ILL make this REALLY SIMPLE!

this type works far better than the others, its nearly impossiable to tell from the pictures here but the inside dia. is tapered and the rings compress as the piston passes thru the ring compressor ring, and they work far easier than those sheet steel band with a radiator clamp style compressors like the one most guys started out with, yes they only work over a limited range in bore sizes say 4.00-4.200 then youll need the next larger size, but Ive got 5 in my tool box and that coveres 3.875"-4.650"

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66766&N=700+115&autoview=sku

Proform 66766 $31

This cheap tool, is worthless P.I.T.A. to use,in my opinion, but there are similar adjustable piston ring compressors that work well

GOOD and VERSITILE

WORKS GREAT BUT LIMITED TO A NARROW BORE RANGE AND EXPENSIVE

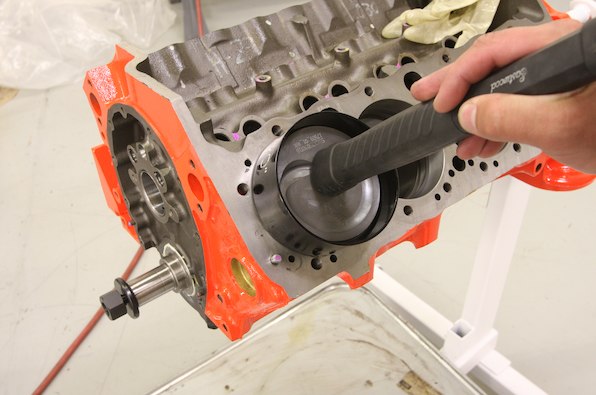

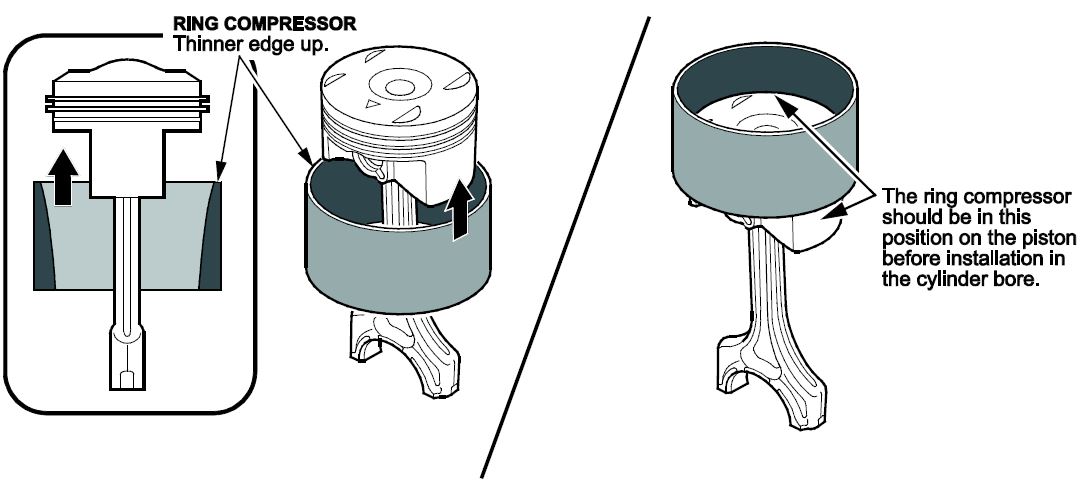

how they work is you clamp it around your piston and adjust it to that size before the rings are installed so the piston is a snug slide thru fit, then, install the rings, dip the rings and piston in a small bucket of clean oil, place the compressor over the cylinder on the block with the base firmly held against the block deck and push the piston into its much larger open enterance, as it slides thru the funnel like construction squeezes the rings into the grouves and they can,t pring back untill they are in the bore, remember to line up the rod bolts and having them covered with the ends of a 3 ft long section or 3/8" fuel line to protect the crank journal is a good idea, having a ROD GUIDE TOOL you can use to guide and PULL THE PISTON INTO THE BORE WITH IS EVEN A BETTER IDEA

youll be surprised at how much easier they slide into the bore if you BOTH pull/guide and push the pistons into the cylinders rather than just beat them in with a hammer handle, it takes some practice but a few taps to get them moving with a fist, while pulling and guiding the rod into its journal is usually all that necessary with a well oiled piston and that type of ring compressor

this type works far better than the others, its nearly impossiable to tell from the pictures here but the inside dia. is tapered and the rings compress as the piston passes thru the ring compressor ring, and they work far easier than those sheet steel band with a radiator clamp style compressors like the one most guys started out with, yes they only work over a limited range in bore sizes say 4.00-4.200 then youll need the next larger size, but Ive got 5 in my tool box and that coveres 3.875"-4.650"

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66766&N=700+115&autoview=sku

Proform 66766 $31

This cheap tool, is worthless P.I.T.A. to use,in my opinion, but there are similar adjustable piston ring compressors that work well

GOOD and VERSITILE

WORKS GREAT BUT LIMITED TO A NARROW BORE RANGE AND EXPENSIVE

how they work is you clamp it around your piston and adjust it to that size before the rings are installed so the piston is a snug slide thru fit, then, install the rings, dip the rings and piston in a small bucket of clean oil, place the compressor over the cylinder on the block with the base firmly held against the block deck and push the piston into its much larger open enterance, as it slides thru the funnel like construction squeezes the rings into the grouves and they can,t pring back untill they are in the bore, remember to line up the rod bolts and having them covered with the ends of a 3 ft long section or 3/8" fuel line to protect the crank journal is a good idea, having a ROD GUIDE TOOL you can use to guide and PULL THE PISTON INTO THE BORE WITH IS EVEN A BETTER IDEA

youll be surprised at how much easier they slide into the bore if you BOTH pull/guide and push the pistons into the cylinders rather than just beat them in with a hammer handle, it takes some practice but a few taps to get them moving with a fist, while pulling and guiding the rod into its journal is usually all that necessary with a well oiled piston and that type of ring compressor

Last edited by a moderator: