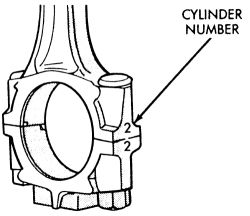

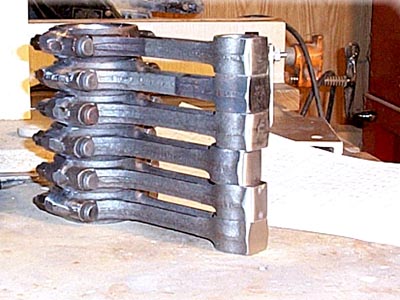

Block is here(we've had it but was at mach shop) had the machine shop check all the stuff. (1) Boring of the cylinders is fresh, with the sonic testing he got with the block I feel confident we have a good block. Mains are straight, decks are square, lifter bores are good. This block has all five mains with four bolts. We have decided on a crane roller cam for it. Even though we have aluminum heads, I wanted to keep the dynamic CR down around 8.25, some of the cams we have been looking at were pushing it up in the 8.35-8.45 range. The rotating assembly is going to be forged he kept wanting to go cast steel and I pushed him to decide on forged. It should be here in the next week or so. (2) The block is already clearanced for 3.75 stroke but I am going to do a mock up assembly when the cam gets here to check all the clearancing points. The rod and main bearings are going to be clevite coated bearings.

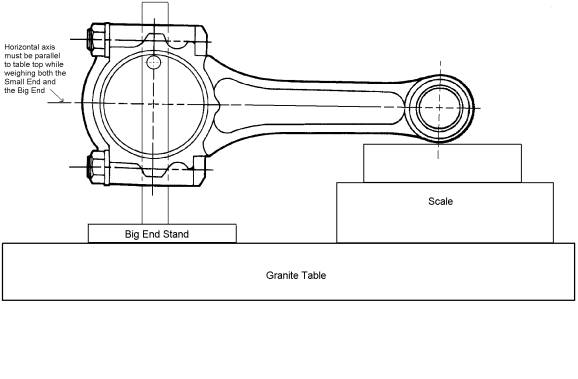

(3) Hey Rick when you did your 400 did you use plastic gauge on both sides of each bearing to check the journals? What I mean is, did you check on the rod and block sides then on the rod caps and block caps? With the bore we have I am going to get a ID mic from work and check the bore and pistion sizes for clearances. Will check the pistons with my standard mic. With the crank and rods being new I suspect my clearances are going to pretty close like they should be, but going to check them anyway.

Once we check all the block clearances and bearing clearances, off to the machine shop for rotating assembly balancing.