http://www.corvetteforum.com/forums/c4- ... tures.html

FOR ALL THE NEWER GUYS READING THIS,ANY TIME YOU INSTALL PARTS, LIKE SUSPENSION, STEERING OR DRIVE TRAIN COMPONENTS THAT MIGHT COME LOOSE WITH VIBRATION, ESPECIALLY IF IT COMING LOOSE , WHILE YOUR DRIVING COULD BE DANGEROUS

NOW I WOULD EXPECT THE EXPERIENCED GUYS TO HAVE ALREADY SEEN PARTS FAIL, AND KNOW TOO THINK THIS THRU ALREADY

I know you know this. SO THIS IS MOSTLY FOR THE NEW GUYS, and yes it takes some getting used to doing it, but I can,t imaging NOT doing this on critical fasteners

nyloc nuts work MOST OF THE TIME,but are very suspect if subjected to higher heat levels using THE CORRECT FORMULA FOR THE INTENDED APPLICATION, of loc-tite on the threads (yes theres several kinds so read instructions and follow directions ,and replacing the standard nuts on those studs with a lock washer and a NYLOC NUTS not on each stud, or BOLT will usually cure the issue of a nut backing off , or bolt backing out.

[/b]

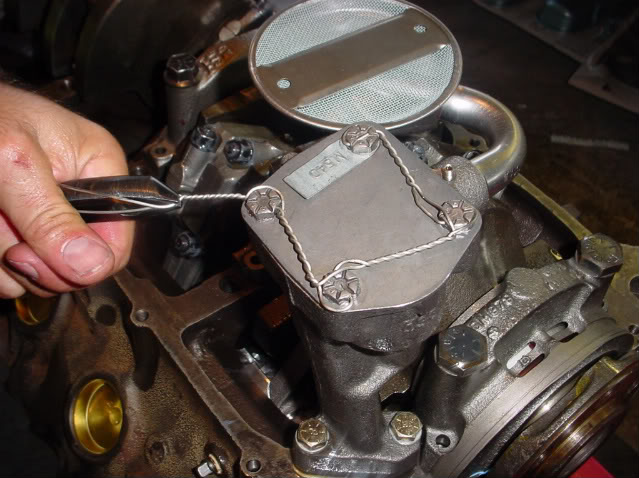

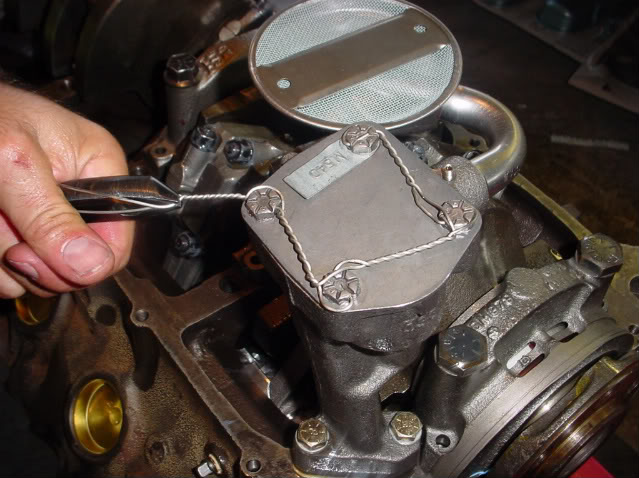

BUT IF YOUR 100% DEPENDENT ON THINGS STAYING AS YOU LEFT THEM USE LOCTITE AND SAFETY WIRE, as the COMBO PROPERLY USED WORKS 100% of the time

READ THRU THIS LINKED THREAD

viewtopic.php?f=50&t=4306&p=48044&hilit=+safety+wire#p48044

viewtopic.php?f=27&t=970&p=45483&hilit=drill+press#p45483

http://sprintparts.com/safety-wire-pliers/

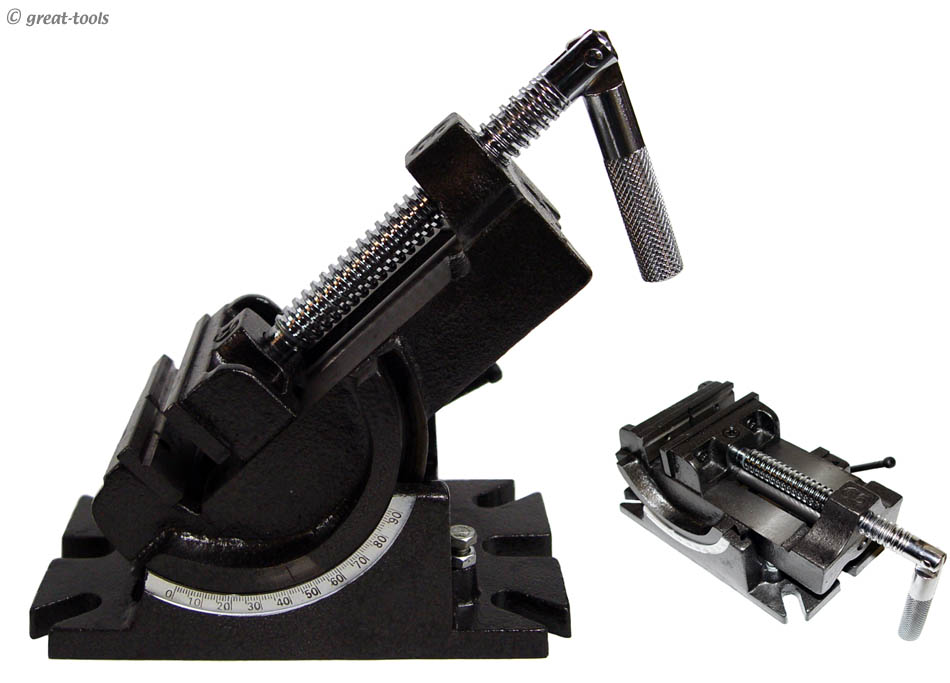

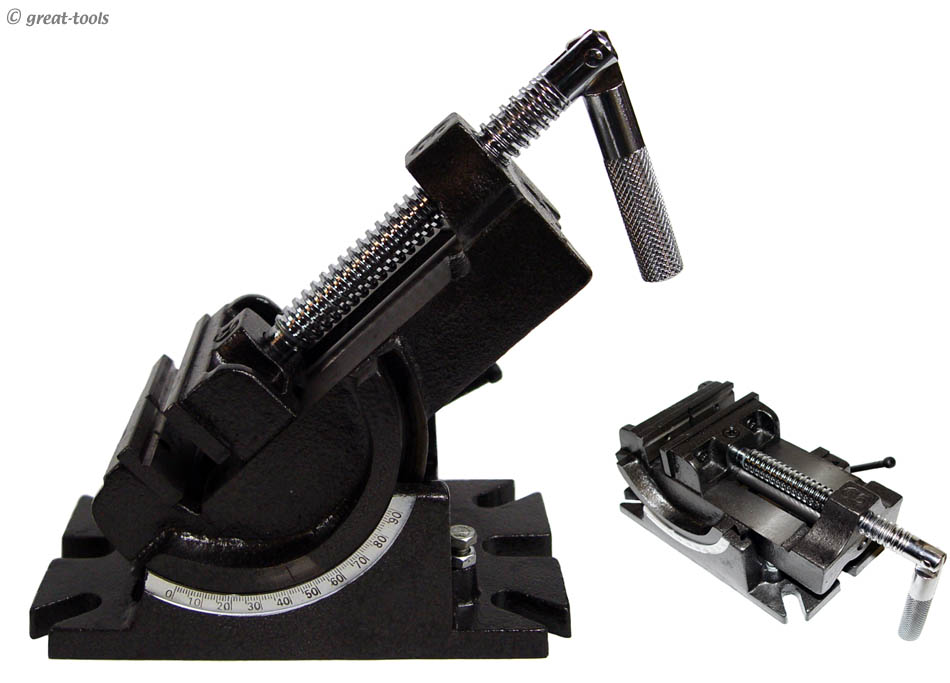

obviously having a drill press with a vise, the proper drill bits, assorted roll pins and an oil can for use when you cool the bits during the drill process helps

if you deal with safety wire and castle nuts and cotter pins youll find a drill press mandatory

