FarNorthRacing

New Member

So I'm rebuilding a Dodge Stealth (Mitisubishi 3.0l V6 6G72) and on the list of things to do is new pistons. New pistons means machining the block to fit, so I'm looking at at least a hone, and maybe a bore+hone.

Honing means torque plates, and there's no way no how that any engine machine shop here in backwoods New Brunswick will have anything that fits up.

So I'm going to make at least one.

I'm wondering though if the proper answer isn't *two*:

1. I'm going to switch from head bolts to head studs. One torque plate means exposed studs on the block while at the shop, which seems like damage waiting to happen;

2. If I deliver the block to the machine shop with the plates in place, already torqued, then I know they have been properly tightened. Otherwise, I'm trusting the shop to do it right; and

3. I can't help but wonder about which stresses distort the block - meaning that as many of the highly torqued fasteners that go into the block should be installed at the time of honing, so that the block is accurately stressed as it would be once installed.

Thoughts?

Has anyone ever glued strain gauges into cylinder bores, started tightening parts down, and measuring the resulting strain?

Honing means torque plates, and there's no way no how that any engine machine shop here in backwoods New Brunswick will have anything that fits up.

So I'm going to make at least one.

I'm wondering though if the proper answer isn't *two*:

1. I'm going to switch from head bolts to head studs. One torque plate means exposed studs on the block while at the shop, which seems like damage waiting to happen;

2. If I deliver the block to the machine shop with the plates in place, already torqued, then I know they have been properly tightened. Otherwise, I'm trusting the shop to do it right; and

3. I can't help but wonder about which stresses distort the block - meaning that as many of the highly torqued fasteners that go into the block should be installed at the time of honing, so that the block is accurately stressed as it would be once installed.

Thoughts?

Has anyone ever glued strain gauges into cylinder bores, started tightening parts down, and measuring the resulting strain?

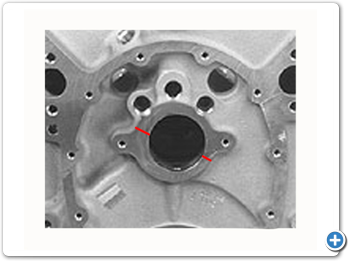

Core shift example

Core shift example