"" HEY GRUMPY?

Is there any merit to this process to determine if you have piston slap on a cold engine:

1) Start engine COLD. Let it run for 15 seconds then shut off.

2) Quickly remove all spark plugs. Squirt 2 squirts of engine oil into each spark plug hole.

3) Reinstall spark plugs.

4) Start engine. Listen for piston slap noise.

5) If noise is gone for the first 15 to 40 seconds of running, then noise returns, you have piston slap.

6) If noise has NOT gone away after restart the problem is not piston slap.

that advise sounds totally bogus to me, adding a bit of oil in the combustion chamber will have very little effect on the pistons bore to piston side clearance.

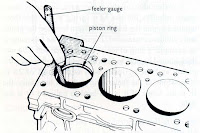

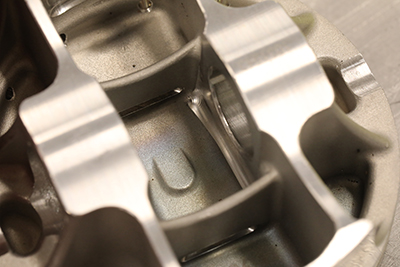

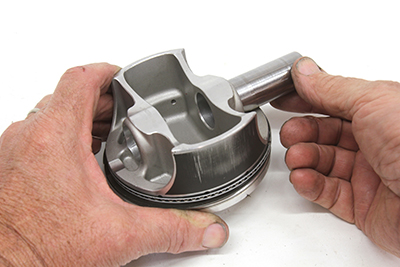

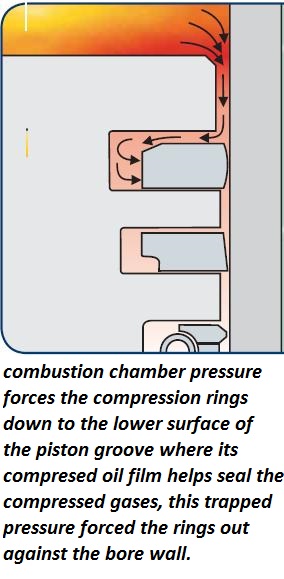

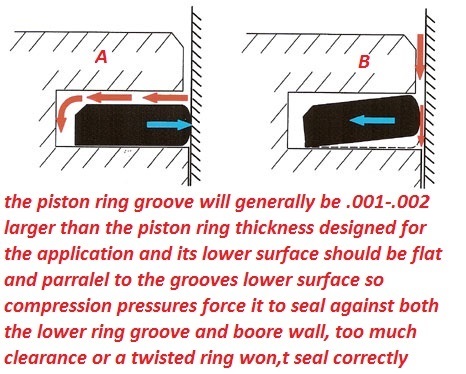

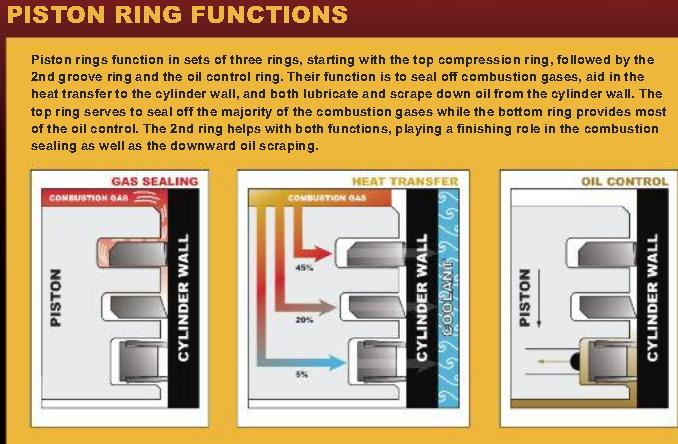

there has to be some minimal piston to bore wall, clearance to reduce blow-bye and some Piston clearance will result in almost no appreciable slap in a properly set up engines rotating assembly, having some bore wall to piston side clearance, is nothing new too piston driven internal combustion engines and compressors. It is the secondary (sideways or perpendicular) movement of a piston against the side of a cylinder bore where the primary movement of a piston is intended to be parallel (up and down) to the cylinder bore. All piston driven internal combustion engines and compressors have a certain minimal clearance and some minimal amount of piston slap. the rings extend out from the piston slightly and both compression and combustion pressure locks the rinds firmly to the lower edge of the piston ring groves this tends to stabilize the pistons orientation to the bore walls,

