" Anti-seize compound

Hey grumpy?

I got gifted a can of Fel-Pro C5-A copper based anti-seize lubricant from an old gent who worked on the Mack Trucks assembly line. He punched a small hole in the lid big enough for an acid brush. Over the years this compound has dried out some...the instructions say to keep the lid on tight and to "not use thinner of any type."

I'm not so cheap that I cannot buy a brand new supply. But I've become attached to that old half-full can and think of him every time I smear some of that lubricant on a threaded fastener. It says 'Exclusive formula suspends copper and graphite in a high quality grease.'

Would any member have a recommendation for something to add to the remaining contents to make it, for want of a better word, spreadable again? "

Well first Id point out the purpose of anti-seize it to provide an air and moisture proof coating on threads that prevents corrosion and reduces friction, the micro metalic slurry mixed into a grease base used in most anti-seize formula uses a copper, aluminum , zinc or nickle powder that acts as a corrosion barrier when mixed in a grease base, after time most grease evaporates but the coat of fine metallic dust forms a barrier layer, I would not hesitate for a second to put a couple tablespoons of marvel mystery oil and pour a fresh can of anti seize into that and mix the result slurry really well, in that can of old dried out anti-seize, which is basically a metallic powder suspended in a grease base, and then stir up the results for about 10 minutes I can,t even think it would do a darn thing but make the result more easily used with a brush

BTW if you really want bolt threads to stay easy to remove , pour in a table spoon of this powder before you stir it up, it makes GRAPHITE look like old rocks, moly dust is slicker that , as my dad used to say

"a red hot nickle on a sheet of dry ice thats on a 45 degree incline"

http://www.opticsplanet.com/lyman-super-moly-superfine-grade-moly-powder-7631412.html

Why should I choose Moly vs. Graphite?

Moly has an ability to adhere to the surface of most bearing materials.

Moly sustains higher loads.

If the surface of the metal is scored or damaged due to abnormal wear, moly tends to repair the surface. (See No. 1)

During break-in, moly allows for metal deformation with a minimum of "chopping off" of asperities that would otherwise occur.

Moly has a lower coefficient of friction.

youll never have a problem getting the threads loose, but if you put a tablespoon of moly dust in the anti-seize you might need to safety wire the nuts to keep them from spinning off on their own

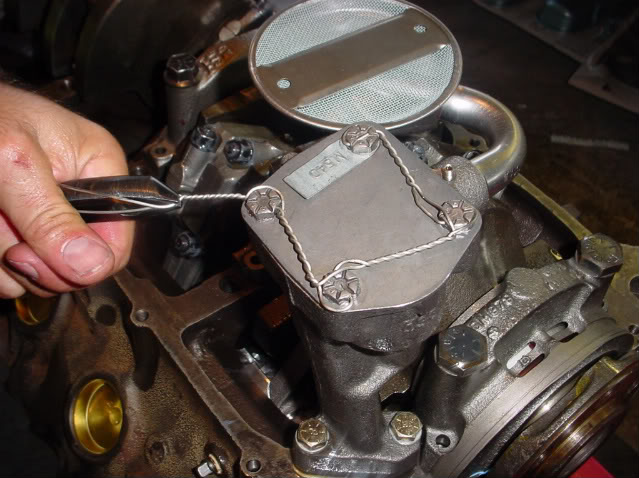

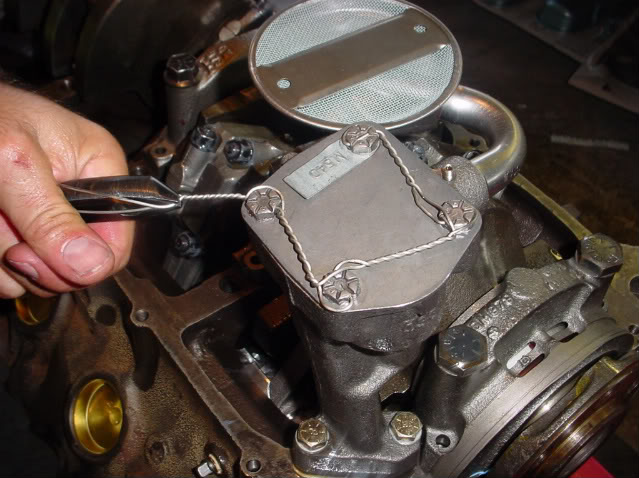

viewtopic.php?f=50&t=4733&p=12852&hilit=cotter+pins#p12852

viewtopic.php?f=50&t=4306&p=11353&hilit=safety+wire#p11353

Hey grumpy?

I got gifted a can of Fel-Pro C5-A copper based anti-seize lubricant from an old gent who worked on the Mack Trucks assembly line. He punched a small hole in the lid big enough for an acid brush. Over the years this compound has dried out some...the instructions say to keep the lid on tight and to "not use thinner of any type."

I'm not so cheap that I cannot buy a brand new supply. But I've become attached to that old half-full can and think of him every time I smear some of that lubricant on a threaded fastener. It says 'Exclusive formula suspends copper and graphite in a high quality grease.'

Would any member have a recommendation for something to add to the remaining contents to make it, for want of a better word, spreadable again? "

Well first Id point out the purpose of anti-seize it to provide an air and moisture proof coating on threads that prevents corrosion and reduces friction, the micro metalic slurry mixed into a grease base used in most anti-seize formula uses a copper, aluminum , zinc or nickle powder that acts as a corrosion barrier when mixed in a grease base, after time most grease evaporates but the coat of fine metallic dust forms a barrier layer, I would not hesitate for a second to put a couple tablespoons of marvel mystery oil and pour a fresh can of anti seize into that and mix the result slurry really well, in that can of old dried out anti-seize, which is basically a metallic powder suspended in a grease base, and then stir up the results for about 10 minutes I can,t even think it would do a darn thing but make the result more easily used with a brush

BTW if you really want bolt threads to stay easy to remove , pour in a table spoon of this powder before you stir it up, it makes GRAPHITE look like old rocks, moly dust is slicker that , as my dad used to say

"a red hot nickle on a sheet of dry ice thats on a 45 degree incline"

http://www.opticsplanet.com/lyman-super-moly-superfine-grade-moly-powder-7631412.html

Why should I choose Moly vs. Graphite?

Moly has an ability to adhere to the surface of most bearing materials.

Moly sustains higher loads.

If the surface of the metal is scored or damaged due to abnormal wear, moly tends to repair the surface. (See No. 1)

During break-in, moly allows for metal deformation with a minimum of "chopping off" of asperities that would otherwise occur.

Moly has a lower coefficient of friction.

youll never have a problem getting the threads loose, but if you put a tablespoon of moly dust in the anti-seize you might need to safety wire the nuts to keep them from spinning off on their own

viewtopic.php?f=50&t=4733&p=12852&hilit=cotter+pins#p12852

viewtopic.php?f=50&t=4306&p=11353&hilit=safety+wire#p11353