yes that .016 difference looks to be excessive, Id call the piston manufacturer and get their tech guys feed back, you'll generally want about a .005 piston to bore clearance with forged pistons but every piston design and manufacturer will have the required specs on file for every piston they make ,that should be carefully followed

don,t forget to ask about ring end gap,ring thickness,ring back clearance and ring groove size, and cylinder bore hone grits to be used,what piston pin and retainer should be used and what the pistons should weight, always ask "what else should I know?" and "what would be YOUR suggestions here?"

https://www.enginelabs.com/engine-tech/engine-blueprinting-how-to-check-piston-to-valve-clearance/

these links, below will hold useful info

viewtopic.php?f=53&t=110&p=3631#p3631

viewtopic.php?f=53&t=1795

viewtopic.php?f=53&t=1017

viewtopic.php?f=53&t=2795&p=7240#p7240

http://www.kb-silvolite.com/assets/auto ... ctions.pdf

viewtopic.php?f=53&t=2208

viewtopic.php?f=53&t=247

viewtopic.php?f=53&t=509

when ever you order parts like pistons that must be fitted precisely to a block,ok the first factor you need to know is the TRUE bore diam. of the block, and if its consistent between all cylinders, youll also need to know the deck height on the block, the connecting rod type, IE, is it set up for pressed or floating pin pistons and if the block ,decks parallel and square to the crank center line, you'll need to order pistons that fit the bore or in most cases you order pistons a bit larger than the current bore size and have your engine builder bore, hone and fit the pistons to your block with the correct side clearance, and order a matching ring set.

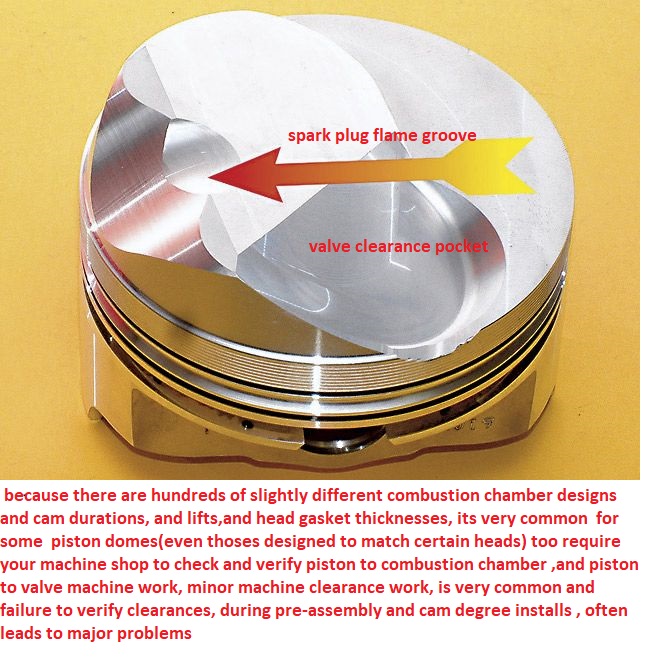

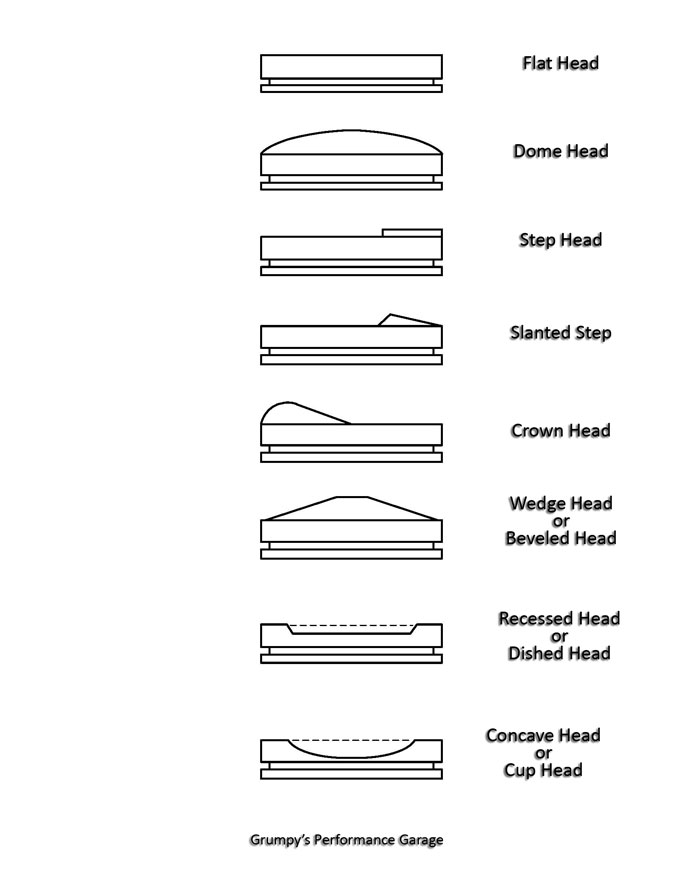

the cylinder heads combustion chamber shape , you chose to work with and location in the cylinder heads of that combustion chamber will determine BOTH the dome or dish size, the pistons require to function correctly and the valve clearance you need, along with the cam you select and the way you degree it in to the engine.

remember different piston materials expand at different rates and require different side clearance and ring gaps.(don,t forget that different rings will require a different surface Finnish on the bore surface)

types of piston dome configurations

as a general rule HYPER-EUTECTIC pistons will require a tighter bore clearance and more ring gap clearance than forged pistons as they tend to run hotter and expand less in the bore, but you MUST use the manufacturers suggested clearance requirements.

not all piston domes are located to clear all spark plugs, valve sizes or combustion chamber shapes, so ask both the piston and head manufacturers for info they might have on potential problems, most engine builder will know how to correct MINOR mis-matches,

but ordering the correct piston machined for the intended application, and carefully measuring components before and during assembly and NEVER taking ANYTHING FOR GRANTED goes a long way toward preventing problems.

factors like the piston pin length and diam. and the piston pin bore thru the piston, the method of locking the piston to the rod and the heat and rpm band your likely to run those pistons under will require some careful thought if you expect the engine to live a long life, surface finish, heat barrier coatings will also effect the choices.

AS LOTS of QUESTIONS before ordering and carefully check clearances during the assembly process.

Youll also want to keep in mind that swapping too new pistons will generally require re-balancing the rotating assembly