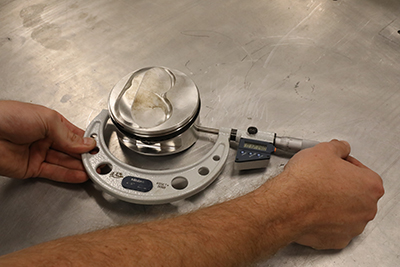

different alloys expand at different rates and the manufacturers will provide you info on the correct side clearance and how and where to measure the pistons.

hyper-eutectic

pistons will tend to expand less between cold to full operational temps, than a forged piston so they will have a tighter bore clearance, than forged pistons.

Theres always minimal piston slap, or clearance in any cold engine until it reaches operational temps, but its usually not something you can hear, it is usually the result of cold pistons that have not reached operational temps and as metal expands as the heat increases the clearance in the bore between the piston and bore decreases, pistons that are well under operational temps have not yet expanded to the correct clearances, resulting in pistons that are too loose in the bore.

most pistons are NOT exactly round and the skirts do not expand enough to limit movement in the bores until the heat of operation expands the skirt, squirting oil will have little effect on how the skirt expands in the bore so I can,t see that test being valid

READ THESE

http://garage.grumpysperformance.com/index.php?threads/piston-to-bore-clearance.4630/#post-48955

http://garage.grumpysperformance.co...on-building-a-383-sbc-stroker.428/#post-57879

http://garage.grumpysperformance.com/index.php?threads/can-you-plan-for-quench.11298/#post-51315

http://garage.grumpysperformance.co...ling-rings-in-piston-grooves.9490/#post-34908

http://garage.grumpysperformance.co...a-cheap-piston-a-bad-piston.10481/#post-44088

http://garage.grumpysperformance.co...in-height-compression-height.5064/#post-66240

http://garage.grumpysperformance.co...nk-durring-short-blk-assembly.852/#post-39525

http://garage.grumpysperformance.com/index.php?threads/383-information-overload.11137/#post-49864

http://garage.grumpysperformance.com/index.php?threads/piston-to-bore-clearance.4630/#post-39780

http://garage.grumpysperformance.co...pull-it-down-and-investigate.5893/#post-37148

http://garage.grumpysperformance.co...ing-piston-to-bore-ring-seal.3897/#post-26602

http://www.federalmogul.com/NR/rdonlyre ... cript2.pdf

http://www.rosspistons.com/information/ ... lation.pdf

http://wicanzayu.wordpress.com/2009/04/ ... nary-tale/

http://www.briancrower.com/je/

http://www.carcraft.com/techarticles/pi ... index.html

http://www.pistonslap.com/whatisit.htm

"Around 1998, GM switched from a "Select Build" method of manufacturing and/or assembling engines to a "Net Build" method, in order to save money on manufacturing and/or assembly. In the Select Build process, pistons and cylinders are matched for size and fit. GM's new "Net Build" method of manufacturing and/or assembly, in contrast, assumes all pistons will fit equally well in all cylinders and does not allow for variations in the size of engine cylinders or pistons. The pistons of slightly varying size (all within spec) are not individually matched with the cylinders of slightly varying size (all within spec).

Excessive “piston slap†occurs because an automobile manufacturer (GM) designs and/or manufactures a defective engine in which the clearance between the piston and cylinder bore is too great. Essentially, the piston moves sideways and “slaps†or “knocks†hard against the cylinder bore and causes damage to the engine pistons and cylinders, excessive smoke emissions, excessive oil consumption, carbon buildup on piston heads, decreased mileage, and a loud and obnoxious “slapping†or “knocking†noise, all of which diminishes vehicle resale value in the trade."

Last edited by a moderator: