first thing Ill point out is there's a good deal of reasonably precise machine work and higher quality materials used in the fabrication of a turbo or centrifugal supercharger, turbos work under marginally higher heat and stress, so they frequently require tighter tolerances and more exotic materials, cheaper versions generally won't use the best bearings or materials or be made to the best tolerances, either, and cooling the intake & fuel charge under boost means an INTERCOOLER, and E85 or race fuel, with a boosted engine is usually a good idea. but the basic tech is generally very old, as turbos and superchargers have been used in good numbers even before WWII, on tractors, busses, trucks and airplane engines for at least 7 decades so that's at least 75 year old , BASIC technology, and with modern cnc machines and better materials available, making the parts is certainly not by todays standards super high tech, thus the components could be made currently at much lower cost than in the past. but your dealing with a rather limited market , if your dealing with the auto performance for aftermarket parts.

Id point out that if you build a serious boosted engine, the turbo or super charger is a small part of the true cost that you will need to do that upgrade. the other components used must match and be fully up to use under the higher stress levels induced by the boosted intake charge, higher pressures and heat!

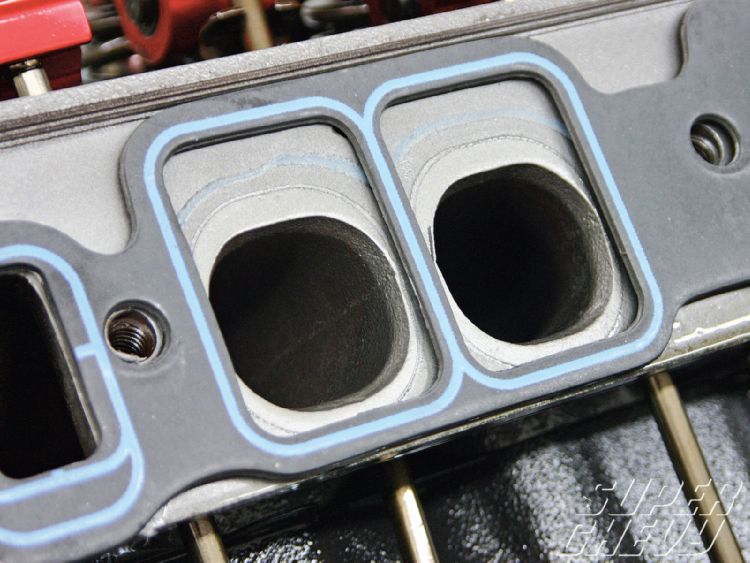

UPGRADES TO THE BLOCK, LUBE SYSTEM, VALVE TRAIN,ROTATING ASSEMBLY,m

COOLING SYSTEM AND IGNITION and HEADERS USED, SYSTEMS BECOME MANDATORY.

(THEN THERE'S THE BRAKES SUSPENSION AND DRIVE TRAIN?)

yes there are much cheaper (USUALLY CHINESE MADE) parts and QUALITY VARIES a great deal.

(that does not mean all chinese parts are crap quality, some are rather decent quality ) and a good deal of failures are related to crap quality low octane fuels used and a lack of skill on the tuners part, so all failures are not the result of lack of quality in the turbo or centrifugal supercharger being used, more than a few engine failures result from mismatched parts like cheap cast or hypereutectic pistons, bad valve train components, or a failure to understand how the ignition advance curve must match the boost, pressure, and a dreadful lack of tuning skills

you have options and a few of the options are reasonably priced for what you get versus what they cost to make, and yeah, sometimes you pay a big premium for a brand name in my opinion.

as always do your research and ask lots of questions and don't assume anything, and keep in mind if you want to exceed 500-550 hp, in most chevy V8 engines ,you really need an all forged rotating assembly and a DART or similar aftermarket performance block, your lube system, valve train components and ignition system all require upgrades, bearings and rings will require clearance changes, and use of ARP fasteners are advised.(as is use of matching header and exhaust mods)

and yeah we have all heard of some guy who stuck a supercharger on a stock engine and made a zillion HP, without any issues

what they fail to mention is stress is cumulative , and your hero will eventually puke parts, burn pistons, have detonation issues etc. if he flogs that stock engine regularly

( keep in mind.. you can get away with a good deal OCCASIONALLY or for a few hours or even weeks at times,

that will trash any engine if done REGULARLY)