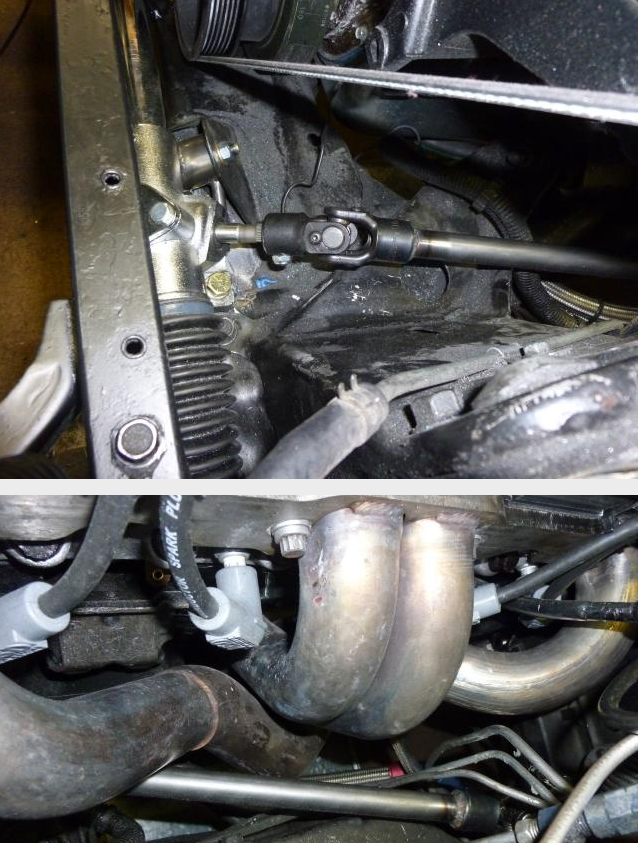

383vette said:Last week I had my fabricator friend install a Pinto manual steering rack in my 84. On my last race, I removed the power steering assembly and ran the Z51 rack with no pump or belt. I gained a tenth but you don't want to do this for long unless you are Charles Armstrong. The Z51 rack was 2 turns lock to lock. The Pinto is almost 4 turns. Obviously the steering effort is a lot less than the Corvette rack with no power assist. The weight difference of the racks is about 4.5 lbs. I weighed the stock rack at about 14 lbs. The Pinto was 9.5 lbs. The pump and bracketry was 7 lbs. The total weight savings is approximately 15 lbs. That doesn't include the chromemoly steering shaft. Along with the less engine drag and lighter weight, I think a tenth or more quicker in the quarter is a good estimate. My fabricator is very meticulous in his work and fabricated my 12 bolt rearend install years ago and I trust him 100%. I wouldn't have anyone do this work who didn't have a lot of experience. You've got to be able steer these things at 130+mph. A perch had to be welded on the crossmember on the passenger side to mount the rack. He was able to use the existing mount, with some fabrication, along with notching the crossmember on the drivers side. You can see how much lower the heim joints are below the control arm. This bump steer spacing allowed at most 1/8" of toe change from full compression to full extension. This should provide good control of the car when it settles back on the ground. The shocks are revalved double adjustable Afco shocks. I had 90-10 Lakewood shocks for years and my friend thought controlling the extension of the front shocks would keep the front end down and the car would be quicker. Here are some pictures...

FOR ALL THE NEWER GUYS READING THIS,ANY TIME YOU INSTALL PARTS, LIKE SUSPENSION, STEERING OR DRIVE TRAIN COMPONENTS THAT MIGHT COME LOOSE WITH VIBRATION, ESPECIALLY IF IT COMING LOOSE , WHILE YOUR DRIVING COULD BE DANGEROUS

NOW I WOULD EXPECT THE EXPERIENCED GUYS TO HAVE ALREADY SEEN PARTS FAIL, AND KNOW TOO THINK THIS THRU ALREADY

I know you know this. SO THIS IS MOSTLY FOR THE NEW GUYS, and yes it takes some getting used to doing it, but I can,t imaging NOT doing this on critical fasteners

nyloc nuts work MOST OF THE TIME,but are very suspect if subjected to higher heat levels using THE CORRECT FORMULA FOR THE INTENDED APPLICATION, of loc-tite on the threads (yes theres several kinds so read instructions and follow directions ,and replacing the standard nuts on those studs with a lock washer and a NYLOC NUTS not on each stud, or BOLT will usually cure the issue of a nut backing off , or bolt backing out.

[/b]

BUT IF YOUR 100% DEPENDENT ON THINGS STAYING AS YOU LEFT THEM USE LOCTITE AND SAFETY WIRE, as the COMBO PROPERLY USED WORKS 100% of the time

READ THRU THIS LINKED THREAD

viewtopic.php?f=50&t=4306&p=48044&hilit=+safety+wire#p48044

viewtopic.php?f=27&t=970&p=45483&hilit=drill+press#p45483

http://sprintparts.com/safety-wire-pliers/

obviously having a drill press with a vise, the proper drill bits, assorted roll pins and an oil can for use when you cool the bits during the drill process helps

if you deal with safety wire and castle nuts and cotter pins youll find a drill press mandatory