one factor many guys over look is cleaning and degrease parts, I like most guys started out using a 5 gallon bucket and a brush and some diesel fuel to clean parts , and degrease bolts etc.

now once you get used to working with degreased components you'll start to wonder why you ever worked on cars without a parts cleaner/washer as it helps a good deal.

now obviously use of flammable diesel fuel as a solvent is not ideal and detergents mixed with solvents and water are highly preferred, from a safety perspective, and you don,t want to use anything that evaporates quickly, stinks while in use or something that's overly corrosive or expensive for obvious reasons

but once you've used a parts washer with a sprayer , drain and pump you quickly get spoiled and can,t consider working on a car without using one to clean components and get the crud out of bolt threads etc.

http://www.amazon.com/Advanced-Tool-Des ... 000&sr=1-2

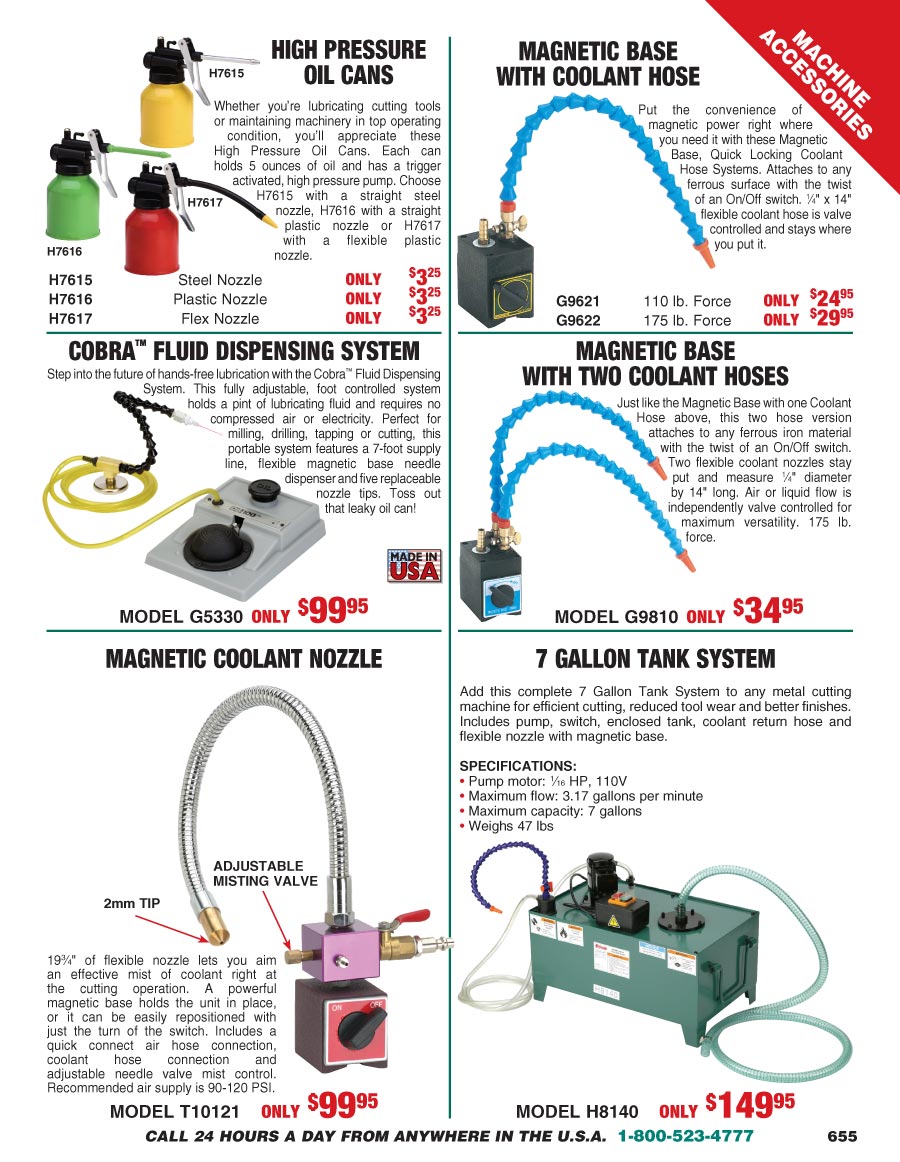

http://www.grizzly.com/catalog/2010/Main/655

http://www.amazon.com/Monster-Parts-Was ... dbs_auto_4

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

http://www.asedeals.com/partswashers2.html

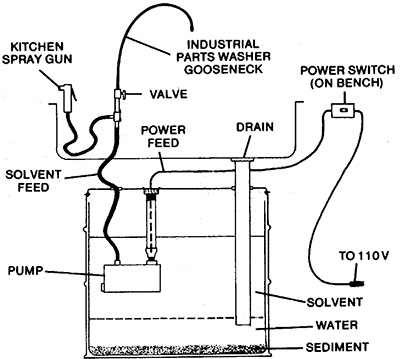

having a pump that plugs into 110 volts and a drain with some type of filtered screen is obviously a big improvement over just soaking parts in diesel fuel, and a whole lot safer.

and having a couple brushs and a constant stream of solvent sure helps.

having a parts washer large and sturdy enough to let you soak a pair of BIG BLOCK CYLINDER HEADS and strong enough to support the weight of a bare block is a HUGE advantage, and it needs to have the OPTION to securely bolt to a wall or the floor for safety reasons as you don,t want it to tip over, as you turn a block or cylinder heads over so think thru your purchase, don,t just select on price alone

http://www.popularmechanics.com/automot ... 13287.html

http://www.homedepot.com/webapp/wcs/sto ... marketID=2

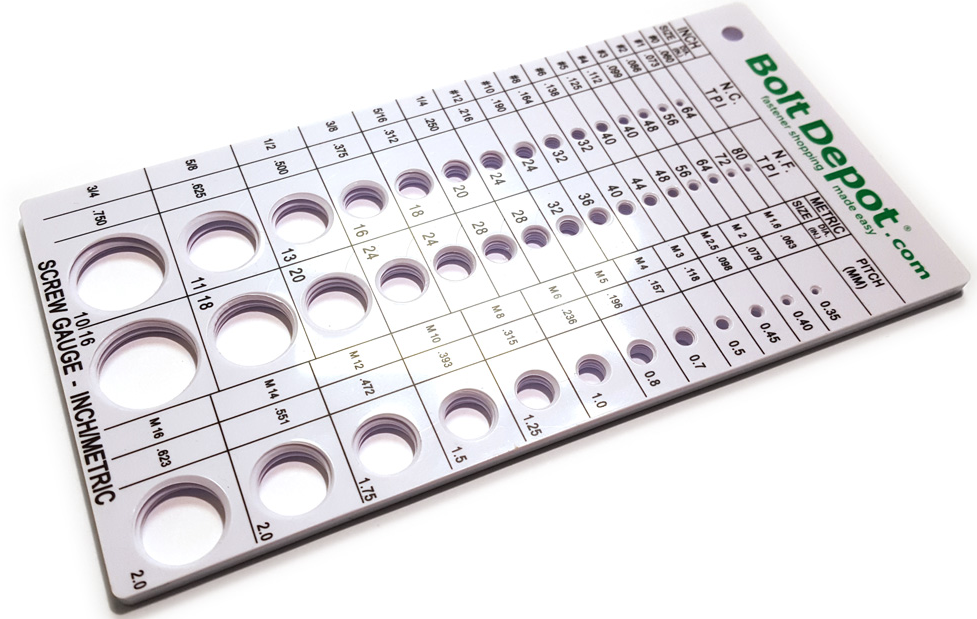

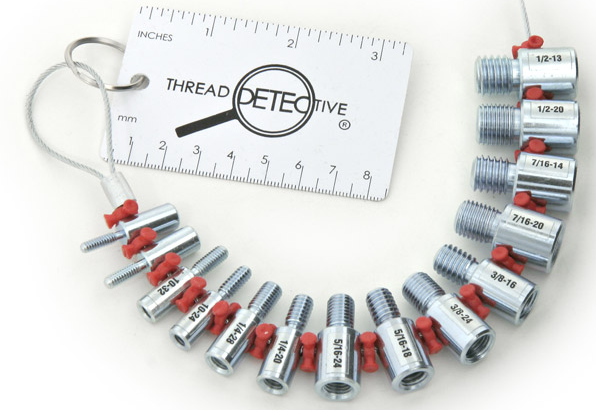

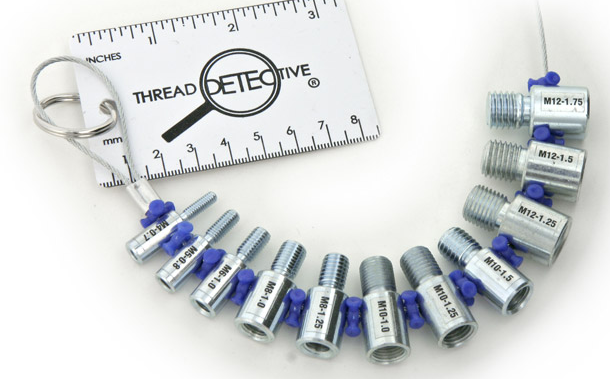

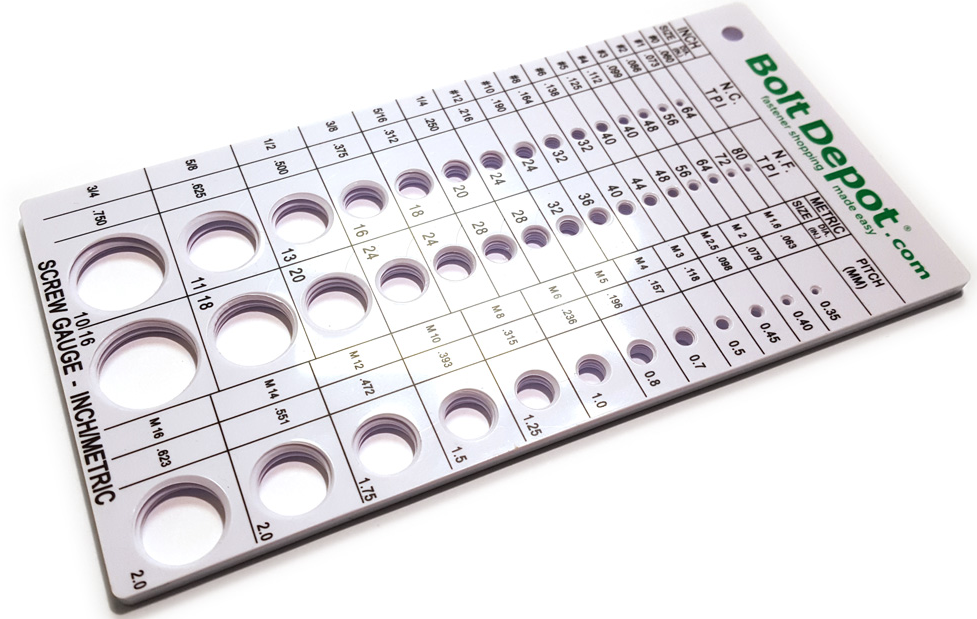

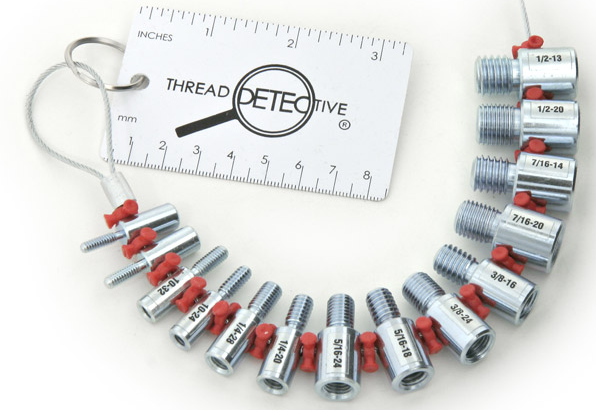

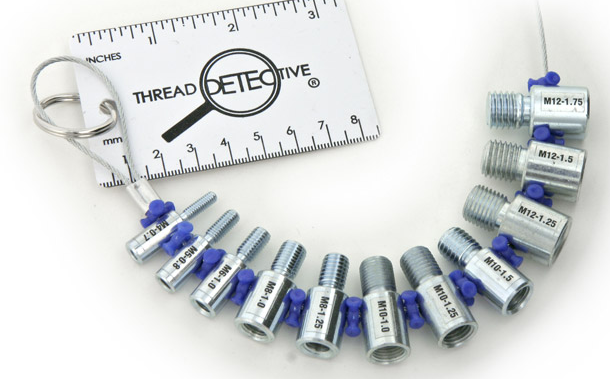

most experienced mechanics have a 5 gallon bucket of assorted bolts and screws to fall back on when they can,t locate a fastener they break or mis -place, youll need to clean used bolts with solvent and a wire brush, but having a bucket of spare fasteners is nearly mandatory, A visit to a local salvage yard with several wrenches and a bucket and a couple hours time, will generally allow you to collect a wide random selection at e a very reasonable price , now you may not find exactly every bolt diameter and length and thread size but you will generally find youve accumulated a good basic selection

https://www.boltdepot.com/Thread_detective_-_Metal.aspx

every mechanic should own a decent 12" caliper to measure the length of a bolt,

that may be missing on any particular application.

bolts used on any application, must not bottom out in a blind bolt hole if the bolt bottoms out it fails to clamp firmly

bolts that are not threaded into a blind hole should extend at least two to three times,

its diameter past the far surface too allow a washer and nut to be threaded onto the bolts extended end to supply clamping force.

so the depth of the item being clamped and the threaded area the bolt secures its threads too should generally be at least 1/4" deeper than the length of the bolt used,

and the threads should extend at least 2-3 times the bolt diameter into the threaded area,

before the bolts clamping force is applied to clamp the item being secured.

obviously you can get a rough measurement with the base of the caliper.

and when in doubt select a GRADE #8 fastener,

as they are significantly stronger than average garden variety hardware store bolts.

http://www.northerntool.com/shop/tools/product_200308979_200308979?utm_source=CSE&utm_medium=Shopzilla&utm_campaign=Construction > Measuring Tools > Calipers&utm_content=56248

http://garage.grumpysperformance.com/index.php?threads/bolts-a-bit-of-useful-info.4868/#post-13372

http://garage.grumpysperformance.com/index.php?threads/parts-coming-loose.11008/#post-48646

http://www.wikihow.com/Use-a-Vernier-Caliper

https://www.boltdepot.com/Thread_detective_-_Metal.aspx

http://www.kimballmidwest.com/Catalog/M ... vellon.pdf

http://www.fastenal.com/content/feds/pd ... alling.pdf

http://www.agriculture.com/machinery/to ... 2192?print

http://garage.grumpysperformance.co...-and-assorted-spare-parts-in.3557/#post-20834

http://mgaguru.com/mgtech/universal/ut121.htm

http://www.unified-eng.com/scitech/bolt/boltmarks.html

http://www.ssina.com/fasteners/

http://www.kimballmidwest.com/catalog/M ... vellon.pdf

http://www.boltdepot.com/fastener-infor ... chart.aspx

http://www.zerofast.com/markings.htm

http://www.nutsandbolts.com/v1-bolt-grade-markings.html

http://www.mechanicsupport.com/AN_bolts.html

http://www.amazon.com/Advanced-Tool-Des ... 000&sr=1-2

http://www.amazon.com/Northern-Industri ... 00&sr=1-10

http://www.northerntool.com/webapp/wcs/ ... _200350440

http://www.asedeals.com/RangerPW.html

http://www.summitracing.com/parts/CLK-MT1110B/

heres (below) some rather cheap and rather flimsy but fairly useful parts washers for light duty use, but hardly something youll want if your equipping more than a hobby shop

http://www.harborfreight.com/cpi/ctaf/d ... umber=7340

http://www.harborfreight.com/cpi/ctaf/d ... mber=94702

once more ID point out that having access to a decent welder and building your own custom version will be a cost saving and far less expensive option at times, and a decent start point can be a large stainless steel sink , surplus used restaurant supply stores and old restaurants can be a great source of stainless tables and larger sinks that can form the basis for building a cost effective parts washer

viewtopic.php?f=60&t=1669

viewtopic.php?f=27&t=81

how many of you gentlemen use or own a parts washer?

how many built their own?

how many guys want one?

or don't you ever find you need to use , used or salvage yard parts that could used a bit of cleaning?

now once you get used to working with degreased components you'll start to wonder why you ever worked on cars without a parts cleaner/washer as it helps a good deal.

now obviously use of flammable diesel fuel as a solvent is not ideal and detergents mixed with solvents and water are highly preferred, from a safety perspective, and you don,t want to use anything that evaporates quickly, stinks while in use or something that's overly corrosive or expensive for obvious reasons

but once you've used a parts washer with a sprayer , drain and pump you quickly get spoiled and can,t consider working on a car without using one to clean components and get the crud out of bolt threads etc.

http://www.amazon.com/Advanced-Tool-Des ... 000&sr=1-2

http://www.grizzly.com/catalog/2010/Main/655

http://www.amazon.com/Monster-Parts-Was ... dbs_auto_4

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

http://www.asedeals.com/partswashers2.html

having a pump that plugs into 110 volts and a drain with some type of filtered screen is obviously a big improvement over just soaking parts in diesel fuel, and a whole lot safer.

and having a couple brushs and a constant stream of solvent sure helps.

having a parts washer large and sturdy enough to let you soak a pair of BIG BLOCK CYLINDER HEADS and strong enough to support the weight of a bare block is a HUGE advantage, and it needs to have the OPTION to securely bolt to a wall or the floor for safety reasons as you don,t want it to tip over, as you turn a block or cylinder heads over so think thru your purchase, don,t just select on price alone

http://www.popularmechanics.com/automot ... 13287.html

http://www.homedepot.com/webapp/wcs/sto ... marketID=2

most experienced mechanics have a 5 gallon bucket of assorted bolts and screws to fall back on when they can,t locate a fastener they break or mis -place, youll need to clean used bolts with solvent and a wire brush, but having a bucket of spare fasteners is nearly mandatory, A visit to a local salvage yard with several wrenches and a bucket and a couple hours time, will generally allow you to collect a wide random selection at e a very reasonable price , now you may not find exactly every bolt diameter and length and thread size but you will generally find youve accumulated a good basic selection

https://www.boltdepot.com/Thread_detective_-_Metal.aspx

every mechanic should own a decent 12" caliper to measure the length of a bolt,

that may be missing on any particular application.

bolts used on any application, must not bottom out in a blind bolt hole if the bolt bottoms out it fails to clamp firmly

bolts that are not threaded into a blind hole should extend at least two to three times,

its diameter past the far surface too allow a washer and nut to be threaded onto the bolts extended end to supply clamping force.

so the depth of the item being clamped and the threaded area the bolt secures its threads too should generally be at least 1/4" deeper than the length of the bolt used,

and the threads should extend at least 2-3 times the bolt diameter into the threaded area,

before the bolts clamping force is applied to clamp the item being secured.

obviously you can get a rough measurement with the base of the caliper.

and when in doubt select a GRADE #8 fastener,

as they are significantly stronger than average garden variety hardware store bolts.

http://www.northerntool.com/shop/tools/product_200308979_200308979?utm_source=CSE&utm_medium=Shopzilla&utm_campaign=Construction > Measuring Tools > Calipers&utm_content=56248

http://garage.grumpysperformance.com/index.php?threads/bolts-a-bit-of-useful-info.4868/#post-13372

http://garage.grumpysperformance.com/index.php?threads/parts-coming-loose.11008/#post-48646

http://www.wikihow.com/Use-a-Vernier-Caliper

https://www.boltdepot.com/Thread_detective_-_Metal.aspx

http://www.kimballmidwest.com/Catalog/M ... vellon.pdf

http://www.fastenal.com/content/feds/pd ... alling.pdf

http://www.agriculture.com/machinery/to ... 2192?print

http://garage.grumpysperformance.co...-and-assorted-spare-parts-in.3557/#post-20834

http://mgaguru.com/mgtech/universal/ut121.htm

http://www.unified-eng.com/scitech/bolt/boltmarks.html

http://www.ssina.com/fasteners/

http://www.kimballmidwest.com/catalog/M ... vellon.pdf

http://www.boltdepot.com/fastener-infor ... chart.aspx

http://www.zerofast.com/markings.htm

http://www.nutsandbolts.com/v1-bolt-grade-markings.html

http://www.mechanicsupport.com/AN_bolts.html

http://www.amazon.com/Advanced-Tool-Des ... 000&sr=1-2

http://www.amazon.com/Northern-Industri ... 00&sr=1-10

http://www.northerntool.com/webapp/wcs/ ... _200350440

http://www.asedeals.com/RangerPW.html

http://www.summitracing.com/parts/CLK-MT1110B/

heres (below) some rather cheap and rather flimsy but fairly useful parts washers for light duty use, but hardly something youll want if your equipping more than a hobby shop

http://www.harborfreight.com/cpi/ctaf/d ... umber=7340

http://www.harborfreight.com/cpi/ctaf/d ... mber=94702

once more ID point out that having access to a decent welder and building your own custom version will be a cost saving and far less expensive option at times, and a decent start point can be a large stainless steel sink , surplus used restaurant supply stores and old restaurants can be a great source of stainless tables and larger sinks that can form the basis for building a cost effective parts washer

viewtopic.php?f=60&t=1669

viewtopic.php?f=27&t=81

how many of you gentlemen use or own a parts washer?

how many built their own?

how many guys want one?

or don't you ever find you need to use , used or salvage yard parts that could used a bit of cleaning?

Last edited by a moderator: