.ford-trucks.com/article/idx/ ... build.html

http://www.off-road.com/trucks4x4/artic ... ?id=198404

http://www.carcraft.com/techarticles/cc ... ewall.html

http://www.autohobbydigest.com/dana.html

http://www.pirate4x4.com/tech/billavist ... Rea%20Axle).PDF

http://www.offroaders.com/directory/axles/dana60.htm

http://www.currieenterprises.com/CESTORE/alldana60.aspx

the ford 9" and dana 60 rear were used for years in trucks and a few cars, theres still plenty out there in salvage yards and many are also reasonably priced

http://wallaceracing.com/axledata2.htm

http://tech.oldsgmail.com/axle_useage.php

http://www.oldsmobility.com/old/10bolt-tech.htm

http://chevellestuff.net/qd/rear_axle_info.htm

http://www.differentials.com/technical-help/differential-identification

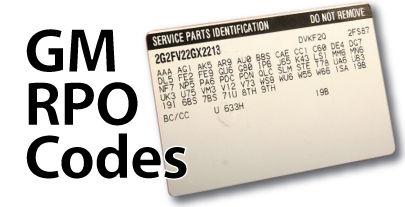

http://www.differentials.com/gm-axle-ratio-identification-codes

http://www.differentials.com/technical-help/differential-identification

http://www.fourwheeler.com/how-to/transmission-drivetrain/1312-10-bolt-builder-s-guide/

Last edited by a moderator: